Steer me away from potential disaster?... (Heat transfer plate install in Europe)

What is the goal?:

Install a floor heating system that has minimum loss of already extremely limited room height.

My concerns of "potential disaster":

1) Is the difference in R value enough to force heat up? Above = 0.7, Below = 3.5

2) Will European PEX-A (16.00mm O.D.) fit into heat plates like US PEX-A (15.88 O.D.)

3) Any risk screwing heat transfer plates into gypsum fiberboard instead of wood subfloor

Background:

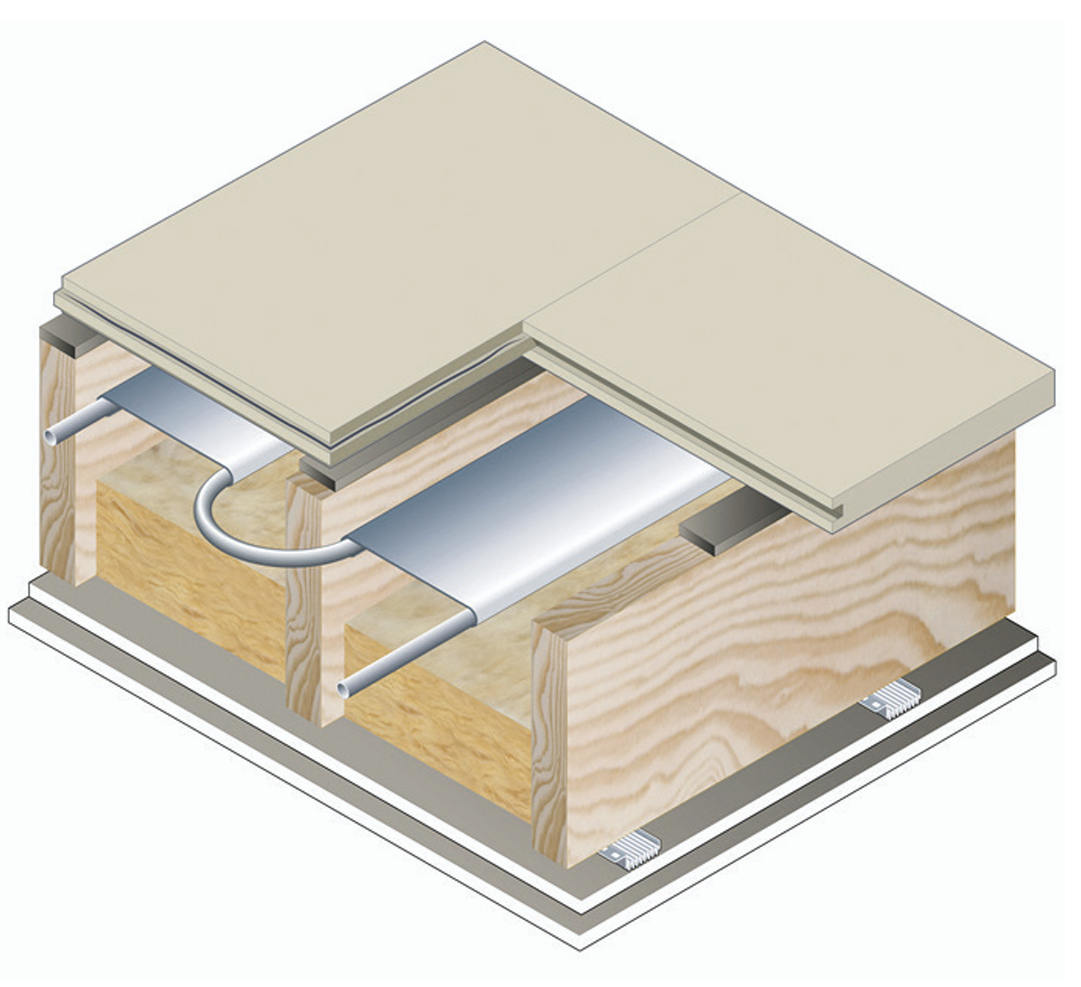

Extruded plates screwed under 1" (25mm) gypsum fiberboard panels ("GIFAfloor" from Knauf) with ~5" (12cm) mineral wool insulation in the joist cavity underneath the plates. Above is glued 3/4" (18mm) end-grain wood flooring (in the living areas) or ceramic tile (in the wet areas).

Visually its like the illustration below. (The illustration is Rauplate which I won;t use. Will use Uponor Joist Trak or Radiant Design ThermoFin.)

Source: 6a994ec1-12c8-44b6-8e3f-fb3be24d62fb

Slightly unusual move is I will ship the plates to Switzerland where European size standard. The plates are sized 1/2" PEX but to use with European PEX.

Questions:

1) Are the R values different enough to drive heat up (especially considering gypsum is more of a heat conductor than insulator….)?

above:

GIFAfloor 25mm: 0.06

End-grain floor: 0.7

TOTAL_________: 0.76

below:

Mineral wool 12cm: 3.5

2) Tubing sizes in Europe are barely bigger - will it fit in the plates?:

US 1/2" PEX-A (ASTN F876) = 15.88mm O.D.

EU 16mm PEX-A (ISO 15875)= 16.00mm O.D. (+0.75% bigger)

3) Any experience / risk of screwing into gypsum fiberboard (dense and hard, not like drywall)?

The potential disaster is I import a few thousand dollars of plates that are not effective.

I think the risk is very low but appreciate your experience / opinion!

I think this may be the first Uponor / Radiant underfloor plates in Europe? For sure the first in Switzerland…

BTW, if you have ~550 extruded heat transfer plant (4 ft long), please send me a message…

Comments

-

With regard to question 1 — R value doesn't "drive" heat anywhere — it just measures how much heat will be transferred for a given temperature change. In this case most of the heat will go into the flooring, and then some will be lost downwards (always is, in radiant floors) but most of it will go into the space above..

I personally doubt that the difference in tube size will make much difference — but I have no experience in that at all. But 0.12 mm isn't a whole lot!

With regard to 3, yes I've done that. It will hold… better than drywall, but not much better. Use the best quality screws you can buy, coarse thread, and sharp — and don't overtorque them.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

-

True, "drive" wrong word. Maybe "dam" is better description.

Simple thinking: R=3 below the heat transfer plates, R=0.7 above. 4.3:1 ratio. Plus, plates screwed/conducting to a high-density, high-mass (~8 lb/sq ft) gypsum acting as a heat 'sink'. Seems to create a scenario for heat to strongly conduct above to floor and room rather than down.

Specific question is if worthwhile to increase R value below the plates to conduct more heat to floor above? Read previously (can find source) a recommendation for 10:1 R-value ratio (below:above) for underfloor heating systems to achieve effectiveness. 10:1 is correct goal or overkill?

Thanks for comment about screws. I haven't screwed into gypsum fiberboard before. Drywall is weak and crumbles - so aiming for better than drywall and realistic that it is not wood. Will test some screw variations once gypsum fiberboard delivered…

Very helpful to hear it has been done before. Thanks for that. 😎0 -

Read on forum the plus and minus of using adhesive between plates and subfloor (in this case gypsum fiberboard)…. Also discussion of adding silicone between PEX and heat plates (or the thin 'foils')…

Manufactures of board and plates are not vocally advocating for adhesive. That is bit of a minus.Some risk a general adhesive is more of insulator than conductor of heat. That is bit of a minus.

Adhesive would add redundancy to fixing the plate to gypsum in case screws loosen/fail. That is plus.

Will investigate further. Thanks for the suggestion.

0 -

Screw-head confrmation is critical. Pan-head or conical? Depends on plate thickness and shape of any pre-drilled hole. Length of screw and a standardized torque achievment would be important. I think there is a Uponor recommended "goo in a gun" that they sell to apply before the pex goes in the channel.

0 -

the plate isn't going to be effectively in direct contact with the subfloor because it microscopically is very rough. the adhesive will conduct more than the air in that space. the adhesive should be sparse and thin enough viscosity wise that it won't keep the plate from pushing up against the panel. i'd use a relatively thin bead or a number of small dots but big enough that they get full contact when it is screwed in place. could use a notched spreader to apply dollops too to control the amount. It will hold to the gypsum better than the screws.

@hot_rod would know better but I don't thin it would ever work if they were depending on conduction between the plate and the subfloor for heat transfer because the contact is so poor(unless that is why the plate is so large).

0 -

I would not leave the tubing fit to chance, when you can get a sample from Radiant Design and Supply and give it a test fit. They are super nice folks to deal with. I am running 3/8" or I could mail you a few cutoffs to try. They loaned me an air hammer for installation. I think it would be even more necessary with slightly larger tubing.

0 -

I would ask Radiant Design about the metric tube fit. I imagine this has come up before.

Which one of their products are you considering? I think both versions of the C fin will accommodate that metric tube.

Knauf gives you all the specs on that board, it seems to be very dense and smooth and flat for the plate contact. You can probably find a similar spec for plywood or other subfloor products to compare.Put a screw into it and pull on it to see how it holds. There is not much weight to the assembly, it is more about a good, consistent contact.

In my last home as an experiment I screwed plates to a finished sheetrock ceiling as a test installation. It held just fine with coarse sheetrock screws, occasionally hitting a ceiling joist :)

I don't remember if you did a load calc to see what temperatures you need to run to the tube?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Thanks for perspective. Believe hole are straight (not conical as plates <0.065“). Therefore panhead screws. Torque applied controlled +/- by using (manual feed) drywall screw gun. Screw length would be slightly less than GIFAfloor thickness of 25mm (~1“). Think all above will offset your helpful „watch outs“ checklist.

0 -

I have a sample of GIFAfloor. Definitely will have microscopic (or larger roughness), but much smoother than OSB or plywood which is the standard material that plates are attached to and measured against for heat conductivity performance.

Get your point about potential additional upside of adhesive. Theoretical: Spray-on / brush-on my be best for uniform thickness and be a thin layer for microscopic roughness. Would add substantial time/labor however.

Like the post from @hot_rod in this thread about screwing plates onto actual drywall.😎👍

0 -

Very generous offer to send 3/8“ plate. Thanks for idea.

I’m planning on 1/2“ for this installation only because it seems the default size.

Metric PEX is 0.75% larger than US according to ISO and ASTM specs (e.g. 16mm vs 15.88mm). First thought would be no difference in fitting into the metal “C” shaped clamp design of the plate. Afterall, the metal (and PEX) has to flex slightly (10%? more?) to allow the standard “U.S. sized PEX” to squeeze through the opening and settle into the C channel.

Would 0.76% bigger metric PEX exceed the normal, underlying flexing and positioning happening with US PEX into U.S. plates?

Wouldn’t think 0.76% matters. But will check with the plate supplier(s).Thanks again!

0 -

AMAZING personal insight - as always.

Will ask supplier about slightly larger PEX into plate.

Will try screw into the sample GIFAfloor that I have now.

Think the bigger challenge will get screws to quickly/easily tap into the gypsum fiberboard. May need to indent with 9d nail or equivalent to create a crater in board for screws (hope to avoid these extra steps!). With drywall, I know it is easy to get screws started because of easy for screws to pierce paper surface…

Asked the HVAC guy to calculate heat load. Dragging his feat so far… But is complete interior renovation (only 4 outside walls at the moment) and rebuilt to “Swiss standards” in terms of envelope insulation, triple pane windows, all new exterior doors, etc. So shouldn’t be a heat-loss-prone building. About 1400 sq ft with low ceilings, so not a massive area or volume to heat. All that gives some confidence that relatively small, relatively tight, relatively well-insulated.

Only major variable would spacing of plates. Aiming for 8” centers…

FANTASTIC example from your drywall ceiling. Ceiling drywall would be 5/8” thick. And not as dense / holdable as gypsum fiberboard. But - as you said - the weight of plate and PEX in minimal. And there is nothing “pulling” on it after installation.Great, relevant, and encouraging example Bob! Very much appreciated!!! 😎💪👍

1 -

-

the tubing and plates expanding and contracting are pulling on it.

0 -

Maybe contact a fastener company and explain what you are screwing in to. There are thousands of specific screws available. Here is one big name example.

Something with a short drill point may help?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements