First time designing and installing radiant - feedback

Hi there, I'm starting a new woodshop build in May. This will be a pretty small structure - 16x22, with a standing-height storage loft above, contained within the building envelop. This is my first time designing and installing radiant heat.

I'm on a budget, so I have to DIY just about everything. Because I am technically building a two-story barn, I was required to have an engineered slab done for my building permit.

The slab I had designed is a 16x22, 6" thick, with thickened edges (16") and a 6" curb.

It will have 3" of rigid EPS under and around the entire slab, including under the thickened edge footers.

I intend to use "Heat Sheet" R12 under the main slab, as I got a screaming deal on it. I'll buy 3" Durospan 250 for under the thickened edge as it is readily available in my area and meets my engineer's 25psi requirement. Last, I'll use 3" XPS vertically around the slab perimter (again, because I got some for super cheap).

Heat-Sheet is one of those 'radiant-ready' insulation products with raised installation pucks, so the PEX will be at the bottom of the slab.

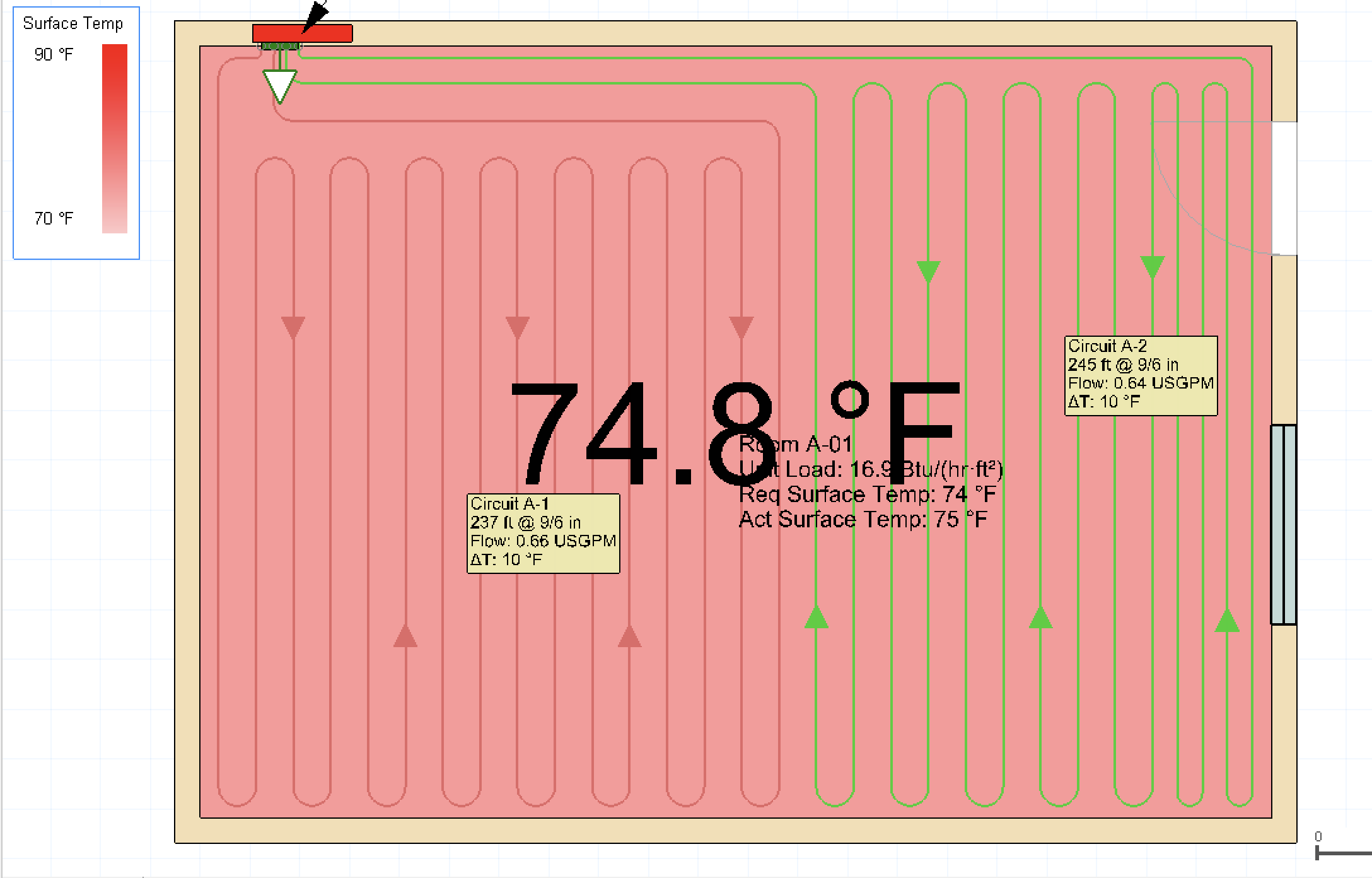

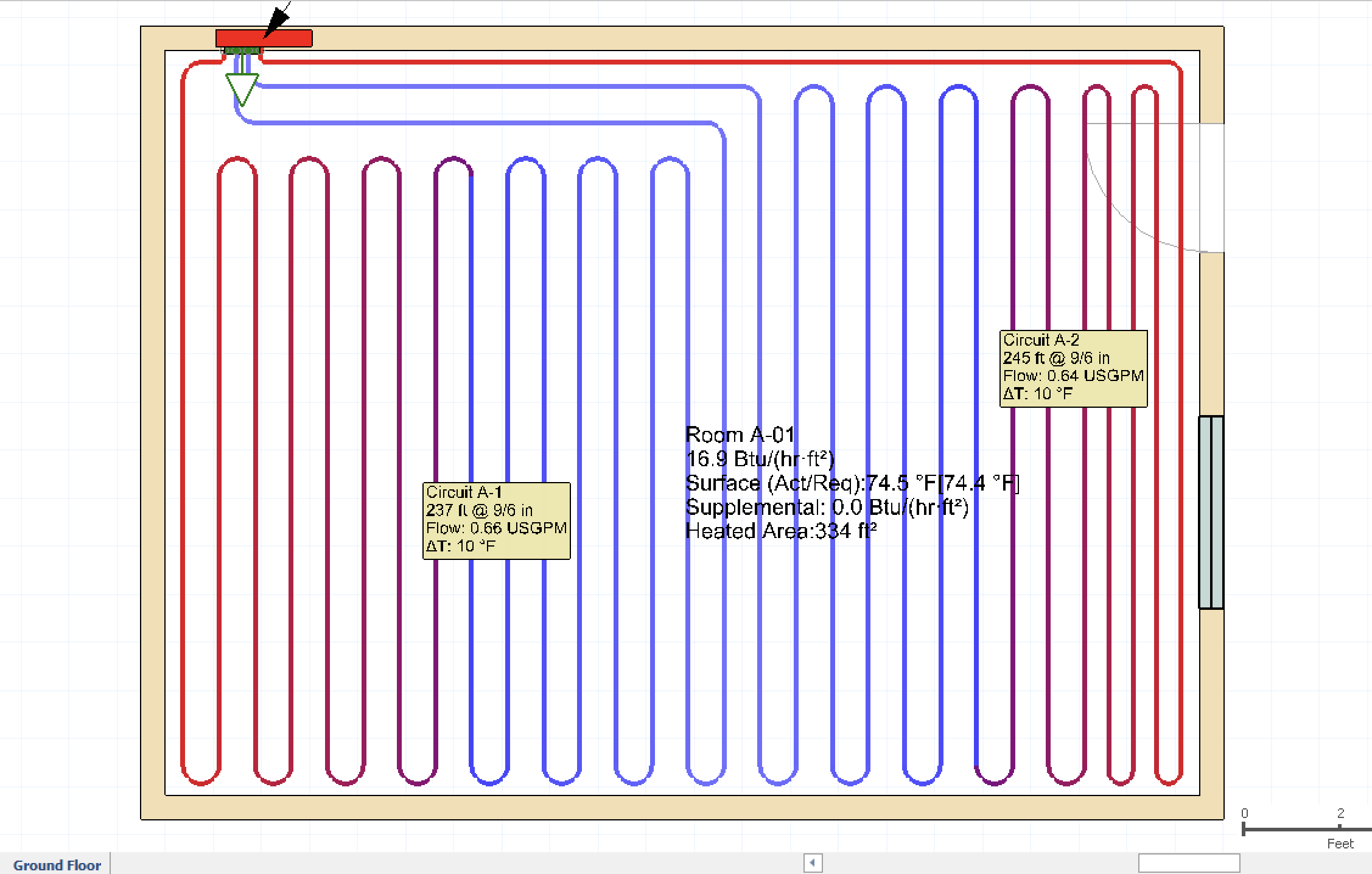

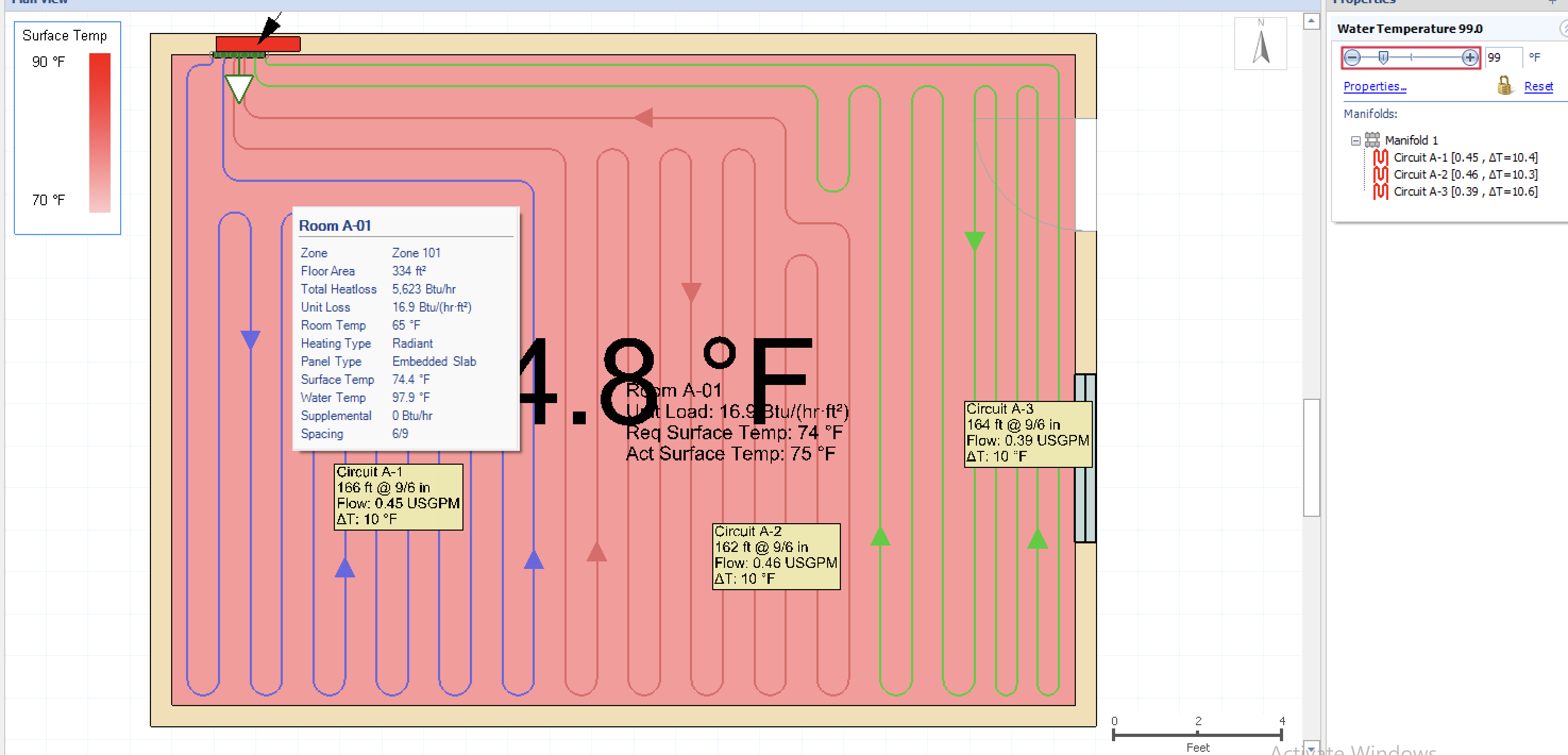

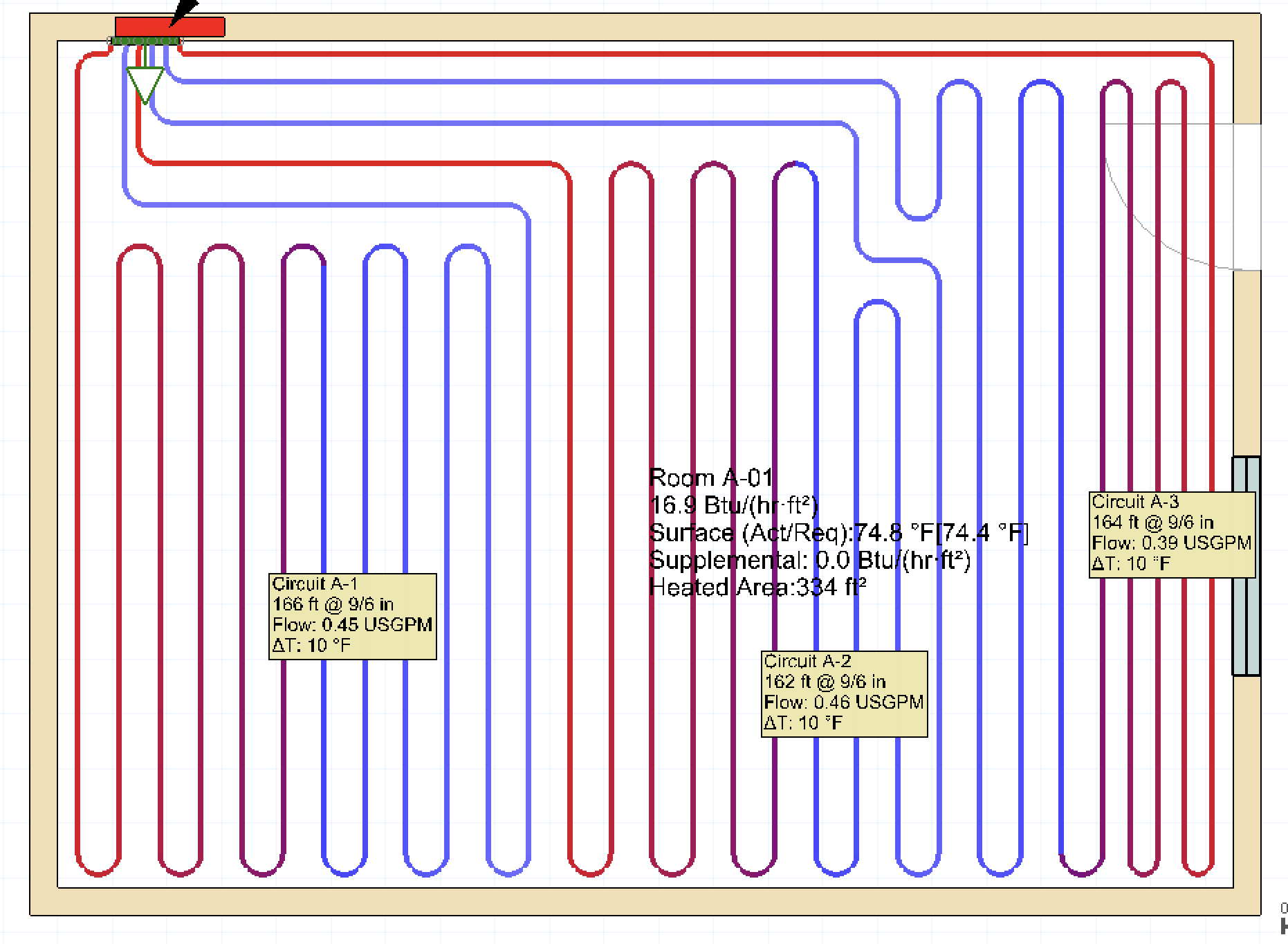

I downloaded a trial of LOOP-CAD and also did a few different heat loss calculations. I think I've got it figured out, but this is very new to me. LOOP-CAD recommended either 3 loops of 165 feet each, or 2 loops of 240 feet each. I'm using RauPEX 1/2" Pex-A pipe. Is there an advantage one way over the other? My intention was to install at 8" spacing. I'm assuming three loops means a faster response time perhaps, and more even heat. But does that really matter in a 6" slab with pex at the bottom? Seems it will be very slow and even no matter what. The two loop option estimates flowing at 0.65GPM. The 3-loop option is 0.45GPM. This assumes a delta-T of 10 degrees F.

The building will be 2x6 walls with Rockwool, plus 2" of exterior rigid foam (R32 total). The second floor is a stick-framed gambrel roof with a cathedral ceiling, with insulation around R40-45 or so. I wanted more, but I'm under a height restriction and can't make my rafters any larger. I'll have three small triple pane windows and an insulated commercial man-door. I've built my own carriage doors, which have 4" thick rigid foam in them, R20.

Winter gets to -40F at the worst here. That said, typical January temps are more like -13F. I'd like to keep the interior at a steady 50-60F, but be capable of heating it to 70F if I have a few weeks off or something.

The heat source will be an electric boiler. My calculations say I'm somewhere around a 3kw (10,236 BTU) boiler, maybe 4.5kw (15,352 BTU) at most if I'm over-estimating my energy efficiency.

Loop layout ideas are attached here. Any red flags?

Comments

-

I have seen where wood shops have a lot of sawdust and small pieces of wooden scraps. Would a wood stove with a water jacket be in the future? How much does electricity cost in your area? Compare that to the cost of LP gas and a small water heater of sorts. 30 Gallon Gas Water Heater can operate on natural gas or propane. The smallest burner for the price and will work with a temperature that is perfect for radiant floor heating. I would not normally recommend that you use a water heater. for a closed loop heating system. This application is different since you do not need water temperatures higher than 120° and the size of the room is small in comparison to a standard home heated with baseboard heat that requires temperatures over 160°. I have actually done this project for someone with a similar need and it is still working over 6 years later.

But your Idea of an electric boiler has merit as long as you can afford to operate it.

Don't be fooled by the electric bill where it says cost of electricity generation some low number like 12 cents per kWh. That number does not include the deliver cost often called transmission charges (the power line charges) and other charges for maintaining the power lines plut the fees and taxes. The best way to find out your cost per kWh is to look at the meter readings to get your total kWh that are included in that month's bill, and divide it by the total amount you pay for that much electricity. You will find that the number on the bill for cost per kWh is lower that the actual price per kWh you are paying.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

2 -

My thoughts:

All electric resistance heat has the same efficiency, COP of 1.0. So an electric boiler won't be any cheaper to operate than resistance mats under the floor. The installed cost of the resistance mats will be cheaper, everything about it will be simpler. The only advantage of the boiler is that if you ever decide to switch to a different source of heat the plumbing will be there.

You're right to think about the responsiveness of the heat emitter (the floor). That's going to be a big determinant of your comfort — and heating is all about comfort. With a 6" concrete slab the responsiveness is going to be poor, especially in a low-heat-load building. At 16x22, that floor is 176 cubic feet of concrete. It will take about 13,000 BTU to change its temperature by one degree. If your heating load is 10,000 BTU/hr, you'd need the surface of the slab to be 14F above room temperature. To get the slab there from room temperature would take 182,000 BTU, or more than 18 hours of full output of the boiler. I'd be thinking about putting the foam over the slab and the tubing over the foam and then a finish floor over that. Does the Heat-Sheet allow that?

I'm glad that you're paying attention to insulation, I like to say an ounce of insulation is worth a pound of hydronics when it comes to comfort. In most buildings most of the heat loss is through windows and doors, you don't say in your description what kind of windows and doors you have. That would be helpful to know.

For the roof, it sounds like what you're doing is a cathedral ceiling, where the insulation runs along the underside of the roof. These are tricky, even pros often get them wrong, and if not constructed properly they are prone to moisture getting trapped in the sheathing which causes the roof to rot. This is especially problematic in cold climates like yours. This article gives good approaches for safely insulating:

If you are height-constrained, one of the approaches is to put insulation between the sheathing and the shingles. At least in my jurisdiction, the extent of a building is the exterior of the sheathing, exterior insulation and siding or roofing is not counted. Check with your building department. Another approach to add more insulation is to fur out the bottoms of the rafters.

0 -

Hi all, really appreciate your input here!

Ed - Thanks for your input. I just checked my electrical bill. I do have an actual 0.095kwh rate here. I think we've got some of the cheapest hydro electricity in north america where I live. Looking at my bill, I also pay a 2.5% tax plus a monthly flat fee of $9 for delivery.

I did consider natural gas as well, but space and installation cost is a concern. I did get a quote for running a gas line to the shop, and it was too much for me right now. If it wasn't pricey to run the gas pipe to my shop, I would probably find a way to do this approach.

Side note, my dad has a much larger shop and uses solar panels to heat his radiant system. They are solar thermal, not solar voltaic, and they keep his shop at just above freezing. Then he flips on a ceiling-mounted heater when he expects to be inside. But again, the panels would cost close to $4,000. Out of my budget.

DCContrarian - you've given me some food for thought. I do not want to run the heating above the pad, though I completely understand your logic here. I've got areas of electric heat under a tile floor at home and it's lovely. But in the shop, with the kind of work I expect to be doing (not just woodworking, lots of metalworking and automotive stuff happens as well), I want a heavy, thick floor I can bash on.

Regarding the very slow response time, that is useful to have some numbers to give me more context. I expected I would need at least a day or so to get it up to temp. At my smallest boiler estimate, with our local rates that would cost me about $6.50 to do. It's not the worst, but it would add up quickly if I was doing so often.

I was considering keeping the radiant heat at a fixed temp 24/7, say 50C at the most. As I am usually only in the shop for a few hours on weeknights, I could use supplemental heat for a quick warm-up of a few degrees I suppose.

Thanks for the cathedral ceiling link. I've read and bookmarked that myself actually! I will be building a vented roof assembly - about 8" of rockwool insulation, with site-built foam baffles that provide a 1.5" ventilation gap below the roof sheathing. That will provide continuous ventilation from eave to ridge. On the interior of the roof, I'll install 1" of foil-faced EPS, taped and detailed as an air and vapour barrier.

Aside from that, do my loop drawings seem solid? is there a benefit to 2 vs 3 loops on a little shop like this?

Thank you both,

0 -

It's possible to run the slab at a constant temperature. What you get is that when the heating load fluctuates (ie the outside temperature changes) the room temperature changes. This is different from what you'd typically do in a residential installation, where you try to vary the floor temperature to keep the room temperature constant.

So what would that look like? The diagrams show the design temperature of the floor at 75F with the air at 65F. They don't show what outdoor temperature that represents, let's say -25F so we can work in round numbers. If you kept the floor at 75F, when it's 75F outside the room would be at 75F too and the heat would be off. Between the design temp of -25F and 75F is 100 degrees, the room temperature is going to move 10 degrees over that range, so for every ten degrees the outdoor temperature drops the room temperature drops by one degree. So with an outdoor temperature of 65F you get 74F indoor, and:

55F→ 73F

45F → 72F

35F → 71F

25F → 70F

15F → 69F

5F → 68F

-5F → 67F

-15F → 66F

Since the air inside the building has a lot less heat capacity than the slab, it's a lot easier for the air temperature to move than the slab temperature.

0 -

Wow, I hadn't considered this, but it makes total sense. Thanks for pointing that out.

0 -

Keep in mind it's your building, you can run it any way you want. But if that's not the behavior you want we can talk about other ways of operating it.

0 -

Totally. My main concern was ensuring the radiant system had the capacity to heat the space to typical interior temps should I want that. But 99% of the time, I just want it to keep the space around 45F, t prevent anything from freezing, and eliminate a freezing cold floor as that's not great to stand on.

0 -

My suggestion is that you look at some kind of supplemental heat for when you want to warm the space quickly. The heated slab is fine for keeping the building above freezing, but when you want to warm up to room temperature it's going to take a day or more. You'll want something that can put out a lot of heat in a hurry to warm things up.

2 -

Hydronic or gas fired unit heaters are great for fast warm up, but they can keep the radiant off, depending on how you control the two different emitters.

The Modine unit that mounts in the center of the room, on the ceiling and blows straight down seems to mix up the room temperature best. Unit heaters in the corner of tall shops never really warm down to the floor.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

When the radiant floor is heating the space to 45F it will probably be around 50F. That's not "freezing cold" but it's probably not the warm toes feeling you're looking for either.

The way to have the floor at 75F and the room at 45F is to only heat part of the floor — about a third based on the discussion so far. If you know where you're going to be standing you could plumb one zone to cover those spots, and only run that one zone.

If you don't know where you're gong to be standing, or you want to be able to move around, I would recommend heated floor mats. They won't use any more electricity than an electric boiler for the same heat output.

I would still recommend some sort of high-output heater to quickly take the chill off. If it has a low setting for when the space is unoccupied, even better.

1 -

Thanks guys. You've given me a lot to consider and I feel I've got the knowledge now to make some decisions.

I have a 1500kw overhead electric heater in my current, soon to be demolished garage. I was going to pull it out and re-use it in the new shop while getting the hydronic system hooked up. It sounds like it would be wise to leave it installed permanently, giving me an option for a quick heat-up while the floor stays at a relatively low temp full time. 50F floors would be more than fine for working in for me.0 -

To get back to your original question of two loops versus three: I would normally default to three to make it easier and lower power draw for the pump (but for your small space and low flow rate it would not actually make a noticeable difference), and in case you have to abandon one in the future (exceedingly rare, but it does happen).

I suggest keeping the pipe pulled in from all the perimeter by at least a foot, or more if you know the outer edges will be populated with tools, cabinets, etc. If you recalculate the loop lengths that way you will probably find you can tighten the loop spacing to 4" for a portion of each loop, and I would do that toward the center of the room. Note that when you tighten up that spacing you will still flare out to do the end turn-arounds with a broader bend (like a shepherd's crook; see attached photo) unless you are using exceptionally flexible pipe.

But you have not said why, if your heat will be electric resistance anyway, you do not want to do electric wire or mat radiant. You could still use the Heat Sheet as insulation, but you will need to tie the radiant wire to reinforcement wire, so will not get advantage of its tracks. Or do you hope, as DC Contrarian mentioned, to use some other source in the future?

As far as quick heating for areas you will stand most often, consider electric radiant suspended ceiling panels, the advantage being you don't have to blow air and dust to distribute the heat.

Sol Brother0 -

I thought I would follow up on this post, as it's always nice to share the final results. Maybe it will help someone else down the road.

Short version - my hydronic floor system is working great. I'm loving it!

Long version -

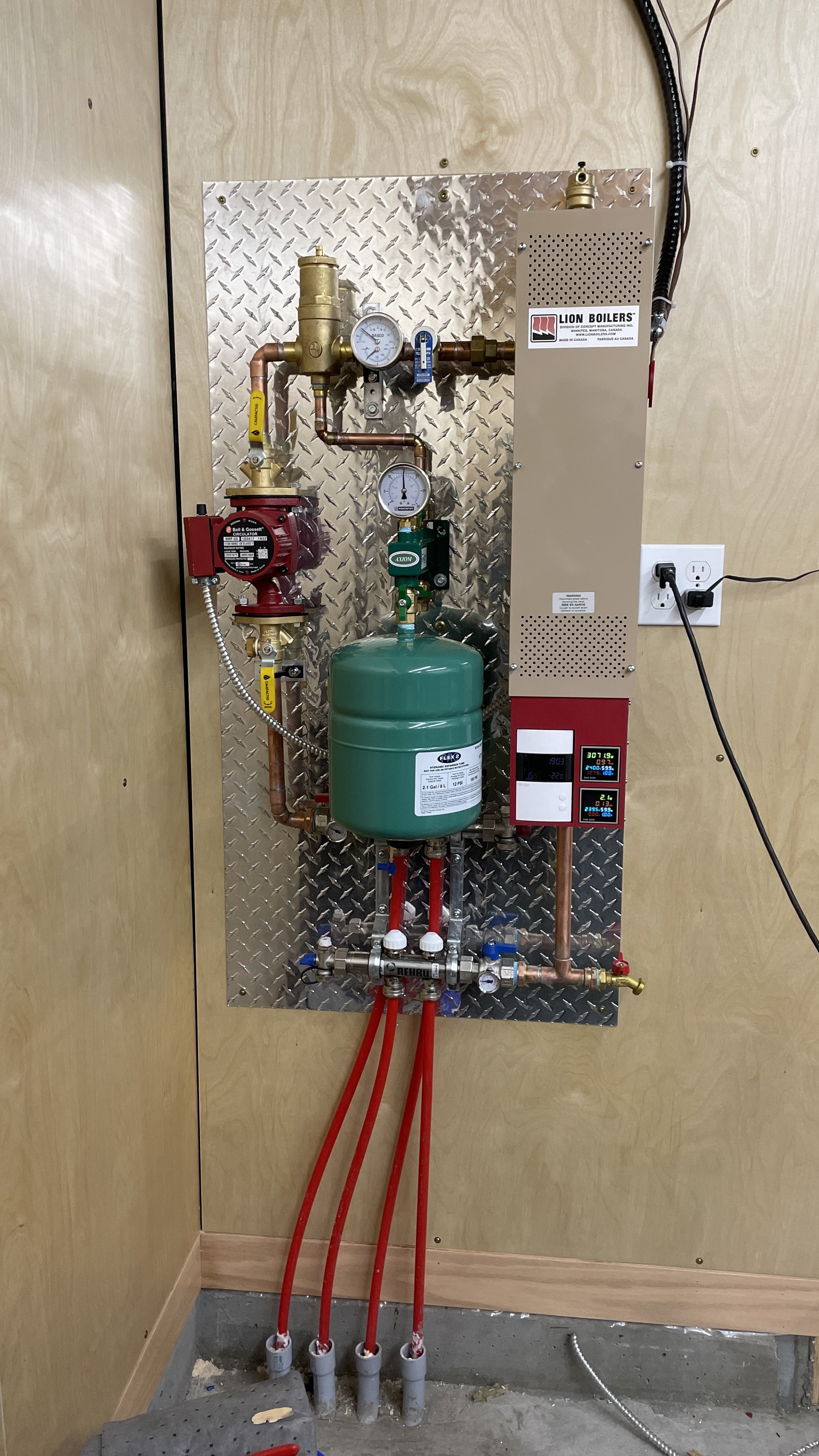

I got my hydronic floor system up and running in December 2025. I went with a 3Kw electric boiler. I worked with a local plumbing supply house for all the components, then assembled, filled, purged and wired the system myself.

I used a Lion LEB dc 3Kw boiler, a Bell & Gossett NRF-25 three-speed pump, copper lines, and am controlling it with a Sinope smart thermostat. The thermostat controls a relay to activate the boiler, as it cannot control the boiler directly. I'm running a 50/50 glycol mix (coldest temp this winter so far has been -38C).

My floor has 500' of 1/2" pex, split into two equal loops. Loop spacing is 9" apart. The concrete is about 6" thick, with a 16" thickened edge. Insulation under and around the slab edges is 3" of EPS. The building is 16x22' with R32 walls, and a second floor with a vaulted ceiling, about R45. There are three triple-pane windows. And shop-built carriage doors, with R20 foam cores.

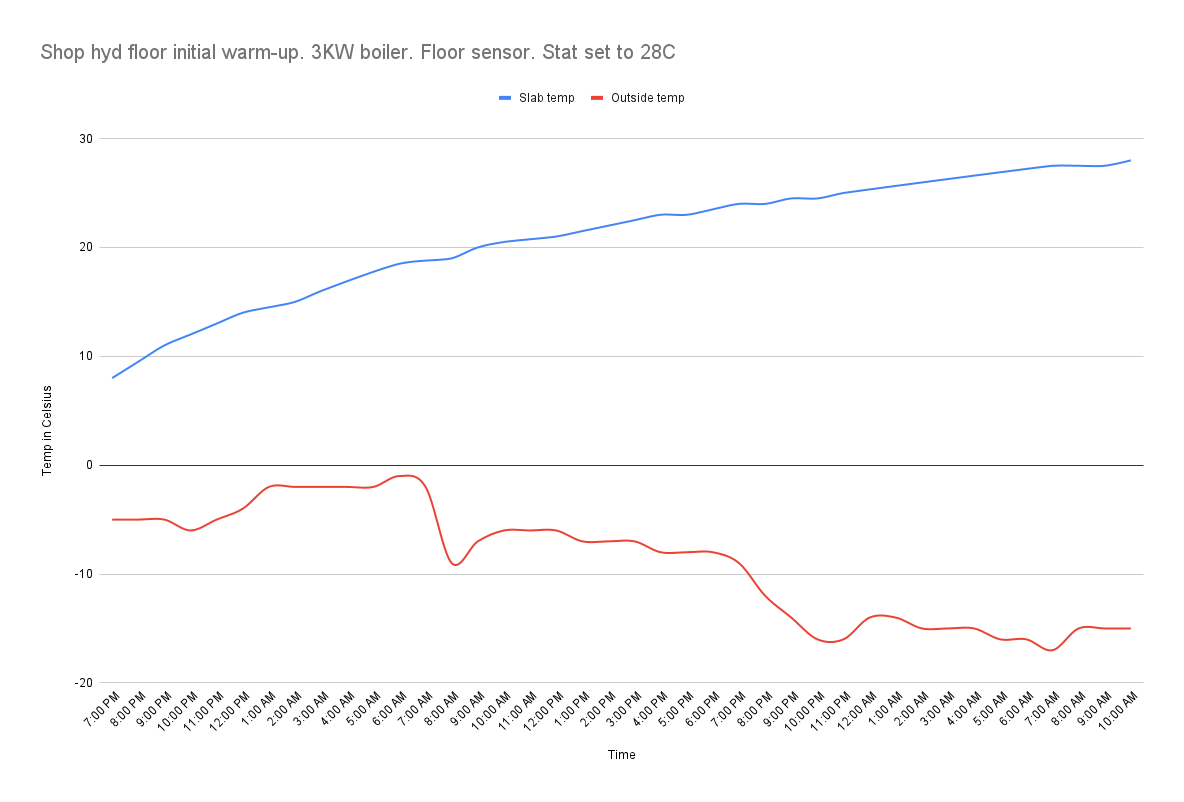

The initial warm-up took 1.5 days. I admit, I got nervous that I had undersized the boiler, as the temperature increase got slower and slower as the heat rose. The floor temp started at 7.5C. It rose about 1C every 60 minutes up to 18C. Then the rate of temp increase slowed. By 24C, it slowed again. However, with patience, the floor reached 28C / 82F while it was -20C outside. That gave me an inside temp warmer than I'd want for a workshop. It was about 21C when the floor temp hit 28C. But I was happy to know the system was capable of achieving that temperature.

At that point, my supply temp was 100F, my return temp was 90F. This matched my LOOP CAD predictions. Prior to this, the supply temp was a fair bit lower. The boiler couldn't heat the glycol to 100F when the floor was cold. I'm not sure if that's typical or not, though, as I've never worked with hydronic heating before. The delta was larger as well, closer to 20F. But as the floor warmed, the supply and return temps also rose. And the delta got smaller.

Since then, I've turned the heat down. I usually keep the floor temp set to 18C or lower. The air temp varies depending on how cold it is outside. If it is -15C or warmer, the air temp is usually around 16C inside. When it gets to -20C or colder, the inside air drops a bit. The lowest I've seen inside is 13.5C. The coldest day on record this winter was -38C, and the floor did just fine keeping the space comfortable for working. I have a supplemental overhead fan heater to give the space a quick bump in heat, but I have only used it twice all winter.

With an 18C floor temp, I'm averaging about 0.8-1Kw of energy per hour. That is averaged over the past 6 weeks. Electricity here is 0.09587/KwH, so my heating costs are around $65 a month. I can easily reduce the temperature while still being comfortable working.

I've greatly enjoyed having a warm floor in the shop. One thing I didn't anticipate was how nice it is to not have a fan blowing warm air around the shop. It keeps the dust down significantly. It's also great to have silence instead of droning fan noise.

0 -

That is a nice compact piping package.

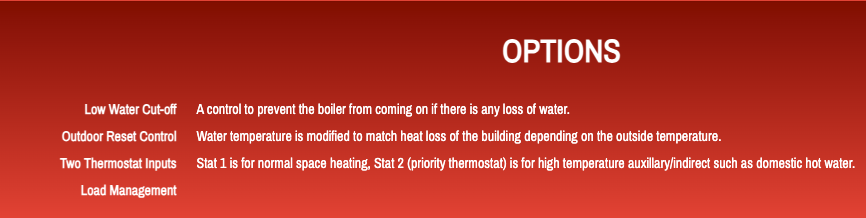

A few thoughts. You can get an optional reset control so the boiler would modulate its temperature based on outdoor temperature . This saves $$ on operating cost and the slab will stay a nice consistent temperature, never over or undershooting. Maybe you have ODR in that boiler control? It is worth the time and $$ to set up.

With the boiler above the piping, glycol with no make up, you want a low water cutout. Maybe the boiler has a pressure switch to protect it and the pump if the fluid drops? If not they have an optional one.

Here are the options listed at Lion Boilwers site.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Those options are for their larger CEB line of boilers. I tried to figure out how to include an outdoor reset control when I was installing this, but couldn't figure out if it was possible. I should reach out to the manufacturer (they are even Iocal to me) as I fully agree with you - some kind of low water cut-off control would be great given I do not have a make-up supply. Appreciate the tips!

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements