Back to heating....

Hello all,

As a plumbing contractor from New England who has been doing business in San Diego for the last 13 years - now recently moved back to the east coast and thought i'd get some input on my new heating system from the heating community…

I am converting from oil to propane. Tank is buried, gas piping complete, signed off and ready to convert to my new system as my oil tank is quickly running towards "empty".

I am installing a Rinnai IP120S to run 3 zones of baseboard heat, and a 50 gallon indirect. Rinnai sized the boiler for me, and I think they are spot on with the IP120S.

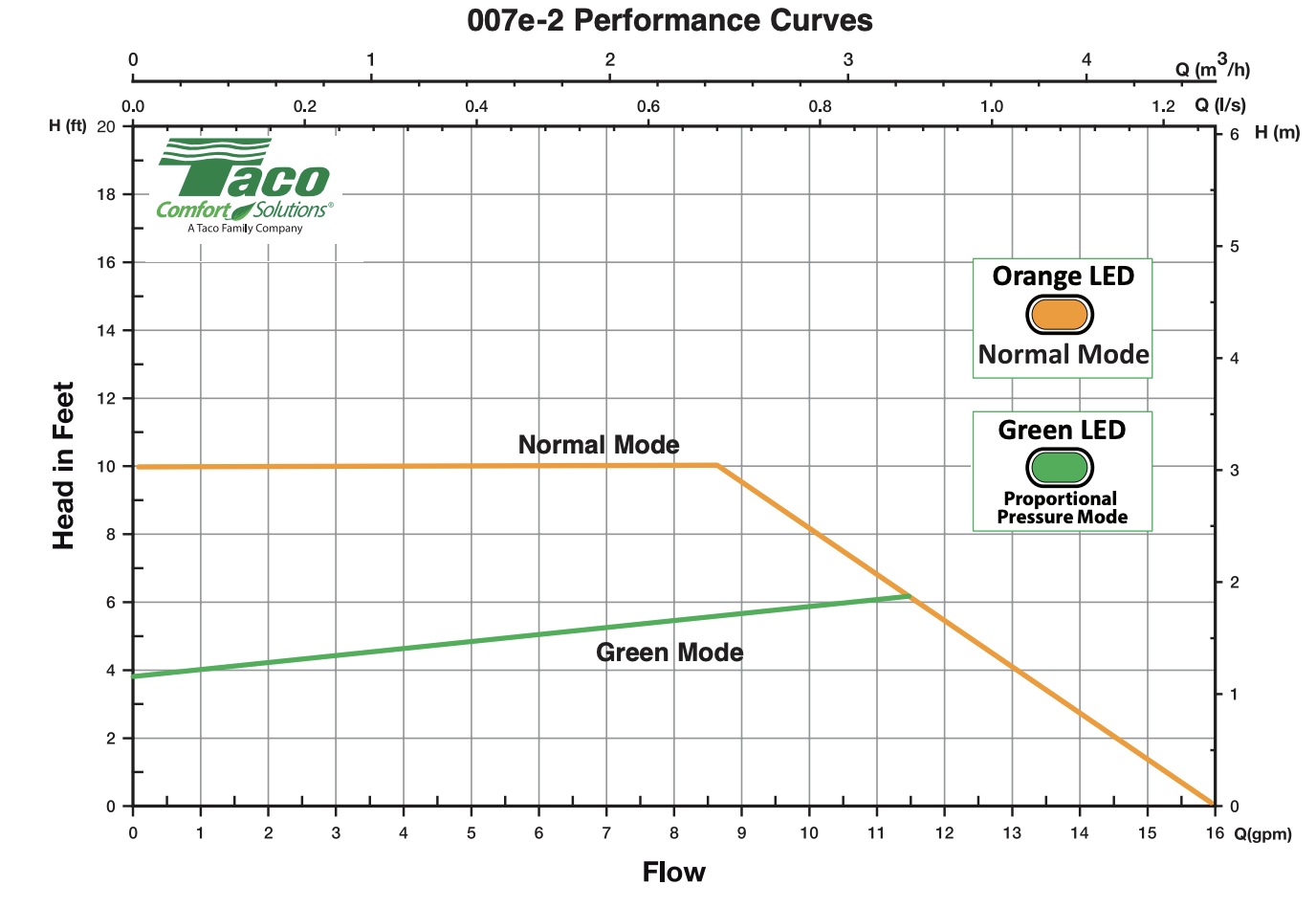

I am trying to decide if I should go with one Taco Delta-t circulator running 3 Taco sentry zone valves for the 3 zones of heat, VS. 007e circulators for each individual zone. I know redundancy is ideal, but I really like the idea of the Delta-t circulator adding even more efficiency to the modulating boiler. With the Delta-t circulator, the pump will drop the GPM through the baseboard for optimal heat output. One concern that I have is that with 007e being single speed, I could be looking at up to 16 GPM though the baseboards and that seems like very high velocity in my opinion, running the return water back very hot, and losing efficiency even with modulation (but maybe im overthinking it?) This is a 2,500 sq. ft. home, and the zones are not that large - the longest heat loop is 65'. I would most likely be using a 007e for the boiler pump, and a 007e for the indirect hot water heater to match the flow of the boiler pump.

Open to ideas, suggestions, critiques and advise!

Thanks in advance.

Comments

-

-

Hi Hot Rod,

Yes, 100% I will be using the outdoor reset. I guess maybe the Delta T circulator might be redundant or fight with the modulation of the boiler as the outdoor reset is trying to tell the boiler what to do?

I honestly prefer a system with dedicated circulators per-zone, regardless of cost. The Rinai has built in controls for up to 4 circulator zones which simplifies things for me and eliminates the the need for a Taco relay controller if i choose to go with zone valves. Again…my concern with running dedicated circulators per-zone might be over pumping. Do you know if the 007e circs have sensors that adjust target ideal flow? Maybe i'll jump on the phone with tech over at Taco directly.

I appreciate your feedback!

0 -

the Delta-T pump will adjust flow based on Delta T and if you're using outdoor reset it will adjust water temperature to satisfy load based on temp swings. the 007e will adjust flow based on system pressure drop and you will be fine with pump per zone which has been done for many years. it's always been the conundrum 1 pump with zone valves or single pump per zone. It's really a design preference.

for additional support, you can reach out to Taco 401-942-8000 and ask for tech support

Joe Mattiello

N. E. Regional Manger, Commercial Products

Taco Comfort Solutions0 -

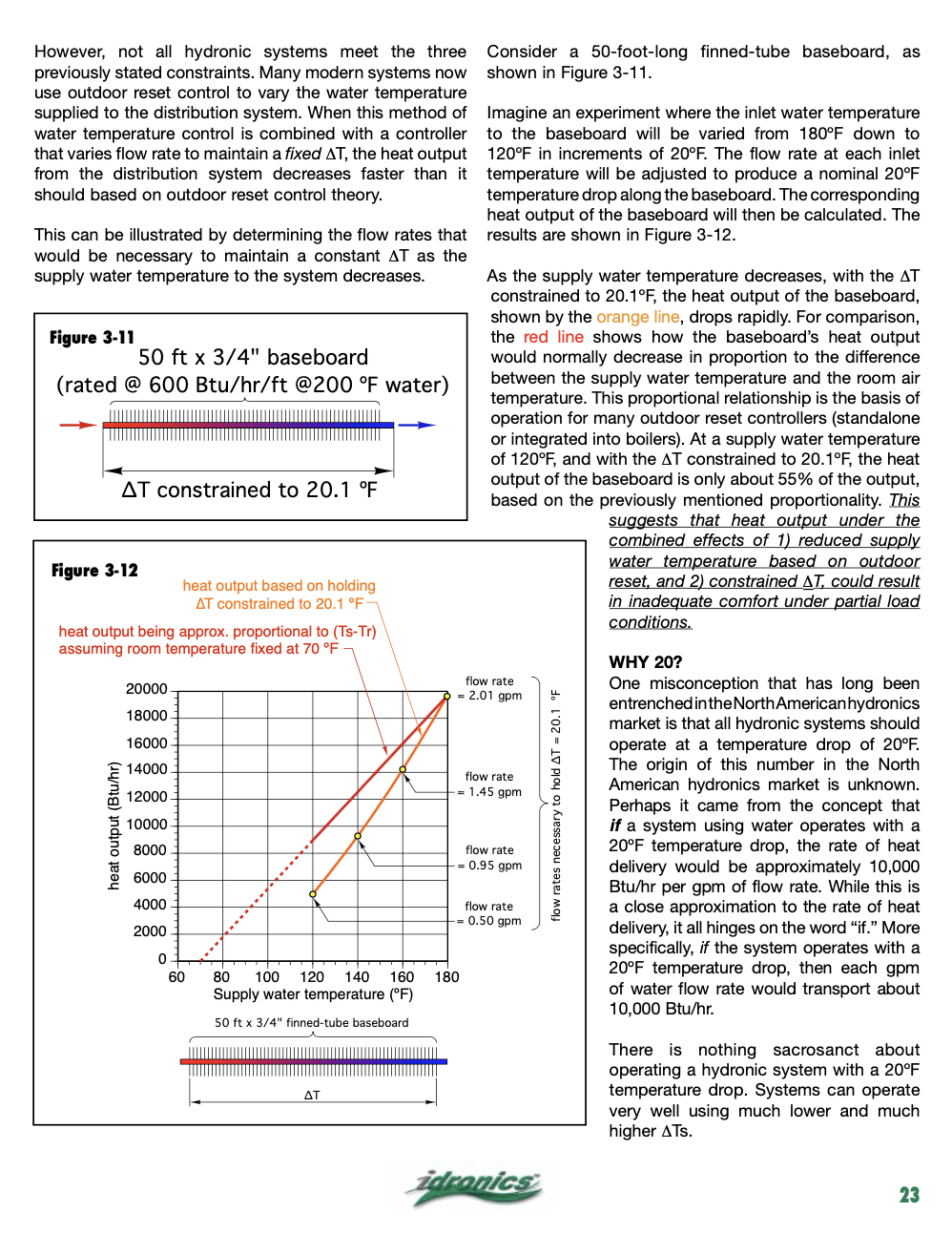

Thank you for that. I assume that the 007e per zone will work just fine for me. I just want to make sure that I am not pumping too fast as I try to keep boiler return water temp low enough to achieve condensing. I want to reach a delta-t of 20 degrees if possible, and I should have enough fin-tube baseboard (65', and 45' loops) to lose that 20 degrees during heat demand…any other info / opinion is greatly appreciated!

0 -

At 3 gpm and 6' of head, the 007e will work for you. But since your pressure drop doesn't change, I'd go with the Delta-T pump, no? You can set it for whatever Δ you want (5-50℉).

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

oil / NG maybe

Oil / LP in NE?

No way

0 -

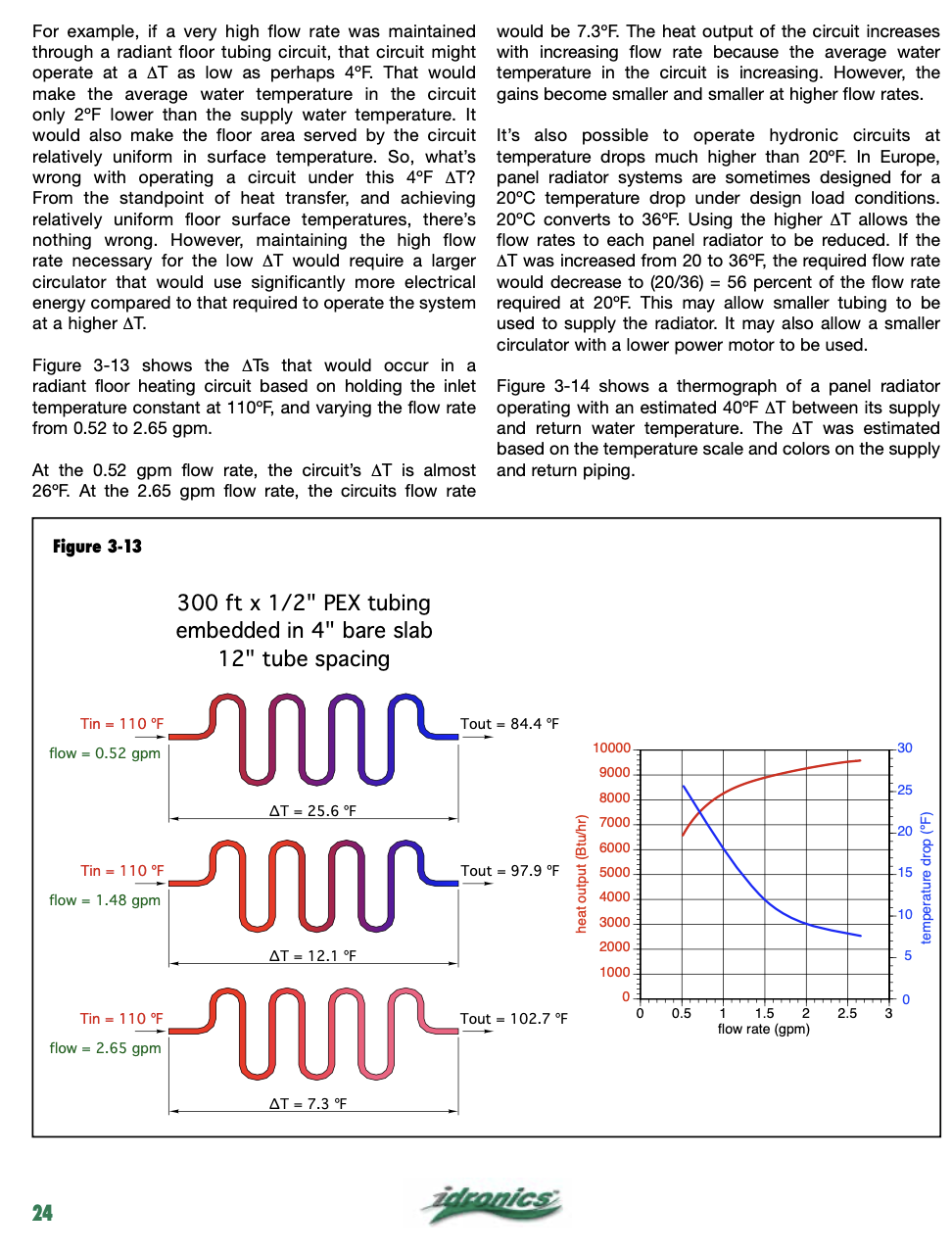

Here is some info about "constrained ∆" operation

First off heatings loads are always moving based on outdoor temperatures, wind, occupant use and indoor gains. They are considered dynamic loads.

So an ideal heating distribution system would be allowed to modulate according to ever-changing loads, a dynamic system matched to dynamic loads.

It is always the case that the load, the distribution connected to the boiler dictates the boiler operating condition.

As such the ODR attempts to satisfy the load with the lowest possible SWT, both for boiler or fuel efficiency and comfort of near constant circulation. With a mod con boiler this is easily accomplished by modulation the boilers burner(output) based on temperature inputs to the ORD control function.

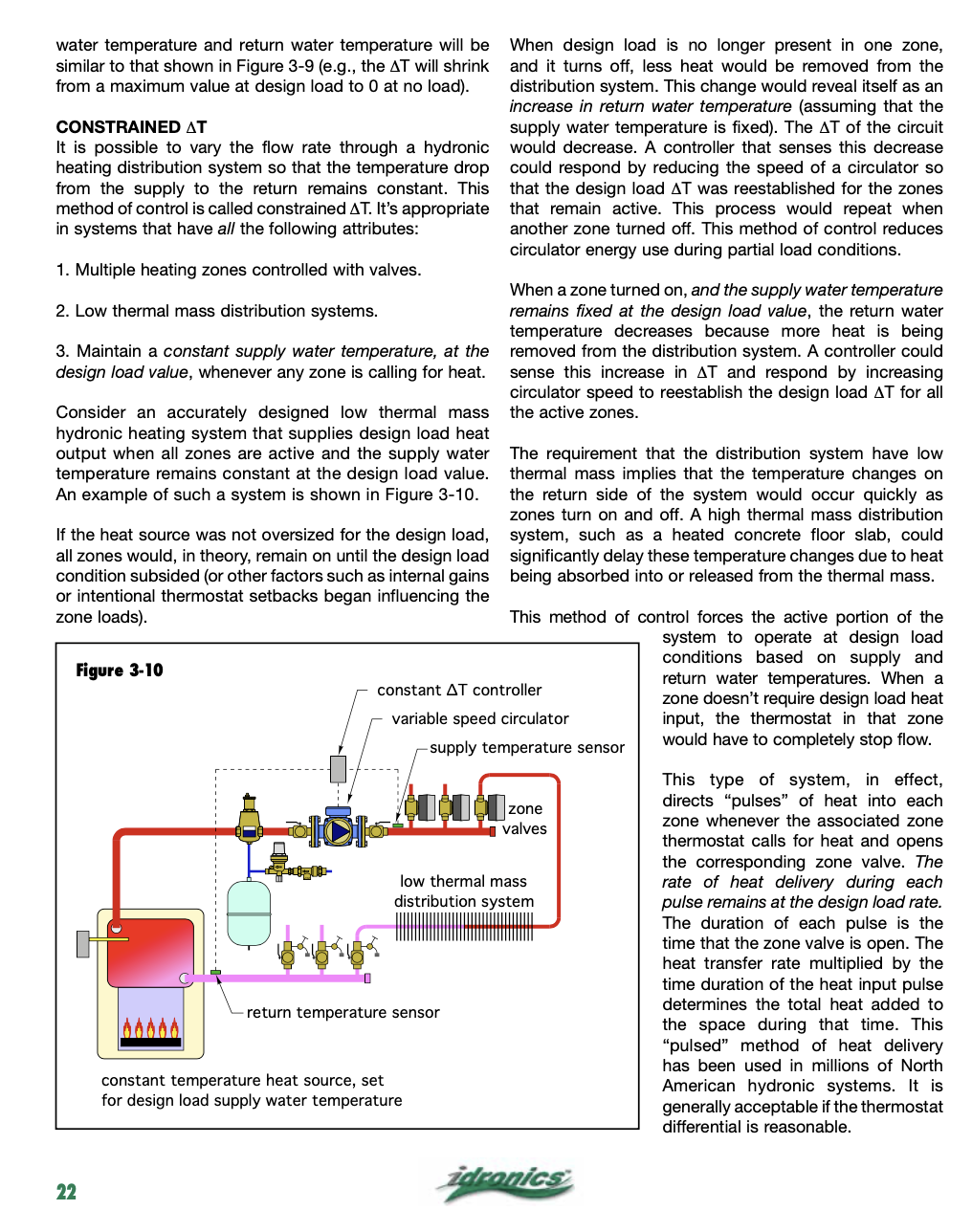

In several issues of Idronics we talk about hoe ODR and constrained ∆ operation. I think you have it correct they are trying to do conflicting functions.

Allow the ∆ to vary as the load dictates. Delta P varies flow rates based on zone requirements. Some suggest ∆P is just for "European" type systems? But you may have noticed every circulator brand now has a wide range of ∆P circulators available.

Suggestions below for the type of a system where constrained T operation may work.

Personally I prefer all the benefits of ODR regardless of number of zones, type of heat emitter, or type of boiler.

Idronics 25 is a good read about heat transfer in general.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements