Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

Pump size help needed

nicholsm4

Member Posts: 18

I have an in-floor radiant heating system in a 2400 sq ft home and did not receive any specs when I bought the home. The system has always had problems heating the farthest zone which also is the coldest part of the home. Last year I had to replace one of the 2 Wirsbo manifolds due to lack of parts availability. I put in a manifold with flow valves and discovered when the full system calls for heat the system flow drops dramatically. I was able to improve flow to the one room but system will not keep up when temps drop too low and all zones call for heat. Do I need to increase the pump size? The system consists of a 80k btu cast iron boiler, one Taco 007-5f pump at boiler inlet and one Taco 007-5F just beyond the Taco 5000 mixing valve that feeds 10 loops controlled by 6 thermostats. 1" copper feeds the 2 manifolds with 3/4" Pex supply and return , the loop PEX is 1/2".

0

Comments

-

What type of radiant are we talking? Tube in a slab? Suspended under joists?

5 loops on each of the 2 manifolds?

Do both manifolds have flow meters on them?0 -

Tube in slab, 7 loops on the farthest manifold 3 on the other one, only the new manifold with 7 loops has flow meters. Thanks

0 -

What manifolds did you use as a replacement.? I had a job fixing a staple up system that had had manifolds replaced that had a huge pressure drop through them. Only 1 loop was getting flow w/ a grundfos 26-99. I replaced the new manifolds w/ simple Sioux Chief models and the problem was fixed.

0 -

I used an Rifeng 7 loop stainless manifold. I can get flow on multiple loops it just drops with each one that is activated.0

-

Hmmm. Taco 5000 Mixing valve fouled?

Integral flow checks in 007's?

To size a pump properly one needs to know the load requirements of the zone/zones. Loop lengths etc.

Did the system always have issues to previous owner?

It would appear from the description this is a P/S piped system.

0 -

A quick drawing of your system would really help.

The length of the tubing is important. Sometimes you can determine the length by looking at the footage marks on the exposed sections."If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

-

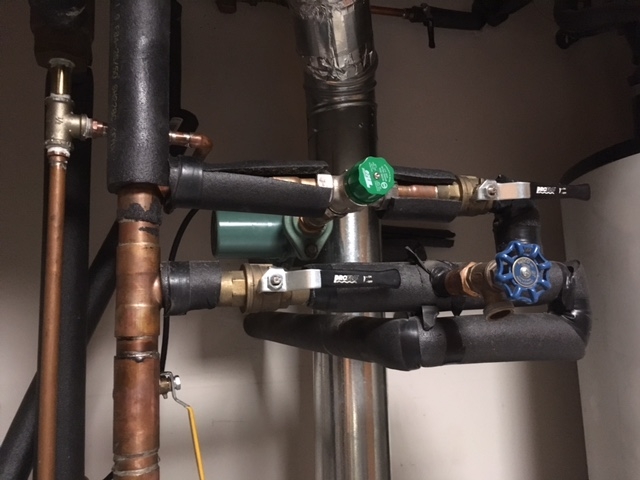

Here are a few photos of the system. When I moved into the home the mixing valve was cranked up to put out about 160 degree water to the zones. One of the pumps went out and when I went to replace it, it was full of rust. I concluded the temps were too high and the system did not have oxygen barrier pex. I have moved temp coming out of mixing valve down to 120. The photo of the valves are original ones that have not been replaced. I can not read any numbers on the pex. I could post a photo of the floor plan if that would help. Someone has recommended a Taco 008 as a solution. Thanks!0

-

An ECM ΔP pump would be a far batter choice (and most have about the same curve as a 008 does.) Grundfos Alpha, Wilo Stratos ECO, Taco VR1816.

No barrier means you need to ditch all ferrous material from the system. Start with the boiler.0 -

I think those zone actuators were a Honeywell Sparco partnership. With crappy fluid, often found in non barrier tube systems they would either stick shut or the powerful gear train inside would blow the end right off the box!

Remove them and see how easily, or not, the valve operates.

Better think of isolating that non barrier pex from any ferrous components, especially a nice ECM circ replacement.

You have some work to do:)

<

img src="https://us.v-cdn.net/5021738/uploads/editor/lc/2pfn7l9vb4mu.png" alt="" />

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

When you say isolate ferrous components what are you recommending, using dielectric unions or something more extensive. "Start with the boiler" are you recommending a new nonferrous boiler? I have considered going to stainless pumps but what other actions would I need to take. You are right about the old valves, the remaining ones I posted the photo of seem to be working fine, I will keep an eye on them.0

-

The copper fin tube HX inside the boiler has cast iron ends. Replacing the boiler with a mod/con would be the best option.

You could install a flat plate HX, additional pump, and controls, but that would probably cost at least half what a new boiler will.0 -

Isolate the fluid in the tubing from the boiler and it's pump and components.

Usually a flat plate HX is used, all the components on the tubing side, pump, expansion, air purgers, etc need to be non ferrous. Brass, stainless, composite bodies.

It adds extra components but assures you will not have corrosion issues in the boiler side.

Here is the start of what that might look like.

Everything on the left side of the HX could be steel or iron, there should be no potential to get O2 into that circuit.

On the right side is where the tubing connects, that pump, expansion tank another component would want to be non ferrous.

Personally I would add a hydronic conditioner chemical

on both sides, Rhomar 922, Fernox, Sentinel are a few of the brands Bob "hot rod" Rohr

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

I really appreciate the input, too bad local inspection did not identify the incorrect instillation of the system. I am assuming the pex is non-oxygen barrier. I rented out the home for a short time and know that the pressure valve leaked letting a small stream of fresh water into the system for a couple months so that could be some of the reason for corrosion. Is there a way to identify if the pex is oxygen barrier, only small stubs are sticking out of the slab and the blue lettering on them if faded. Can you tell from the photo? The home was built in 1999 in Albuquerque NM and in-floor radiant systems are not too common. I am looking at recommendations and thinking that it might be best to scrap boiler and maybe go with a new condensing one to avoid using a heat exchanger.0

-

-

Here is the new manifold I installed without automatic valves and flow meters.

0 -

Albuquerque has a fair amount of radiant, though it's more common up north at higher elevations (and higher average incomes.) It's somewhat rare down here (Silver City.)

Can you read any of the markings on the tubing? If it was Wirsbo tubing it would be marked with hePEX and not for potable use if it is barrier and AquaPEX if it is non-barrier.0 -

What I can read is WIRSBO AQUAPEX ICB ES ER5142 ER4407 Hauser0

-

-

I guess my dilemma is wether to try to get some more use out of the system or to rebuild it. I read on this site that temps under 140 would help keep rust at a minimum. That with another pump such as the recommended Taco VR1816 might keep me going a few more years. I see little corrosion in the boiler. Is there any danger of damage to the pex?0

-

Return temps under 140 actually accelerate the rate of corrosion inside the boiler and of other ferrous components. The mixing valve they installed sends water at a fixed temperature through the tubing. What you want in a radiant floor system is for the water temperature to cool as the outdoor air temp warms up. We use the term Outdoor Reset (ODR) to refer to this. Modulating boilers include this capability in their onboard controls. You could add it to your system, but it would probably run 20-30% of the cost of a new boiler.

You should be able to buy some time by flushing and cleaning the system using a hydronic cleaner (Rhomar, Fernox) and then adding some hydronic conditioner. Installing a magnetic dirt separator would also be a good idea. You may want to consider hiring someone with the proper gear to do this. If budgets are tight and you have the time & skills we can help you through the process but you're probably going to need to buy a pump and a filter along with the chemicals.

The VR1816 is only available with a cast iron volute. The Grundfos Alpha is available with a stainless volute so I would probably suggest one of those. It will be re-usable when you replace the boiler.

I'm not certain whether rusty water has long-term effects on PEX or not. It's quite likely someone here may have more information on that.0 -

So what temp would you recommend the boiler operating at? I have the temp after the mixing valve to the zone valves set at 130.

0 -

Depending on the control scheme and piping on the boiler side of that valve, the 130°F setting may or may not cause issues. The boiler should probably be set to supply a minimum of 160°F water in order to maintain a 140°F return temp, but specifics would depend on the boiler size (relative to the load) and the specific pump and piping layout.1

Categories

- All Categories

- 85.2K THE MAIN WALL

- 3.1K A-C, Heat Pumps & Refrigeration

- 55 Biomass

- 424 Carbon Monoxide Awareness

- 73 Chimneys & Flues

- 1.9K Domestic Hot Water

- 5.2K Gas Heating

- 129 Geothermal

- 160 Indoor-Air Quality

- 3.3K Oil Heating

- 61 Pipe Deterioration

- 884 Plumbing

- 5.9K Radiant Heating

- 376 Solar

- 14.7K Strictly Steam

- 3.2K Thermostats and Controls

- 58 Water Quality

- 49 Industry Classes

- 89 Job Opportunities

- 28 Recall Announcements