Baseboard heaters lukewarm despite boiler being hot

I have a Burnham Revolution Gas Boiler and I'm at my wit's end as to how to get the house warm. It's an old boiler (about 24 years old). We are located in Massachusetts (cold weather) and bought the house earlier this year and immediately did some renovations before moving in. In the early days of the renovation (Dec/Jan timeframe), every time I visited, the house was very hot (the workers used it quite a bit). By mid-January, it had stopped heating up and I had a plumber look into it. We moved in in March and it was better but the weather wasn't too cold either.

The house is about 3000 sq ft (400 sq ft in finished basement, 1500 first floor, 1200 second floor). Now that the cold is back, the boiler can't keep up. When it's below 20F outside, the rooms can't get above 63F.

The boiler has 5 zones (1 basement, 1 first floor, 1 upstairs and 1 master bedroom upstairs and an indirect hot water tank). There is 1 TACO cast iron circulator pump, 1 TACO 6 zone valve controller, and I have 5 TACO zone valves. The thermostats are fine and the relay calling for heat lights up when the thermostats call for heat. The boiler temperature gauge typically heats up to 220F anf the pressure gauge still gets to between 20F and 25F. The supply pipe on the boiler seems to get hot (although it never feels scalding and can leave my hands on it for about a minute). However, the baseboard radiator pipes don't get as hot (feel warm at best) and the air coming out doesn't feel hot. Even my basement with its smaller sq footage and proximity to boiler doesn't get hot.

I've had a few plumbers come to take a look but it's still not fixed. Things tried so far:

- Draining each zone: I drained each zone (except the water heater) for about 30 minutes and it made no difference

- Replaced circulator pump: One of the plumbers did this and no difference

- Replaced Air Vent Valve: Mine had leaked so another plumber did this but also made no difference

I'd have thought it'd make sense to replace the boiler at this point but it seems to be working fine i.e. supply pipes are getting hot. The plumbers I've used don't have answers. Would appreciate any guidance here please.

Comments

-

-

with the stats calling,

do you see the lights lit on your controller?

and are the manual levers free swinging on the valve bodies?

if you're sure the circulator is running, then you're probably air bound,

is the circ hot? too hot to touch?

known to beat dead horses0 -

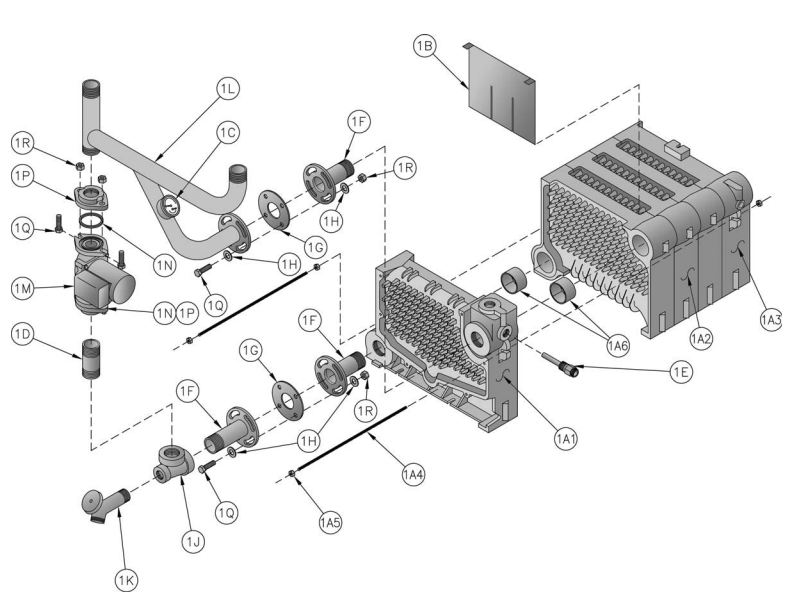

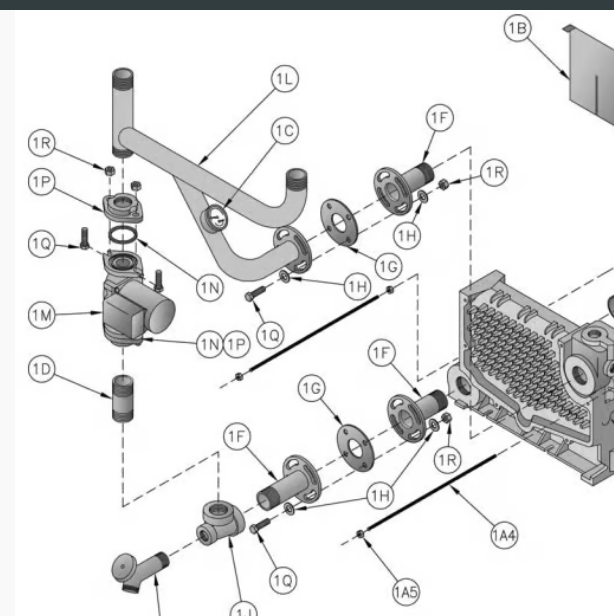

here is what they look like under the hood and there were a few different versions of the beast.

Manual attached below

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks. I already replaced the circulator pump. Are you saying there's another pump to be considered?

0 -

Thanks. The lights are lit fine on the controller. The manual levers have a lot of friction and seem fine. I also recently replaced one of the valve heads for one of the zones. No real difference made to that zone in terms of temperature.

The circ isn't too hot to touch. But when a zone is calling, I can hear it operating and the pipe on the outlet is very hot.

Can I still be air bound? I just spent about 3 hours bleeding out the zones a couple of days ago. The pressure of the water coming out of the return valves into the hose didn't always seem high though. But it didn't seem like there were any air bubbles by the time I was done.

0 -

@yoyotogblo you mentioned the boiler was at 220 degrees. Then you mentioned you touched the pipes near the boiler but they were not scalding hot. For reference, if you grabbed a pipe that was 110 degrees on the outside with bare hands, you could not keep your hand on it for more than a few seconds. My point is, it sounds like the boiler water is not actually circulating.

Based on the manual that Hot Rod (Bob) linked it appears there is some sort of factory bypass. Like others mentioned, maybe there are two circulators? Maybe the system circulator is fine and the boiler bypass circulator (Taco 007 as per the diagram) has failed?

1 -

Very interesting. Thanks for this. I just tried holding it again and actually, I was very off . Can only hold it for about 2 seconds before it burns my hands.

Didn't actually realize there was another circulator pump on the boiler but see that now. Shouldn't be too complicated to change as the system circulator is very similar (also a Taco). Do you still think it could be the circulator pump especially considering that the supply pipe is actually very hot?

0 -

Fwiw, I can only hold the pipes from the open taco valves for about 3 seconds before it burns my hands.

0 -

That boiler has both an internal bypass circulator and an electronic injection controller that operates it. Either can fail and cause the symptoms you have noted, and since they are inside the boiler cabinet the failure is not obvious to those not familiar with that particular model.

This happened in a building where I lived in Boston. The boiler techs were mystified until I told them about the extra pump and controller, after which they were able to fix it.

—

Bburd0 -

How much water pressure is in the system? Should be 15 psi for up to a two-story house. Look for a heating guy instead of a plumber

0 -

if the internal circ is not running, or the control for it is bad, it will not flow properly. It’s a simple fix.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thank you! I am going to check the internal circulator (didn't previously realize there was one) and if it doesn't seem to be working, will go buy a replacement and get it changed out. Lowe's sells the taco 700f also so that works out perfectly

0 -

Thanks guys. I checked and the taco 007f in the boiler wasn't working. I then changed that to the Taco ecm 007e and that wasn't getting power (no orange LED). The VS3000 circuit board of the boiler has the green LED on so it might be a problem with a wire. Going to have an electrician come check it out. Appreciate the call to check the circulator pump. If there's anything obvious I can try myself before calling an electrician, would appreciate suggestions also. Thanks!

0 -

the circ inside the boiler needs to be a non ECM type

It has a tekmar variable speed control operating it, so only the old style PSC pump will work

Grundfos 15-58, 007, Wilo Star 21, etc

In a bind you could jut wire a cord to the pump inside the boiler and let it run until you troubleshoot the control

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

Make sure your boiler is at a reasonable pressure when bleeding the system or you could be wasting your time. I'd say anywhere from 15-20 psi depending on how many stories your house has.

0 -

Crap. It was so difficult to change the circ pump because there was barely any spacing between the 2 pipes.. Had to remove the other circ pump and loosen a lot of bolts in the boiler itself to be able to move the pipes.

Thanks for letting me know. Can the system circulation pump be ECM? Maybe I'll just exchange them. The new system one is currently a TACO Cast Iron pump (looks like what was in the boiler and system previously).

0 -

I thought when bleeding, I needed to increase the pressure so it could properly bleed out the top floor (and any other floor with low pressure).

0 -

i'm not a fan of mod cons that cram a lot of extra stuff in them for this reason. also many more things to leak on the control board.

0 -

Yes the way the installed that circ inside on rigid pipe makes it a job to get out and a new one and new gaskets in.

I would have just swapped out the powerhead with the allen bolts, leave the old body in if you had an exact replacement.

The Revolution was Burnham's answer to the very popular Weil GV series, but it was a beast of a boiler to install, had a one off control system, had a weird factory vent termination, and I think some came with Honeywell Smart valves which added insult to injury.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Burnham leaves a lot to be desired IMHO

0 -

Had been away but just got back and now, need to deal with this.

I hard wired the pump for now and that resolved the issues. I've also ordered a new control board and would replace it once that arrives.

I have a new issue though unfortunately. My house has 4 zones (excluding the hot water zone). 3 of the 4 zones get very hot (touching the pipe from the taco zone valve for a second is scalding). However, the upstairs zone valve pipe gets very hot but not scalding. Because it's upstairs, the baseboard heater never actually gets hot.

I've replaced the taco valve head but that didn't make any difference. I've also manually opened the valve but no difference either. I'm beginning to think there might be something wrong with the zone valve.

Any thing else I can try to single out the issue? Thanks

0 -

Turn all the other zone off and run just that upstairs, do it get hot now? If so it has adequate flow and you may need to balance down the lower, shorter zones to allow more flow to the longest most remote zone.

Did the upstairs heat adequately in the past?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Still doesn't get hot. It used to get very hot upstairs so something has changed.

0 -

Did you introduce air in the system with the work you did? Must have if you changed the circulator? Did you do a thorough purge? Air tends to get stuck on the highest part of the system.

0 -

I haven't purged since replacing the circulator pump. Let me do that now then. Thanks

0 -

Yeah, just started purging the upstairs zone again and there's a ton of air (water barely coming out actually , mainly air) and the water is very dirty. Must have introduced a lot of air when I changed the circulator pumps. Going to purge all zones now.

Thanks

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements