Need help to find EDR per section for this rad

Hi, can somebody tell me what is the EDR per section

for that kind of radiator. It is wall mounted. It is 16 5/8" high and 3 1/4" wide. Looks like 2 tubes, but it is not open between the tubes. I don't know if it connects inside to become 1 bigger tube. I have several of these radiators that I plan to reuse. I have searched the internet, but couldn't find anything like this. Thanks in advance!

Comments

-

Are you going to connect them to a steam boiler? They appear to be connected to a Gravity Hot Water system that may have been upgraded to a forced hot water system with a boiler replacement some time ago. The reason I ask is that you only need EDR for sizing a steamer. If you are using them on a hot water boiler in approximately the same location as they used to be, then you need a load calculation for sizing the replacement boiler.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I see some lettering on the radiator around where the bleeder is- what does it say?

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

@Steamhead Must be a chunk of paint, I don't see any lettering around the bleeder, but there's a "1" at the other end of the section. Other sections are numbered "2", others are numbered "3"

0 -

-

@EdTheHeaterMan No, I'm not going to connect them to a stem boiler. A forced hot water system will be used. I am living in an old school, and I am renovating everything. The big cast iron boiler that was there, was removed years ago. There were a couple or circulators in the system and the water was moving trough 3" steel pipes. The system worked fine when I bought the place 20 years ago. Then, the boiler broke and I stopped everything. All radiators were disconnected. I have several other rads. Some are 4 tubes, 32" high and some are 4 tubes 26" high. For these, I've found the EDR. The 32" are going to be reused in my woodworking shop and some 26" are to be reused in the basement mudroom along with some wall type rads like the one in the pics. Another part of the building will be radiant floor. I have 4 - 54 sections radiators in the basement that are made from the same sections you see in the post. I need the EDR for these so I can decide to where to use them.

1 -

@EBEBRATT-Ed the sections are 16 5/8" high and 3 1/4" wide. I need the EDR per section since the rads will probably be shorten.

0 -

I don't own the book, but Dan Holohan published a book called Every Darn Radiator (EDR) . I'm not sure if that one is in there, however maybe someone with that book can look for it. There are some standard or common radiator charts that have some EDR that you can interpellate a close approximation from those charts.

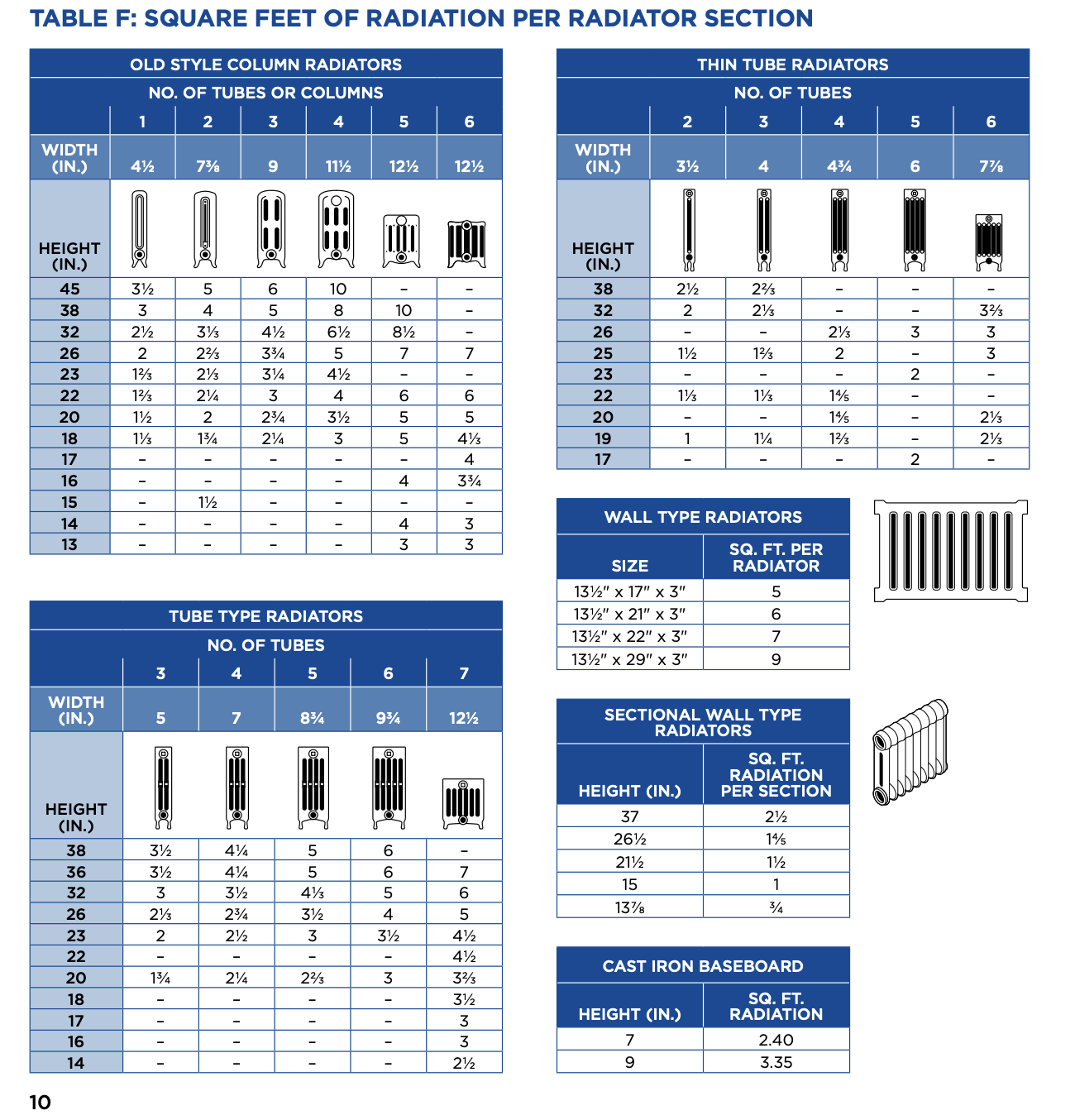

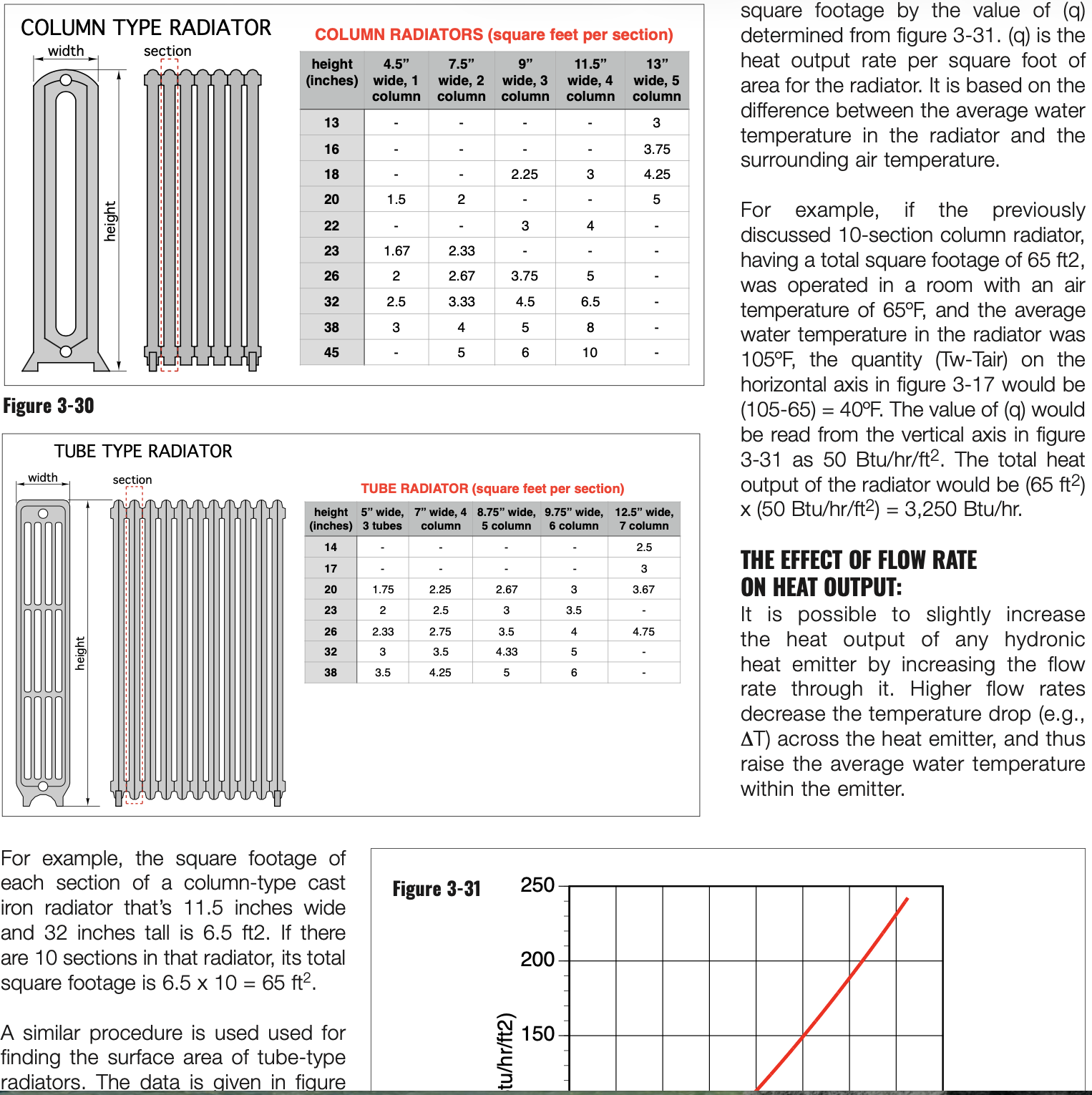

For example Weil McLain has a sizing guide that shows column small tube and large tube radiators. The one column radiator indicated a dimension of 4 ½” by 18” tall having 1.333 EDR compared to your 3-¼ by 16-⅝” single column section. That radiator is clearly larger than yours.

They also show a thin tube two column radiator that is closer to yours at 3-½” x 19” at 1 EDR which is about the same width but taller than your example. and may have more surface area, since there is two tubes while you have one column. Then there is a wall radiator that is 15” tall but it does not indicate the width dimension, that has a 1 EDR rating. That is close to your example. So I might suggest that your radiator section is between 0.75 and 1.0 EDR.

If you were going to chop up your sections in hopes of getting a working radiator of 10 sections, then I would take a “WAG” at about 8.5 EDR. If you were going to have more than 50 sections in one room, then I would like to be a little more accurate. But if you are using 10 sections or less for any particular room, then the 0.85 per section is what I would use. Remember this calculation is not Rocket Surgery. You want to get close and adding a section or two to a room may not be such a bad thing. Get close and let the other adjustments like TRVs or ODR do the fine tuning.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

@EdTheHeaterMan thank you very much! That is great help. I think the sectional wall type 15" tall will do just great. I will take your suggestion 0.85 EDR/section and I plan to use TRVs. So like you say, if there's a section or 2 extra, that would not hurt anything. I have another question for you: I calculated my woodworking shop heat loss at 39952 Btuh (yes, it's huge!). I already have 4 - 32" tall 4 tubes radiators for 109 sections in total in there. I calculated 3.5 EDR @180 average temperature that equals to 170Btuh/sq. ft. that gives me 595 Btuh per section X 109 sections= 64855 Btuh. Or I can go down to 150 average temperature that gives 385 Btuh/section for a total of 41 965 Btuh, that is closer to what I need. Should I lower the water temperature in order to keep all the radiators in that room? With a TRV on each radiator will there be some problems if I the temperature is higher or can I go lower temperature= more radiators (I have plenty of those!) Am I hard to follow?

0 -

I'm pickin' up what you're laying down @Mariobee!

The lower you can operate the boiler the lower your operating cost will be. Consider that every pound of water takes one BTU to get it one degree hotter. If you can operate at 150° then you are saving 30 BTUs for every pound of water being heated. Not just the total volume of water in the system but the recirculating water that is heated over and over again. And that is measured in gallons per minute, so that is a big number, since there are over 8 pounds of water per gallon and 60 minutes in an hour. (30 x 8.3 x 60)

Now the heat loss depends on the outdoor temperature as you may already know. So if you can use an outdoor reset control (either built into the boiler or as an additional control) then you can use even lower temperature water when it is higher like 50° outside, and 150° when it is near your winter colder design temperature

Now If you connect these radiators to a cast iron boiler, you will need to have boiler protection to maintain a 135° minimum return water temperature within the first 10 minutes of burner operation. If the boiler sees 110° or 120° return water temperature for the entire operating cycle, then the flue gas can condense on the cast iron metal surfaces inside the boiler flue passages. The flue gas contains carbonic acid and sulfuric acid in trace amounts that get taken away up the chimney under normal operation. If there is water condensing on the metal then those acidic byproducts of combustion can accumulate in the water and when the water evaporates away, the acids are still there and become concentrated, and eat away as the cast iron boiler.

So 135° is the return water temperature you need to get to within the first few minutes of burner operation on cast iron boilers. If however, you are using a condensing boiler then you want the lower temperature return water in order to achieve the highest operating efficiency, Either way the lower you can maintain the radiator temperature the lower your operating cost will be. But you must maintain a temperature high enough for the other parts of the house to get enough heat. If you have a section or zone of radiators that must be 180° to heat properly then the system must be able to achieve that 180° temperature. Then the rest of the building can use the TRVs to compensate.

Hope this is helpful.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

@EdTheHeaterMan yes! This is very helpful, thank you! I don't think there will be other part of the house/school that need 180 degree water, I've got enough extra radiators to fill all the rooms and run the boiler at low temp. I live in Québec, about 45 minutes south of Québec city and about 90 minutes from the US border in northern Maine. My DTD is 84 for an indoor/outdoor design temp 70/-14. We don't have a "gas culture" here, the electricity is cheaper than oil, propane or natural gas, so I'm looking to go with electric boilers like an Hydra that heat water on demand. It is clean and I think, 100% efficient. I say boilers in plural, because I am well over 100 000 Btuh to heat the "beast". I think it's possible to use multi boilers. Do electric boilers have the same issues with low return water temperature, like corrosion or other "diseases"? BTW, I have installed a 320 amp service. Here's a photo of the school. As you can see, there are a lot of large windows! There are the same on the back.

0 -

Great looking building!

You may find some useful info here for operating systems atb lower temperatures.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

That looks like a nice project. A real good place to learn about this heating system. (pun intended)

Low temperatures on cast iron boilers have problems with flue gas condensation. If you are using an electric boiler, there is no flue gas to worry about. I believe you can run them as low of a temperature as you want. You will want to explore outdoor reset especially with multiple boilers. Tekmar has a nice control that will stage your boilers on in sequence as the outdoor temperature drops. The colder it is outside the warmer the water temperature in the radiators need to be.

For example:

- You can operate one boiler to make a the radiators have 110° water when the outdoor temperature is say 50°

- When the outdoor temperature reached down to 40° you may need the second boiler intermittently to get the water temperature up to 120°

- By the time the temperature reaches down to 30° you may need both boilers operating at 100% to get 135° to all the radiators

- When the temperature drops lower then the third boiler may be needed to get the water to the radiators up to the 150°

- And so on…

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Thermo 2000 a Quebec company builds nice electric boilers. The elements and temperature modulate based on outdoor temperature.

The alt has a tank for dhw so you could charge the tank off peak, if you have those rates.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@EdTheHeaterMan thanks! May need some more advice as I go along with the project!

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements