Burnham ES2 - ES27 Spill Switch

Comments

-

is it possible that you have a large enough basement according to the minimum requirements but your home is so well insulated and sealed and that you are not getting sufficient draft at some point when a exhaust fan or clothes dryer is operating, that you actually get the down draft that would cause the rollout switch to trip? Leaving a basement window open to provide that low pressure relief would solve the problem. Since you mentioned that with the window open there has been no problem. Did I understand that correctly?

If your open window has mitigated the issue, and you don’t want to leave the window open all winter, then an outdoor air intake may be the solution. Place the opening some distance from the boiler and run a 5” or 6” round pipe across the basement ceiling in order to allow the cold winter air to warm up a little so you don’t bring in sub-freezing air past any pipes that can freeze.

Ask me how I know this

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

3 -

All troubleshooting involves guessing. The results of each guess move us closer to a valid solution because of the tests we do after each guess.

I troubleshot a lot of military gear in my working career and I became the chief troubleshooter because i developed a knack for making educated guesses that got me to the correct fix in the least time.

Bob

Smith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge2 -

@EdTheHeaterMan Ask me how I know this

please if there is a good story behind would love to hear

Thanks

0 -

When you are a hammer everything looks like a nail.

When you are an electrician, every problem is electrical.

Near 5°F in Cape May County, NJ. (Design temperature is 17°) and the high temperature for the day was 13°. A neighbor who worked for an electrician called my office at about 11:30 that day and since he was near my home, I said he would be the last call for the day. and it was a very busy day. 4 full time mechanics were going to be working overtime with the amount of service calls that were pouring in. One of the full timers lived three houses down from me and 5 houses down from the electrician apprentice.

My office got a call from him every hour for the next 7 hours. In the meantime he attempted to find the problem himself. There was no heat in one of three zones that were operated by three circulators. He had a Taco SR503 relay to operate those three circulators. The older style with the ice cube removable relays. By the time I got there after 10:00PM the relay socket had been ripped from the circuit board from so many test and diagnostic procedures the electrician performed on his system. Wiring and rewiring, swapping circulators from one zone to another. Wiring the circular directly to 120 v.

My apprentice mechanic, who lived nearby arrived at 9:45 PM and was looking at this mess. When I got there I did some basic tests and saw the damaged 3 zone control and within 10 minutes, I determined that it was not an electrical problem. The circulator pump was operating as it should, there was a blockage in a pipe somewhere or the zone was air locked. Connect the garden hose to purge the loop only to find that no water would flow through the piping. I asked where the crawlspace opening was located.

Around the back of the house was a 2’ high x 3’ wide plywood panel (not insulated) to access the crawlspace. I opened the hatch and looked straight up to find a ¾” copper pipe that had not yet burst. I added some heat with an electric heat gun to the pipe… and Woosh… the heat started to flow.

So the Electrician tried in vain to repair a frozen pipe with screw drivers, meters and a heavy hand on the zone control. That was over 15 years ago and to this day, I believe he still has only two working zones. One of the working zones has 2 circulator pumps connected to it. (and he wanted to negotiate the cost of the service call after the price was quoted and agreed to and approved because we were “Friends” from the same neighborhood). I have not done any service calls for him since. My neighbor still talks to him, and that is how I know that he still has 2 working zones.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

"I opened the hatch and looked straight up to find a ¾” copper pipe that had not yet burst."

Just curious: How were you able to tell that the blockage was there? That is, how can you tell that a pipe is about to burst? Does it bulge? Please keep in mind that we've only had one winter cold enough to cause pipe to freeze since I moved here in 1957, so I don't know these things.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

I will jump in with the story of my own to answer your question Alan although I still love to hear what Ed has to say

I was called out on a Tuesday morning by customer this past winter saying the whole house had no hot water, I checked around the house cold water was fine but no hot water, which lead me to check at the hot water tank and I noticed the cold water feeding was kind of warm I opened the union at the hot side there was no water flowing so I started "guessing" that the pipe froze the night before was in the 10° I followed the cold line in the ceiling and yes it was open to room that was open to the street after about 20 minutes with heat gun my "guess" turned out to be reality water started flowing again in the pipe and life was good

Should someone tell me how they would "Test" not guess where the line is frozen I'm open for training all the time, that's the primary reason I'm here listening how people talk on paper, and you learn something new every day

Thanks to all of you

BTW I hope @jdigangi will come back on to tell us what's happening with his spill switch please

1 -

Homeowner = My heat isn't working, can you send some one?

Contractor = Yes, we will send our best guesser!

-1 -

A first guess can be fun, to see how well you guessed, when the repair is done. To me guessing, educated guessing (backed up by experience) and testing are all different. Guessing (of any type) when possible should be backed up by testing.

Troubleshooting can be done without guessing. You just use knowledge, Logic and follow the evidence with the appropriate test equipment.

Just random guessing can point you in the wrong direction just as easily as the correct direction.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

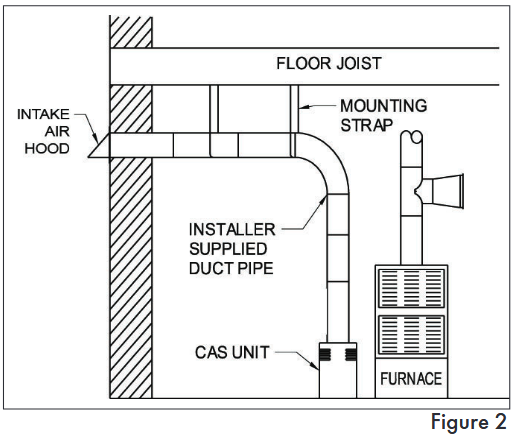

My guess from here, with only the multiple spill sensor failures and the open window test as data. Is an air intake like the image below sized correctly so you don't need the fan (CAS Unit), is what is needed. Combustion analysis could confirm the guess or point to another issue.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System2 -

Let me guess it was raining in the basement ?? The CAS34U came today I need to figure out what wall I am going to mount it to. I have a bunch of options to get the pipe lengthy I was shooting for 10-12 feet for good measure. Condensation is the concern with this system they recommend length of pipe based on BTU of the boiler. Length is to allow the air to warm up before it spills on the floor out the can.

The house is 10 yrs old……very over built & well insulated

Its an atmospheric gas boiler… its not its oil fired….I can't adjust the air bands or the nozzle or the depth of the nozzle to change the conditions. Its a gas valve a manifold and burners, if I felt buying a combustion analyzer would have given me some magical data I would have got one. There is a gas (NG) detector by the boiler as well as a CO detector with both show PPM

As the old saying goes those that can't do ….teach…perhaps Jim should keep his comments to himself. If you don't have anything nice to say…perhaps you should not say anything. For the others that have provided constructive information I thank you all

0 -

I don't disagree with you at all, in most cases this would be a clogged chimney or something. The frequency of when it occurs its very random and infrequent. I also don't currently have a method of knowing when it exactly occurs so I notice a lack of hot water or the thermostat is calling but no ones home.

0 -

-

The parts cannon people guess. The rest follow the clues. Like a detective. Interview the victim (homeowner). "Just the facts, ma'am." Then we go solve the crime. Sometimes the culprit leaves an extensive trail in its wake before you catch up with it. Sometimes you catch it red handed (I don't even know what that means) the first place you look.

0 -

" I also don't currently have a method of knowing when it exactly occurs so I notice a lack of hot water or the thermostat is calling but no ones home. "

Since you live there and you seem to like to tinker with the issue, I would have wired a Sonalert across the spill sensor. So when it opens there is 24 VAC across the open sensor activating the alarm. As an example,

https://www.digikey.com/en/products/detail/mallory-sonalert-products-inc/PK-41N29W-24VQ/21823271

If you really wanted to get exotic a device that gives a GPS time stamp could be put across the spill sensor so when it opened you would have a time stamp with one second resolution. Many ways test things to acquire data.

Also in my opinion 'inspection' is not guessing, it is part of a logical troubleshooting strategy. Eliminate from the testing process what is not the problem.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

This would likely be my preferred path (Shelly), I built a proper humidifier control system with 2 of these and a bunch of humidity sensors home assistant and node red. The shelly devices are smart so I can tie them into my home automation and set various alerts etc.

0 -

Sure if they make a unit that that accepts a 24 VAC input to trigger an alarm, using the filter on the web page I could not find one. I'll look again. You could buffer it with a small 24 VAC relay, so a Shelly unit only sees a contact closure.

Seems like the Shelly products are more about power control and little with the monitoring of user connected device with alarm outputs.

Maybe the " Shelly Plus Add-On "

Although their web page would not let me open the documentation for this device, so not getting a real good vibe.

Many things you could do, just don't make smoke.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

45 years of combustion testing, training and consulting, in 44 states might be enough experience. I teach techs not to guess and cause people harm. Google "Jim davis carbon monoxide" on the internet. Combustion analyzers don't tell you what's wrong. that takes experience.

How does a rooftop unit run out of combustion air?

If there is not enough combusion air in the room, what were you breathing?

1

Categories

- All Categories

- 87K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 57 Biomass

- 425 Carbon Monoxide Awareness

- 116 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.7K Gas Heating

- 109 Geothermal

- 160 Indoor-Air Quality

- 3.6K Oil Heating

- 70 Pipe Deterioration

- 984 Plumbing

- 6.3K Radiant Heating

- 389 Solar

- 15.4K Strictly Steam

- 3.4K Thermostats and Controls

- 54 Water Quality

- 44 Industry Classes

- 48 Job Opportunities

- 18 Recall Announcements