Cold Radiator

Thought I had posted this a couple days ago, but not seeing it so posting again.

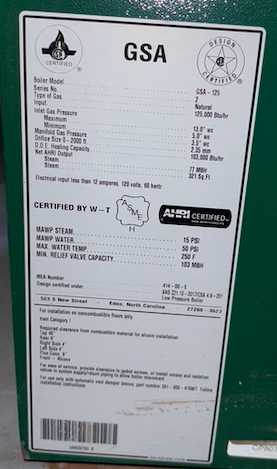

Newly purchased circa 1925 home. 1 pipe gas fired steam boiler (relatively new, photo of info sticker on boiler attached). Single main loop running through the basement. 5 rads on first floor, 4 on second floor. House was closed on end of May so no thorough vetting of heating system was done before closing. I recently fired up the system and find that one rad (small Sunrad type in bathroom on 2nd floor, see photo) is not getting heat (all other are).

Pipe to the rad taps off near the end of the loop, just prior to the main vent. Another radiator (to kitchen on first floor) taps off there as well and gets hot.

I believe that the pipe to the Sunrad originally went about 2 feet horizontally from the main and then about 9 feet vertically to the rad, but at some point a one-story addition was added to the house pushing out the back wall and the pipe was rerouted. The vertical was removed and replaced with a 5 foot horizontal (to a different exterior wall), a 9ish foot vertical and a 5 foot horizontal back to the rad (a big "C" loop.). I can see the 2 horizontals, but the vertical is buried in a wall.

When I fired up the boiler all the other rads in the house get hot. The lower horizontal of the Sunrad also gets hot (over 190 degrees as measured by my thermal camera). The upper horizontal stays cold (again measured with my thermal camera).

I put a level in the lower and upper verticals and both seem to be pitched up to the rad.

I removed the air vent, and still cold. I then sucked on the vent hole with my shop vac and started to get some action. I could hear some gurgling, and hanging some light paper in front of the hole could tell air was escaping. Thermal camera also showed upper vertical getting warm, but not hot.

Fired up boiler again 2 days later. Waited for lower horizontal to get hot. Again could hear gurgling and detect air exiting the vent hole, but 15 minutes later still no heat in the rad or the upper horizontal.

Any thoughts ??

Comments

-

The piping should slope toward the main(the big pipe around the basement), the condensate has to drain in to the main. if there are pockets of condensate trapped in the pipe, that condensate will cool the steam and cause it to collapse until it has heated that water to steam temps, the radiator won't heat until that water is steam hot. The correct fix is to fix the pitch so that the water drains to the main.

Can you show us pictures of what you can see of the runout to that radiator?

If you click the little ribbon to the upper right of your post it will e-mail you when someone comments on this thread.

Is the valve open all the way? if the valve is partially open the valve can trap condensate in the radiator. That radiator should probably be pretty close to level so that neither the nipple from the valve to the radiator nor the bottom tapping of the radiator are pitched in the opposite direction of needed condensate flow.

1 -

Where you hear the gurgling there probably is trapped water (condensate). The steam pressure may push the air in that part of the system out through the water. However the trapped water may cause the steam to condense right there so it never gets into the radiator like it should. Find out why the condensate is trapped where you hear the gurgling. If at the valve, maybe the valve seal has become detached from the valve stem.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

Thanks… Valve is fully open. Pitch on the pipes seems correct (down slope back to the main) as far as I can tell, but the upper horizontal is a bit tricky to check as it is in a narrow space between ceiling below and floor above. I will check pitch on the rad when I get back there tomorrow. Will also try to get photos of the pipes and some thermal images.

0 -

-

A faster air vent might he;p and it's cheap enough to try.

That air valve looks more like it's meant for hor water than steam. Replace it with a Gorton og maid o misy air vent. The kit is your best choice so ypu don't p[lay the which size orifuce do I need game. These are getting hard to find so ac quicklu/

Bob

Smith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge0 -

A faster vent is a good idea but NO vent is something you an try immediately.. take it out, fire the boiler, and see if it makes a difference. If the radiator stays cold, now you know there's a blockage of sorts in the riser.. either a water puddle, or a problem with the shutoff valve.

Also I second the Maid-o-Mist recommendation, but (i) last fall they were widely and inexpensively available, it's all I use, and (ii) for a small system like yours, all you'll ever need is #4 and #5 vents.. I have ten of the former and two of the latter, which is what it took to achieve good balance. The bigger ones go on the radiators that are on the far end of the main.

An apartment building is a different animal, but a single-family house with steam heating is duck soup to set up if the piping is right.

cheers -matt0 -

I had removed the air vent. Made no difference.

The bathroom was remodeled at some point prior to purchase so rad would have been mucked with. It is currently shimmed up but who knows how that relates to pre renovation.

one correction from my initial post. Went back to check the lower horizontal. It is pitched up towards the boiler, not the rad. (Rad left, boiler right in the photos).

On a related note, the kitchen was remodeled at some point and a wall was installed nearly below the rad. I am thinking if I can punch a hole up thru there i can remove the whole “C” loop and run the vertical almost straight up to the rad.0 -

The radiator pitch has nothing to do with it. A puddle in the bottom of the rad isn't great, but if steam gets in there, it'll heat up.

The reverse pitch is your problem. There will always be water in the low spot; condensate that wants to but can't return to the boiler. Fix the pitch and your problem will disappear. I expect it's easier said than done.

Now if you've lived a good, clean life, all you'll have to do is lower the horizontal elbow so you have even pitch towards the main. More likely, it'll be major surgery and early August is a good time for it :)0 -

thanks for all the suggestions. Unfortunately (for me) my daughter is not moving in for a couple more weeks. So I have time to try to rectify this and a boatload of other issues.

I am leery that leaving that big “C” loop in as it may be a recipe for problems in the future. I have to open a ceiling in the area below the rad for a different issue so I think rerouting the vertical pipe straight up might be worth the extra work.

0 -

If it is pitched and supported properly and insulated it should be fine

0 -

Oh my Eyes…

There was an error rendering this rich post.

0 -

It likely needs swing joints at the corners of the u to be able to get the proper pitch.

0 -

Assuming the floor is basically level and the pipe at the center top of the picture is headed towards the boiler, if you look where the pipe sits in the notches cut in the floor joists it looks pitched wrong. which your level confirmed. The far end near the electrical box needs to be raised. Raising the radiator some more may also help with that agenda.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

A minor (?) comment. You have a notches in those joists near mid span on the bottom side. They couldn't be in a worse place structurally. DO NOT CUT THOSE NOTCHES DEEPER! Figure out a different way to get the proper pitch.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

Great observational skills by 109A_5. And per mattmitch an indication that I have not lived a good, clean life.

On closer inspection of that rear notch where the pipe appears lower I find that a PVC waste pipe was added as part of a bathroom install or rehab. The PVC is exactly in the line of where the steam pipe should be so I’m guessing they just lowered the steam pipe. Marvelous.

Looks like I will get a proposal for rerouting steam pipe in a way that eliminates the “C” loop.

1 -

-

Probably only with steam you can't get away with that waste pipe maneuver. I can think of 4 possible ways the fix that, may be there is more.

1) If the part of the pipe going back to the steam main has excessive pitch lower that upper right elbow in the original picture.

2) If the wet return is near by add a drip to the low part of the horizontal run and drop it down to the wet return level and connect it to the wet return. Add a flush out port too.

3) Stair-step it. Cut (or raise if it does not cause other issues) the vertical riser that goes up the wall so the horizontal part goes over the waste pipe then drop it down on the other side the waste pipe to connect with the original horizontal pipe. Since a new bored hole would have to go through the floor joist over the waste pipe I would sister in a new 2 x ? (maybe 2 x 8) to make up for the loss of integrity.

4) Cut the waste pipe raise the steam pipe to where it was, then install a trap (or slight trap like structure) to go under the steam pipe. You may also have to put a pipe over the steam pipe to maintain the venting capability. Add a clean out too.

You will have to determine the practicality and economics that is best for you.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

If the height of the main is such that you can't get it to slope toward the main without cutting the joists, you can do as @109A_5 alluded to in 2 and bring the line below the joists, slope it toward the riser anmd tee a drip off the bottom of the riser to bring the condensate back to a return below the water line. the drip can be up high until it gets to the return as long as it has slope toward the return.

0 -

thanks for all the input. I will do some measuring and see what works.

0 -

5) Since the waste pipe seems to pitch up in the direction of the steam main (although that would make the 'Y' in the waste pipe seem odd), maybe the run-out can take another path and have sufficient pitch to drain correctly. Go parallel with the waste pipe over the wall then under the waste pipe. The steam pipe pitches down as the waste pipe pitches up. When you get it working support the pipes well.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements