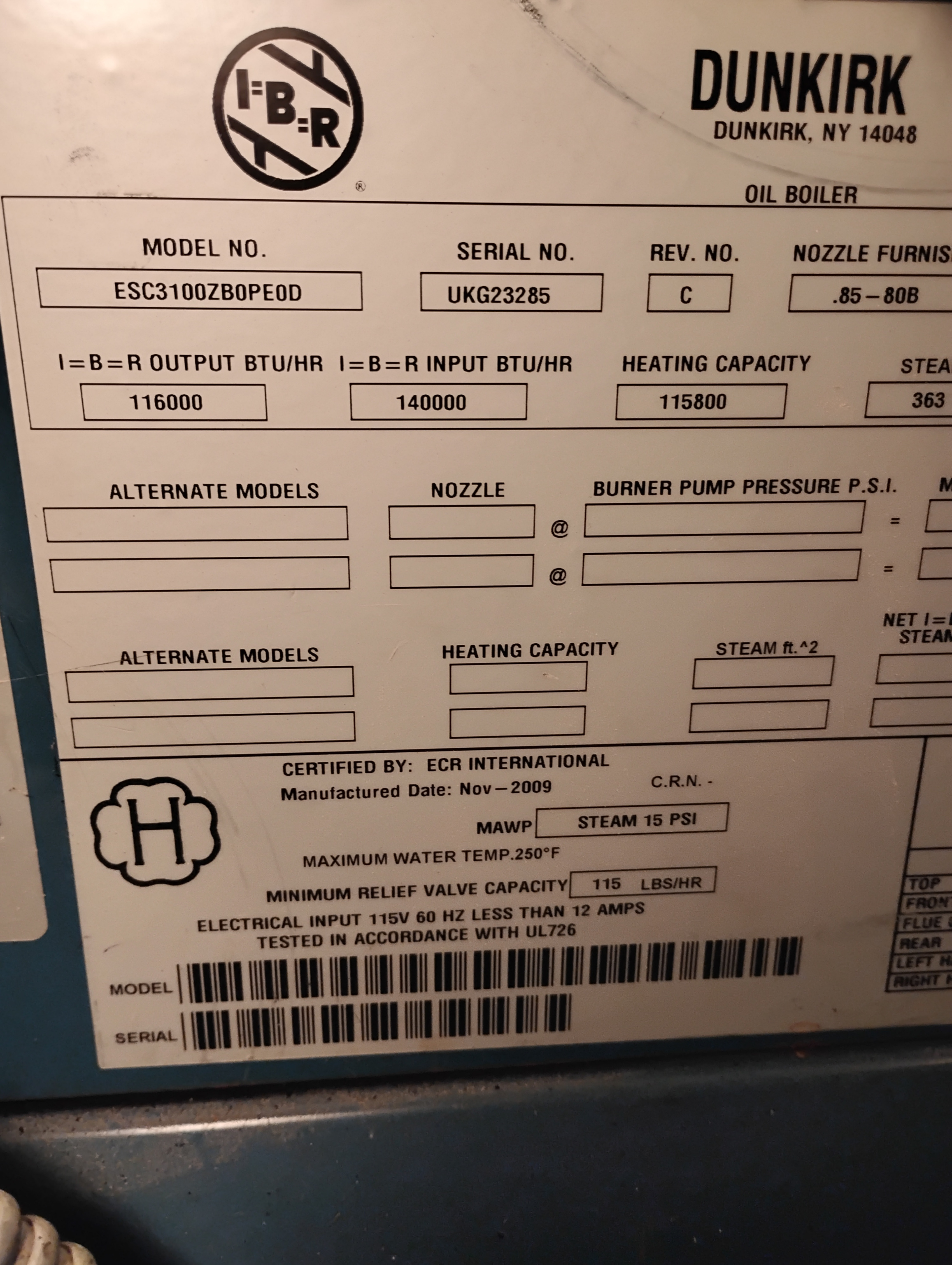

Multiple Steam Issues - Dunkirk Oil-Fired Steam Boiler

I'm on my second Dunkirk. First one installed in 2010 and failed after 9 years. Had issues with first installer so when heat exchanger was replaced under warranty, I went with a different installer. Second Dunkirk will be 7 years old in April. No warrenty.

I get Heap which opens in Nov. and they offer a "clean 'n tune". The last two heating seasons, it has been Feb. before I get it serviced. Last season (2024/2025), it was blowing a lot of black soot over the top of cover. When installer arrived for service, he said that was normal and no big deal. After service it did not blow soot again until the end of season then it started again. When he services, he changes the "wooly" filter, nozzle, checks combustion at burner and pipe—then he's done. Every couple of years he pulls the probe and pigtail. Last year he pulled probe and pigtail. Probe was dirty black when he pulled it out and he just put it back in without cleaning it. Pigtail, he swished water through it and put back in. So I'm still blowing soot this fall/winter. It also started calling for a lot of water this fall. Every time it runs through and completes a cycle, it calls for water. I had my oil tank filled and went through a half tank in two weeks. I always walk around and check rads and valves. I noticed two rads were cold after a cycle. I have extra vents so I replaced them. The next time, those two rads were hot and two different rads were cold. I pulled a cold rad vent and shook it and it was full of water.

I pulled my probe and it was encased so I soaked it all day in vinegar/water solution and scrubbed a little with a toothbrush to get it clean. Re installed and it doesn't call for water as much but still calls everyday.

I bought a new probe but have not installed it yet because I'm not sure if it is the problem or part of the problem. If there is something else going on here I could still return and get my $89 back.

After cleaning— I was afraid to scrub the white insulator part.

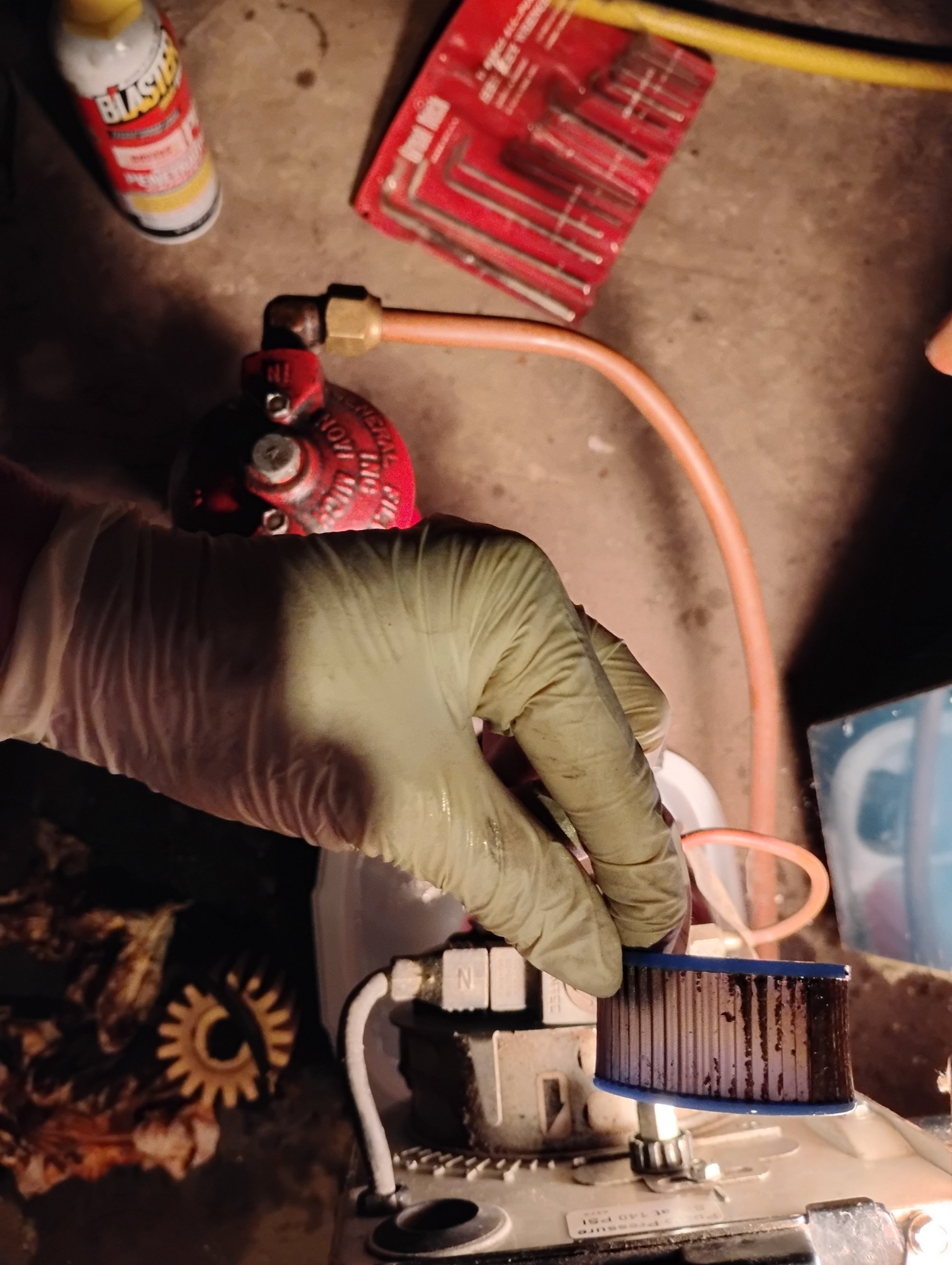

I bought a new "wooly" and nozzle and checked electrodes.

Installer put the white filter in the last time (Feb 2025) and I didn't like it. You can see chunks of it in the cup. I replaced with "wooly". Had to scrub the inside of cup with a toothbrush to get all this crap out. Oil tubes to nozzle were partially plugged. Had to spray a couple of times with PB Blaster to clear.

And lastly, I pulled the screen filter by pressure pump. Cleaned and put back in. This has never been checked by installer.

So I replaced "wooly", nozzle, cleaned screen and probe. Yesterday I went down to the freezer and it cycled off and I heard a dripping noise. Got down on hands and knees and looked all around the bottom and didn't see anything. It does not smell "steamy" and I see no whiffs of steam. No moisture on floor. I'm still going to pull the pigtail and sight glass to check them since I did everything else. Installer has pulled sight glass before but only cleans the glass—does not flush it with a bucket underneath. I can't check combustion because I don't have an analyzer and I would have to learn how to use it—though I get the idea after watching the installer use his.

I feel like I'm not getting good dry steam and that it is pushing water, maybe because I wasn't getting a good flame? Should I pull the top cover and brush the nipples and clean the chamber since it has never been done? That would allow me to check for wetness in the chamber since I heard a dripping noise. I have the boiler cleaning brush needed for this. Do you think the probe is part of the problem? Keep in mind, all components date from 2010 when I got my first Dunkirk. Only heat exchanger was replaced.

The whole shebang.

Not as much soot as before. But still . . . I run my finger through it. My black pipe was replaced with all copper when the first Dunkirk was installed. I argued against it and lost.

The copper pipe at the top of Hartford Loop has leaked since day one (2010). Slow drip . . but still. I argued with that installer that it needed to be fixed/resoldered. After all, it is a closed system. Their "steam expert" said it wasn't going to hurt anything.

I blow down every Sunday morning from the two ball valves above. But since it calls for water every time it cycles, the water at blow down is crystal clear—so I have not been doing it.

Lucky for me, I also supplement with a coal stove in the kitchen for when the temps drop to make it easier on my oil consumption. I've been trying to wean myself off coal since I'm now 63. So far, I have been buying more coal than usual to take the load off the boiler and it's problems. Some specs . . .

I'm using .75-80A for nozzle. That is what was in it. According to the book, it is within it's limits and uses less oil than what is on sticker. I also figured combustion was setup for that size.

Please Help!

—Oil-Fired Steam Boiler, One Pipe System with 8 Rads—living in Western NY.

Comments

-

Well, to start, if it's making soot — any soot — the combustion is out of adjustment. Now you don't need a steam familiar person to adjust the combustion — an oil burner is an oil burner. Does your fuel oil supplier have a service department? Might try them (if that isn't where you were already…).

So that's where I'd start.

But that much crud in the filter also makes me wonder about the quality of your fuel oil. Shouldn't do that.

Now it shouldn't use much water. However, you do have known leaks so that maybe where the problem is. Copper, installed that way, is very likely to leak.

What is the pressure setting of the pressuretrol? A picture, please, if you are not sure.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

Your two problems are soot which a modern boiler/burner should not make. Dunkirk make a pretty good boiler but they didn't install it right.

2d problem is excessive water MU. If you are adding water you have a leak. Hopefully not the boiler as it is only 6 years old.

You can lose a lot of water without seeing much. Packings around valves and air vents.

Excess MU water will make a boiler fail early.

0 -

And that oil filter canister shows evidence of water getting into the oil tank. Need to find that problem too, and fix it.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting3 -

if it is a probe type lwco it doesn't require periodic blowdown.

if the boiler install is that knuckleheaded i would be surprised if all the vents and valves were verified to be leak free.

0 -

Soot = bad combustion.

Your nozzle looks very dirty - just replace it as it's a cheap part that should be changed with boiler maintenance.

Changing nozzle for a different type, you need to adjust air ratio. Your oil burner has two air adjustments: band and plate near the burner on the left side. Your burner manufacturer has specs for each nozzle set-up.

On my steam boiler, inept maintenance person changed the nozzle for the one used for hot water without adjusting air ratio - this produced VERY sooty boiler.

I'm afraid if you lift the top plate you will discover a very corroded boiler…

»»» See my steam heat YouTube videos:

https://www.youtube.com/@HeatingBlog1 -

Installer does not wipe out the cup to get it super clean like I do. After a new boiler install my auto feed typically adds water about once a week. So that is a good baseline. I didn't want the copper. I argued against it because I knew it was bad in the long run . . . but I was overruled—they are the "experts". I had black pipe prior. My pressure is suppose to be at 1.5 psi. Difficult to gauge on the printing on Pressuretrol.

0 -

I realize I have two problems—soot and water. I'm really more concerned with the water problem. I KNOW that excessive MU water is the slow death of a boiler.

When you say "it is not installed right" do you mean the copper piping? The copper at the top of the HL has leaked since the first Dunkirk in 2010. You never see water on the floor but, you can run you fingers around the copper at that seam and it is wet. It probably evaporates from the heat of condensate returning. First installer that put in the copper refused to resolder it. "They all turn green". Second installer refused to resolder when they replaced the heat exchanger. "That's not a big deal" . Well it is a big deal in a closed system!!

None of my valves leaked but I repacked all valves about 15 years ago for good preventative maintenance. None leak now either. All steam vents were old and I never saw Dad replace any of them. I bought all new vents at the same time as the repacking. Bought the Hoffman 1A I believe. Used plumbing tape on each on install. I kept all old vents and put them in the Hoffman boxes and labeled each box with what room it came from. All valves and vents are good.

I believe I will have to live with the copper leaking until the next boiler replacement because nobody will touch it. Also, when this install was new and copper was leaking at the HL, it still only called for water about once a week.

The Dunkirk Owners Manual says to blow down once a month. Both installer's have said to blow down once a week to keep ahead of sludge. I draw off about 2 cups worth from each of 2 valves into my bucket. It is always brown "chocolate water". When I asked how much I should draw off at each blow down, both installer would not answer and just scrug their shoulders. So I am for 2 cups each.

I have well water that is a little hard. BUT, this house had all new galvanized pipe put in for plumbing kitch/bath and dairy barn in the early 50's. It is now only starting to fail around some of the joints in the house. I have bought pex & fittings to replumb my house—just haven't done it yet. Original boiler was dated 1899 on the door. All steam piping dates from that time and none of it leaks. So I guess it is not my water quality as the installers try to imply.

I've had two subpar installers. I don't know how to find someone that truly knows what they are doing. I live 1 hour from Rochester. There are a lot of big old mansions in Rochester and some have to be steam. I don't know how to find out who the "go to steam" people are in Rochester. Don't tell me to use your contractor finder because it only lists people in NYC area/Connecticut.

I need to zero in on the water problem. Tomorrow night will be colder and I can switch back to coal and power down boiler. I need to know if the boiler is leaking or the probe malfunctioning. I can fill the boiler to the risers and let it sit and monitor it. But how do I test if the probe is the probem?

0 -

I didn't know if the soot was an adjustment problem or a dirty oil problem. Could the adjustment be good and soot is from dirty oil? The two oil tubes leading to the nozzle were partially plugged and I blew them out with PB Blaster.

0 -

Every time I get an oil delivery, I have to run out and check my filler cap. I have found it tittering on the top and not screwed on and I have found it laying in the snow. REALLY!! I turn it on so it is tight, then back it off a 1/4 turn. That way I can gauge if somebody messes with it. Trust but Verify!!

0 -

-

Well, poor quality oil isn't helping the combustion settings — and therefore the soot — at all. Whether it is the rot cause or not, is another question — but if the oil quality is poor and the nozzle is getting a little wonky, or there are bursts of water or sludge, or whatever, the combustion is going to suffer.

So you really need to do both. Use only good quality oil from a reliable dealer. Replace the filters and make sure the new one or ones are clean. Clear all the oil lines (one hopes the tank isn't too badly sludged up…) New nozzle. Pump set at correct pressure. Correct nozzle type. Someone who had and knows how to use combustion test equipment to set the air properly.

Not one bit of that is steam specific. As I said, an oil burner is an oil burner. Surely there is some quality oil dealer in the Rochester area who has at least one competent tech.

Be nice if they could clean the boiler at the same time, but at least get the burner set right.

Now the piping and the leaks and all that.

First, if you have a probe type low water cutoff there is no need to blow the boiler down except maybe once per season. Maybe not even that. So stop. There will be some initial accumulation of sludge from the initial water fill, but so long as additional water is not added, no or very little additional sludge will turn up.

Losing a gallon of water a week is a bit much, perhaps, but not catastrophic. Worse, it can be hard to pin down losses of that magnitude. One single drip every ten seconds or so will be that much water! And drips have this way of evaporating on steam pipes…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

Soot = bad oil/air mixture. Period.

Bad oil can cause soot because by delivering oil + dirt, you offset the oil/air mixture (by clogging the nozzle).

»»» See my steam heat YouTube videos:

https://www.youtube.com/@HeatingBlog1 -

the copper can pull the sections of the boiler apart and make it leak because the copper expands more than iron and there are no threaded joints to twist a little.

softened water will kill a boiler too.

0 -

-

As I asked before,

I need to zero in on the water problem. Tomorrow night will be colder and I can switch back to coal and power down boiler. I need to know if the boiler is leaking or the probe malfunctioning. I can fill the boiler to the risers and let it sit and monitor it. But how do I test if the probe is the problem?

0 -

Geez, I don't want to hear that. There is nothing I can do about that now anyways . . . .

0 -

Oil around here is sourced from Rochester. Now how individual oil suppliers then store and care for the oil before delivery is another matter. Two years ago when having my boiler serviced, he opened the cup and the filter was quite red. Installer said that was from water and suggested I talk to my delivery man. I mentioned it to him and he said he would test their underground tank. The next we spoke, he said their oil tested fine.

So what do I do with that? It could be the big Rochester supplier problem or individual company. How do you think I'm going to find good oil? They all would say their oil is the best. My delivery used to come from a small operation 1/2 hour away that was bought out about two or three years ago by Miribito (sp?) located in Binghamton. They are using the same tanks and trucks from the small operation.

If I have sludge in the tank, there is nothing I can do about it now. That is a warm weather project. I replaced my wooly filter and nozzle on Dec. 6 so it has been a month. I will pull the wooly and check it again and replace it if needed. I could replace it monthly to get me through the heating season just to head the sludge off at the pass. Right? So, how do I get good oil? Everybody is going to say their oil is the best when it comes from the same source.

0 -

How many of you all have steam heat and do you service it yourself?

0 -

" I live 1 hour from Rochester. "

Have you tried Isaac ? They seen to have a huge coverage area. I have no idea if they are any good or not, their web page claims they do boilers.

You seem pretty handy, I'd repair the Hartford loop leak myself, plenty of videos on YouTube on how to sweat copper pipes.

" I need to know if the boiler is leaking or the probe malfunctioning. "

These are two very independent issues, which requires different tests.

Over filling the boiler would test if the boiler's heat exchanger has rotted out above the water line.

Draining it below the probe level should cause the LWCO to trigger the water feeder to fill it up to at least to the probe's level.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Based on the photos, you seem more handy than most home owners.

Based on the photos of your rusty chimney vent, i'm almost certain you have a hole in your boiler. The excessive water make-up indicates that. That said, it's not as bad as one thinks. Each gallon lost is costing you only $1 for the extra oil it takes to heat it up to atmosphere (where it's going through the hole). Of course that means $$ to replace it in the summer, but you should be OK through the winter.

Some water in radiator vents is normal (it condenses and often has no way out).»»» See my steam heat YouTube videos:

https://www.youtube.com/@HeatingBlog1 -

At the 3 week mark, I pulled the cup to check and there was some sludge in bottom of cup. Cleaned and replaced filter. So I ran out of oil on Thurs. I found out last night they would deliver today (Sat.). Went down early this morning and took the plug off the top of tank. Extended a camera down in there that has LED's on it and took a couple of pictures. Wasn't sure what I was looking at but looked like it could be sludge near the fitting. I have two fittings on bottom of tank. I opened up the drain valve and dumped in a quart of hot water at the top. I got a quart of black water in my bucket. So I kept repeating this and got a lot of black water with sediment. Sometimes I got a steady stream, then surge and spit. So I know there is sludge floating around in there. Decided I would use my small ShopVac to reach in and vacuum most of it. Before I got that far, I heard the deliver truck pull up. I could have stopped him but it can take up to seven days to get him back and we are in for a big storm. He gave me 220 Gal. He arrived at 10:30 a.m. I have not fired yet. I'm worried I may have loosened too much stuff with the hot water. Is there any advantage to letting the new oil settle or blend with the sludge? Should I dump in "Diesel 411" in the tank?

0 -

I've sweat before. Don't like it, not good at it. But have done small repairs like at my sink. I would not touch the copper return line. If it was that easy, the installer could have re-sweat it, in say, 20 min.? He would use MAP. I use the blue can. And I think, this is an off-season repair in case things go South.

I think the installers in Rochester all say they do boilers. But who is experienced in steam? That's the big question. I have browsed their websites and still comparing. I pulled my cup after 3 weeks and had some more crud.

0 -

I would NOT have put water in the tank. If you wanted to dissolve the sludge, you should add something that will mix with the oil.

If you have a filter at the tank, remove the filter housing and open the valve to drain out a gallon or so of oil until the oil is red and clear. It wouldn't hurt to add an additive that absorbs water, but I'd mix the additive with a couple of gallons of diesel before adding it to the full tank.

1 -

As @MaxMercy says! Open the drain (have a big transparent container handy) and drain oil until it is completely red and clear in colouor when standing for a few minutes. Even a small trace of water or sludge will make it very difficult if not impossible to get your boiler going again.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

I did a global search and came up with hot water to soften and loosen. That makes sense. I don't have a filter at the tank, just at the front of boiler. Before I started messing around, I turned off valve that feeds boiler. I have a second valve that I opened with a pail underneath. I have Diesel 411 and I have diesel fuel in the shop so I could do that.

0 -

I added an entire bottle of 411 in diesel can and added 2 1/2 gallons of diesel. Gave it a little shake and dumped into my fuel tank.

0 -

I have added a bottle of 411 to the tank. I also brought in my air gun handle because flow comes and goes. When it stops I can give it a burst of air to clear debris away so it can flow. How does that sound?

0 -

Go back to what I said. Drain fuel from the tank into a clear container and let it settle. Keep doing that until there is no water or sludge layer visible (the water layer will be at the bottom with fuel on top; the dividing line may not be all that obvious).

If you are getting inconsistent flow — suggesting sludge blockage — keep going until it is good and even and smooth.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

I've been to Tombstone, I've seen the wild wild west—😎.

0 -

The copper isnt the end of the world, its not great, but the threads will move and leak before the cast rots. The leak at the Hartford needs to be fixed. You dont need a steam man to do it. Any plumber can as long as you know the specs. Keep the tee at the right height and the street 90 going in. The rest is coupling work. Just find a licensed plumber over the age of 40 and they should be able to sweat a few joints.

2 -

I drained out about 15 gal. of fuel oil before it stopped being chunky and was clearer. It also began foaming a lot in the bucket. I knew foaming was a good sign. So I cleaned and changed my wooly filter. Pulled the little round screen in the fuel pump and that had chunks in it. Cleaned and wiped and put back in. Pulled the nozzle and tube—cleaned put back in. I was afraid to drain the copper line from tank to wooly cup. I don't like cranking on those fittings. I fired the boiler and sat with it. After a few minutes, I noticed fuel oil dripping out from under the burner and risers were not getting warm. Then boiler started smoking and I powered off. I visually checked all connections that I had messed with and there was no fresh fuel oil around them. I contacted HEAP and they will pay for repair/replacement and they give you a list of vendors to contact. I have to get 2 proposals for the fix and HEAP picks the vendor to use. The list is 43 vendors that cover my county. I have called about half on the list and can't get anyone to come. They either don't do oil, or I'm out of their service area (even though they are on my county list), or they don't return my call, or their mailbox is full and can't leave a message. So I'm still trying to call people and I've lost another week without heat. So, is there anything obvious I could check? Could the chunky oil that was running through it have damaged the fuel pump? Should I make a new gasket for the oil pump as mine did look fragile. I could not see real good down there but did run my finger along the seam and did not get any fresh oil on my finger. I have a roll of gasket for work on tractors. ???

0 -

I am speaking as a fellow New York coal burner for all my heat and hot water here; I would keep calling to find a HEAP certified contractor that has a steam licensed plumber as you have been short changed here.

The New York State plumbing code allows copper to be used for steam-YUUUUCKKKKK.

If it were me I would buy enough black iron pipe and fittings to have on hand when you replace the boiler and save the receipts to return the unused black iron pipe.

The ceramic insulator is damaged and cracked by the looks of it in your picture. I would replace it and only blow down the boiler once a year as Brother Jamie has said.

What really concerns me is the flue pipe condition and the barometric damper on your steamer, there is no adjustable weight scale on it and the handle is gone and the seams on the joints are very rusted and you should have no soot coming from your flue gasses.

Do you have a hand fed coal fired steamer or a stoker?

Oil fuel is a real pest especially when it gets water in it.

When I used oil heat I got so fed up with the water and crud issues I invested in a RACOR 500FG fuel filter.

I quit using oil only because Suburban let me run out of fuel multiple times; one excuse was "my driver is on vacation and I would have to call him back to work"; their drivers were required to keep track of their automatic delivery customers.

The RACOR 500FG fuel filter uses a stationary turbine to spin the dirt and water out of the fuel as it enters the fuel filter. The dirt and water flow against the clear poly carbonate bowl and settle to the bottom and the manual drain valve allows you to drain of the water and the dirt without having to bleed the system of air as long as it is pulling fuel.

The 10 micron fuel filter cartridge for the 500FG fuel filter will filter 10,000 gallons of fuel before it requires changing.

For what it is worth there are 2 brands of coal fired steamers here in the east that have oil burners for a backup heating method.

The EFM DF520 is an underfed burn pot/tuyere fired coal stoker which uses Rice Anthracite Coal for fuel. The EFM DF520 has an 8 inch flue breech. The auger feeding the burn pot is standard equipment. The EFM DF 520 is certified for steam heating.

The Alternate Heating Systems S260 is a rolling fire grate coal stoker that uses Pea and buckwheat Anthracite Coal. The S260 can be certified for steam heating paying an extra charge.

The S260 requires you to fill the hopper manually or it can be equipped with an auger for an extra cost.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements