First New install

I’m installing a new Utica Oneida CO-150 combination boiler/water heater in a new addition

Going to a new radiant floor system imbedded in concrete

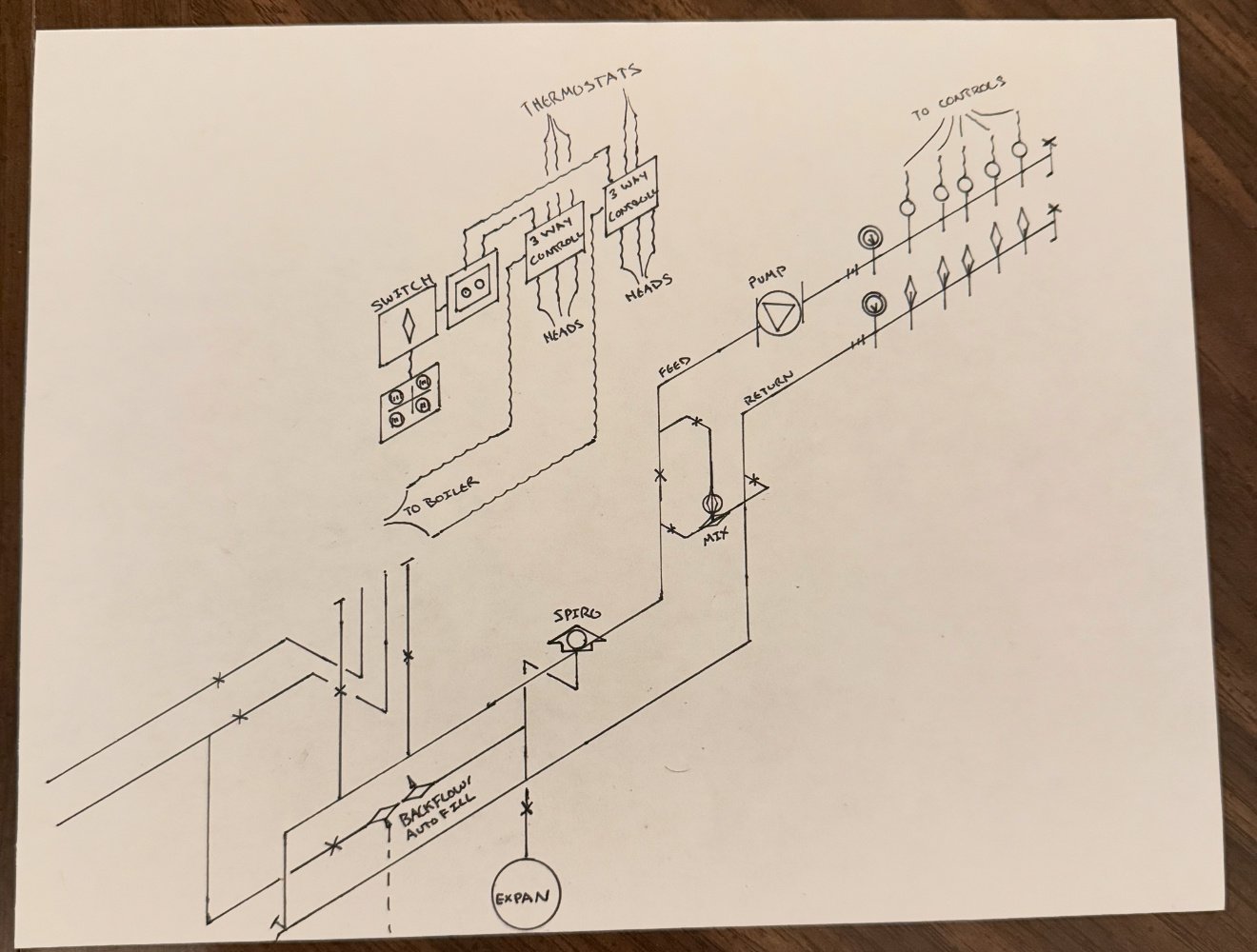

5 zones, Am I missing anything? Couldn’t find a good diagram to go from so this is what I drew up

Any advice would help tremendously thank you

Comments

-

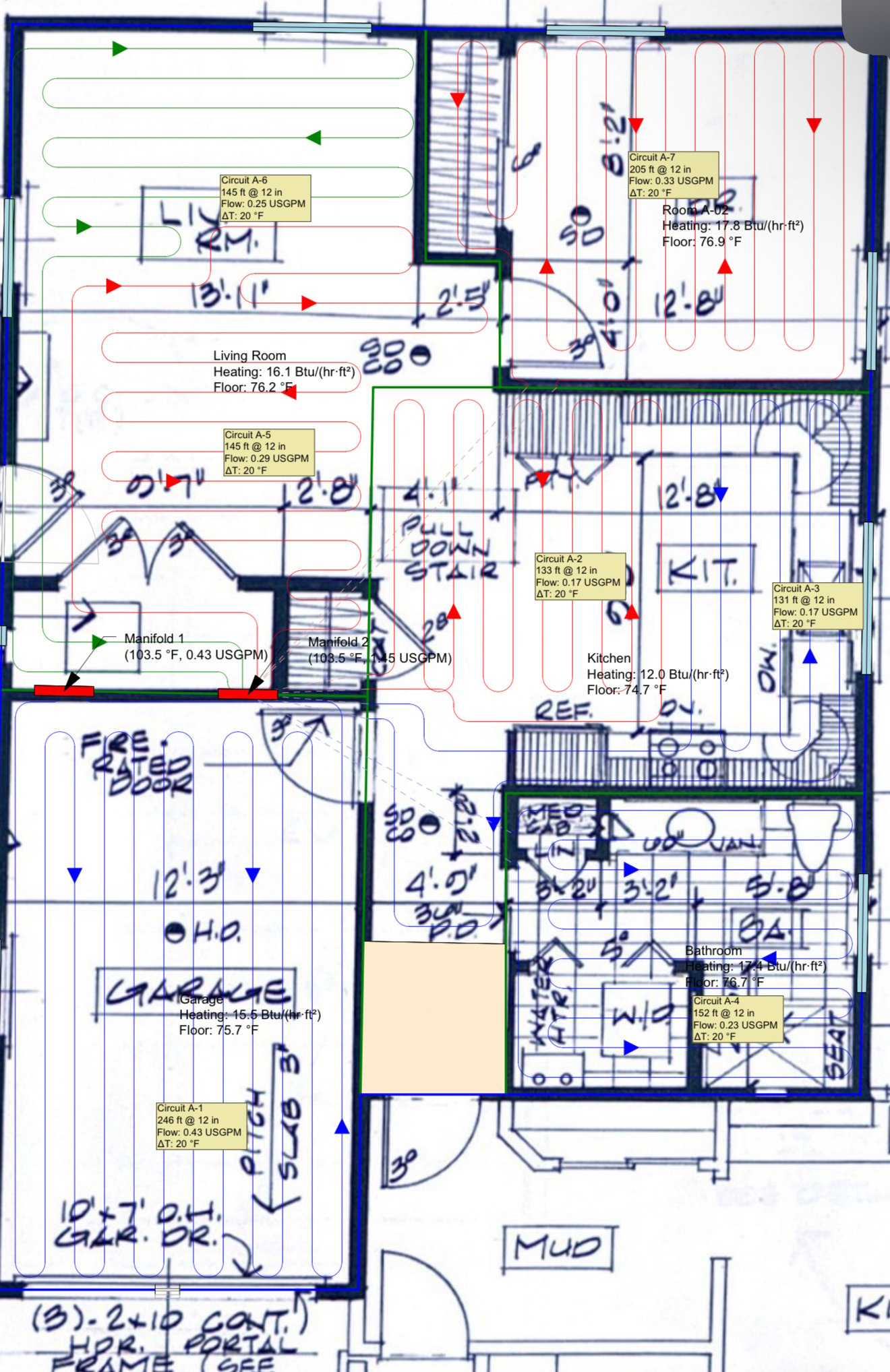

you need to start with a heat loss calculation then use radiant design software to figure out your loop layout and if 5 loops is appropriate.

I'm not sure the relationship of the circulator and mixing valve are correct. If you use a boiler with the correct controls you can just set it to an outdoor reset curve for the radiant on a domestic heating call and avoid needing the mixing valve.

1 -

-

You will short cycle the boiler to death with 5 micro zones like that. And they’re probably not necessary or effective unless there’s a thermal break between each zone.

As hot-rod stated, there’s no need for a mixing valve unless there’s a different WATER temperature zone that’s not shown. The ODR function of the boiler is all you need to control the water temperature and it will do a much better job than a thermostatic mixing valve.

As mentioned, you need to start with an accurate heat loss calculation (Manual J) since that’s the foundation for properly designing everything.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Thanks for all the helpful info,I’ll definitely look into it

here’s the layout from the program with the heat loss calc, and the loops are already run out in the floor.

I’m just unsure how to pipe the boiler device and such

It’s a combi unit so it does heat and hot water but the only heat on it is the radiant floor. So I probably wouldn’t need a mixing valve but just looking for opinions

0 -

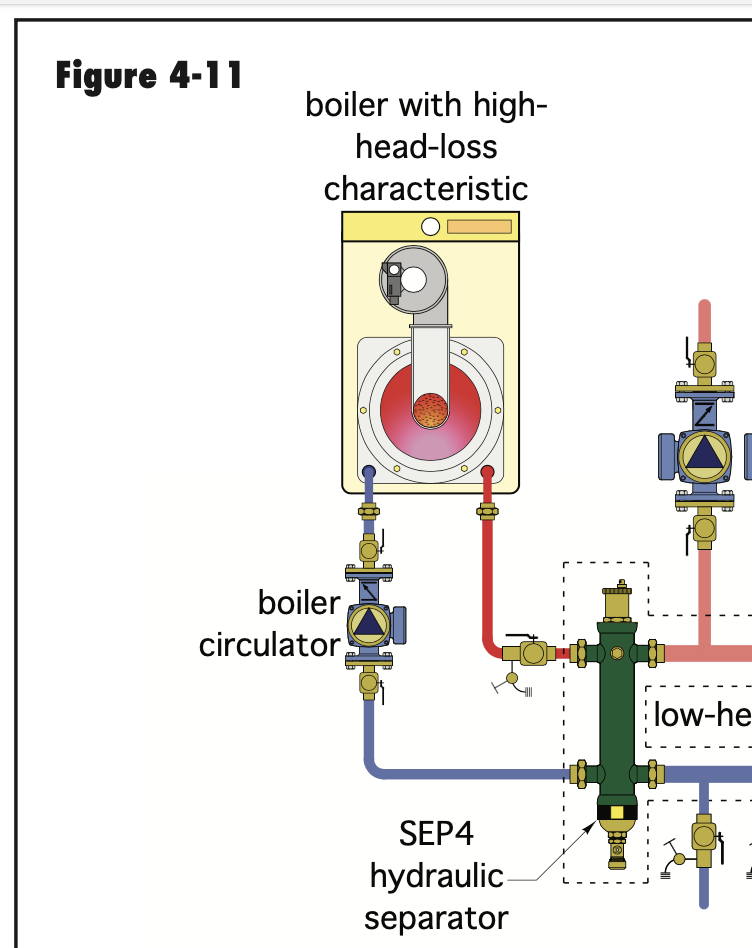

No mix valve needed for space heating then. Your general schematic is correct but I would cut out the mix valve, and separate the boiler from the system with a hydro separator. I prefer the caleffi sep4 with magnetic dirt separator and air separator. If you use the sep4 or similar I would then move the expansion tank to the return on the boiler side with service valve attached, the hydro separator will also be taking over for the spirovent. Since your combi boiler will have a built in pump locating the expansion tank on the return of the boiler side of the hydro sep will position the tank well to establish a point of no pressure change. I would also urge you to use some sort of controlled make up water system, a glycol feeder filled with DI water (or glycol mix if using glycol) or a field constructed filling station. I don't like having an uncontrolled domestic water connection on a boiler system if I can help it, I'd rather know there is a leak and then fix it.

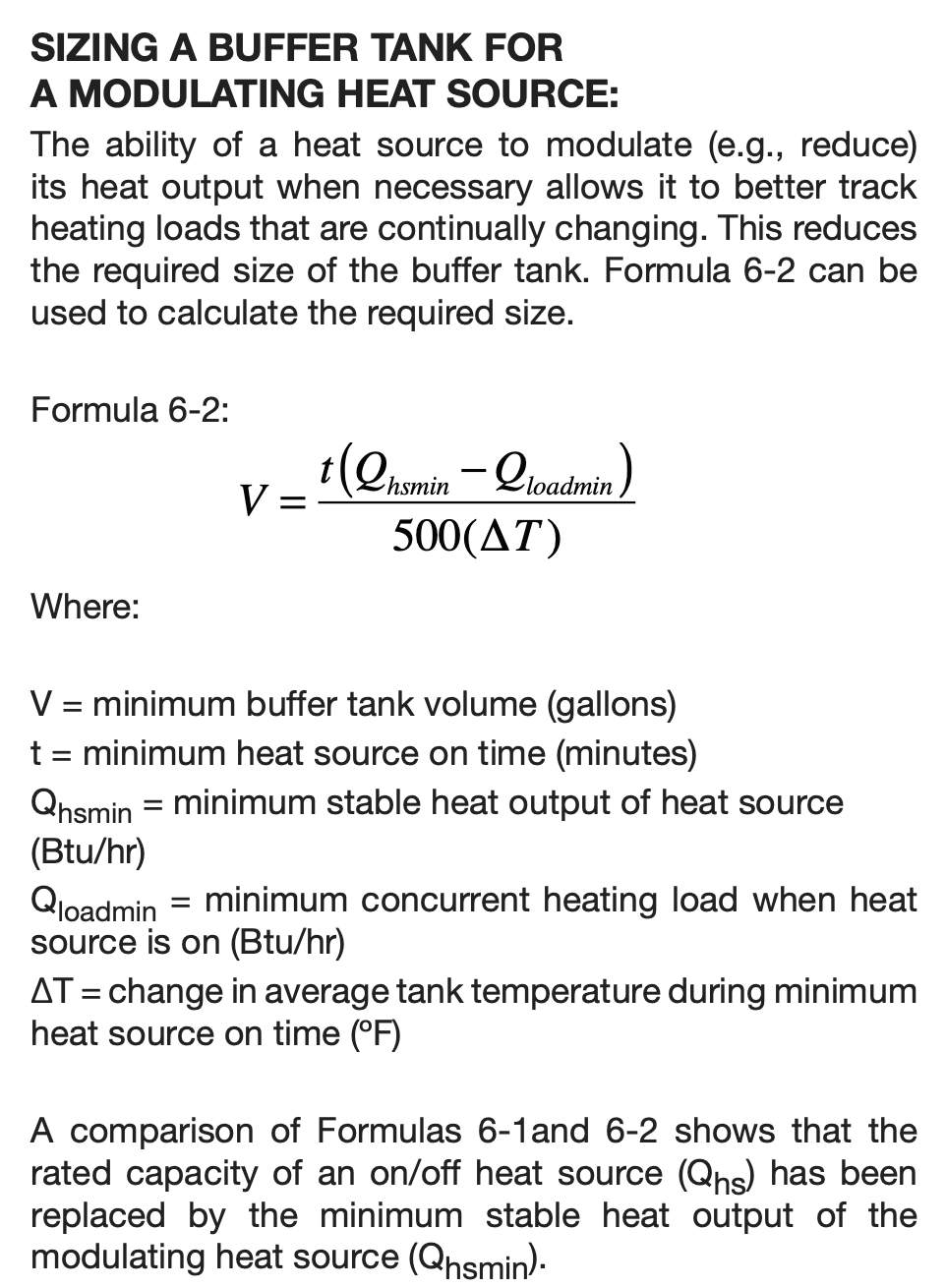

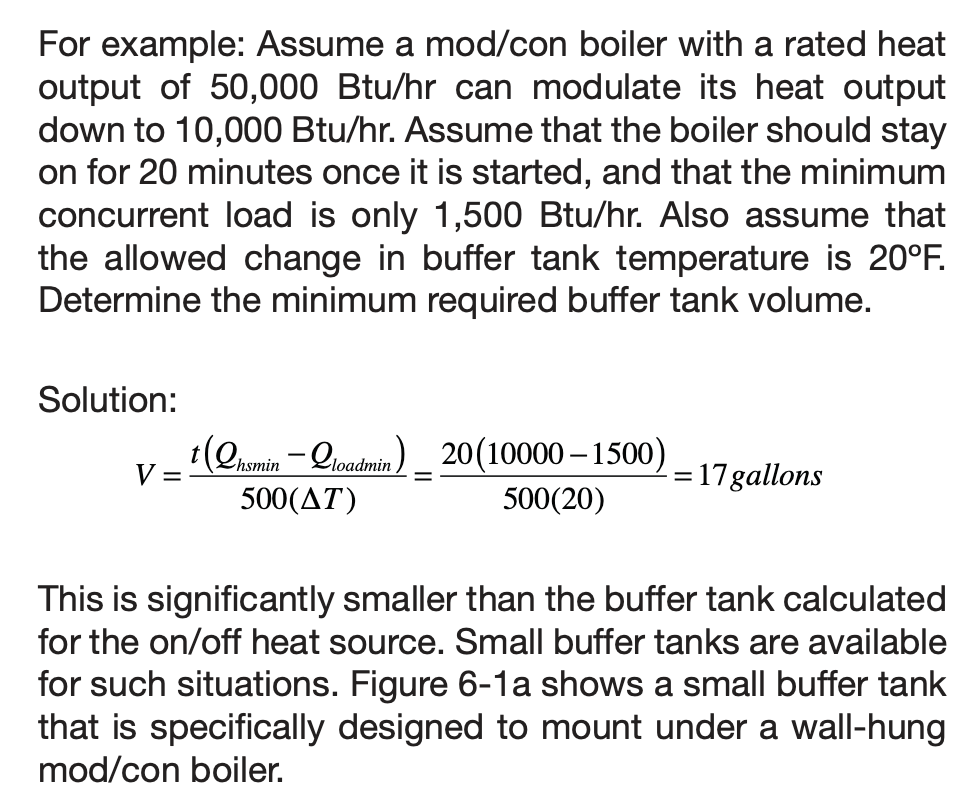

There is some validity to micro zone concerns even with a mod/con. Usually I would try to size the boiler and layout zones, so that the smallest load zone is greater than the boilers low fire rating. This is hard with a combi sometimes as your DHW load is typically higher than the space heating load. If your boiler won't turn down low enough for your smallest zone I would consider a small buffer tank. Depending on exactly how micro the zones are this may or may not be a big concern. Best practice would dictate the use of a buffer tank in place of a hydro sep, but there are lots of well functioning systems that probably should have a buffer and don't.

1 -

Zoning is one of the selling features of hydronics, but there are pros and cons.

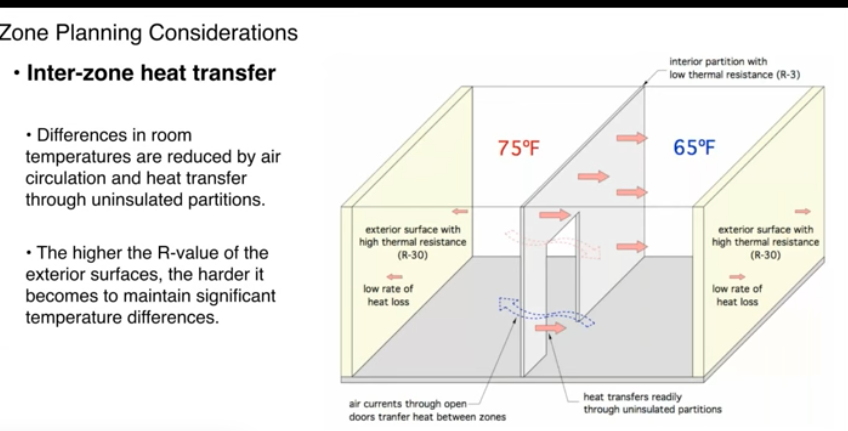

If the goal of individual zones is to keep rooms at different temperature there are some limitations on how much temperature difference is obtainable. This graphic helps explain the concept of inter zone heat transfer.

Your boiler control can maybe help cover some of the issues that may crop up with micro zones.

I have a Lochinvar Knight and it has some control options that help lessen short cycling

Gradient Limiting if the boiler temperature is rising too quickly the control reduces the firing rate to the lowest setting

Ramp Delay, you can program the boiler to stay at the various firing rates, for a programmed time period. So I keep mine at the lowest turndown, 15% for 10 minutes, next step for 10 minutes, etc. 6 limit intervals can be set with any desired time.

Anti Cycling, this keeps the boiler from re-firing for the time period you set. So you could force the boiler to stay off for 15- 20 minutes. However the tradeoff for that is you are not heating the space if the boiler is being held off😯

See what options the control on your boiler has to fine tune it to your system.

I like adding buffer tanks to completely eliminating any short cycling, but it adds cost and complexity. Here is the formula.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements