Magna3

Comments

-

Did you happen to see my mother in-law sneak by? It doesn't take much.

0 -

It's been year or two, but I thought there would be an error signal with a bad sensor? Screen turns red or has a red indicator? The newer ones could be different.

0 -

Haha! She gets hot 🔥 does she?

0 -

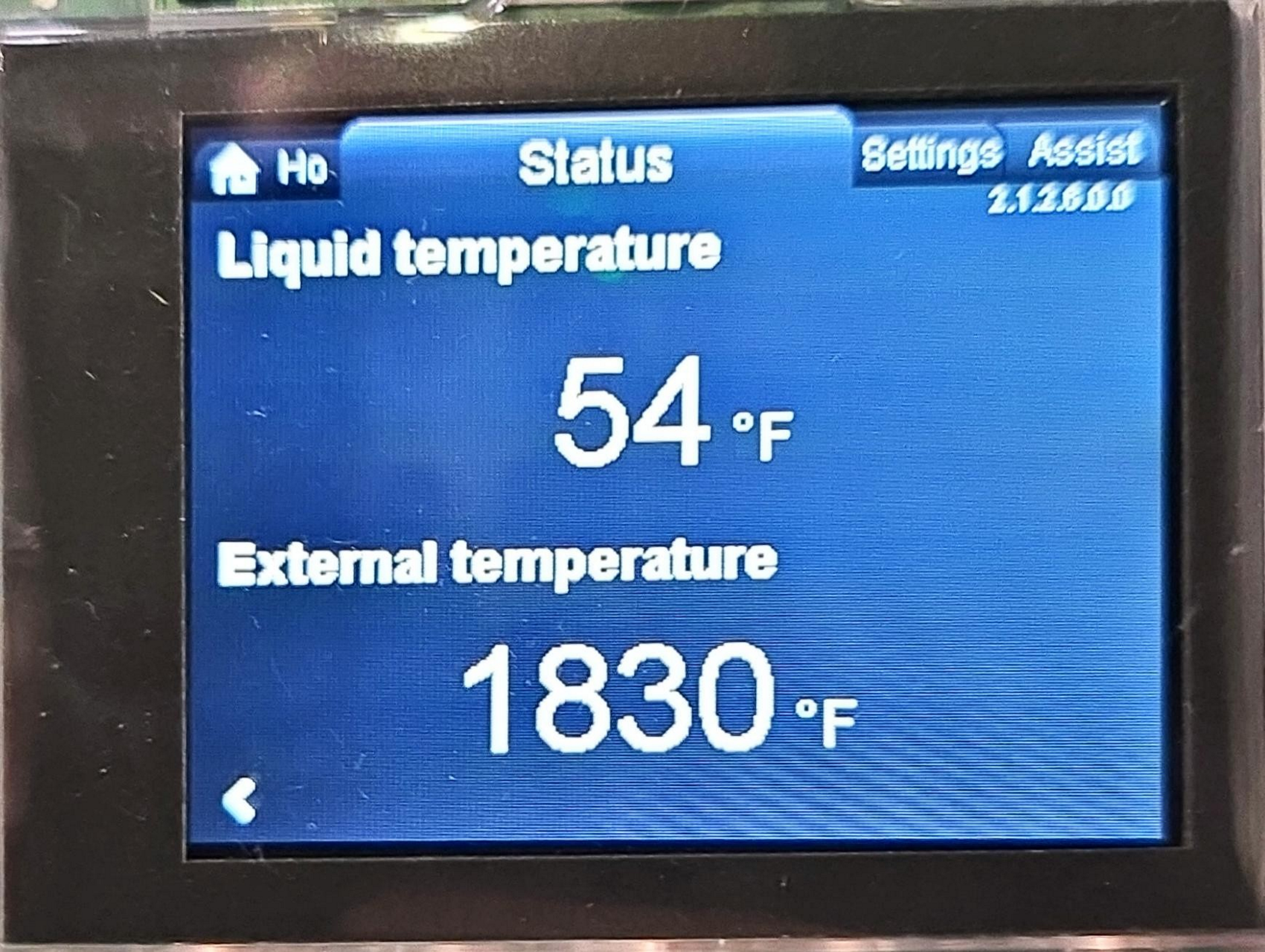

There was ne error signal. The pumps just went into limited speed. Minimum speed actually. This is a twin head pump on a geo ground loop. Must have been that way for a while. Long enough to burn out 2 10 ton compressors. I disabled external limiting till I can get them fixed.

0 -

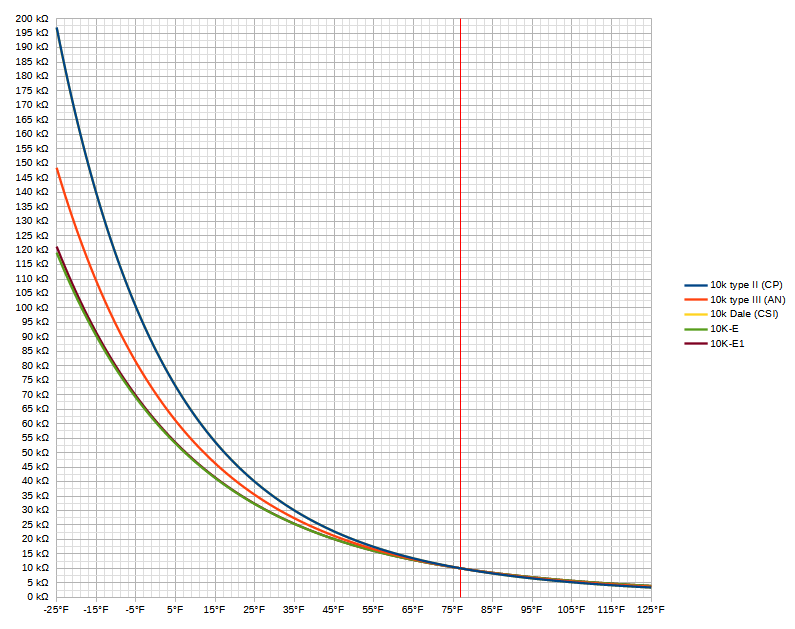

Could be the sensor, but if it is a common 10K thermistor the wires to the sensor may be shorted.

https://www.workaci.com/resources/calculators/thermistor-curves

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Good point. It is a 10k sensor.

0 -

Note that there are several common flavors of 10K thermistors. They'll read identically at 77°, of course, but the further they get from that the more they vary.

0 -

Good point. I've talked with sensor manufacturers and they suggest using the sensor replacement that the control can with. Not all sensors are the same profile.

On many of the Grundfos Magna pumps one sensor does flow and temperature or flow and pressure. These vortex shedding sensors are right in the pump body. An early Magna example in my shop.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@hot_rod is there any reason I would need to keep the sensor? The pump is controlled via 0-10v signal from a GEO Flow controller operating on the ground loop delta-t.

0 -

The manufacture put the sensor there for a reason. I would suspect some aspect of the operation is not working as efficiently as it should or could be.

As far as the the sensor type curve if you remove the short circuit I suspect the actual sensor may be fine.

I'd look for the wires being crushed somewhere.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

The sensor allows various modes of operation using the onboard control. I'm not sure that it performs any essential function outside of that... If it does not function as a critical safety, I would just as soon do without it in this scenario.

0 -

The Grundfos VFS Vortex Flow Sensor is mainly giving the control flow and temperature data to the pump readout. I agree the 0-10VDC operates the pump. I'll bet it runs fine without it.

We used the same Grundfos sensors in our Solar Pump Stations. The Resol controls would take the Grundfos VFS input

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements