Need Help Rebalancing a 1-Pipe Steam System

Hey all,

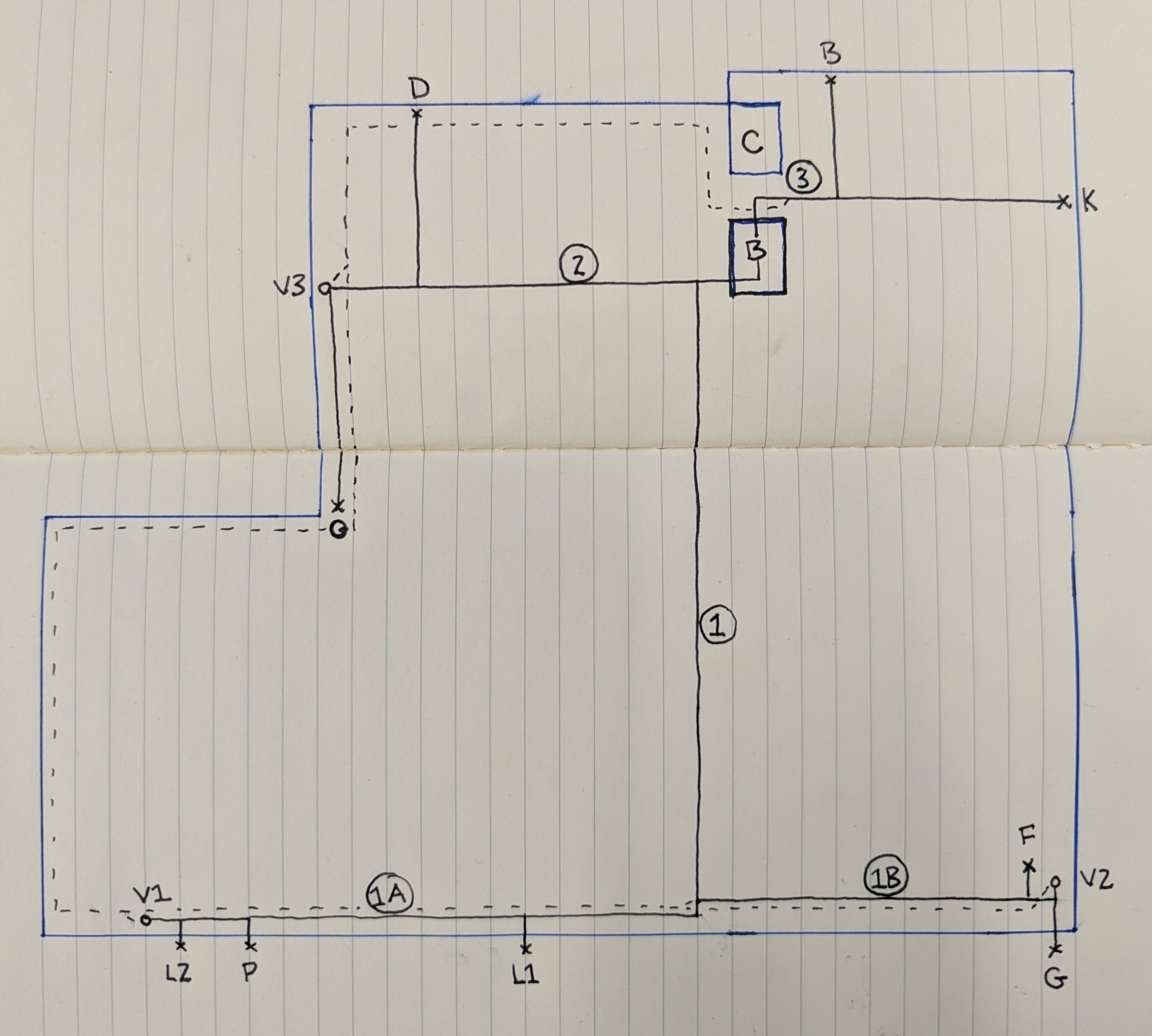

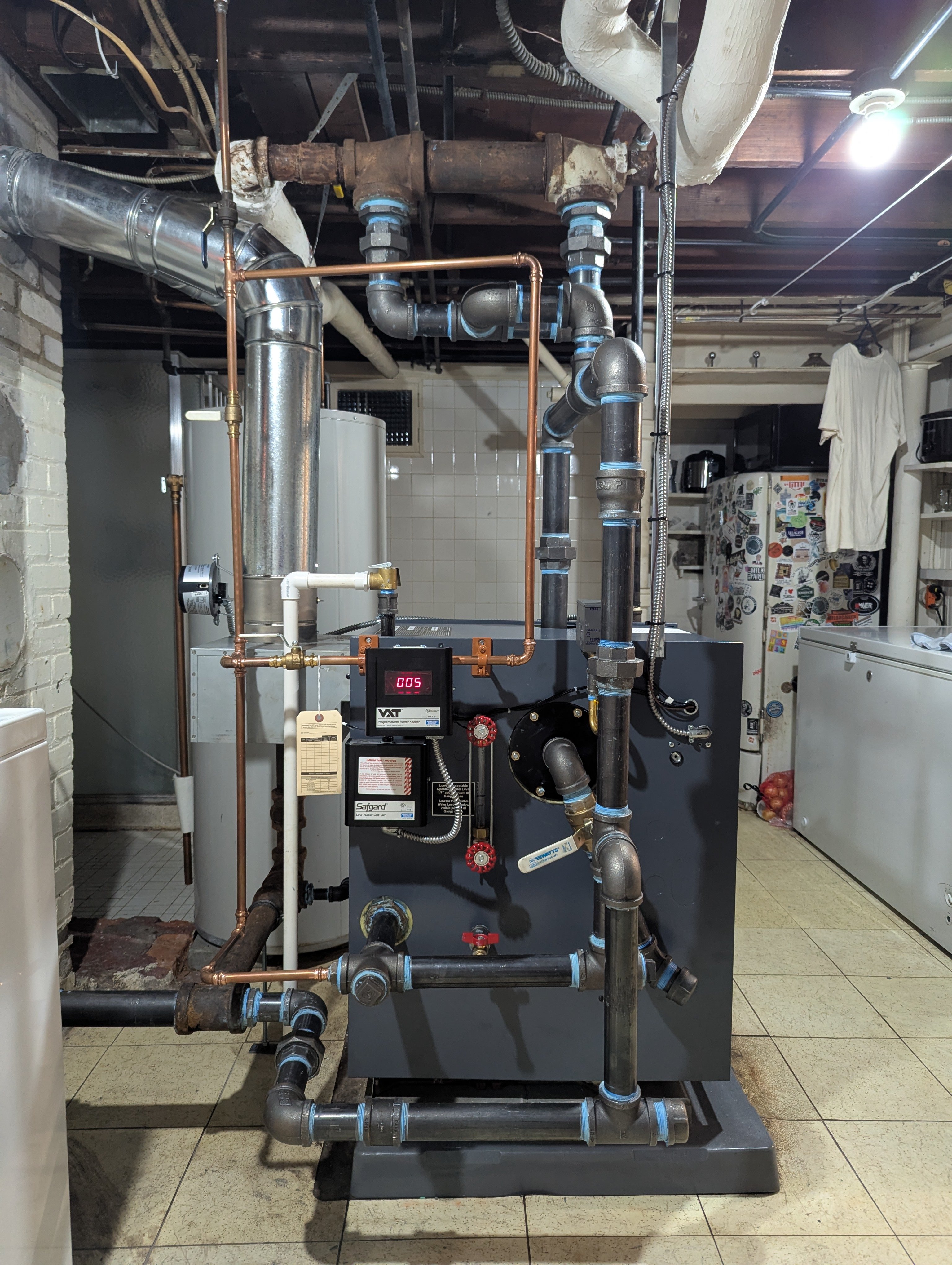

We finally replaced our old, oversized, and incorrectly piped Utica boiler. Our new Weil McLain EG-40 (many thanks to all that commented and advised back in 2024) and its near boiler piping were a big improvement, and as part of the work, we reopened two capped main vent tappings. Years ago I went through the effort of balancing the system with the old boiler and only one functioning main vent, and so, I now need to retune everything.

I know I made some mistakes in the past, and so, am hoping to not knucklehead it up this time.

The system as it stands today is as follows:

Weil McLain EG-40 Boiler serving a 343.5 EDR System

Main | Piping Measurements | Air Vol | Radiators | Vent |

|---|---|---|---|---|

Header | 8' of 2" and 2' of 3" | .290 cf | n / a | n / a |

1 | 2' of 2" and 16.5' of 1.5" | .277 cf | None | None |

1A | 14.5' of 1.5" | .203 cf | L1, P, L2 | (V1) Gorton #2 |

1B | 11' of 1.5" | .154 cf | F, G | (V2) Gorton #1 |

2 | 3' of 2", 6.5 of 1.5", and 3' of 1.25" | .190 cf | D, O | (V3) Gorton #1 |

3 | 3' of 2" | .069 cf | B, K | Converse flow |

Rad | Main | Branch Piping | EDR | Valve |

|---|---|---|---|---|

L1 | 1A | 4' of 1.25" | 42 | Gorton #5 |

P | 1A | 14' of 1.25" | 45 | Gorton #6 |

L2 | 1A | 2.5' of 1.25" | 42 | Gorton #5 |

F | 1B | 1' of 1.25" and 2.5' of 1" | 55 | Gorton D |

G | 1B | 13.5' of 1.25" | 36 | Gorton C |

D (t-stat) | 2 | 6' of 1" | 42 | Gorton #5 |

O | 2 | 21' of 1.25" | 36 | Gorton C |

B | 3 | 6' of 1.25" and 14' of 1" | 21 | Gorton #6 |

K | 3 | 3' of 1.25" and 5.5' of 1" | 24.5 | Gorton #6 |

Current Issues/Symptoms:

- Uneven heat (no duh)!

- Radiator F is the coldest, with B & K heating too quickly.

- Quiet puffing/whistling of radiator valves (skimming has diminished this, as several used to gurgle).

- Clicking/tapping water hammer in branch line to radiator O.

Initial Thoughts/Questions:

- To balance the mains: Install a Gorton #2 vent at V2, and install a second Gorton #1 at V3.

- Is this venting capacity too rapid? Should I slow everything down?

- Current vaporstat goes down to .5lb. Would getting down to 2-3oz really make a difference?

- Radiators B & K heat way too quickly, likely due to being on the converse flow main and having valves that are too fast.

- Perhaps dropping from a #6 to a #5?

- Is there anything faster than a Gorton D for radiator F? Do I have to slow the rest of the system down to balance it out?

- Radiator D should be slowed down, due to t-stat being in the room.

- Perhaps dropping from a #5 to #4

I am open to any and all feedback and suggestions.

Thanks!

Comments

-

Radiator venting , you need resistance upstairs to direct steam down the main first . We want to heat all the radiators the same time at first .. The steam will follow the least resistance way .. . I use the adjustable Hoffman . I first set the small radiators to A , medium to B and large to C. Don't over adjust , try it for a few days . All too loud raise them all up a notch . Room to warm , better to size smaller then opening the others .. Noise = too little venting and unbalanced to much venting …

There was an error rendering this rich post.

1 -

Great job of drawing up your system!

First check the pitch carefully on that line to radiator O. Any level area or sag that could collect a bit of water? Might also want to do this on the stretch of pipe 1b.

Seems like some big vents overall on not too big radiators. Gets very hard to balance when everything is venting so fast IMHO. I would start off dropping the vent sizes on those two radiators close to the boiler probably to 5's if not 4's.

You could consider another Gorton #1 at V2 but I really don't think you need it. You total main venting is more than sufficient for the volume of pipe it is handling. Looking at the situation where steam gets to the 1a/1b junction the total venting in the 1a direction (choosing 2oz cfm) is about 39% more than the venting in the 1b direction but to the end of the mains at least the pipe volume is 32% greater in 1a than 1b. So, maybe the main would fill slightly sooner in the 1a direction. The takeoffs to the radiators are quite short along 1a thus the slower venting on those rads vs F and G makes sense. I would try going slower on those before trying to find a faster vent for F and G. Just seems potentially something else is slowing F and G thus my suggestion to really check the pitch of 1b and the takeoffs to the radiators F and G.

Quite honestly if it were me I would tend to start out with everything ~ #5 and bump down initially on the overly hot and up to 6 on the cold. If piping is correct (pitch and pipe diameters which they should be if original) I don't think most any radiator should need anything faster than a 6.

2 -

Quite honestly if it were me I would tend to start out with everything ~ #5 and bump down initially on the overly hot and up to 6 on the cold. If piping is correct (pitch and pipe diameters which they should be if original) I don't think most any radiator should need anything faster than a 6.

In my opinion, this is the way. You can't do it with math. And change just one vent at a time (with Maid O Mist you can just change out the orifice on top of the vent of course) then see how it feels.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Is this a mythical "Triple Header" system? Do I see a traditional header with a single riser….that goes into a bullhead-Tee header….which splits into two more bullhead-Tees that feed the two mains that are combined? Am I missing something?

Why couldn't they have split the two mains and fed each of them independently off of the new header?

Just a homeowner here so just trying to learn…not trying to sling anything at you 😊 I'm sure there were obvious reasons that I'm not experienced enough to notice.

1 -

Thanks @dabrakeman ! I wanted to provide as much info as I could.

So it seems like my main venting could stay as is, but I need to slow down of radiator vents? Does the imbalance between V1 and V2 matter much, or because its on the same shared main, its okay…especially with the venting capacity between Main #1 (V1 & V2) and Main #2 (V3) being pretty balanced?

Is there any sense of how much the converse flow main affects venting speed? Does the upward slop outpace the friction from the condensate flowing through the same pipe?

@AdmiralYoda the weird header situation is due in large part to wanting to avoid breaking apart the three mains from the large original header. We already were carrying a bunch of repipe work, including a bunch of condensate return not visible in the photos. I know this isn't the best excuse, but we needed to keep the job from getting too expensive.

0 -

@dabrakeman the slope on Main 1B seems to be fine, with 1/8" per foot. Could the position of the new vents at V2 and V3 affect anything? The original tappings are on the vertical of the return just past the end of the main, whereas V1 is at the end of the main just before the return.

V2

V1

0 -

I would certainly prefer to see that Gorton #1 (V3) vent raised higher up. Where it is I could see potential for condensate getting into it. Looks like there is plenty of head room. Regarding B&K the steam is obviously preferring that path and we can speculate on the reasons but with all you can and should do is slow those radiators down.

0 -

Fair enough! I'd be a little nervous about it too but I wonder if breaking those 3"-to-2" reducing Tee's (guessing on size) and re-piping it properly might actually have been cheaper. You might have used less elbows, Tee's, nipples etc just going straight from the new header to the two individual mains.

They did the right thing and used unions top and bottom of the new header(s) assembly so this still could be done relatively easily at some point. You could re-use the new fittings too.

Food for thought down the road…..maybe during an off season. In the end would it make your system work any better? Probably not but who knows? I'm a tinkerer so this would bug me. 😁

2 -

This may help slow down the main w the most rads on it . In my experiences mains w more rads on them similar to yours and main w 1 or 2 always lag due to have a slightly more restriction due to less radiator and vents . Since you have them switch out the no 1 and no 2 location and see if there's any improvement i would also raise the one vents height as suggested . The installer could have done a better job and removed that way original header and re pped new drops i'm sure i would have but it would have costed a premium . Hard to tell from the pic but should have done a 2 /12 riser to a 3 header but thats me and it would have cost more also . Strangely enough is that a plastic pad it sitting on or some thing i have not seen and i know weils are rated for installation on combustional flooring .

peace and good luck clammy

R.A. Calmbacher L.L.C. HVAC

NJ Master HVAC Lic.

Mahwah, NJ

Specializing in steam and hydronic heating0 -

@clammy good eyes. Yeah the equipment base is rated for relatively high het, but they still topped it with concrete pavers, refactory mortar, and a fireproof blanket. It was a field decision to accommodate the surprise the installers of the previous boiler left for them (a large hole in our floor slab with a cavity beneath. They filled the whole void with compacted stone.

Thanks everyone for your advice. I will plan on slowing everything down, and will continue skimming the boiler some more.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements