Munchkin 80M

My old natural gas Munchkin is still chugging along in my hydronic baseboard heating system. It is backup for my outdoor wood burning boiler, which sprung a rust-hole leak towards the end of this heating season.

I bought it in 2005.

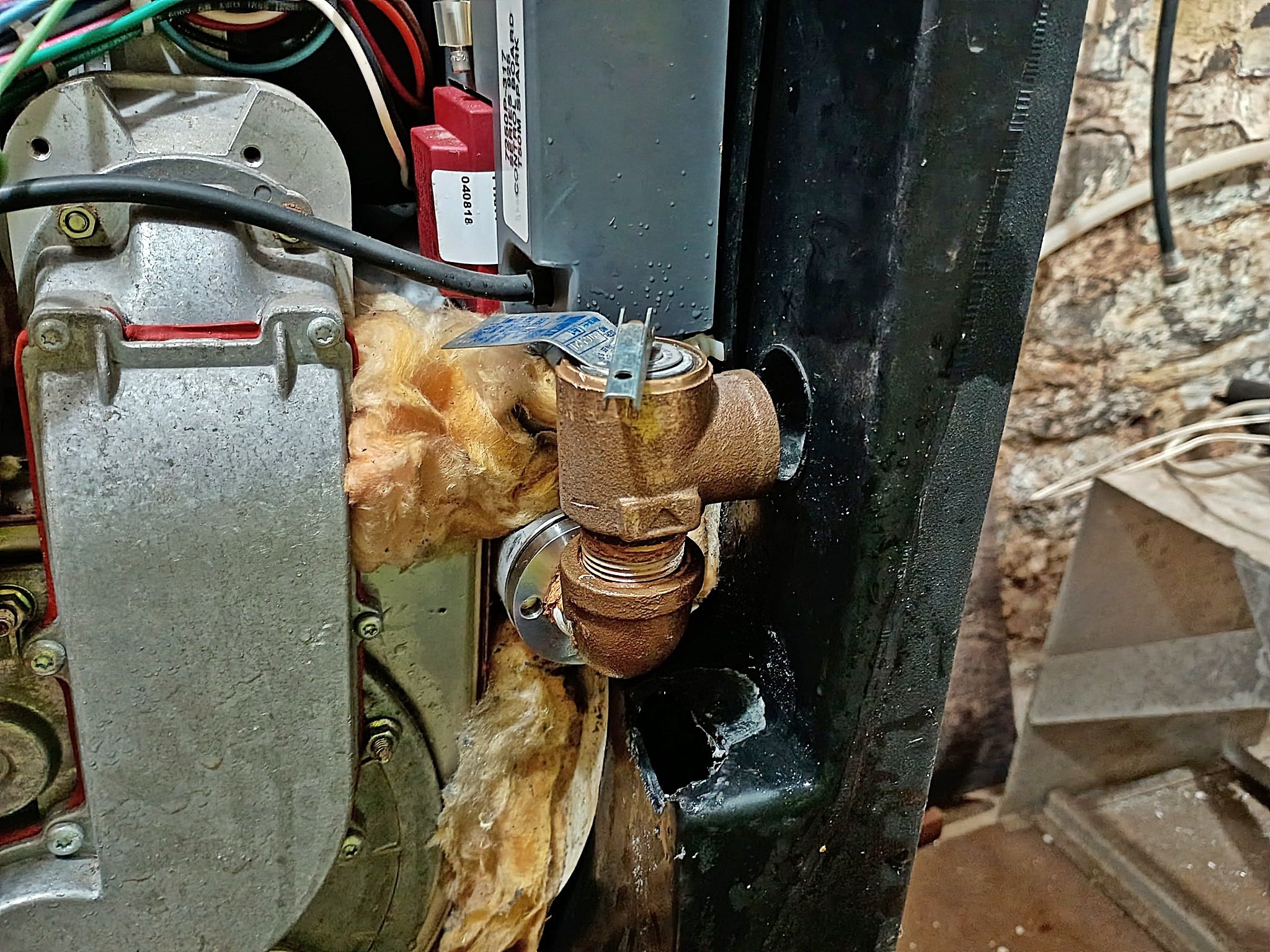

The poor thing finally had an issue. The t&p valve developed a leak at the seat.

So, today I went to the basement to attempt to remove the valve. I had been dreading it. There's not much room to get a big wrench on the valve. I had a small 6" pipe wrench that would fit, but couldn't get any leverage.

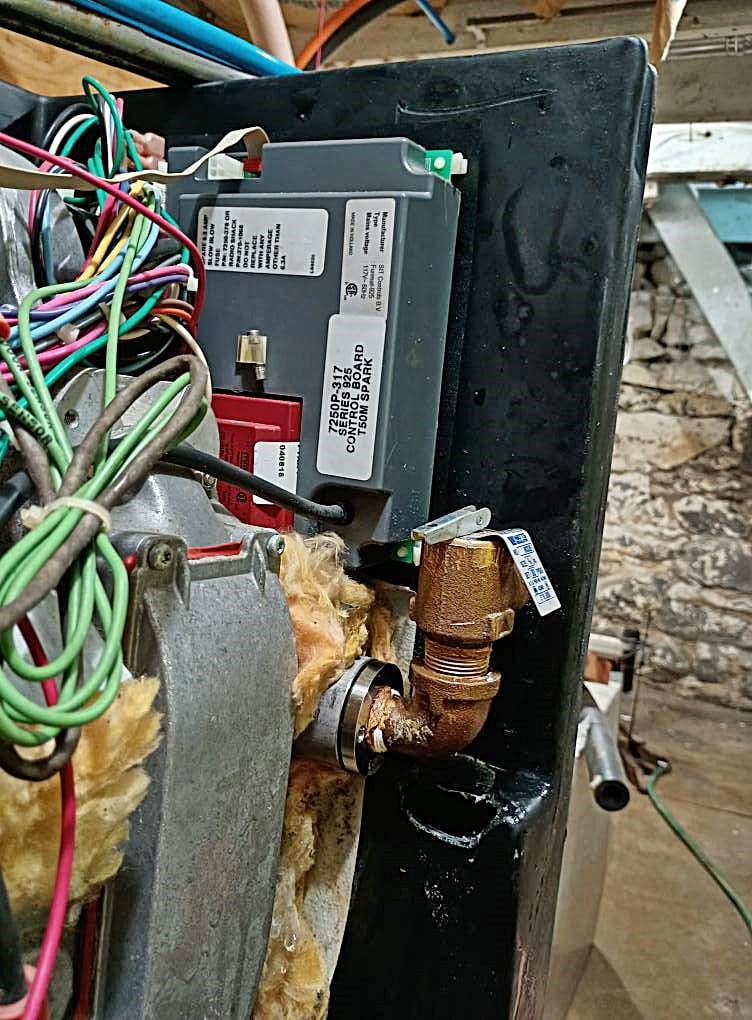

Then I thought I'd try unscrewing the elbow itself from the boiler… with just a little persuasion, it backed out~ but it wasn't just the elbow~ the stainless steel plug was unscrewing from the header it's in! That was enough to let me get at the t&p valve and remove it.

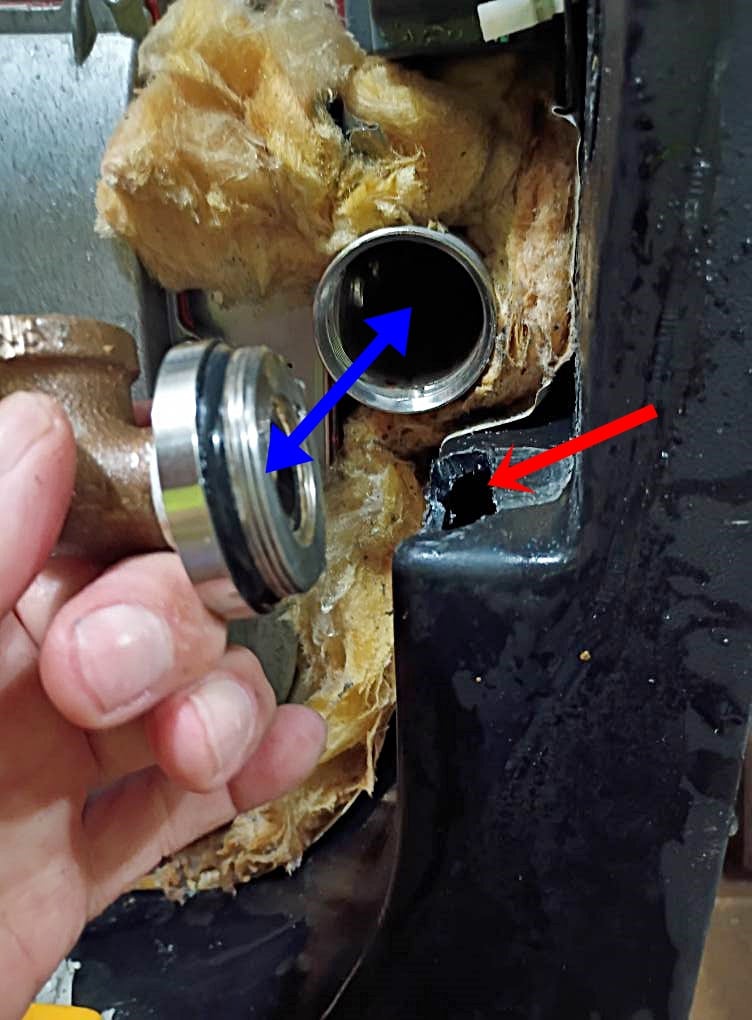

Since I'd gone that far, I went to remove the stainless plug/brass elbow combination… but the plastic boiler housing wouldn't let it rotate completely around.

Went and got a pencil/die grinder and cut out the offending plastic housing.

Unscrewed the stainless plug completely… it's got an o-ring seal.

Looked inside the manifold… slick as a whistle, no mineral buildup inside it.

Before last heating season, I removed and replaced the working part of the Spirotherm air vent… pictured it here, as well.

Comments

-

-

Clamp the street ell in a vice to remove the relief valve. Do you have an accurate pressure gauge onj the boiler? It could be going over 30 psi, from a failed expansion tank, or fill valve leaking. Does it have glycol. Looks like the Spiro vent had leaked on thje threads.

Have you taken the burner out, that is often where the cleaning needs to take place.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

I'm a little skittish to remove and clean the burner…. don't want to disturb the gasket or anything else that may be brittle….

No glycol… and not sure why the corrosion on the Spirovent…I think it had something to do with the flux when I soldered the copper tubing to the fittings on the vent. Never had any water leak out of the vent…Valve came off easily after I got it horizontal.

Yea, accurate pressure gauge. When I built this system, I used the "closely spaced Tee's" method. I made more outlets/returns than I actually needed, though. One of those I didn't use leaks…

I don't have an automatic fill valve, I manually refill the system (through one of those extra outlets) when it drops below the Munchkin pressure cut-off.

I also had a 20 year old (at least) expansion tank- it was used when I installed it 20 years ago… I never checked the air pressure in the tank after initial installation…

I'd usually fill the system to 25 pounds~when I'd do that, the needle would bounce when I'd close the valve upon filling… so there had to be "some" air pressure remaining, just not enough.

I put a new tank on when I repaired the Spirovent… it's all new.

Anyhow, it took 20 years for it to do what it did….0 -

Those Munchkins last longer when they heat high temperature systems. Less condensation to eat away the HX.

I've never seen that header cap unscrew before. Thanks for the dramatization.

"I'm a little skittish to remove and clean the burner…. don't want to disturb the gasket or anything else that may be brittle…."

It's not so much the burner needs cleaning although it could use a looking-at. I'd be concerned about the heat exchanger itself to see if there is any buildup of debris inside and also to pour some water in there to make sure it drains well. I'm seeing a lot of clogged traps on the Munchkins I service which can generate F09, "No Flame Detected" error codes.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements