Inside Heat-timer Varivalve Radiator Vents

Ever wonder what's inside a Varivalve vent? Or what makes them spit water or why they fail?

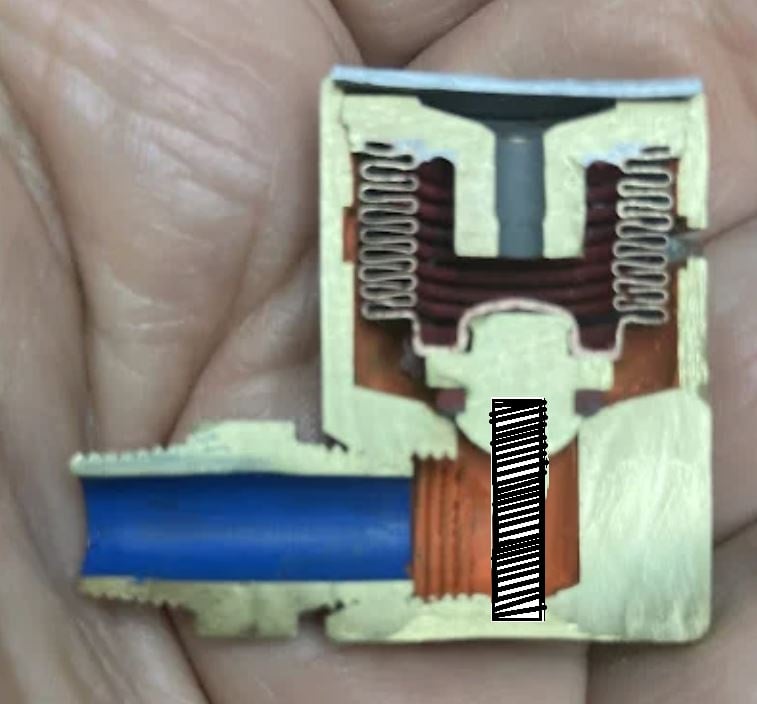

I looked inside. I really wanted to love these. Beautifully machined American made brass gems that emit a bodacious amount of air - faster than many main vents. An adjustable slide varies the output. Good if you have a clean, dry steam system and bad if you have anything else.

Advantages are a self cleaning valve seat, an o-ring valve that seals against the seat and a bronze sylphon, just like a little steam trap. Disadvantages are no float to keep squiring water off your floors, and the fatal one to most of these vents - a plunger that falls out from the sylphon bellows sealing its seat permanently.

In the cut-away below, you'll see the brass "plunger" that the bellows presses against the seat when the valve closes. Unfortunately this plunger is retained in the bellows with a press-fit. After the bellows expand and contract over and over again, the bellows swell and distort, finally ejecting the plunger out of the bellows and onto the seat. Gravity then keeps it there - plugging the seat forever.

And that's the end of the valve. About a third of the ones we've installed have failed this way in the first two years.

_______________________________________________________________________________________________

Below is the original 1950's "temperature adjustable" Heat-timer adjustable vent. "The radiator vent with a built-in thermostat" also spat water but was constructed differently and didn't fail closed like the present design. The "factory calibrated thermostat" knob on top simply raised or lowered the sylphon bellows lifting the plunger from the seat:

Comments

-

Thanks for that. I too want to love these vents, they are apparently made (or at least the HQ is located) about 10 minutes from my house.

Side note: Gorton and Maid O Mist "floats" don't float

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

I wanted these vents to work also, but most of them failed in this exact manner. They also vent too aggressively even on a low setting which tends to throw the balance off…. Also annoys me that Heat Timer will not acknowledge that there is a defect in the design that causes failures in a high percentage of vents. Many people complain about this problem. All you have to do is give it a gentle shake and you can hear the separated valve seat shake. The vent is then toast…. My system also consistently ran at the proper very low pressure with dry steam when I tried these vents, for those who say its a system problem…

2 -

Can you explain that? I've had several 'system flood' events, the most recent when chimney guys dropped debris on the ball valve handle, opening the fill! (I've since removed that handle) The MoM and Hoffman valves closed, I had a Varivalve that spewed water.

0 -

The MoM have a plastic "float" that is solid and more dense than water.

As for gorton, I have the video below.

So why didn't they leak in your case? Maybe they were failed closed, or ?? I wasn't there.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Ok, for arguments sake, if that bimetal arc is what closes the valve when it gets hot, it's probably supporting part of weight at all times. so to close in a system flood, the 'float' doesn't need to lift the entire weight, just add enough 'lift' to the bimetal support to close the valve. Can I assume you haven't bench tested just flooding a vent under tap pressure?

0 -

It can't provide lift if it sinks in water, but feel free to make your own experiment to disprove mine!

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

Obviously the bimetal is capable of supporting 100% of the floats weight when hot, If the bimetal supports 50% of the weight when cold, and the air inside supports 60% of the weight, it will float even if it sinks in your beaker.

0 -

If the strip is adding lift, then it's adding weight as well, so the "float" would actually need more buoyancy to float. If it didn't have to float the weight of the strip, then it's lifting off the strip and only needs to float it's own weight, which Paul's experiment proved it's incapable of.

As he said, please provide the results of your own experiment to show us, many of us like learning new things. If it does float, I'd like to see how it's floating since Paul's experiment shows it sinking.

0 -

"If the strip is adding lift, then it's adding weight as well". This is false logic. The bimetal is essentially a spring whose tension varies due to temp. It's not adding weight. Picture it being a coil spring under the float, would that be adding weight?

0 -

Strip is in the open position not moving. If the float is lifting off of it, how is it providing lift?

If it was attached rigid to the float, at some point the weight of it comes into play, because again it's cold and in the open position, it will not move to closed without steam heat. So it's weight absolutely would come into play.

It's NOT a spring, it's a bimetalic strip that moves with heat, they are very different things.

1 -

In Joseph Gorton’s patent for their vent he refers to the “float” as the Bell Valve. I would think that when water enters the vent it would trap air in the bell causing it to rise and seal the vent. In Edward Jacobus’s patent he refers to the “float” as the bell or float. I think the older Jacobus vents had a bell and not the solid plastic float like their current product. I have not done an experiment to prove or disprove if they do in fact seal against water that enters the vent housing.

0 -

Also, I had heat timer vents on my rads for like 10 years before I replaced them with Gorton’s 15 years ago and never had any issues with them.

0 -

As said above....Extremely nice dry steam...no.problem..Wet Steam? They will gush like a tub spout. They are a chunky little piece of brass. They do add some heft to the scrap bucket. Mad Dog

0 -

perhaps the needle used to be soldered to the bellows and they decided they didn't need to do that anymore.

0 -

If that needle was soldered on, I would love these for certain applications where huge venting was needed and steam quality was good. Alas, as they are they fall apart.

0 -

Continued….

They can be disassembled and "repaired".

You pluck out the aluminum nameplate either prying with a small screw driver or by punching a screw through the top and pulling it off. It's glued on.

The top of the sylphon is brass and it's pressed (or glued) into the body. It has a hole in the top that is used to fill it with its alcohol mixture. You can thread a steel 5mm machine screw a few turns into the soft brass and use it as a grip to pull the sylphon out.

I pulled on it with a small slide hammer made to remove faucet handles. It pops right out and the disconnected plunger, pin or button flies across the room. It disappears like magic.

If you find it, you'll see it was attached to the bellows with glue. It wasn't even pressed in. It's a lose fit without the glue.

I assume Heat-timer used a high temperature adhesive like Loctite 603. The problem is that the bellows is thin bronze and flexes. That flexing causes the glue to fail and the plunger disconnects from the bellows. Then it falls down onto the seat.

So I'll glue it back and see what happens.

Can it be soldered? I tried but just couldn't heat the sylphon face while keeping the rest cool. The heat would probably cause it to over-extend and explode. It has to be soldered before the sylphon's charged and sealed.

2 -

Designing and controlling tolerances on the press fit on the bellows side I can see being difficult. More robust design would have snapped the bellows onto the syphon but that too would have required incredibly tight tolerances on some small bend radii.

0 -

When all else fails, use glue. They should just solder them on, but that would be a lot of work.

0 -

As long as they could be soldered before the bellows is "charged".

I'd expect bad stuff to happen if you tried to do it after they're filled and sealed.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

You would want to restrain the bellows while you soldered it. You could heat it either inductively or with a hot and small torch or high mass iron to heat just that part quickly. You could perhaps even heat just the needle and have it heat the tinned and fluxed bellows.

i'd try maybe rtv to glue it in, it would be high heat and flexible. jb weld would be my next try. the rtv will flex a little. I'd be concerned that either most glues or solder would fatigue and break off.

1 -

-

Great discussion, @Long Beach Ed , thank you for showing us what's going on in these.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

-

-

Groove and snap ring would be a solution on the manufacturing side.

Glue. Sheesh!

Good thread!

Trying to squeeze the best out of a Weil-McLain JB-5 running a 1912 1 pipe system.0 -

The pin/plunger is actually slightly grooved radially as seen in the cut-away. I figured it was to help retain glue or provide a friction fit? Perhaps they snap fit before the bronze flexes a thousand times and internal pressure gradually spreads the dimple.

The phosphor bronze sylphon is simply dimpled to accept it.

0 -

I don't know, but I'd think a very light spring compressed in this position in two pockets would solve the issue.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

you could probably install that arthroscopically.

Maybe the original design had a snap ring on the needle that clipped in to the bellows and they decided that was too many manufacturing steps and too costly.

or there was a groove rolled or coined in to the bellows that the needle snapped in to and that was removed to simplify manufacturing and replaced with glue.

3 -

-

Stainless, of course. The bellows open with quite a bit of force and would overcome a spring. Sounds like it would work well. The double-threaded nipple is removable, accommodating installation of the spring in the valve body. A hollow tube would hold the valve while unscrewing the nipple.

Also a cheap repair for my bucket of previously failed valves!

You're truly on to something Chrisj!

0 -

that will cause a weird failure mode too because it won't keep it from venting altogether on most systems but it will delay it until it builds some pressure. slow to heat isn't something you'd think of from a bad vent.

0 -

I still like the idea of a solenoid at each radiator with a bimetal switch set to trip at 180F.

Those go back to a main control that also monitors room temp and decides when to run the boiler. Every room becomes it's own zone and the "thermostat" treats the entire building as a system. It can close vents early, but the bimetal switches make sure they never vent steam.

Sorry, completely separate subject, but I figured while we're re-engineering a vent… 😋

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

2 -

Add that to a vacuum return system, with 1/4" PEX returns to a solenoid controlled manifold along with your selector…

0 -

-

Those Heat Timer radiator vents make pretty darned good Main Vents when you don't have a way to add a proper Gorton or Hoffman main vent. You can drill and tap thread right into the pipe. Sometimes you have to make do. Its the best use I came up with for those hissing spitting vents.

Dave in Quad Cities, America

Weil-McLain 680 with Riello 2-stage burner, December 2012. Firing rate=375MBH Low, 690MBH Hi.

System = Early Dunham 2-pipe Vacuo-Vapor (inlet and outlet both at bottom of radiators) Traps are Dunham #2 rebuilt w. Barnes-Jones Cage Units, Dunham-Bush 1E, Mepco 1E, and Armstrong TS-2. All valves haveTunstall orifices sized at 8 oz.

Current connected load EDR= 1,259 sq ft, Original system EDR = 2,100 sq ft Vaporstat, 13 oz cutout, 4 oz cutin - Temp. control Tekmar 279.

http://grandviewdavenport.com1 -

I did as you suggested, grabbed some hardware from the drawer, and set a bucket overhead with a hose siphoning out. High pressure water would not be a fair test, if I blow hard through it, it closes. As you can see, this crappy old MoM clearly closes. Not perfectly, there's probably some crap on the float or seat. But there's a big difference between a small amount of water on the floor and water running from the ceiling!

1 -

Yes, Jells. The Hoffmans, Gortons and Maid-O-Mist do block water. Just try using Heat-timers and compare.

0 -

That's a great test. Now I have ammo against people who ridicule the MoM's "float"

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

To All, A while ago I opened a discussion "Vent Testing and Repair" The reason I did it was to show how vents operate and how to properly test and identify vent issues. Since then I have made several comments about determining the condition of vents. Such as will the floats float and determine if vents will close. I have noticed that people will post test [Not just with vents] that are invalid. In one case, I was told by a manufacturer's tech support to use a test that was not valid. I will not tell you not to post test that I do not like. As an engineer I will say that when you test a device in order to have a valid test, The device tested must be tested as it operates in the field. Example: Operating pressure 2psi maximum, case temperature 140F to 210, position vertical, ambient temperate 60 to 85F, steam cycle on time 6 min ect.

1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements