New Propane Boiler Options

Greetings! First time home owner and poster - thank you all for helping me learn.

Tldr: It seems like heating companies want to install an oversized boiler. What do you recommend?

The House: 1973 walk-out ranch in Northern Vermont (-20F most winters). 1900 square feet. 2x4 walls with fiberglass insulation.

Situation: Need to replace the old oil boiler. The whole system is unsafe (chimney, oil tank, oil lines, boiler, piping, etc) so we are going to switch over to a new propane system.

Energy Needs: A local company's energy audit said we need 43k-46k BTUs. Their system maxed out at -6F, so they recommended that I compare to the old system of multiplying the home's cubic feet by 3 (average) or 4 (loose) to get a higher BTU rating. If I multiply the home's cubic feet by 3 I get 50k BTUs, by 4 I get 66k BTUs, so I think we are right in the 45-65k BTU range.

Quotes: I have quotes from 5 companies. Most companies are recommending the Weil McLain GV90+4, which has a DOE of 97K MBH/BTUs. Other companies recommended the Systems 2000 EK1 Accell LP (unknown BTUs), IBC SFC199 (I think 27.1 – 111K BTUs), or an Ideal 155K BTU (123K BTU) unit. I will not include specific pricing per the forum rules, but the GV90+4 is significantly cheaper than the other units.

Question: It seems like companies are recommending boilers that are rated a minimum of 30K-60K more than it seems our house needs. I understand that it is not good to have an oversized boiler. Should I try and push or get a quote for a different/smaller boiler? Would the GV90+3 be a better fit at a DOE of 65 MBH/BTUs?

Thank you all!

Comments

-

There are 3 separate BTU numbers on each boiler. Prior to 1968 there were only 2 but when the government got involved with the department of energy they needed to have an equal footing to measure furnaces and boilers for those yellow Energy Guide stickers on each heating appliance to make it easy to compare the different systems. But I digress

Back to the three different BTU numbers.

- Gross Input aka Input aka GPH on oil fired equipment = How much energy goes in

- Output or DOE output is how much energy gets put into the home (maybe). Or better described as what is left over after what is lost out the vent pipe.

- NET output aka I=B=R NET and now known as DOE NET. This is the number that you are supposed to use when you know the actual heat loss of the building. It is actually a 15% lower number that takes into piping and pickup consideration on a water boiler. (it is 30% on steam boilers)

So when you know that you need 46,000 BTU per hour on a design day (that is what we consider the average coldest day of the year for an area) Then you use the NET number which is much smaller that the Input that the boiler usually is sized by.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

The GV90+3 would be right, based on your estimated heating demand. The System 2000 EK1 is a bit large for you application, but has rather sophisticated controls which enable it to work well on smaller loads — and is a very high quality boiler.

At least as imp;ortant is the craftsmanship and skill of the installer. A good installer can make even a mediocre boiler at least OK; a poor installer can make the best boiler in the world a mess. I believe the EK1 has a limited selection of installers.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

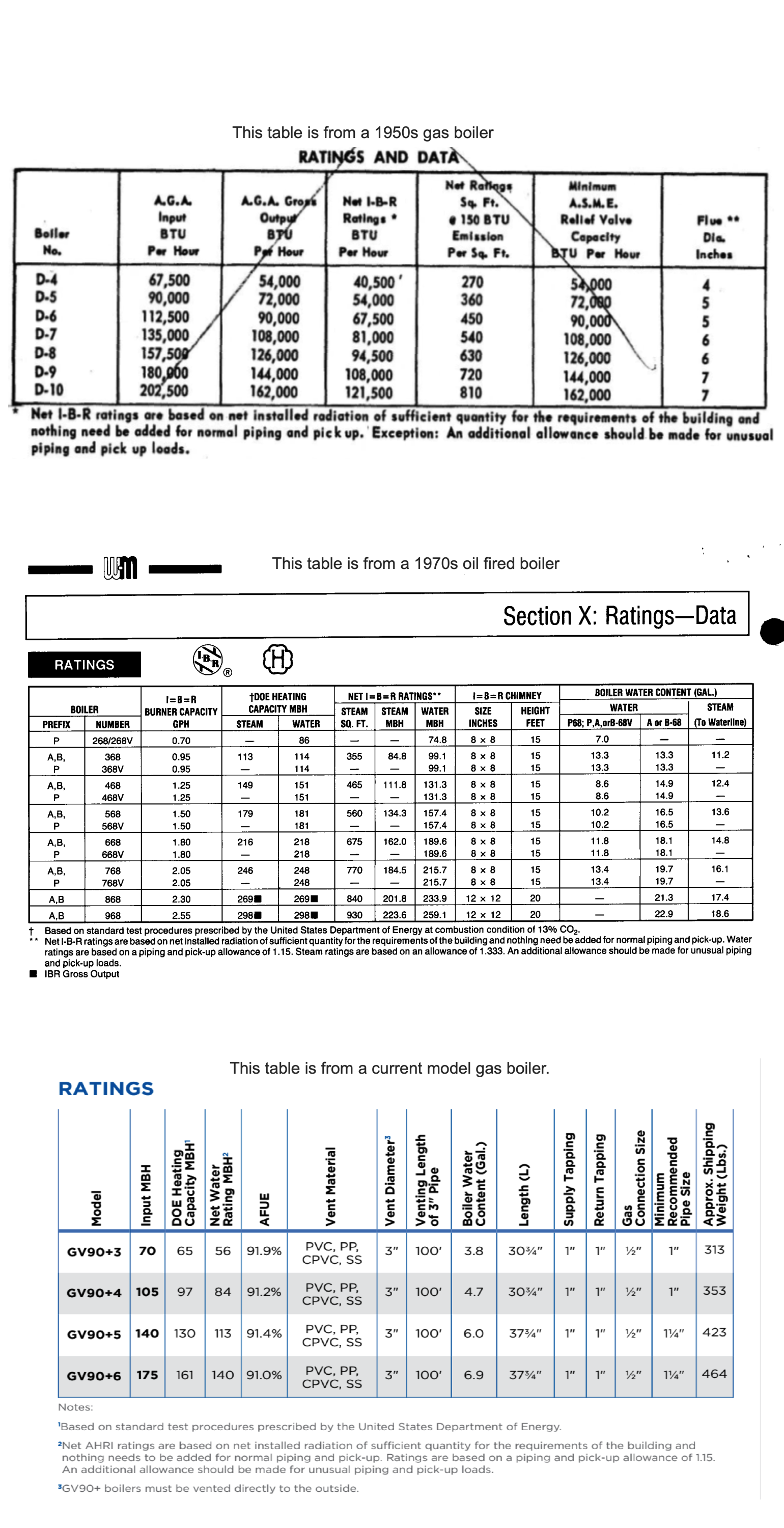

Here are three different rating tables from three different boilers

You can clearly see before there was a Department of Energy in the 1950s boiler rating were dome by the American Gas Association (AGA) and the Institute for Boiler Ratings (I=B=R) and all the boiler manufacturers used these ratings to rate their boilers. The Weil McLain model D boiler that has an I=B=R Gross output of 90,000 was about 80% lower than the Input of the boiler at 112,000

When the 1970s oil boiler was rated they used GPH for the I=B=R input and Gross output was changed from I=B=R to DOE output. That would make that oil burner about 84% efficient since one gallon of fuel oil is equal to about 140,000 BTU of energy. At this point there are no yellow AFUE stickers yet but the Department of Energy has been formed to keep the cost of oil from getting out of hand.

In the current gas boiler you can see that the numbers are still the same but they all are under the direction of the DOE.

- Input

- DOE heating capacity or output, and

- DOE NET

Still the same numbers as in the 1950s but the names have been changed to protect the innocent. So look at the NET number when the boiler says 70,000 it is really going to do a good job all the way up to 56,000 BTU heat loss on a design temperature day. I believe you will be just fine with the GV90+3

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

-

Thank you everyone for your replies!

@EdTheHeaterMan thank you for the detailed explanation. I have learned a lot about the different BTU ratings. We should need between 45-65K NET BTUs. Based on what I can find online the boiler options we have been quoted are:

- Weil McLain GV90+4 DOE 97k, NET 84K BTUs.

- NET is 19K above our max estimated BTU needs.

- Systems 2000 EK1 Accell LP, input 90-120K BTUs so I guess NET 86-116K

- NET is 21-51K BTU above our max estimates BTU needs.

- IBC SFC199 DOE is 27.1 – 111K BTUs.

- Our BTU needs fall at the lower end of this range.

- Ideal 155K with a AHRI NET Rating of 123K BTU.

- NET is roughly 60K above our max estimated BTU needs.

@Jamie Hall and @EdTheHeaterMan I agree, it looks like the GV90+3 would be right sized. It would provide 56K NET BTUs which seems to be appropriate for our system.

@EBEBRATT-Ed I was definitely interested in the EK systems, and the company sent me several local contractors. I reached out to them all and have quotes, but every single one of them recommended that I go in a different direction, usually the GV90+. Not one of the System 2000 dealers have recommended their system without me asking specifically for an EK quote in addition to the GV90+.

I definitely want a high quality install. Unfortunately, there are no contractors listed on this website in my area of Vermont (closest is in New Hampshire). All of the companies I have quotes from have good reviews online, but how else do people evaluate in advance if the install will be high quality?

0 - Weil McLain GV90+4 DOE 97k, NET 84K BTUs.

-

Thank you for your post, @FirstTimeHomeOwner , and for everyone's kind comments about Energy Kinetics.

I'd recommend reaching out to Marc Debois, Energy Kinetics territory manager in Vermont and New Hampshire. He can be very helpful in facilitating dealer interactions, answering questions, and with technical and other information. He can be reached at (603) 493-0508.

The Accel CS (EK1C) is the smallest size modulating condensing boiler we offer and it's built to last with a super durable design that we manufacture in the US (New Jersey). The oversized plate heat exchanger design for hot water combined with thermal purge operation deliver the best in condensing operation. The increased condensate keeps the boiler cleaner and thermal purge provides extremely high efficiency even with very small loads. The Accel CS also has the top performance in the world according to AFUE, but even better, it's real world heat and hot water efficiency separates it even further from other condensing boilers.

If you are interested, this post, I describe how to calculate heat loss using gallons of oil per year. This figure estimates design day including hot water (if applicable).

Please feel free to reach out to Marc, PM me, or call Energy Kinetics at 908 735-2066.

Thank you,

Roger

President

Energy Kinetics, Inc.5 -

Thank you @Roger ! I have read many positive reviews of EK on the forum. I did reach out to Marc back in May and he connected me with the EK contractors in my area. I had very positive interactions with everyone who came through for a quote. I appreciate you reaching out on the forum!

2 -

The important bit is not the max output as most will cover your load but the minimum output. You want this as low as possible to avoid cycling.

Around me propane heat is only a bit cheaper than resistance heat so you have to take some care to get actual cost savings.

This means setting an aggressive outdoor reset curve and not micro zoning. Ideally you want to boiler to fire end of fall and not shut off till after winter. That won't happen in the real world but you can get close with the right equipment and proper configuration.

Most hydronic installers will push for an indirect for hot water. These are not as efficient and most believe (best case is mid to low 80's) and more expensive than other options. Cheapest hot water is a heat pump water heater, next best thing if you water quality is decent, is a propane tankless. Power vented tank water heaters can also work but have similar operating cost as a resistance tank around here.

1 -

do we have enough information about the life of the refrigeration system in hp water heaters to work out if the tco is less than an indirect or gas direct fired water heater? with an indirect the important thing for efficiency is to make the tank large enough that the boiler only fires for larger loads.

1 -

@Kaos , you’re spot on about micro zoning - it will keep the boiler idling and waste energy.

But the most efficient state for a boiler is when it’s off, so the best design is thermal purge so no energy is wasted at the end of each cycle. Properly designed indirect tanks with plate heat exchangers and thermal purge will exceed the efficiency of combi boiler water heating. Last month's ASHRAE journal also had an article that highlighted why heat pump water heaters have major issues (water damage and mold in enclosed spaces of outside walls due to cold discharge air), they operate at outputs and efficiencies far below their ratings (the rooms cool off and drop performance as there is no external heat source to feed it). Further, Vermont has relatively “cheap” residential electricity ($0.225/kWh recently) compared to the rest of New England, but that’s still $6/gal propane and $9/gal fuel oil equivalent so the cost to operate the heat pump water heater is more even without including the effective impact of running a small air conditioner in your home in the winter. Most of the boiler country in the US does not have comparatively inexpensive Canadian electricity prices found in some provinces you reference.

RogerPresident

Energy Kinetics, Inc.2 -

@mattmia2 That is a fair point. HPWH manufacturers have not been doing themselves a favor as recent generation seems to be less reliable. LG is out with some newer stuff and their engineering tends to be better.

A larger indirect tends to make the install BOM cost even worse as they tend to be significantly more expensive than smaller ones. A larger tank that can stratify with a dual coils can improve efficiency but again, but the cost math won't work out.

@Roger I've been running an indirect with a plate HX fed before by a modcon before (now an air to water heat pump). I have not done official measurements on efficiency but have had instrumentation on it to see temperatures. The issue is that outside of very large draws like a tub-fill, the RWT is to high to get much condensation. Running to makeup for standby losses is even worse. Thermal purge only works during the heating season and even up here in the great white north, that is about half the year.

If a bit of cold air is creating mold issues in the house, the house has major building envelope issues. Not saying that those are not out there, but those houses will have mold issues even without a HPWH which should be fixed.

0 -

Here’s some more info on calculating heat loss by fuel usage.

https://forum.heatinghelp.com/discussion/187373/heat-loss-calculation-accuracy

0 -

@Kaos , the controls have to be designed to allow stratification of the tank so that continuous cold water make up feeds the plate heat exchanger. The entire system has to be designed properly or you end up with lower performance and the boiler finishes hot which wastes energy (as it does with a conventional indirect tank and combo/instantaneous systems).

Regarding heat pump water heaters, the article indicates this is a common problem that has to be solved before widespread use of heat pump water heaters. This makes sense because the rooms (and outside walls) are chilled as part of normal operation. This introduces a new mold and condensation problem in the outside walls that did not exist before the heat pump water heater was installed. The authors identified the following issues:

- Inadequate heating capacity compared to advertised specifications.

- Real-world efficiency significantly lower than rated efficiency.

- Moisture-related damage and mold growth.

And believe the issues generally track back to two primary causes:

- Insufficient access to the thermal resources inside the building.

- Improper handling of cold exhaust air.

Roger

President

Energy Kinetics, Inc.2 -

Thank you @Kaos and @Roger! Your posts raised a few good questions for me.

- Minimum output: I believe the Weil McLain & Accel CS are not modulating boilers, which I think means they are more "on/off" versus adjusting for the heat needs, is that right? In which case the minimum output would be the same as the NET, correct?

- Micozoning: The house currently has 2 zones (Zone 1 basement, Zone 2 upstairs, each 1k square feet). I had planned to add more zones to separate living areas and bedrooms (I perhaps incorrectly thought it would be more efficient) and to give the option for indirect DHW, but your posts made me think this could be a bad idea since microzoning increases cycling (hurt efficiency and longevity of the system). Do you think I should stick with 2 zones?

- @Roger The quote I received for the "System 2000 EK1 Accell LP Boiler" does not mention domestic hot water, but the website makes it seem like the boiler and water tank are one system. I will call the contractor to confirm but do you think the quote includes the DHW capability?

@HydronicMike unfortunately I do not think a fuel usage calculation is super helpful in my scenario because I just bought the house. I called the oil company who said the previous owner received fuel assistance. He used 500 gallons of oil last year, but had the basement turned to 55 degrees and was gone all Spring. I did use the link you sent and did some of the calculations but came up with 20.5k btus/hour, which I do think is too low. I would probably have used a lot more oil than the previous owner.

Thank you all!

0 -

You're welcome, @FirstTimeHomeOwner .

The Accel CS is a modulating condensing boiler and can modulate down to 18,000 BTU/hr.

We recommend that you zone comfort areas, so your idea of separating living areas and bedrooms is a good one, but you could leave your zones as they are if the heat uniformly. Just do not zone each bedroom separately, which would be micro zones (an exception may be a separate zone for a master bedroom with a master bath).

I am not sure if your quote includes the domestic hot water system, your heating pro would need to clarify that for you. Each Accel CS does come with controls so it is ready to add an indirect tank or plate heat exchanger and storage tank with thermal purge (which is much more efficient as the boiler finishes cold each hot water cycle vs finishing hot with an indirect tank).

Best,

Roger

President

Energy Kinetics, Inc.2 -

@Roger Thanks for sending that article along. BSI stuff is usually well researched but there are some real issues with the article. When they are doing the calcs for heat extracted from the house air, they don't take into account that all exterior walls are radiating heat into the house, a large volume of air like that barely budges in temperature. They also don't mention that a HPWH in a 60F dewpoint place is actually dehumidifying the basement, the issue is there is not enough mixing with house air.

There are definite issues with HWPH install instructions, the min recommended room size doesn't work unless there is a heat source in it. Usually, the best option is to duct the exhaust, this lets you put it where the cold air helps (ie near HVAC return or behind fridge). They really should say something about watching where the exhaust goes especially in humid places.

I'm in the land of near universal basement dehumidifiers because without it houses (especially older ones) do get up to 60F dewpoint at which point they are musty. So people generally never keep a house that humid. The bonus is the dehumidifier makes for a nice space heater which is exactly what the HPWH needs. Here is what that looks like:

0 -

the heat pump water heaters also tend to do resistance heating during big demands unless they are very large

0 -

Thank you for the article you posted, @Kaos , these are all good things to explore. The example in that article presents a scenario requiring room air dehumidification when it was 90°F outside; this is much different scenario than operating a heat pump water heater in cold climates when outside air is cold and dry.

The ASHRAE article I referenced indicates that heating discharge air from a heat pump water heater is a possible solution as the air impacting a surface can cool it down below the dew point. This is not easy without an external source of heat. Although the discharge is localized, it is informative to see the following analysis on the impact of a heat pump water heater on a room the size of an entire home:

"The best-case scenario for installation in an enclosed space would be a closet the size of an entire house. …The HPWH would be able to extract about 6.2 kBTU of heat from the air (5.3 kBTU sensible + 0.9 kBTU latent). This is not enough heat for a single heating cycle in a typical 3 to 4-person household of this size. Furthermore, cooling indoor surfaces down near 45ºF for more than an hour, multiple times a day, carries a high risk of moisture damage and mold in most climate zones. If the air mass in a 1,625 ft² room does not contain enough energy to heat the water, neither will the air in a smaller room."

Roger

President

Energy Kinetics, Inc.2 -

I think HPWH have a long way to go to be reliable. To me they are an expensive throw away appliance.

Who are you going to call when you have a refrigeration issue? The MFG will say scrap it its not worth fixing. The plumber who installed it probably does not know refrigeration. Is an HVAC company going to want to bother with it?

Unless it is a simple fix the cost of replacing a compressor or the controls will exceed the appliance value.

And guess what, any energy you saved is GONE. Quality is not ther.

I can't even find a window unit that will last.

1 -

if you want on that lasts you're going to have to find a used one that is 20+ years old.

0 -

"…The HPWH would be able to extract about 6.2 kBTU of heat from the air (5.3 kBTU sensible + 0.9 kBTU latent). This is not enough heat for a single heating cycle in a typical 3 to 4-person household of this size"

This is the bit that is plain wrong. Air inside the house touches many surfaces. All those transfer heat, there is a lot more heat in a house than just the air, more than enough to supply a HPWH.

Lets look at it another way. An air to water heat pump is essentially a 4000BTU water source AC. Pretty much the same as the smallest window shaker, runs maybe a couple of hours a day.

If you look at it like that, you can install it anywhere you can install a window unit. It also becomes obvious that it is a bad idea to have a window unit blowing directly at a wall or pretty much any equipment, same with a HPWH.

0 -

And those other surfaces are heated (almost exclusively in the heating season) by the primary heating system. So it’s just moving (heat pumping) energy from the primary heating system into the water tank. And it dries out the room air which needs to be circulated past the heat pump water heater to keep it warm enough to prevent resistance water heating elements from kicking on. Sounds a bit convoluted…unless you’re in a hot climate or you can efficiently run the compressor during winter outdoor temperatures and have access to outside air.

For reference, residential hot water usage has historically been rated at 64.3 gallons per day, or about 42,000 BTUs per day with a 77° F rise. That’s more than a few hours of runtime with any heat pump water heater, especially when the capacity age efficiency is reduced because of cold ambient air.President

Energy Kinetics, Inc.0 -

How much heat does a refrigerator put into the space 1000- 2500 BTU/ hr. while running? That would be available for the HPWH. Other appliances, computers, etc?

Ducting the HP seems to becoming more common.

It always comes back to how much DHW are you trying to generate, at what ∆

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

it looks closer to 400 to 800 BTU per hour for modern refrigerators, so it will be challenging to capture enough to meaningfully contribute to hot water. You can look at the wattage of computers to figure out the heat gain, but that’s not continuous.

President

Energy Kinetics, Inc.0 -

Regarding the hot water usage of 64 g/day:

While the 64g/day makes sense, the amount of oil consumed to produce this in a direct fired water heater is more than double that value. The Bock uses approx. 1.1 g/day in the summer for producing hot water for two people. It only runs for four hours in the morning and four hours in the evening (with a timer) but it still manages to utilize an input, on oil, of 154K for the day. Surprising but documented.

0 -

in winter months the heat comes from what ever warms the space. In the summer heat gains are from appliances, humans, but also thermal gains through ceiling, floor and wall insulation and windows. I’m sure the gains could be calculated then matched to the HPWH demand based on DHW consumption.

Thermal solar covers the majority of my DHW, and costs me a small ECM pump load :)

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

@Roger In the winter about 2/3 of the heat a HPWH uses for the hot water does come from space heat. That is no different than an indirect.

In the summer, a boiler/indirect is adding hear to the house (which the AC now has to remove) whereas a HPWH is helping to cool it. That is a pretty good deal in most places where summer cooling is the norm. I'm in pretty cold climate but my cooling season is still about 5 months.

0 -

@LRCCBJ , with a 77° rise, that would be about 26% efficiency; I don’t see how that’s possible unless significantly more hot water (or less oil) is being used.

@Kaos, Indirect tanks can add heat to the home, but electric water heaters and well insulated indirect tanks only have standby loss of about 60 to 80 BTU/hr.

President

Energy Kinetics, Inc.0 -

I agree with @Roger up there, @LRCCBJ . Something is amiss with those numbers. I have two Bock 32 gallon water heaters to manage, both running .75 gph nozzles. One is in a single occupancy buiding, and runs perhaps 15 minutes, twice a day, when the occupant uses hot water. The other has four people to work with, and runs not more than an hour total in a day. And no one skimps on the hot water…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

I agree that the numbers don't quite make sense. The oil consumption is exact as it utilizes the electronic gauge and it has regularly consumed about 8 gallons per week for the past six weeks.

Now, I cannot account for the usage by the significant other. I take a ten minute shower…………she might take a 30 minute shower.

The Bock does lose energy to a greater degree than anticipated. It is much greater than 1 degree per hour………..my undocumented guess is close to 2.5 degrees per hour. If accurate it will operate every three hours to maintain which is not calculated, of course, in the usage.

One additional point to note:

The Bock is a 51e operating with a .75 nozzle, 21 years old and definitely has accumulation at the base of the tank. It is noticeable by the slight crackling sound. The stack temp is 500F. It's going to use more oil than anticipated. I did find another Bock that is 6 years of age and will probably swap them when I get the time.

0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements