Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

pressure/head loss, resistance of baseboard loop

Options

dpenny

Member Posts: 24

in Gas Heating

Background: am replacing current baseboard heater/boiler cuz it could not keep house at 70F this past winter. I have 5 quotes/bids that differ GREATLY as to equipment & price. 3 utilize primary/secondary setup, while 2 say primary only is fine for my single loop situation. We have mild winters, one week at 20F. I want to figure the pressure loss in loop to help me evaluate the circs being suggested. Which of the following would you trust more:

- First principles: length of baseboard piping (house perimeter) + elbows + up/down into crawl space = 286 equivalent feet. 3/4" copper @ 8gmp ⇒ 25 psi loss or 57 feet.

- Use existing pump curve & current flow: Grundfos UP 26-99F @ 4gpm ⇒ 30 feet head.

#2 include loss of boiler, whereas #1 does not.

Are these two close enough to size new circ pump to then compare what is in the several quotes? Please don't wander too far from my Q.

THX.

0

Comments

-

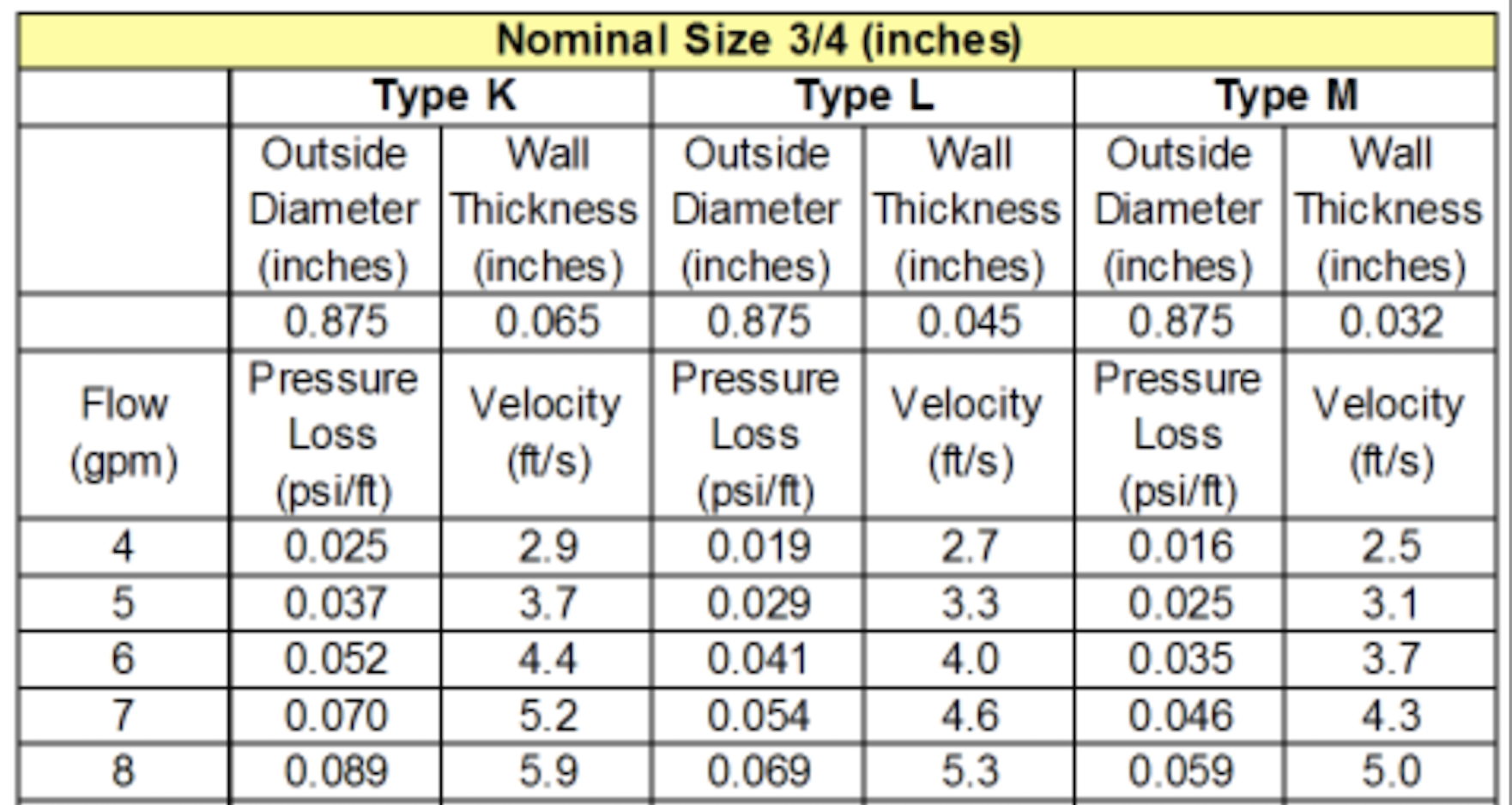

- 8 gpm is way to high of a flow rate for 3/4 copper, 4 gpm is best practice,

- 4 gpm in 3/4 copper type M is 2.5 fps velocity.

- .016 psi/ ft pressure drop. So call it 300 feet of equivalent length gives you 4.8 feet of heat

- So the circ spec is 4 gpm at 4.8' head. Well within a small residential circulator.

- Pressure drop through the boiler depends… a basic cast boiler next to nothing. A restrictive mod con would be more restrictive, that is where primary secondary or a hydro sep comes in. Separate the two circuits.

- 8 gpm in 3/4 copper would be 5 fps (feet per second) velocity, that will be noisy and cause wear in the tubing and ells. 4 fps is about as high as you want for velocity. Rule of thumb 2- 4 fps.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Why wouldn’t you figure out the btu requirements first? Then all sizing flows off of that.

0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements