Pump selection for GeoCool 4 ton inverter heat pump

The documentation states 5.3~19.8 GPM, and also has a note:

There should be a ten degree temperature difference between incoming and outgoing water.

Based on those requirements, is the Taco 007 VDT a good choice? It can track the 10 degree differential and follow the variable output of the inverter HP.

https://www.supplyhouse.com/Taco-007-VDTF5-007-Variable-Speed-Delta-T-Cast-Iron-Circulator-Pump-115V

Comments

-

-

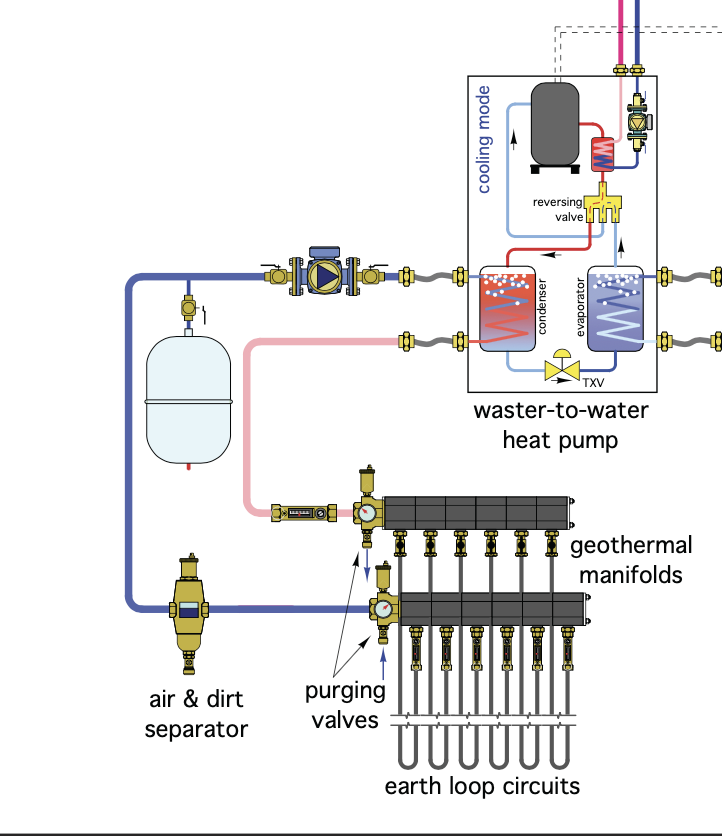

is this a geo heat pump? If so the loop size needs to be part of the pumps requirement.

You need to know the fluid, required gpm, and pressure drop of the circuit.

Usually the manuals give you pump spec options.

Many newer hp use variable speed pumps, that are controlled by the hp, via a 0-10 or PWM signal.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

The HP manual has no other pump info other than " the pump should be less than 600 watts", and system pressure between 25 and 50 PSI.

I have two sets of loops that can be operated together or alternately, 3/4" PEX

3x500' ~2.5 Tons

4x500' ~3.3 Tons

These are home runs to the equipment room, connecting to 1" manifolds with individual valving.

I can give it any multiple of 500' of loop.

The loops are -3' to +3' as referenced to the equipment room floor. Pretty flat situation.

With the individual valves we should be able to burp it loop by loop easily.

Fluid is going to be 20% glycol.

Looking at the diagram, the HP will power the pump directly L1 L2 . I'll have to use one for the 115V Taco if I go that route.

It really has no other data besides the GPM range, differential, and wattage and I just figured out that is because it is supplying the line power through an internal relay.

This system will be for a brief summer cooling season, and the house has hydronic for the heating.

Unfortunately my hydronic heat pump is on backorder so I will get occupancy with this unit, and test and commission the hydronics with a water heater as discussed in that thread.

0 -

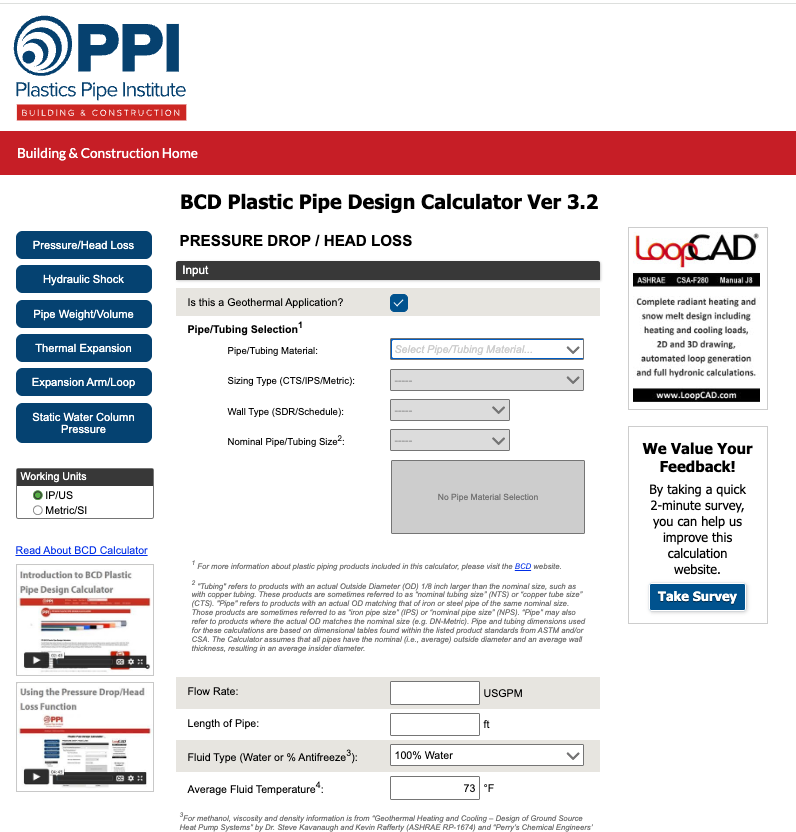

Here is a pressure drop calculator for plastic tube of all sorts. Enter all the info. Type of tube, size, length, fluid, temperature and gpm. This give you the pump head for the loop field. Generally you need 2-3 gpm per loop. Just guessing 500' per ton of horizontal loop.

A GEO system should be calculated to the location, soil type, equipment requirement, load size, etc. There are software programs to do this.

Somewhere you need the info for the HP flow requirement, and related pressure drop. That needs to come from the manufacturer.

It sounds like you are just spitballing the design? :)

Here is a graphic of the components.

So you need the flow info and then calculate the pressure drop in the loop field, the piping from the manifold to the HP and the pressure drop of the HX in the unit. That pump is generally a 240V, operated from the HP control, as you suggested.

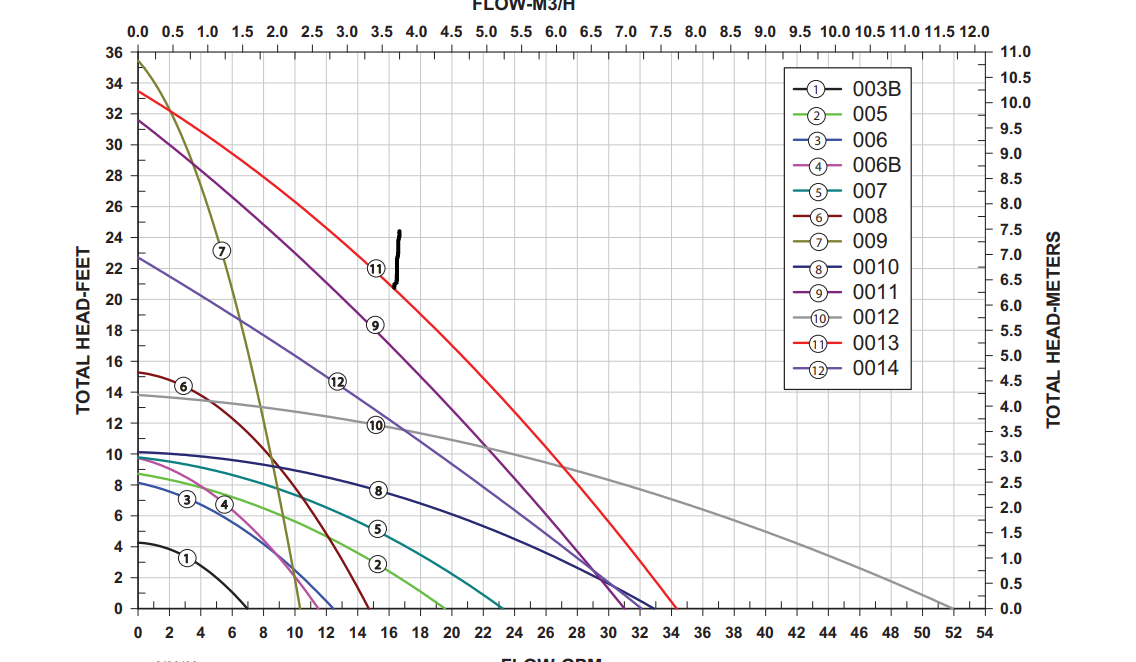

I doubt an 007 will be even close to the pump you need.

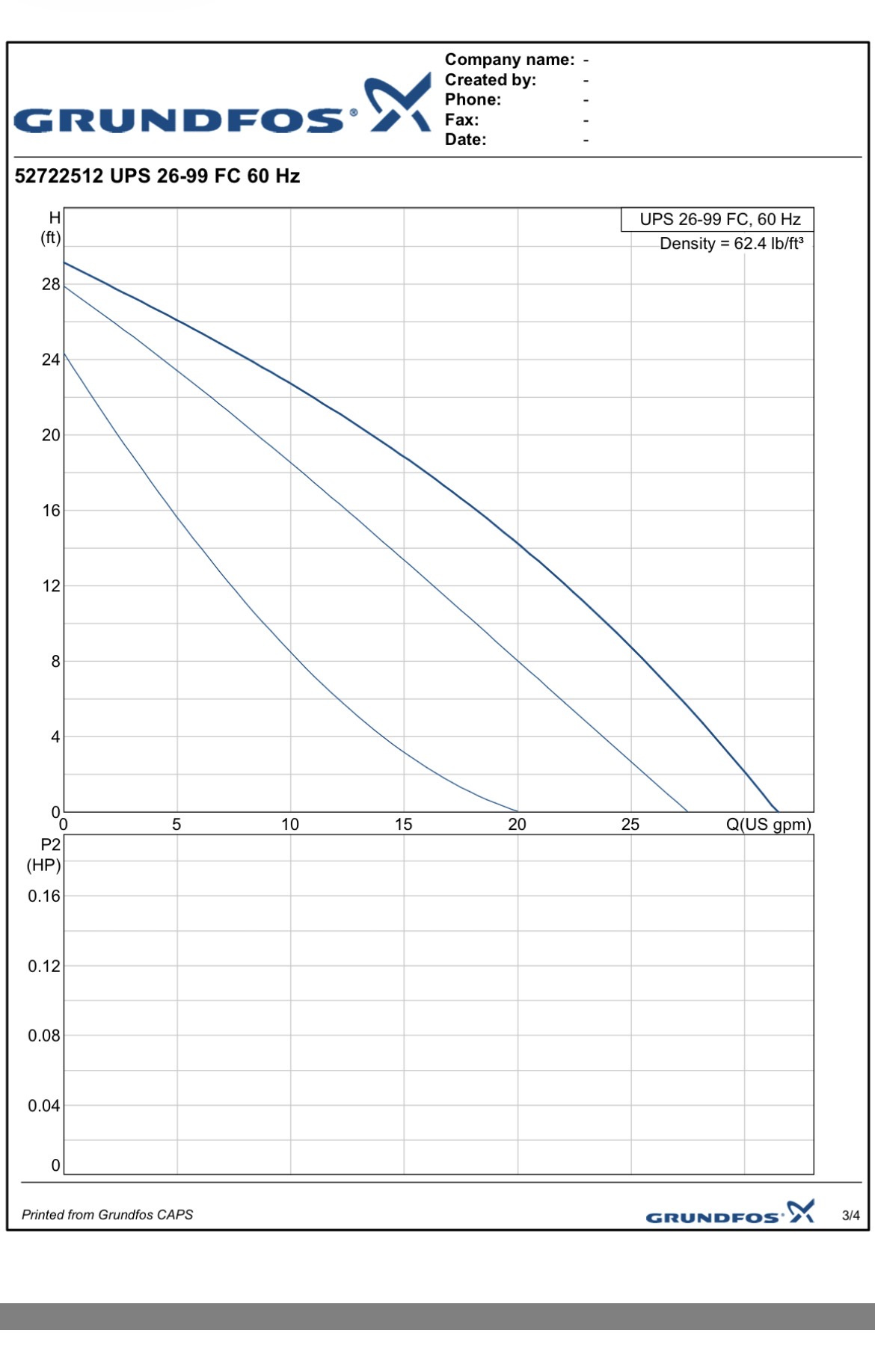

Look at typical GEO pump modules here, they start at Grundfos , generally 240V pumps to wire to the HP 26-99

\

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

I registered at Geo-flo and used a single unit calculator, and got 21.3 Ft of total head at a nominal 10 GPM on

all 7 loops.

The Taco 013 charts at ~16GPM at that head.

The Taco 012 looks like it could do the trick too.

I was WAAY out in the weeds with the Taco 007, thank you!

0 -

"It sounds like you are just spitballing the design? :)"

Kinda Sorta, you got me.

I built my fields and headered them that way so I can alternate fields to feed the hydronic HP and let one recover. I am intentionally over-looped.

They home run into the room, a few feet away from the hydronic HP and 10' of pipe away from this air handler/HP.

The installation manual only mentioned the things I have listed.

I go to a sales brochure and get "7.93 GPM" in both full load and part load. That sounds bogus, and nowhere do I find a mention of pressure drop across the HP.

0 -

-

Thank you Bob. you would not bother with a pump that tracks a Delta T then.

0 -

there are variable speed GEO specific pump stations with the larger sized pumps. That 007 isn’t going to work.

But some control, usually in the heat pump control board, tells the pump how to vary its speed.

If you plan on running this for cooling, you will need to insulate the pump and piping. These GEO pump centers are tightly insulated so the don’t sweat.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

this video explains how the variable speed pump and controller work on the loop field. In this example they choose two different flow rates as it is a two stage hp that it connects to. He mentioned 3 gpm per loop on this application.

If you want to spend the money for a variable speed pump, and there is now control interface on your unit, this package makes sense to dial in all the parameters and monitor performance

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

This HP does not have a PWM out, it just has a relay and supplies power to the pump so it can sequence it to start prior to the compressor.

That is why the TACO that comes with sensors and a way to set up a Delta T seemed like a good deal. HP turns it on, then being an inverter with a wider range of capacity it could track that and vary the flow as needed.

In cooling mode, the ground loop piping and the pump will get warm with the rejected heat, so sweat on that unit is not the issue.

It will be a thing on the hydronic HP. I am insulating everything in the room, and I also have a Heat pump water heater in there with a condensate drain, which will keep that room pretty low humidity. I will take whatever help I can get.

The backordered hydronic HP does have a PWM out to the pump.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements