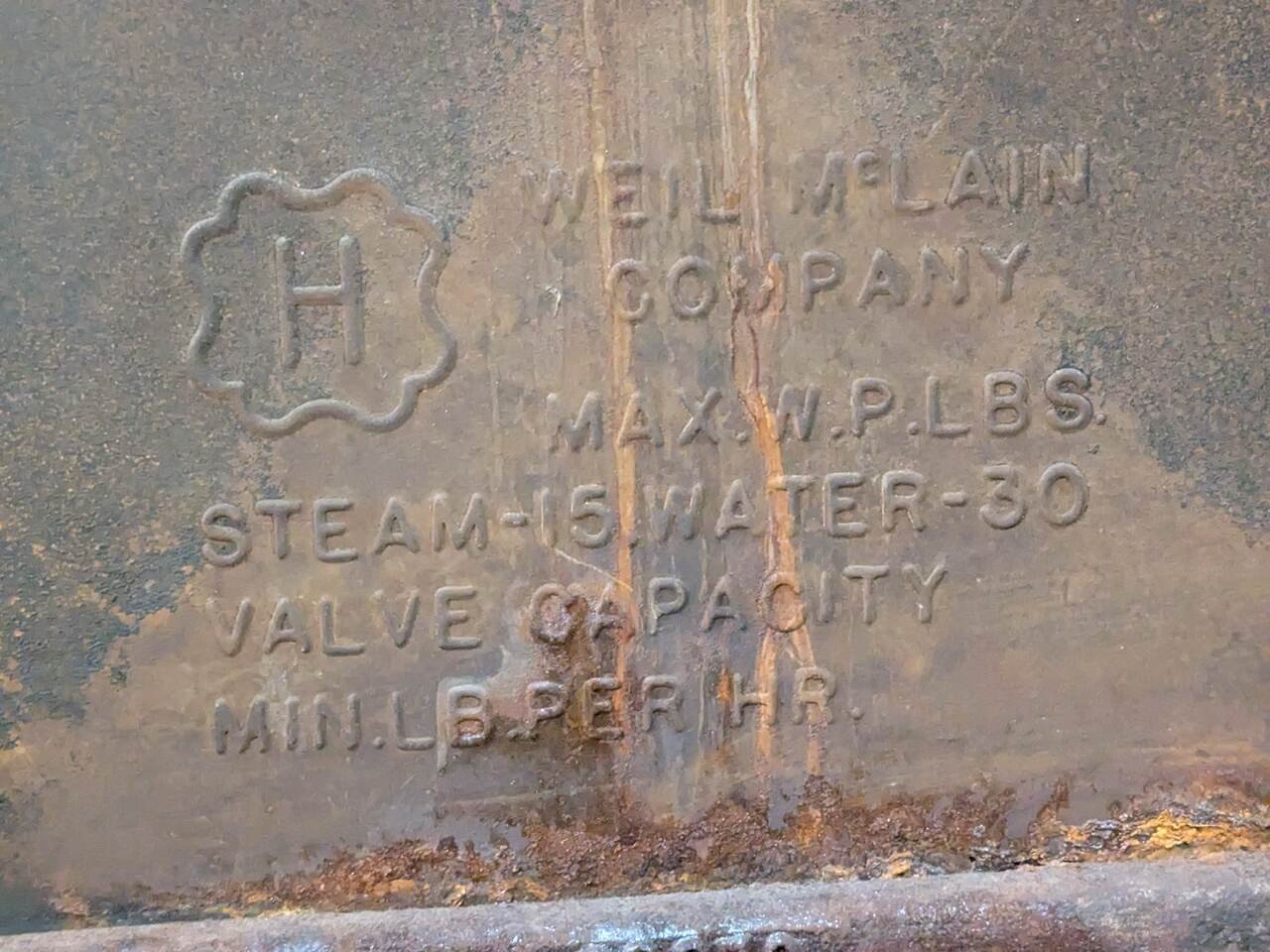

1915 House with Weil-McLain 62, waterlogged tank? (rads cold on 3rd floor)

Preamble: No "Boiler service" in this town - local guy who tuned it up last has now retired, nearest experienced company is five hours drive!

We have this leaky 6000 square foot brick building (former convent) and the biggest oldest basement rads always run way too hot for their space, but the little baseboards in kitchen, bath, and rectory aren't warming their spaces much. Boiler is in the basement, 1st and second floor room rads are basically 'fine' but the third floor rads are cold. Input pipes to the 3rd flor rads feel warm.

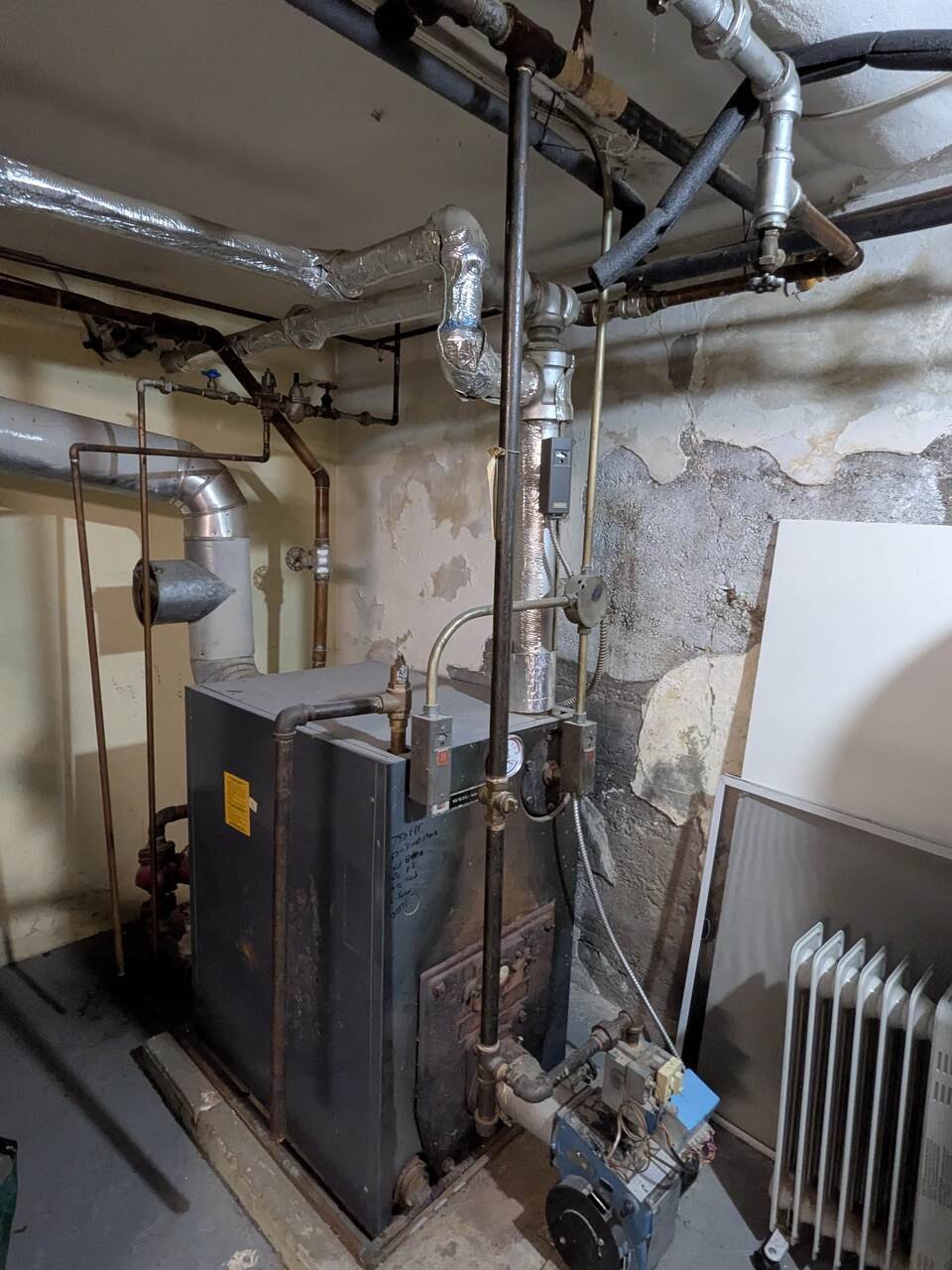

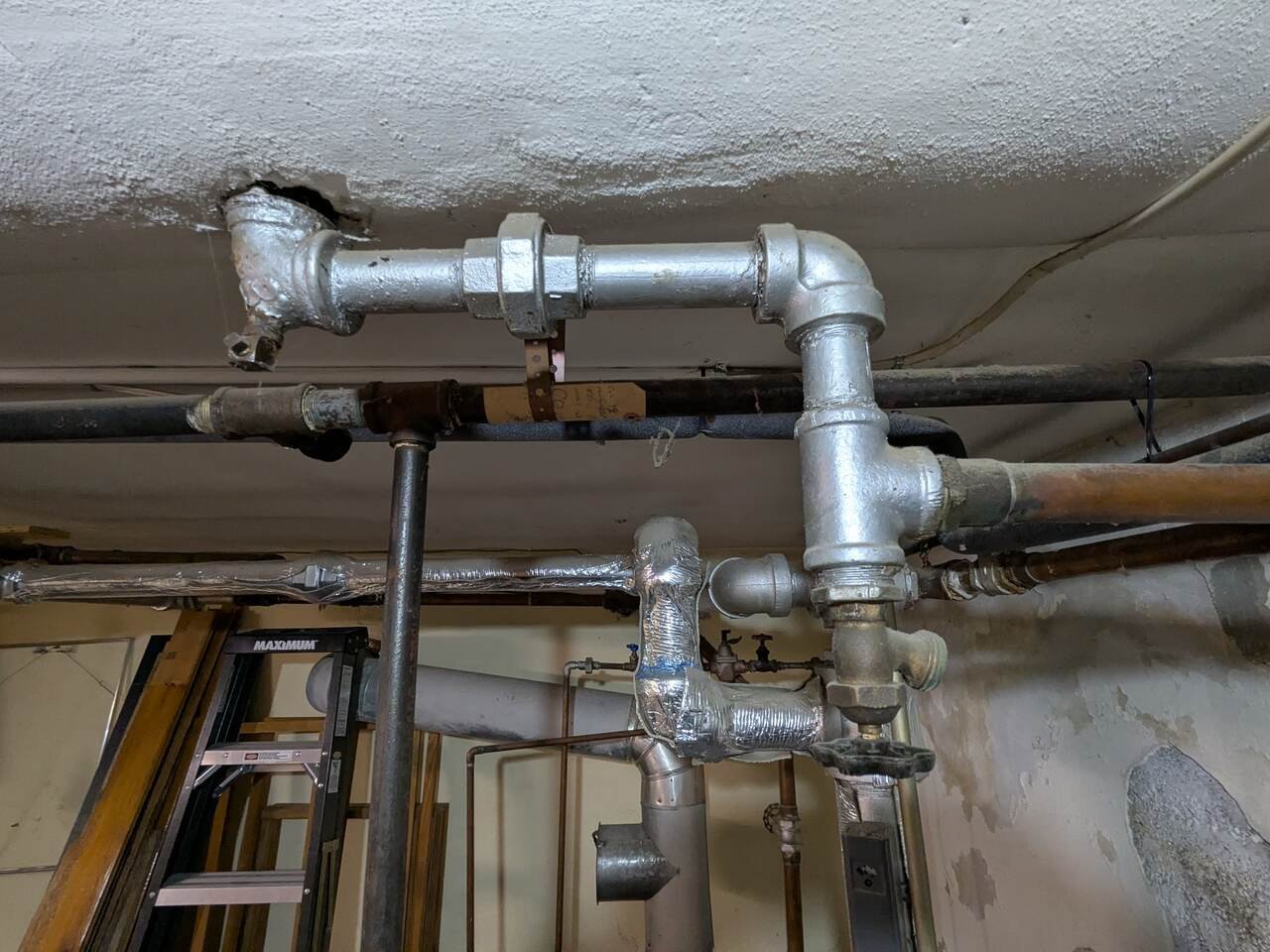

The boiler room:

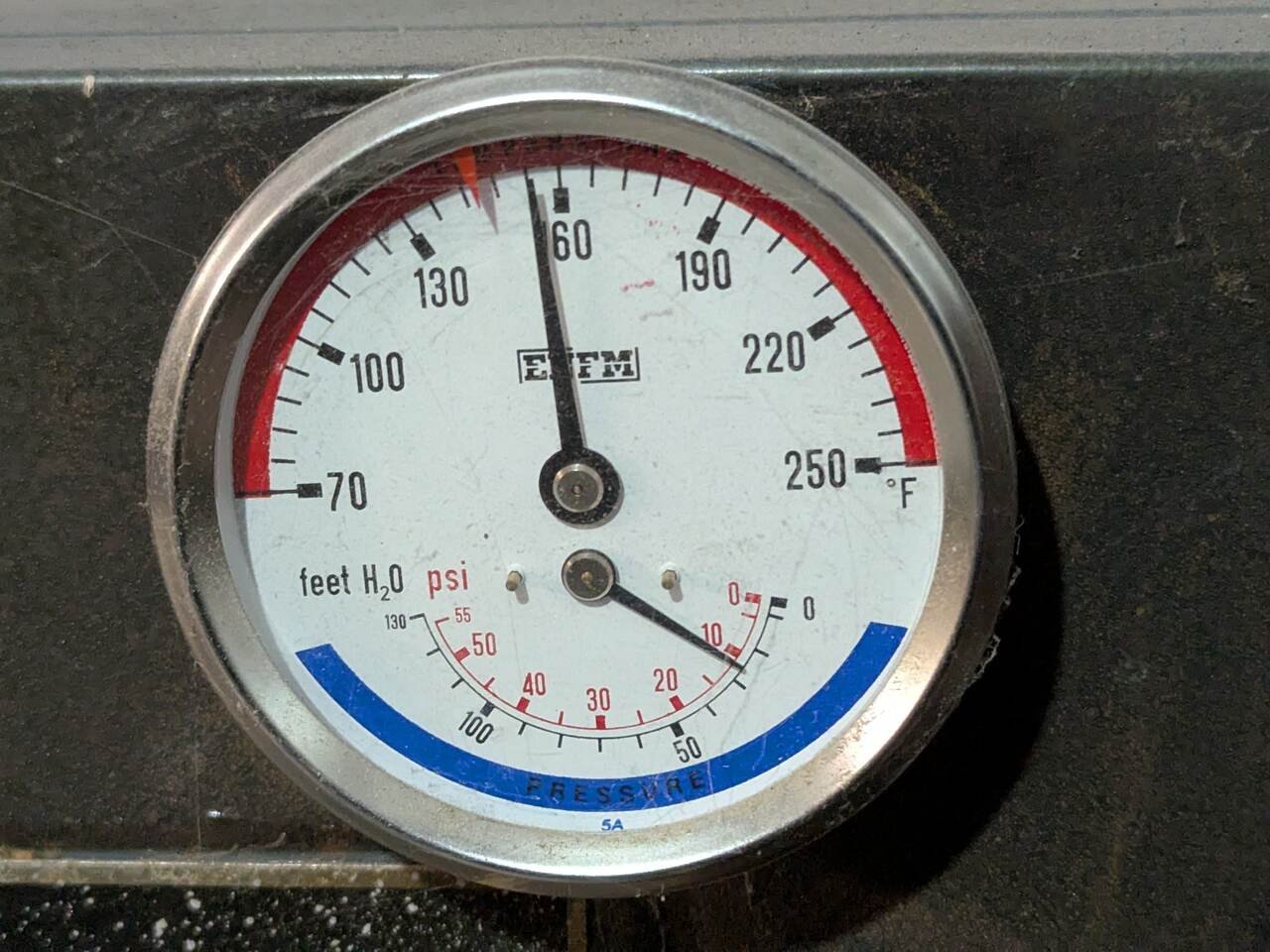

Weil-McLain 62 gauges say we are running 155-ish and ~12 psi

I've done a lot of googling and then had a long long detailed back and forth chat with AI. My proposed workflow courtesy of the AI (after I get bleeder keys) is outlined below. Seems reasonable BUT as always "Gemini can make mistakes, so double-check it". So I thought I would ask here, where actual real knowledge can be found!

=======

Here is your Morning Checklist for when you have your tools in hand tomorrow:

1. The Prep Phase

- Staging: Place your new keys, PB Blaster, and rags at each of the three 3rd-floor radiators.

- Containment: Ensure your "catch basins" (pots/bins) are still in place under the basement relief valves and the boiler drain.

- Clearance: Double-check that all furniture and curtains are pulled away from the 3rd-floor units to allow for heat airflow once they "wake up".

2. The Pressure Bump

- Fill: Lift the silver lever on the Watts valve slowly while watching the gauge.

- Target: Stop exactly at 18–19 psi.

- Power Down: Flip the Red Emergency Switch to "Off" to stop all water movement.

3. The Bleeding Sprint

- Start Furthest: Go to the 3rd floor and start with the radiator furthest from the stairs.

- Key Technique: Use the new radiator key to turn the valve counter-clockwise just until you hear air hissing.

- The Close: Close the valve as soon as a steady stream of water (no bubbles) hits your catch container.

- Repeat: Do this for all three radiators as quickly as safety allows.

4. The Recovery

- Power Up: Flip the red switch back to "On".

- Final Pressure Check: The gauge will likely have dropped after bleeding the air; use the lever to top it back off to a stable 15–16 psi.

- Monitor: Watch the gauge for 15 minutes to ensure it doesn't spike toward 30 psi (the waterlogged tank test).

=======

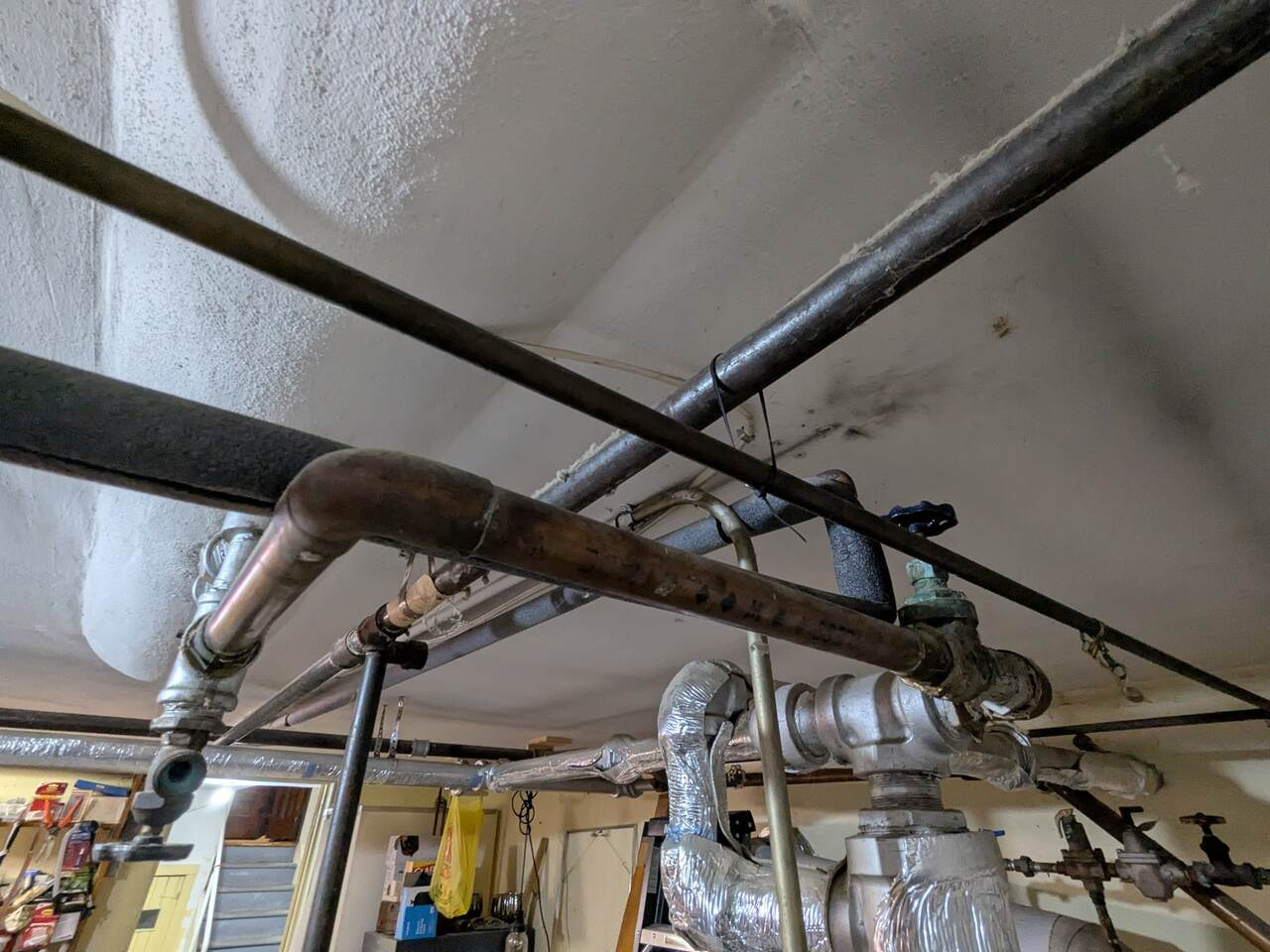

That's just the outline, there was a whole lot of detail I won't bore you with. My concern is if the tank is WATERLOGGED, I'm not going to get the pressure up. (AI suggested the boiler drain valve can be used to relieve the pressure in an emergency - I'm planning to hook up a hose). I'm wondering if the reason the system has been set to 12 psi in the first place is that the previous owners knew the tank was waterlogged and didnt want to deal with it. (It's lathe&plastered into the ceiling of the utility room - see pics)

The AI was adamant that the head pressure to get from basement up to third floor rads has to be higher than 12psi - "physics"! Thus, gotta add some water to the system…

Interestingly the WATTS valve for auto-fill is tagged 12psi (I have no docs on whether that's original or not)

If indeed it's waterlogged I was thinking maybe I could drain it by shutting off the blue valve to the right (by boiler) and then opening up the blue valve feeding tank to the left :

Am I correct in guessing if I drain water out that way, air is going to come up the same tube to replace it?? I dont see any sort of "bleeder valve" lt air back in (maybe been plastered over??).

Maybe that square thing in the corner of where pipe enters tank??

And then there is the question: if the tank is really water-logged, how much to let out? Should it be half-full of air to start? No idea how big that tank is…

Anyway very low on funds (money pit house syndrome!) and even if I was flush with funds the expert professionals five hours away aren't probably keen on driving out here for a job anyway (its -15 to -30 all week). So I am looking at DIY, if it's feasible. I guess that's the question! Any or all advice is extremely appreciated.

I'm pretty sure that running the extra three little radiators third floor properly is a worthy goal, making a "heat cap" for the house, so to speak? Dunno if there is any truth to that concept!!

We don't use that 3rd floor space much but I think "heat on all three floors" would be a good feature for when I sell the house in the near future. I bought this place with good intentions (and my wife has been very happy to use the space for her non-profit dog rescue "RUFFCUE") but my finances have taken a big downturn and I need to move back to positive cashflow as I'm only seven years out from mandatory retirement. You know the drill! 🙂

Anyway much thanks in advance for reading, and Merry Christmas to all 🎄🎄🎄

Comments

-

The 'square thing in the corner" might be a way to let air in- let's have a close-up. Also, where are you located?

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

I would pump the pressure up slightly by adding water to the boiler. You are about 12psi now. Get that to 15 psi. If you get some pressure out of the third-floor vent you have enough water pressure. If no pressure try 18psi. This dependent on building height and only building height. Check this with boiler and pump s are off.

Don't mess with the expansion tank yet. If the boiler relief valve is not dumping water the ex tank is ok most likely.

Bleed the 3rd floor and report back.

1 -

They even gave you a handy drain valve. Which, once you have opened it, will leak when you try to close it, so get a cap for it and use that (should be the same as the cap for a garden hose bibb).

Then it's easy. Close the valve from the system to the big tank. Open the drain valve. It will glug and gurgle and release a pretty fair amount of water, at a guess. Be patient. You want ALL thew water out of it, and since that drain is all you have it's going to take patience.

Once you are reasonably sure it's really truly empty, close the drain and open the valve to the rest of the system. Then go and bring the pressure up to where you want it — around 18 psig cold should work.

You may have to repeat the bleed process on the radiators… sorry about that.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements