Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

Low loss header - boiler side - pump away? (or to the boiler?)

Options

Chuck_17

Member Posts: 143

Typically for a primary secondary boiler connection, the boiler (secondary) pump would pump "to" the boiler.

But what about if you are using a packaged low loss header?

The Lochinvar boiler install manual shows the boiler pump pumping "to" the boiler.

The B&G low loss header shows the boiler pump pumping "away" from the boiler (to the header). (Actually it shows the boiler pump pumping away for the example secondary loop also.)

The system pump would pump "away" either way (not in question).

I'm inclined to go with the boiler detail. What do you think?

But what about if you are using a packaged low loss header?

The Lochinvar boiler install manual shows the boiler pump pumping "to" the boiler.

The B&G low loss header shows the boiler pump pumping "away" from the boiler (to the header). (Actually it shows the boiler pump pumping away for the example secondary loop also.)

The system pump would pump "away" either way (not in question).

I'm inclined to go with the boiler detail. What do you think?

0

Comments

-

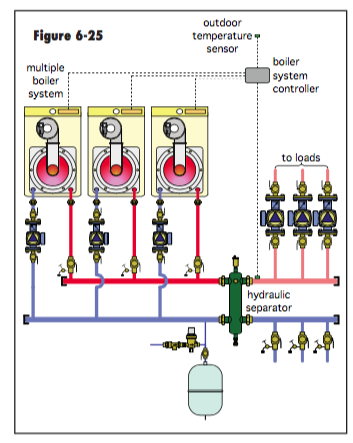

the lochnivar boilers do not have a substantial pressure drop across there heat exchangers... i believe the wh and khns are very low .....the reason most modcon boilers show the boiler pump on the return is because of that substantial pressure drop on that specific boiler ..... best way is pump away from "the point of no pressure change" using a low loss header i would pump toward the boiler on the the boiler side of the header....( LLH is the point of no pressure change for the boiler pump) install the system pump on the supply of the LLH , pumping away from the expansion tank....Caleffi idronics has nice diagrams for this.ASM Mechanical Company

Located in Staten Island NY

Servicing all 5 boroughs of NYC.

347-692-4777

ASMMECHANICALCORP@GMAIL.COM

ASMHVACNYC.COM

https://heatinghelp.com/find-a-contractor/detail/asm-mechanical-company1 -

A properly proportioned separator presents very little pressure drop in the system. Ideally a 3-1 ratio, pipe size to barrel dimension.

As such, expansion tank connection near any of the 4 ports establishes the PONPC through the vessel.

On caution is to avoid the expansion directly below the sep to prevent any dirt removed from settling on the diaphragm in the expansion tank. If you use the bottom connection install a tee and pipe the expansion tank off the branch.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

Which Lochinvar boiler specifically? Some of their older designs use high head loss heat exchangers and those are quite different with respect to pumping requirements.0

-

Just thinking out loud, but on the low mass mod cons, if you pump towards the boiler you keep the water at the HE at the highest pressure in the loop/system. This "might" help in certain conditions where the fluid against the outer wall of the HE might want to flash.

It's more of a worse case scenario thought, but even the best system design and installation someday will suffer from some form of issue and why not give it the best chance of the least amount of trouble when that time comes.1 -

-

More so high pressure drop type boiler HXers. Copper tube boilers are considered low mass, low water content, but have large short tubes, not as much pressure drop as some coil type mod cons.Firecontrol933 said:Just thinking out loud, but on the low mass mod cons, if you pump towards the boiler you keep the water at the HE at the highest pressure in the loop/system. This "might" help in certain conditions where the fluid against the outer wall of the HE might want to flash.

It's more of a worse case scenario thought, but even the best system design and installation someday will suffer from some form of issue and why not give it the best chance of the least amount of trouble when that time comes.

There are some brands of mod cons that have pressure switches on the boiler for low water conditions, you defiantly want to pump into those.

Really no harm in pumping into any boiler, as long as the expansion tank is located upstream of the circ pump.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2

Categories

- All Categories

- 85.2K THE MAIN WALL

- 3.1K A-C, Heat Pumps & Refrigeration

- 55 Biomass

- 424 Carbon Monoxide Awareness

- 73 Chimneys & Flues

- 1.9K Domestic Hot Water

- 5.2K Gas Heating

- 129 Geothermal

- 160 Indoor-Air Quality

- 3.3K Oil Heating

- 61 Pipe Deterioration

- 884 Plumbing

- 5.9K Radiant Heating

- 376 Solar

- 14.7K Strictly Steam

- 3.2K Thermostats and Controls

- 59 Water Quality

- 49 Industry Classes

- 89 Job Opportunities

- 28 Recall Announcements