Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

Do I need to replace my expansion tank?

Options

NTL1991

Member Posts: 104

I've just checked the pressure in all three of my boiler's expansion tanks. All three tanks are Watts ET-30 expansion tanks. The 1st and 2nd floor both have 12PSI of pressure with no trace of water. The 3rd floor tank is at 24PSI, and when I check the pressure, I get water dribbling out. I am assuming that the bladder is ruptured.

Does it make sense that for the past couple of years, I've had a problem with air gathering in the radiators on the 3rd floor? Gurgling and things of that nature? I've just assumed it needed to be bled, and have had that done every year when the boilers get cleaned...

How do I go about replacing this tank? The 3rd floor boiler (a little natural gas unit) is set to 25PSI cold (at 85 degrees F). Is that why I'm getting the 24PSI in the expansion tank?

Attached are the pics of the boiler/tank in question.

<img src="http://i12.photobucket.com/albums/a212/NTL1991/Basement/DSC08196.jpg" width="600" height="800" alt="" />

<img src="http://i12.photobucket.com/albums/a212/NTL1991/Basement/DSC08198.jpg" width="600" height="800" alt="" />

<img src="http://i12.photobucket.com/albums/a212/NTL1991/Basement/DSC08199.jpg" width="600" height="800" alt="" />

<img src="http://i12.photobucket.com/albums/a212/NTL1991/Basement/DSC08199.jpg" width="600" height="800" alt="" />

Does it make sense that for the past couple of years, I've had a problem with air gathering in the radiators on the 3rd floor? Gurgling and things of that nature? I've just assumed it needed to be bled, and have had that done every year when the boilers get cleaned...

How do I go about replacing this tank? The 3rd floor boiler (a little natural gas unit) is set to 25PSI cold (at 85 degrees F). Is that why I'm getting the 24PSI in the expansion tank?

Attached are the pics of the boiler/tank in question.

<img src="http://i12.photobucket.com/albums/a212/NTL1991/Basement/DSC08196.jpg" width="600" height="800" alt="" />

<img src="http://i12.photobucket.com/albums/a212/NTL1991/Basement/DSC08198.jpg" width="600" height="800" alt="" />

<img src="http://i12.photobucket.com/albums/a212/NTL1991/Basement/DSC08199.jpg" width="600" height="800" alt="" />

<img src="http://i12.photobucket.com/albums/a212/NTL1991/Basement/DSC08199.jpg" width="600" height="800" alt="" />

Nick, Cranston, RI

0

Comments

-

Tank Is Bad

If you're getting water from the schrader valve, then the bladder is ruptured and the tank must be replaced.

Removing the tank is simple: it unscrews. The more complicated part is that the tank must first be isolated from the system and it does not appear that you have an isolation valve in the supply line in your pics. If this is true, then you'll have to drain the system before removing the tank. You should have a valve installed at this time also, that way you won't have drain and re-fill and purge the next time a component fails. Also, Watts has a small check valve that screws on the end of the tank so that all you have to do next time is unscrew the tank. This is a separate part that may not come with the tank.

Set the air pressure on the new tank @ 18psi before putting any water pressure on it. It comes with about 12psi, but you'll need 18psi for a 3rd story.

Your fill valve will also need to be set @ 18psi with the system cold. Now would be a good time to replace that also and install a valve between it and the Tee above the expansion tank so it can be isolated too.

One other thing: Is that 02 barrier pex connected to the loop? I've never seen that color 02 barrier before. Everything sold in our area is red or orange. If it's not, it will ruin your boiler. It should be stamped on the pipe.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Thanks

Thanks for the quick reply.

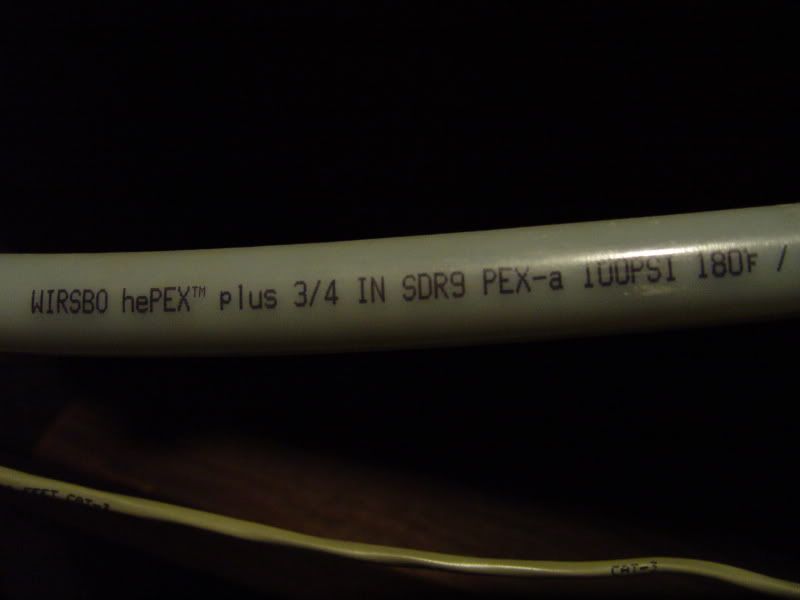

The tubing is marked as "Wirsbo hePEX plus 3/4" SDR9 PEX-a 100PSI 180* F"

After some research, I found that it is, in fact, Oxygen Barrier PEX, so I guess that's one less thing to worry about.

I purchased the expansion tank today. I'll be putting it in tomorrow. Because I don't have an isolation valve on the supply side, I'd like install an isolation valve, since I have to go through the trouble to drain and purge the system anyway...

Would I install a ball valve on the copper section after the Air Purger and before the supply PEX? Also, would it be possible to install a threaded ball valve rather than soldering one on? The copper has a soldered male threaded fitting on it. Can I just unscrew the pipe and install a threaded ball valve before this, and then screw the copper into the valve? If so, what type of thread sealant can I use? Should I use pipe dope or Teflon tape?

Thanks.

Here's the PEX tubing label...

Is this where I will be installing the isolation valve? Right on this copper section?

Here's picture of the threaded fitting on the copper pipe. Can I just screw a ball valve in here? Nick, Cranston, RI0

Nick, Cranston, RI0 -

Ball Valves

You can get ball valves with "sharkbite" connectors on them that are rated for 180deg. All you have to do is cut out the amount of pipe equal to the width of the middle section of the valve and push the copper lines into the valve.It's that easy.

Make sure the portion of the pipe that goes into the sharkbite is clean and round as that is where the "o" ring seals. Also, make sure the cut is clean and square so as not to tear the "o" ring when the pipe is inserted.

If you can't find the valves with the sharkbites already on them, use a threaded valve with two sharkbite male adaptors screwed in it. Use tape and dope for a sure seal on any threads.

Put one on the fill line also so you won't have to drain any thing when that needs replacing (down stream, between fill valve and tank Tee).

And yes, that copper section is where to install the valve in the hydronic loop. Don't try to unscrew any thing. Just cut the copper with tubing cutters.

Any thing beyond this, and you'll have to call a heating contractor.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Thanks

Thanks for the reply.

Should I be concerned about the reliability of the SharkBite type of connection system, or are they proven and reliable? I have a pipe cutter so there shouldn't be any problem with out-of-square cuts. I just don't want the thing leaking on me a few years from now...

I've got a ball valve before the fill valve, so I'll shut that off and put a valve between the tank and the valve to assist in replacing that valve in the future.

I'll pick up some pipe dope while I'm out looking for the ball valves.

I might also just solder in some ball valves if I cant find the SharkBite type valves rather than having more fittings (one more place to leak) than I need.

Thanks for all the help,

NickNick, Cranston, RI0 -

All Done

So I charged the new tank to 18PSI, Drained the System, Cut the Supply Pipe, Soldered on a 3/4" Ball Valve, Soldered on a 1/2" ball valve after the fill valve, installed the new tank with pipe dope, filled the system, checked for leaks, and purged it.

Now, I know I need to get 18PSI of system pressure when cold. When filling, the gauge topped out at about 5PSI. Am I filling the system correctly?

After purging, I closed the hose bib valve on the return line above the circulator. This closes the system. So, to increase the pressure, I added water by raising the lever on top of the automatic fill valve. I couldn't get the pressure to rise above 5PSI. But, I had a few dribbles out of the pressure release valve on the boiler...

I turned on the boiler and let it run a couple cycles. The temp rose to 180, cycled off, and then back to 180. I turn the boiler off. At this time, the pressure was about 28 or 29PSI. I had another dribble out of the pressure release valve.

Right now, I'm letting the system cool off to double check the pressure gauge to see what it is when the system is cool. Could my gauge be bad or am I doing something wrong?

Thanks,

NickNick, Cranston, RI0 -

18 PSI

Is what you should have cold. Sounds like the gauge might be bad.

You shouldn't have to lift the lever on the fill valve: that is for manual bypass filling and purging. Use the lever to rotate its cap off the valve and expose the adjustment stem underneath. Turning the stem clockwise increases pressure in system. It comes pre-set at 12psi. If it continues to increase the pressure with the boiler off, the fill valve should be replaced. Set to 18psi cold and make sure lever is down when checking.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0

This discussion has been closed.

Categories

- All Categories

- 87K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 57 Biomass

- 425 Carbon Monoxide Awareness

- 112 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.7K Gas Heating

- 106 Geothermal

- 160 Indoor-Air Quality

- 3.6K Oil Heating

- 70 Pipe Deterioration

- 979 Plumbing

- 6.3K Radiant Heating

- 387 Solar

- 15.4K Strictly Steam

- 3.4K Thermostats and Controls

- 54 Water Quality

- 44 Industry Classes

- 48 Job Opportunities

- 18 Recall Announcements