Honeywell Zone Valves

Questions first…

Does the sealing ball on a Honeywell zone valve ( V8043 ) ever go bad and leak through ?

Is there typically and NEED for check valves on a system with these zone valves ?

The reason I ask is because I looked at a job and the complaint was that one particular zone is getting way too hot.. This particular area is getting up to 83 degrees even with the thermostat off. First, I DID double check operation of the Honeywell zone valve motor with the thermostat. And it DOES operate with thermostat, opens and closes. I pulled the motor off of the valve and turned the valve by hand and it also operates freely. So I'm wondering if the ball inside is just not sealing off when closed.

Now another problem with this particular zone is that it is a small radiant in-floor (concrete) zone with no mixing valve !! So it is getting 180 degree water. (The rest of the house is all baseboard fin tube.) Don't know who did this or how long it has been this way. But the customer says that it "been a long time". So I will have to look into adding a mixing valve for this zone as well.

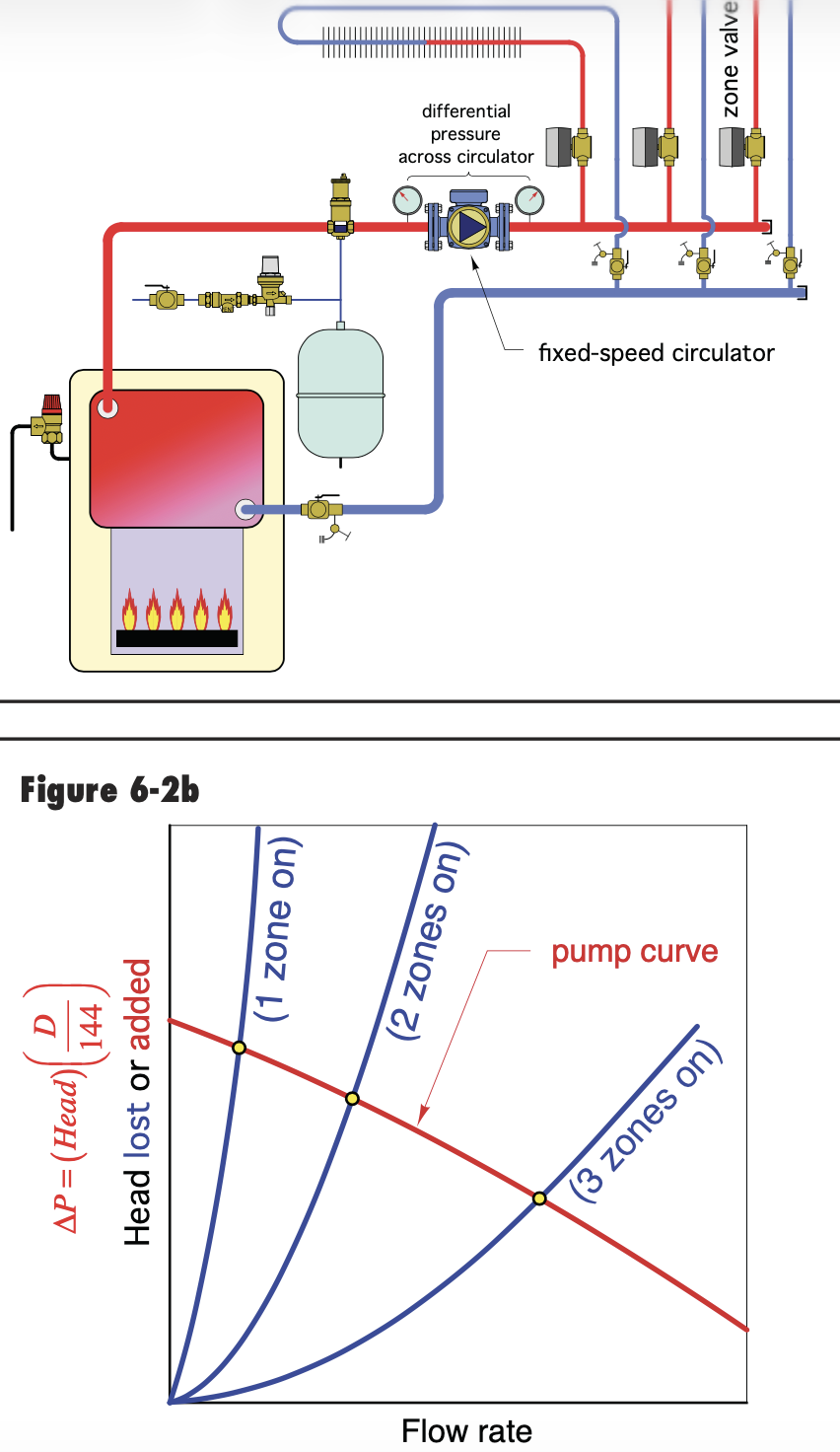

The system itself has 3 zones total, with one circulator pump. The circulator is installed on main return line and is pumping away from exp tank.. The 3 Honeywell zone valves are on the supply side. It is 1 1/4 main with 3/4 branch tees to zones.

What do you all think about my questions on this ?

Comments

-

The ball of that zone valve is rubber.

I have actually is a couple cases witnessed the stem its is attached to snap off.

It is w/in the realm of possibility that the rubbed could wear down…especially if the water quality is poor.

Yes by all means get a mix valve on that radiant.

0 -

Yes, they can leak. If the valves are the newer style where there's a gap between the actuator and the valve body, it's an easy swap. Or you could upgrade all the zone valves while doing the mixing valve.

0 -

Yes I know the ball inside is rubber.. I've just never seen them leak thru before.

But I have no other explanation why that particular zone is overheating.

I didn't think any check valves would be needed in a system with zone valves to prevent "ghost flow".

Is there ant reason that check valves would be necessary in this situation ??

0 -

-

A few thoughts. The most common, on the shelf HW 8043 is a 8 Cv, 8 psi shut off. In some cases with high head circs, they can push through a bit. Lower Cv of any ZV will always have a higher shut-off rating.

Also check to see if one spring have been disconnected, this is a common hack on HW if they experience water hammer noise. But it lowers the shut off pressure, so they may leak through.

The ball on the shaft rotates, so it closes off in a different location every time. Over a period of time you get a lot of criss cross imprints and can get small leakage. Same thing with the higher head circs allowing some flow to leak through.

Aggressive fluid can cause the ball to deteriorate also. Allegedly these valves were two years old! Perhaps an agressive acid cleaner was put into the system??

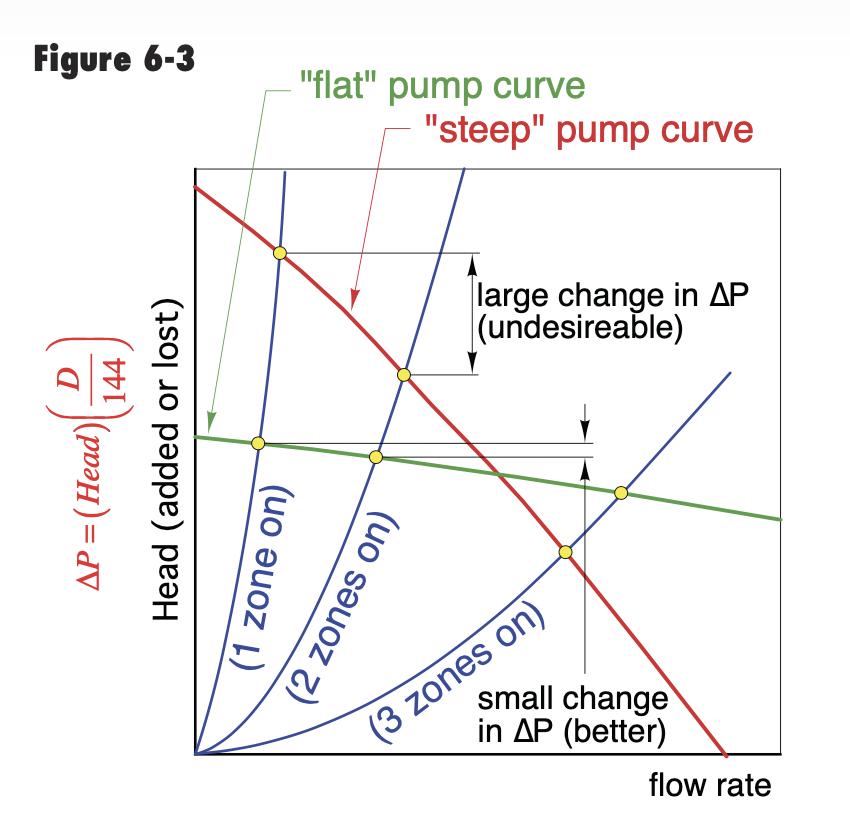

Best practice is to use a pressure bypass valve if you have 3 or more zone valves on a fixed speed circ. You want a flat curve circ on zone valve systems. As the valves close you run up the pump curve. Or better yet a delta P circulator

Fig 6-3 shows the difference between steep and flat curve circs and the ∆P difference as valves close off. On the vertical axis these two circs are about the same gpm, but the head is quite different.

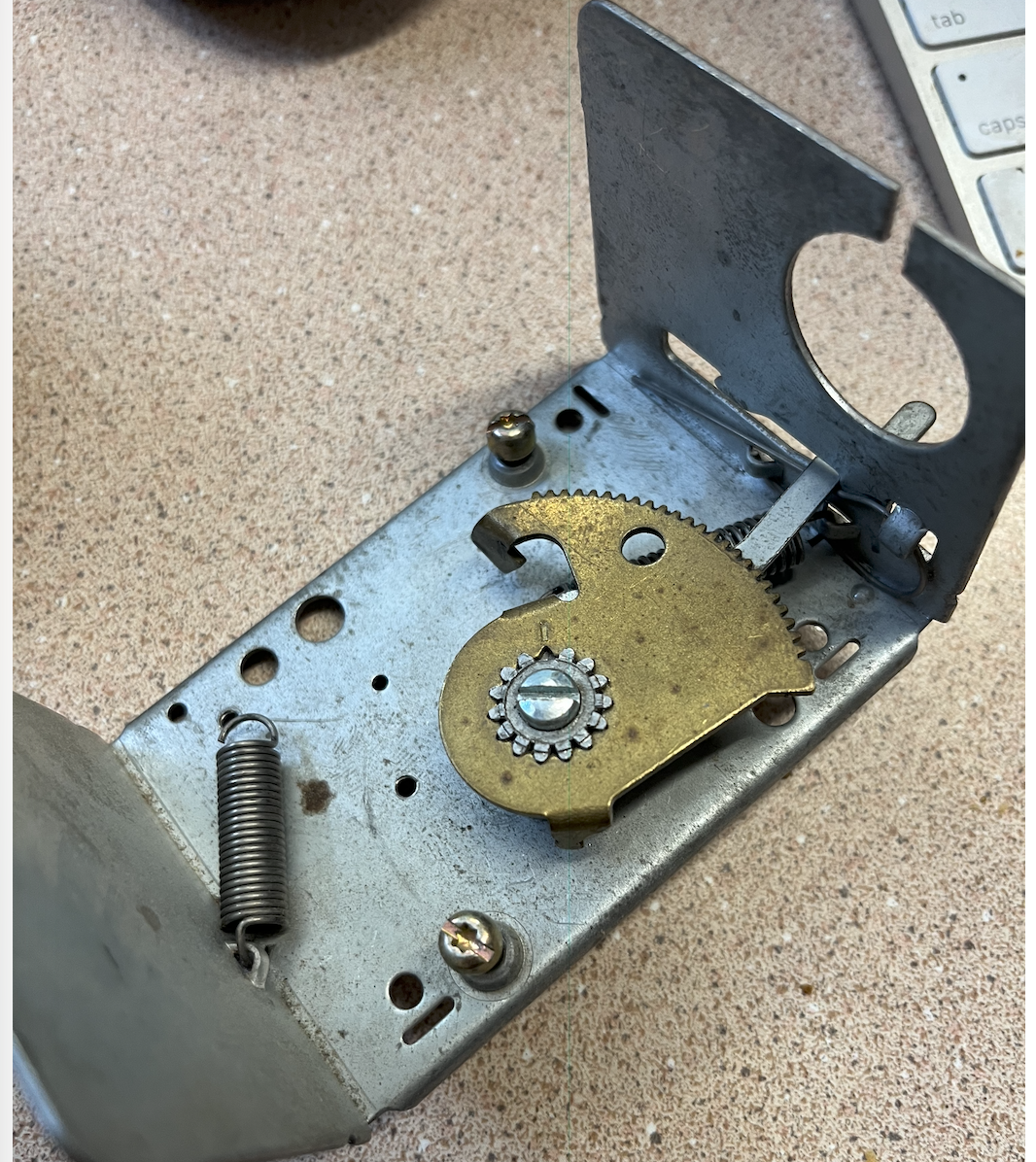

All these factors were considered when the Caleffi Z-One was developed. It has a peroxide cured EPDM flapper. A coils spring that is torqued on every valve. Thicker gears with lost motion disconnect.

We have had an ocassional water hammer so the close-off torque has been reduced, dropping our 20 psi close off down around 15 psi, but slowing down close off a few seconds.

That is the trade off with spring return valves. Enough torque to hold 12- 15 psi, but slow close off to avoid water hammer potential.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I have a theory regarding the question: “Is there any reason that check valves would be necessary in this situation?”

Without a mixing valve serving the radiant floor zone, that zone would likely receive water at too high a temperature. Radiant floor systems require lower supply water temperatures than standard baseboard or high-temperature zones.

It is possible the installing contractor was unfamiliar with the lower temperature requirements of radiant floor heating. When inquiries were made about the overheating issue, someone may have suggested that “ghost flow” was the cause. A common response to ghost flow is to install a check valve on the opposite end of the zone from the zone valve.

However, if the underlying issue is improper temperature control rather than unwanted circulation, adding a check valve would not correct the root problem.

You still have a overheating problem. You still don't have a mixing valve. So you still have an overheating problem.

I might suggest that you drain the boiler or zone and install a mixing valve. While the system has no water pressure in it, open the zone valve and inspect the ball inside the valve to see if there is a problem?

If you have a section of pipe at 180° with a valve on either end, (Check on one side and zone valve on the other) and there is no expansion tank within the two valves, when the water cools off and the water pressure turns to a vacuum, that can be enough pressure differential in the system to destroy the rubber ball on the zone valve. Remove the check valve while you are making the other repairs.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

just a little bit of leakage of the zone valve of the 180f water in to a zone that requires maybe 110f could cause significant heating of that zone.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements