two boiler piping

Message:

Need some help with piping two boilers to a multi zone radiator heating system. I have a conventional oil fired boiler in my shop and a combi boiler in my basement connected with underground insulated piping shearing the same water and it's about a 100 ft apart . In the house is a 6 zone hydronic system with circulator pumps with a common supply manifold and return manifold. My goal is to be able to run the boiler in my shop as a primary and in case of a fault the basement combi boiler would kick in as a beck up. How do I connect the two properly and to control them as simple as possible ?

Comments

-

is the oil fired large enough to handle the shop and home?

The combi in the home is it gas or LP?

It seems that would be the less expensive to run boiler as the primary?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I'm just taking a wild guess about this. Is the oil fired boiler in the shop operating on waste oil? That would be the least expensive heat since you need to pay to have waste oil removed as a hazardous waste. Some would say that is free fuel, but that is wrong. Burning it actually makes you money since you don't need to pay someone to remove it.

Caleffi publishes a series of booklets called Idronics. volume 10 has information about wood burning boilers (Stay with me here). starting on Page 27 it describes pretty much what your are doing. just substitute the words "Oil Boiler" wherever it says Wood Boiler, and you will get the idea.

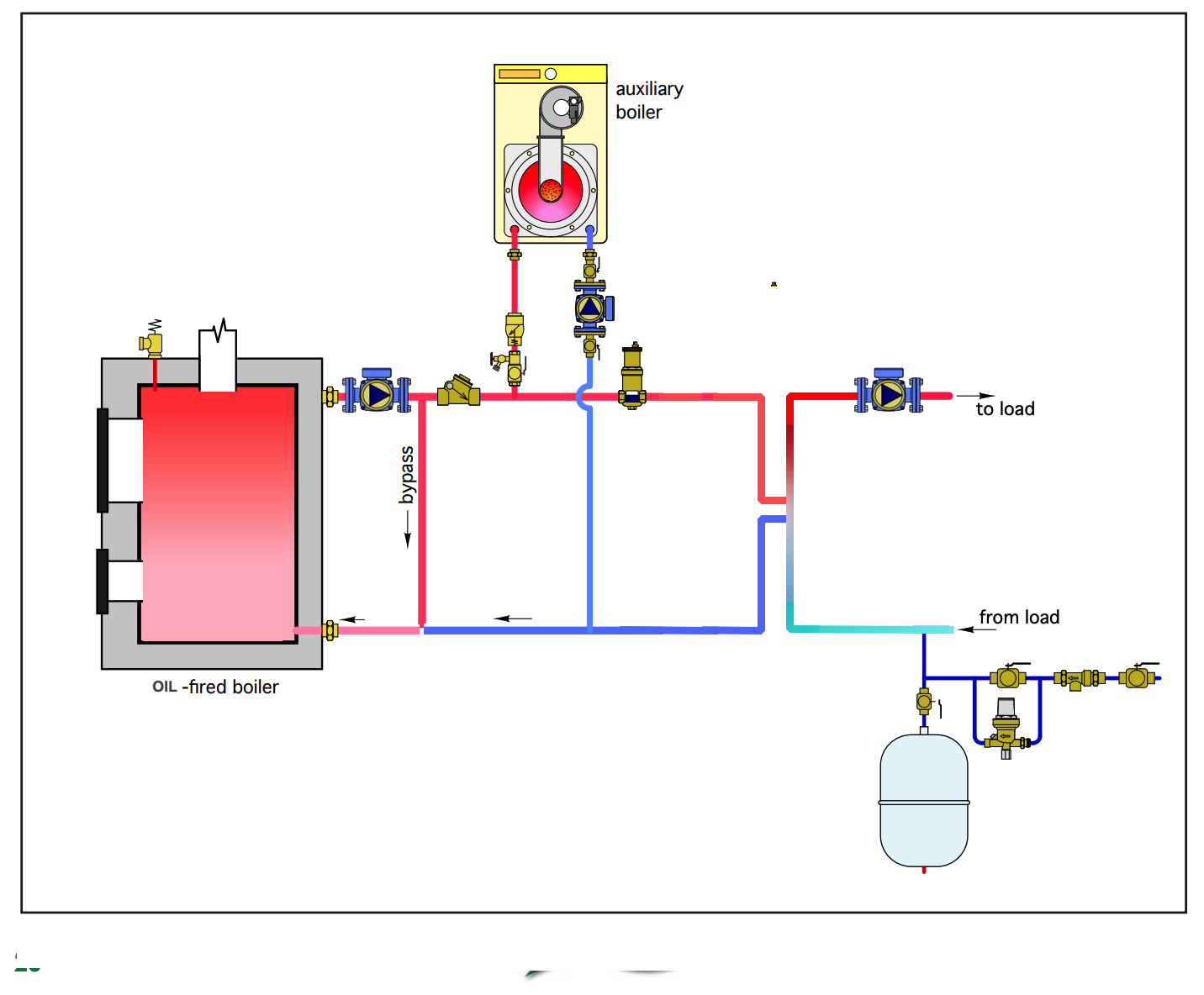

The simplest way to address this is to use primary secondary piping. This will allow one boiler to operate without the other boiler being affected from the use of the other. Here is an example of one way not to pipe the boilers from Page 28 of Idronics Vol 10.

With this configuration both boilers must have heat from the other boiler pass thru it. This turns the non operational boiler into a large radiator that sucks heat from the system without any benefit to the area being heated. It just heats the unused boiler and that heat can go out the vent pipe or heat the space around the boiler even if you don't want that space heated to 70°.

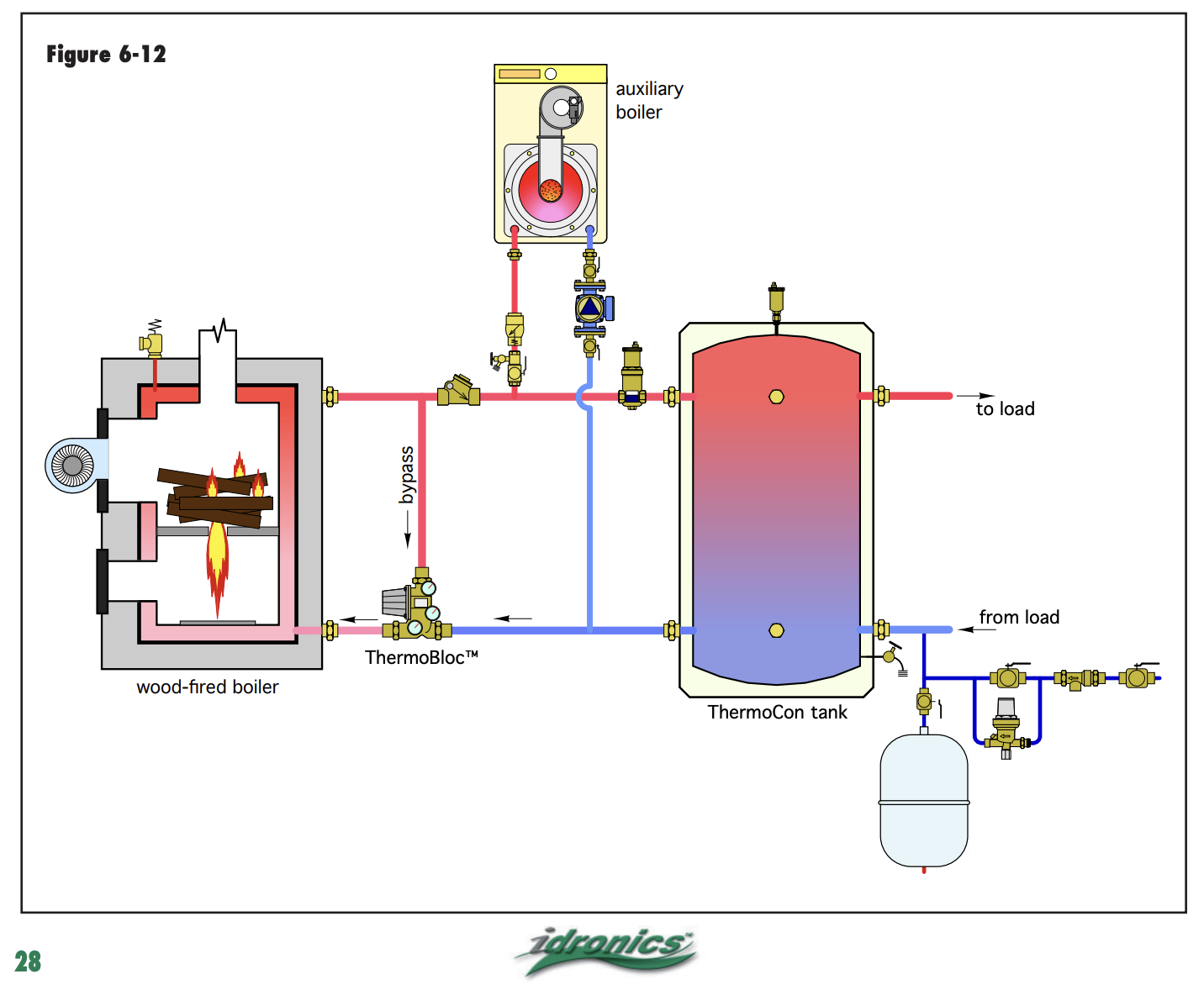

Primary secondary allows for hydraulic separation of different sections of the system. If the Combi Boiler in the basement is not in use, the heated water will just pass by it. If the oil boiler is off for maintenance, You don't need to send heated water 100 feet into the shop for no reason. If there is a zone that needs to be heated in the shop, then you can control that zone to call for heat when needed

There are other ways to hydraulically separate the boilers from each other so the heat from one does not affect the other. This is one way to use a buffer tank, It stops short cycling and allows you to draw heat from the storage/buffer tank and protect the boiler with higher temperature return water

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

If the boilers are 100' apart that complicates things. You want to sent heat in either direction based on ?? cost of fuel,, failure of the oil, backup or redundancy??

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

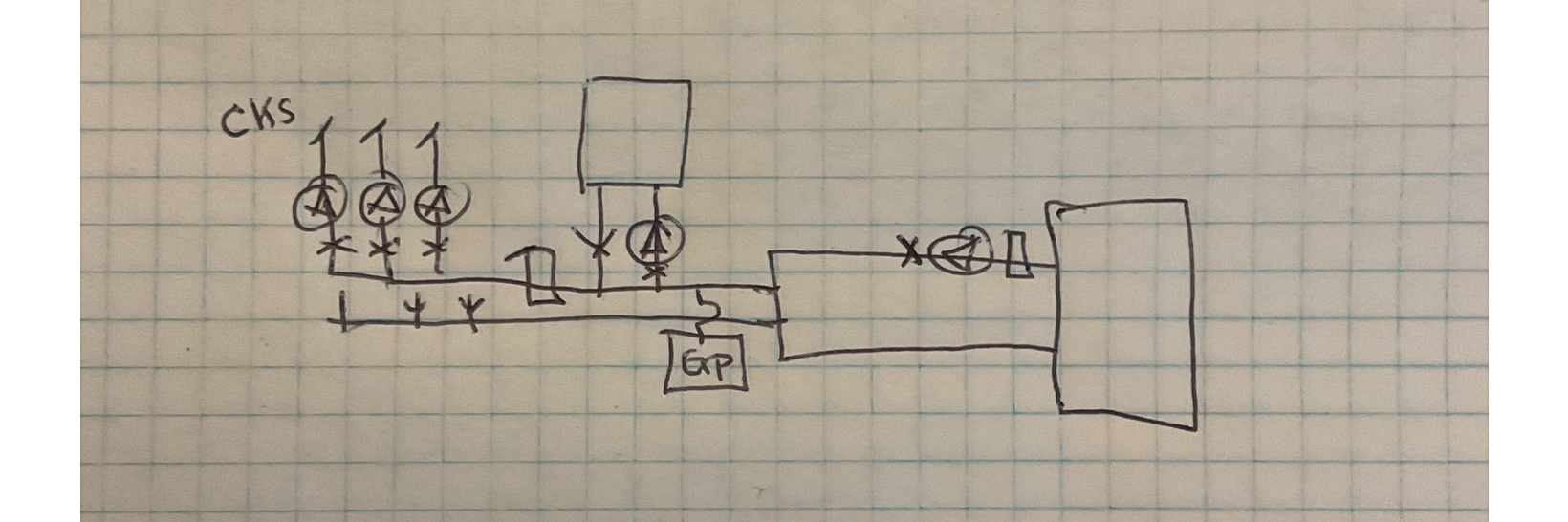

Here's a rough sketch someone suggested , what you guys think ?

0 -

Do you want to be able to use the combi to heat the shop, also. Or just the combi for the home?

Do you really have 7 zone pumps?🧐

the piping you show has the oil boiler pump in series with the zone pumps. Ideally you want hydraulic separation between the circulators. If the oil boiler has a minimum required flow it should be a circuit of its own, as the combi is.

This concept gives both boilers a loop with the required circulator sizing to maintain flow, zone pumps parallel to each other, to allow the same SWT to each.So the distribution loop is the primary loop as it has the expansion tank in it. Boilers are both secondary’s.

This would not allow the combi to feed to the shop however. If you want that, it would need to pipe so that the combi never flows through an unfired oil boiler. Else you send heat up the flue of an unfired boiler. Checks required at every zone circulator. A mag sep would be a good addition if ECM circs are ever used.

2028 all circs will be ECM.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Yes this is what I'm looking for . Thank you, Do I need anything to control the system ?

0 -

do you want a manual or automatic switch from oil to combi?

When we do hybrid boiler piping with wood boilers , for example, a few controls monitor temperatures and switch one off the other on

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

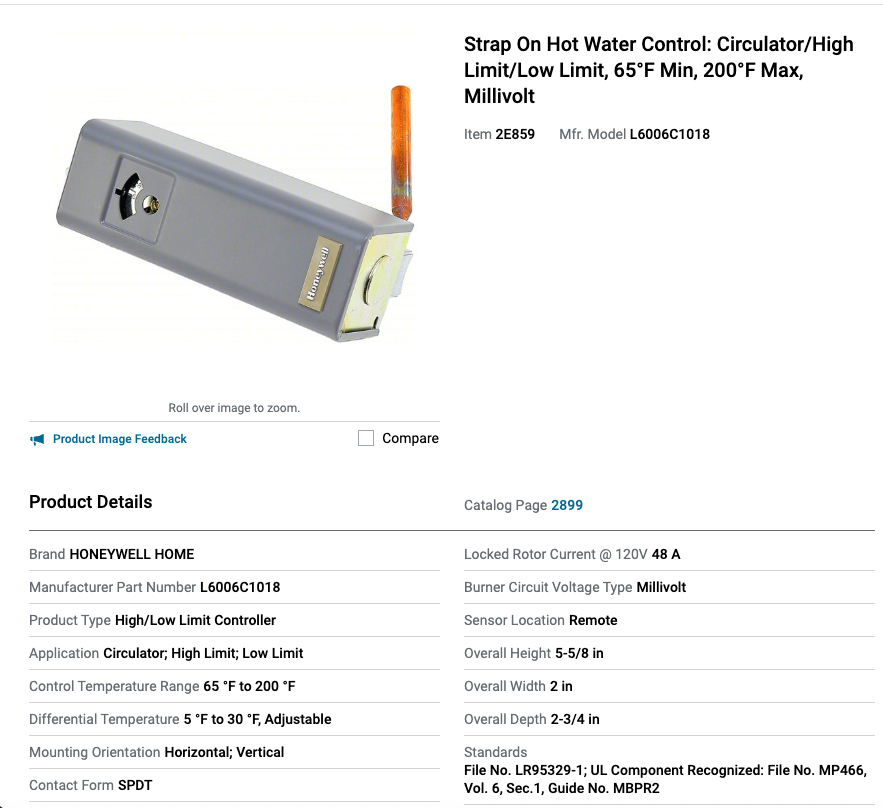

Automatic . I was thinking to set the primary boiler to 180 and the backup to 160 this way if the primary stops working the backup kicks in.

0 -

check to see what the differential us on the oil noiler control. If it is off at 180 back on at 160, plus some heat loss through the piping, adjust the control that calls on the combi boiler accordingly

A simple strap on type control on the piping to call on the combi, so it senses the oil boiler is not heating

Is the oil boiler large enough to cover both buildings?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

yes it's big enough , Thanks for the info

0 -

Here are some control options. This strap on has a good temperature range and adjustable differential for fine tuning.

I prefer electronic type controls Ranco, Honeywell, Johnson Control, etc. you get more features and have the digital temperature always reading out.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements