Leaking relief valve and possible ghost flow to indirect water tank

I'm struggling with a long-term problem with ghost flow/thermal migration in my hydronic system that currently has my tap water scalding hot and my boiler temperature/pressure valve dripping on the floor. As it stands, my usual plumber wants nothing to do with the problem, since he can't stand behind any solution. So some background...

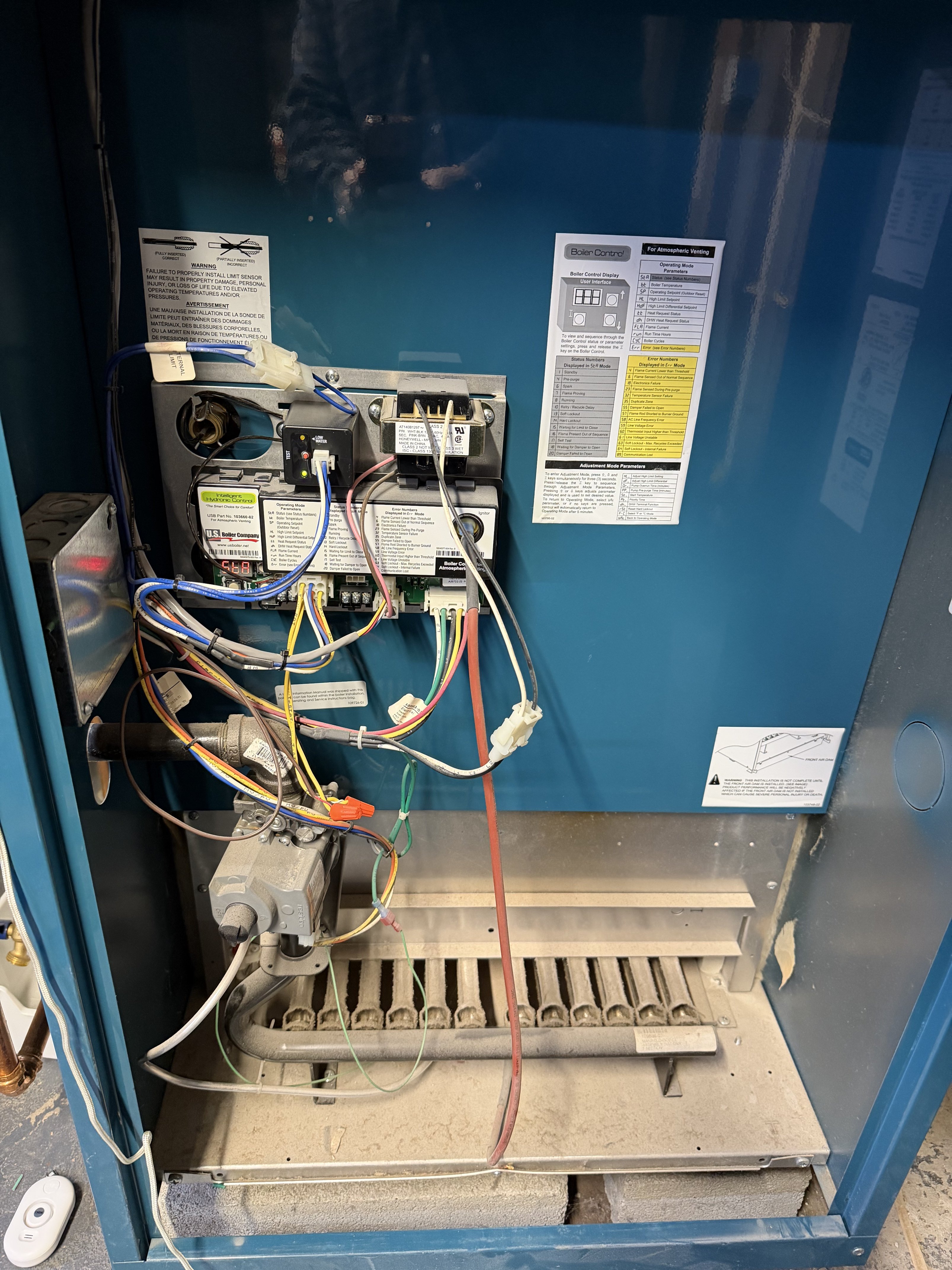

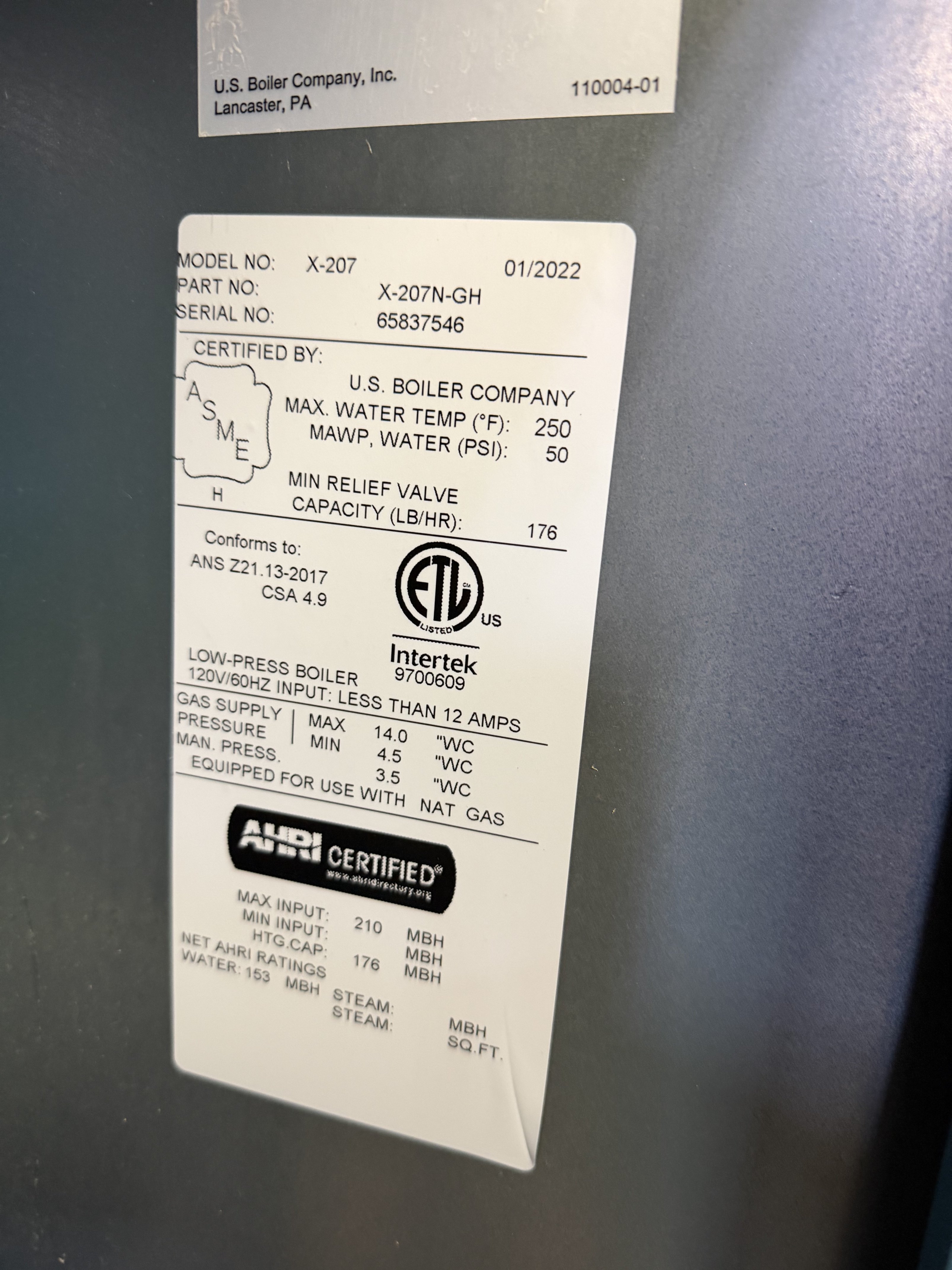

About 2 years ago, I converted my oil boiler to a gas boiler. The current unit serves 5 zones. Of those 2 of them are single rooms (additions to the house), and one (the basement is never used as there's never been a need). So really, the main factors are the main house zone (that's the black circulator pump) covers both floors (which always results in a cooler upstairs, but that's the pipe layout I'm stuck with) and the water tank priority zone.

When the new boiler was first installed, we had all kinds of ghost flow issues, where hot water flowed to zones that weren't calling. This meant that even a room with the heat totally off would be 85 degrees. It took the plumber doing the install several consultations with other plumbers before they started putting check valves anywhere they could think of. Along the way, we had the transformer for the main board fail, as well as 2 of the circulator pumps — which I doubt is relevant, but figured I'd include for completeness. I'm unconvinced they understood the underlying issue(s), but a bunch of hasty valve installs seemed to solve the immediate issue of my house being a sauna, and we called it done.

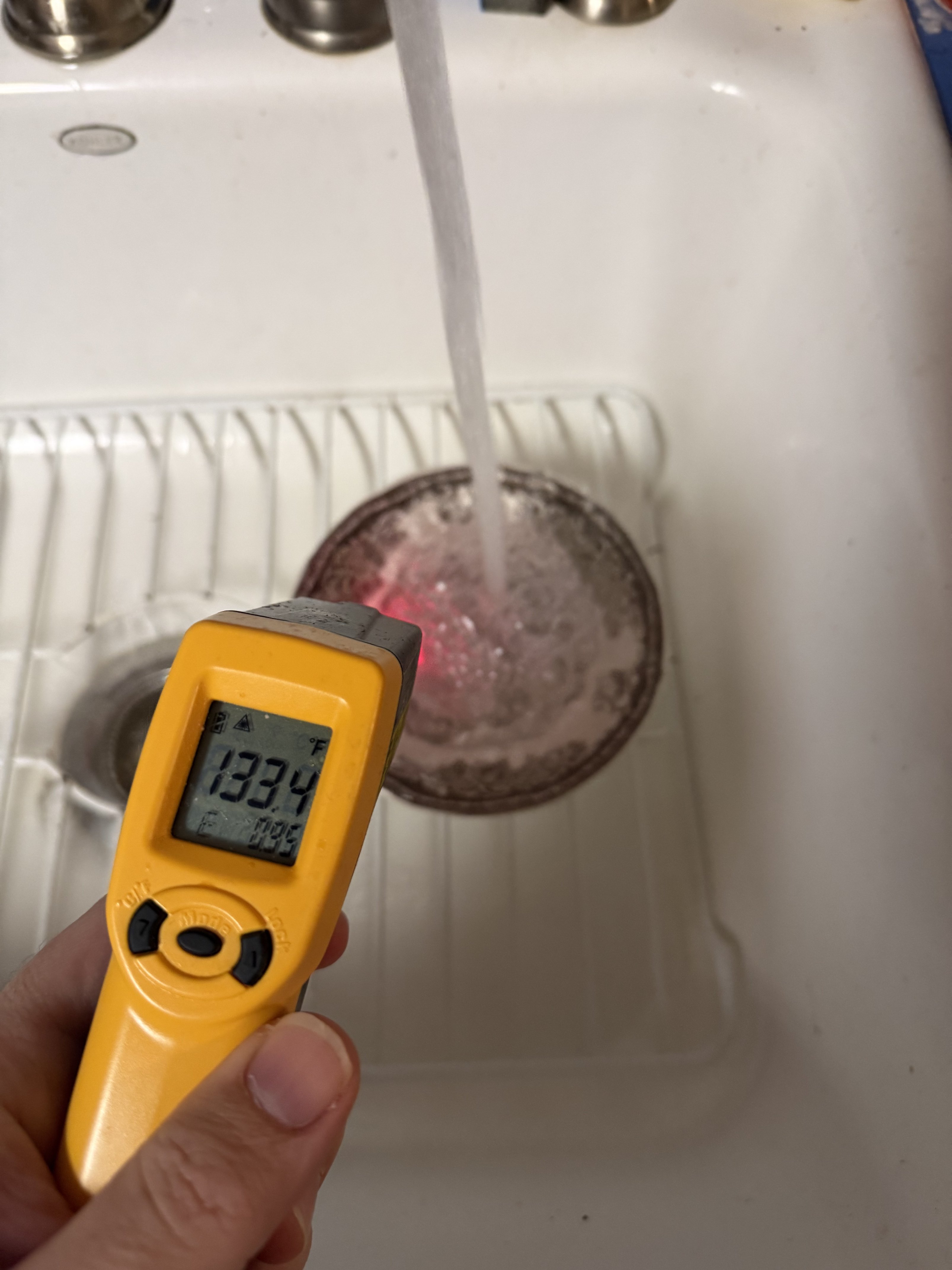

Later, I started noticing my tap water was really hot. The new system brought with it a 55 gallon indirect water tank (the prior system just heated water on demand I believe). So we measured the tap temperature, and cross-referenced with the setpoint of the aquastat on the tank, thinking it was just a linear adjustment. But it wasn't. There was no clear connection with the aquastat setting and the tap temperature (always much hotter). As you might guess from the picture, we replaced the aquastat (the old one is sitting on the boiler), though not the probe, since the way it was installed would have required a huge effort to change. This didn't change anything, and i Just resigned myself to being careful with the hot tap. The 133F reading you see is at a 118F aquastat setting, by the way.

A few weeks ago, I noticed a puddle on the floor under the overflow pipe, and noticed the pressure was right around the trigger point for that valve (30psi I think?). It wasn't a lot of water, and it had probably been leaking for some time and evaporating. But once I put that white ice bucket under it, I realized it was a fair bit of water. I had my usual plumber out, and he checked to see if the expansion tank was in good shape (it was), but couldn't find anything else. He didn't want to replace the overflow valve, as he felt he couldn't stand behind just treating a symptom.

I continued monitoring all this, and everytime there was a leak, I got an alarm. And what I noticed is that no zone was calling when the pressure climbed up around 30psi and the water release began. So after doing as much reading as I could, I can think of only 2 alternatives:

1. The probe in the indirect tank is causing issues in terms of asking for too much hot water, and therefore bringing the pressure of the system too high. This seems unlikely, given that the tank isn't calling when the issue occurs, but maybe I'm missing something on this possiblity.

2. There's ghost flow/thermal migration where the boiler water is slowly migrating into the indirect tank, heating it when no call is happening, raising overall temperature and pressure. If this is the case, I guess the solution is more check valves? But no one seems to know where that would go, if that's the solution.

I've included as many pictures as I thought might be useful. But let me know if zooms, or labeling on my end would be useful for troubleshooting. I feel like someone else must have seen this combination of scalding tap water and pressure buildup and have an idea no one here is having. Thanks in advance!

Comments

-

You say you checked the expansion tank… how? What is the system pressure when the boiler is off and at least cool, if not cold?

And where is that tank connected relative to the system pumps?

I must admit that I have my doubts on that tank being big enough… but it might be, I suppose…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

I now realize I posted to Radiant Heat, when maybe Gas heating would have been better. Ah well - can't change that now.

But when I had my plumber out, he tapped on the expansion tank, telling me that a hollow sound was good and a solid thud was bad. Were there other diagnostics he should have done?

The pressure reads about 12-15psi under normal conditions (it's never quite off here in the Northeast in December), and just around 30 while leaking.

The tank is connected around 18in to the left of the boiler and its pumps.0 -

first, where are you located, we might know someone competent to fix it.

second, if you turn the boiler off, does the pressure still creep up?

0 -

btw the indirect should be set up with a mixing valve to keep the dhw at the desired temp. there are lots of reasons the tank might overshoot the aquastat not the least of which being that the differential may be 20 or 30 degrees depending on which model you bought. it is generally in the installation instructions for the indirect.

0 -

Check the charge on the thermal expansion tank , it will be on the cold water line . They tend to loose its charge .. Set it to system pressure ….

The hot water migration problem , I would say you have a bad shower or faucet body .. They bypass when they go bad …

The aqua stat , try setting it lower then what you want ..

Hope this Helps

There was an error rendering this rich post.

0 -

The first quick check for the expansion tank is to push in the needle valve under the silver cap. Air should come out, of water squirts out, the tank needs to be replaced.

If the pre-charge pressure is off it will not accept the expansion, you need to drop system pressure below 10 psi to check that.

The small lever on those red flo-checks, is it screwed all the way CW? That is the only position they work as a check.

Could be a leak in the indirect coil causing tank water to cross into the hydronic side

Relief discharge is often one of these 3 issues.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I assume that the boiler is operating at 180 deg SWT. If the boiler gauge reads 12-15 psi cold, it means that the pressure regulating valve is set at 12 to 15 psi cold water supply to the boiler. That's good. That the pressure on the gauge goes to 30 psi and there is leakage from the pressure relief valve, it means that the pressure relief valve is functioning properly, doing its job, and that the air charge on the Ex tank is much less than the 12-15 psi that the pressure regulating valve is set at (most likely) or that the heated volume of water in the boiler sys has expanded beyond the Ex tank ability to accept the expanded volume of heated water (less likely).

I would check the air charge on the Ex tank and set it at 15 psi. If water comes out of the schrader (tire) valve, you will need a new tank. I have used your size Ex tank #30 in sys with 38+ gal @ 180 deg water with out any problems. so, I expect your tank is big enough. If you do check the air charge, you will probably have to drain down the water in the sys, If that is the case put in a Webstone valve which makes doing that really easy. It's directional.

https://www.supplyhouse.com/Webstone-40612-1-2-Threaded-Pro-Pal-Full-Port-Ball-Valve-w-Hose-Drain

I wouldn't have used those B&G flow-check valves, a volute check valve at the pump and an inline check valve at the circuit return would have been my choice. That would prevent any thermo siphoning. That means a check valve on the indirect tank loop to the boiler, too.

0 -

Lots of great advice here - thanks everyone!

So here’s the summary:

The expansion tank gives me a reading of 12.5psi and does not leak waterEven when only 1 small zone is calling, pipes to all zones (even those with thermostats off) are fairly hot to my touch.

I’ll try to summarize what I’m reading so far, and my efforts to confirm it.

@Jamie Hall wonders about the validity of the expansion tank check, and the size of the tank.

The manual for my Extrol EX-30 expansion tank says that the main diagnostic is to tap on the tank and look at the window on the end of it. The window doesn’t appear discolored, the tank sounded alright to me, and a reading on my tire gauge gives me 12.5psi.

For the tank sizing, I went over to https://www.watts.com/resources/planning/etp and entered in 55 gallons, along with the charge of the expansion tank (12psi for the EX-30 the manual says), and a final pressure of 25psi (85% of overflow per instructions). It seems to say that my 4 gallon tank should work.

@mattmia2 suggests he may know someone to help - so I’ve reached out to him. I’m going to test the issue of the pressure creeping up with the boiler off next time I catch it leaking.

He also suggests that there should be a mixing valve somewhere. I don’t appear to have one now - so that’s something to look into. I dug through the manual for the Weil-Mclain Aquaplus 55 indirect water heater, and didn’t find anything useful about differentials in their temperature adjustment section (https://www.manualslib.com/manual/766061/Weil-Mclain-Aqua-Plus-35.html?page=24#manual). I’ve been reluctant to put it far below 120F for water safety reasons (I was at 118F on the aquastat and then went to 111F), and the manual seems to suggest the thermostat should be essentially true to set point. This may need more investigation.

@Big Ed_4 suggests that there may be a bad shower or faucet body. But since the high temperatures are consistent across all fixtures in the house, I think I can rule this out. But I did set the aquastat down even more.

@hot_rod suggests checking the small levers on the red Flo-checks. They appear to be as tightly screwed clockwise as they can go - in the sense that I couldn’t move them with a reasonable amount of wrench pressure. He also suggests a leak in the indirect coil. The flo-check settings seem worth looking into more.

Lastly, @HomerJSmith suggests looking at the pressure on the Amtrol EX-30. This led me to check the pressure, which as I mention above, looked good, with no water release. He does suggest upping it to 15psi though - so that seems worth considering. He also makes great points about how this probably should have been put together in the first place.

So given that the tank isn’t obviously defective, it sounds like the remaining things to check are a leak in the indirect coil or something with insufficient check valves? The tank is less than 3 years old, so that seems unlikely, but then again, 2 of the circulator pumps failed on day 1.

0 -

A plumber with x-ray vision. Wish I could do that. If your having any pressure issues the expansion tank is always suspect.

Looks like a job to get that tank out of there. The original installer did a dumb move putting it there. If you get water out of the ex tank air fitting its shot as @hot_rod mentioned. Even if you don't get water it could be bad but to test it it has to be removed to do that. Might as well replace it at that point. if it was me it would be in an accessible spot with an isolation valve

0 -

Also shut off any fill valve to make sure it is not allowing water in and over pressuring the system

The tank will always read the system pressure!

The only way to check pre charge is to isolate it and bleed off water pressure at the tank, or

Drop system pressure below 10 psi pump tank to 12 psi, or

Remove tank and check pressure, adjust to 12 psi

It nay nit be so easy to “shake” a tank mounted like that to determine if there us any water in it

When the boiler is iff, cold the tank us empty

As the water heats-expands ut starts pushing into the tank

Generally you don’t want more than 65 % of the tank being water, this is where the acceptance number comes from. At the boilers highest temperature it should be below 27 psi, that is the psi Amtrol uses in its calculator, unless you change it.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Generally, one disconnects the Ex tank from the sys and measures the bladder air pressure and set the pressure to the same pressure as the boiler cold water fill valve setting. 15 psi?

Here is a way to do it without disconnecting the tank from the sys that I think will work:

- Do this with a cold boiler. Shut off the cold water feed to the boiler. Your boiler gauge should read 15 psi.

- Add air to the tank while watching the boiler pressure gauge. When the gauge read 28 psi, stop putting air into the tank.

- Slowly open the boiler drain valve, releasing water from the sys until the boiler gauge reaches 15 psi. Close the boiler drain valve.

- Add more air. see #2

- See #3

- Repeat this until adding air doesn't move the needle on the gauge. This means that the water has been expelled from the tank and adding more air just raises the pressure on the air bladder side of the tank .

- Pressurize the tank to the cold water feed valve pressure ( pressure regulating valve,15 psi).

- Open the pressure regulating valve, allowing water into the boiler, pressurizing the sys. The boiler gauge should read about 15 psi.

Have a Happy New Year!

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements