Faucet Washers

Where do the sizes of faucet washers come from? Why aren't they the actual size?

Comments

-

Kinda like women's fashions. 😉

Trying to squeeze the best out of a Weil-McLain JB-5 running a 1912 1 pipe system.0 -

-

-

They are strictly made for the faucet manufacturers specifications. So many different types of faucets are out there now. A lot more than when I first started.

Are you having trouble finding matching sizes? The kits that have a mixture of sizes are still pretty good.

0 -

what is in the water that is a concern?

If it destroys typical faucet washers, it may not be water that you want to drink or bath in?

There are other materials used for flat washers.

If you buy flat sheets, the durometer is important for compression seals.

Peroxide cured EPDM should handle most any hydronic or plumbing seal

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I was always told it was best to use neoprene for hot water.

That said, I thought neoprene tended to hold up very well in general?

It even does alright with methyl formate, which is impressive.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

-

It isn't entirely clear what the ones you get from a hardware store of home depot are, they hold up ok but when they go it is because they are deteriorating from being in water, not that they are wearing out. Teflon doesn't deteriorate and works great in service valves but takes a lot of force to get to seal in a faucet that is used regularly because it is fairly hard. The seat is fine. I just want something that lasts more than a couple years. I don't think that the moderately high chlorides in my water are helping anything.

Danco offers 2 "grades" of washers but doesn't say what material either is. The general purpose ones from Mcmaster Carr are buna n.

Both Buna-N and Neoprene are acceptable but not great for water. Teflon is great for water but too hard. EPDM is softer and excellent in water. I couldn't seem to find them premade but maybe @hot_rod has a source.

1 -

If i try to search for "delta rubber" even in quotes i still get hundreds of pages of seats and springs

0 -

I try to stay away from that stuff (washers) unfortunately one of the most confusing topics there is. I don't think I have ever had any luck rebuilding or repairing faucets. Put whole new cartridges in a set of Symons bath faucets once and that worked probably my only success.

With my bad luck I usually rip and replace

You spend more time on trying to find price and availability and the right part than the cost of new faucets

0 -

If it is a real old faucet the brass seats get brittle and chip, then they tear up the washers quickly. Grinding the seats is a short term fix. Best to replace seats and stem assembly. Then you get new stem o-rings, washer and seats.

Do you have chlorine or chloramine in your water? That seems to be more aggressive towards rubber.

Caleffi switched to the crosslinked (peroxide cured EPDM) in most seals, some Buna rubber or silicone in high temperature solar components.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I prefer the Forecast sales beveled washer & bibb screw kits. In the mid 1980s, when I started, there were still tons of old style faucets & shower bodies. It was fun to rebuild stems & I have a full tool box with 6 different seat tools, et cetera. Mad Dog

2 -

It is chloramine. The road salt goes in to the river too.

The washers in the cold last a decade plus but the washer in the hot is more in the 5 year range. It is a shower valve and a laundry tray that i'm mostly looking at. I plan to repack it with teflon. The valve body gasket I think got replaced with something in the nylon family when I rebuilt 25 or so years ago.

What are these o-rings you speak of?

0 -

The compound in the hot water washer hardens after a few years then eventually splits from exposure to hot water just like o-rings that are the wrong compound turn flat after then have been in service for a couple years.

0 -

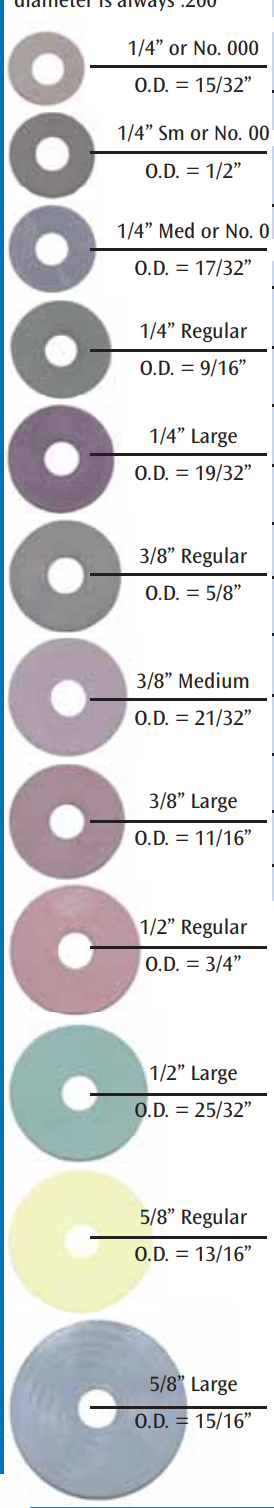

I mainly wanted to know what the deal was with the sizes having like 4 sizes that were 1/4" and none of them were actually 1/4" and @Jamie Hall answered that.

0 -

-

-

There's some real junk out there. I have buildings full of bib faucets, so I change stems and seats and washers. When I buy quality assortments I generally get some good service out of them. Where I get burned is with some nasty yellow brass Chinese bibb screws which turn to dust in three years. They're Phillips head so I have to cut slots in them to get their stripped stumps out with a straight blade screwdriver.

1 -

Ann Arbor water will dissolve brass screws after a while regardless of quality. Stainless screws are readily available and cheap now. Monel is not that hard to find either. There were a lot of deposits of scale on my shower faucet stem this time, so much so that I had to walk the stem out of the bonnet back and forth several times to clear the end of the threads to remove the stem. I think they started adding more corrosion inhibiter after flint.

0 -

The one thing I ALWAYS do with replacement stems, bibb screws, et al, is use copious amounts of high temp faucet stem grease IN the female threaded holes AND in the bibb screw thread. They last longer and you can get them out much easier in the trs ahead. Mad Dog

2 -

Thanks, Dog. Never thought of greasing or antiseize on the screws…

0 -

-

you can probably buy a sheet of whatever they used and punch them out but my problem is the compound hardens because it is only sort of compatible with water and it keeps taking more and more force to compress it.

I used teflon pipe dope but it only helps so much when the head of the brass screw dissolves in the water. I didn't have any monel/stainless screws that were the right size. I think I kind of assumed I put a stainless screw in there last time.

0 -

oh, and none of the service valves that i installed 25 years ago when i got rid of the last of the galvanized pipe when i bought the house functions completely properly

0 -

-

-

-

-

The bib screws I used were monel and they had tread locker built into them, like a self locking nut has.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Many of the Michigan cities are adding phosphates. Mainly to keep a coating on lead pipes. That inhibitor should not cause brass to dissolve, if anything it protects the metals

Look for low ph or other additives in the water aggressive to brass.

The downside to phosphates is they contribute to the algae blooms in your lakes and rivers

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

how much phosphate does that put in waterways compared to farm runoff? or how much did phosphate household detergents for that matter?

according to the city the ph is about 9. could the chlorides disssolve stuff? even when i lived in an apartment almost 30 years ago when I first moved here it was really aggressive to valve parts and I think they used less corrosion control then.

here is the report:

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements