new boiler versus old boiler

New boiler near piping installed nov 2025. Old boiler installed 1964 - it replaced a coal gas fired boiler. Original two pipe vapor system (1926) to converted gas fired original boiler to Weill Mclain 120000 btu (1964) to Utica 150000 btu (2025).

Prior to the new Utica boiler, the system had performed exceptionally - no banging, all radiators were hot.

Currently the only way to get upper room lower radiators hot requires setting thermostat 4 degress higher. 5 radiators lower floor. 3 radiators on upper floor. Raising temperature 2 degrees - upper radiators - no heat. lower radiators only warm.

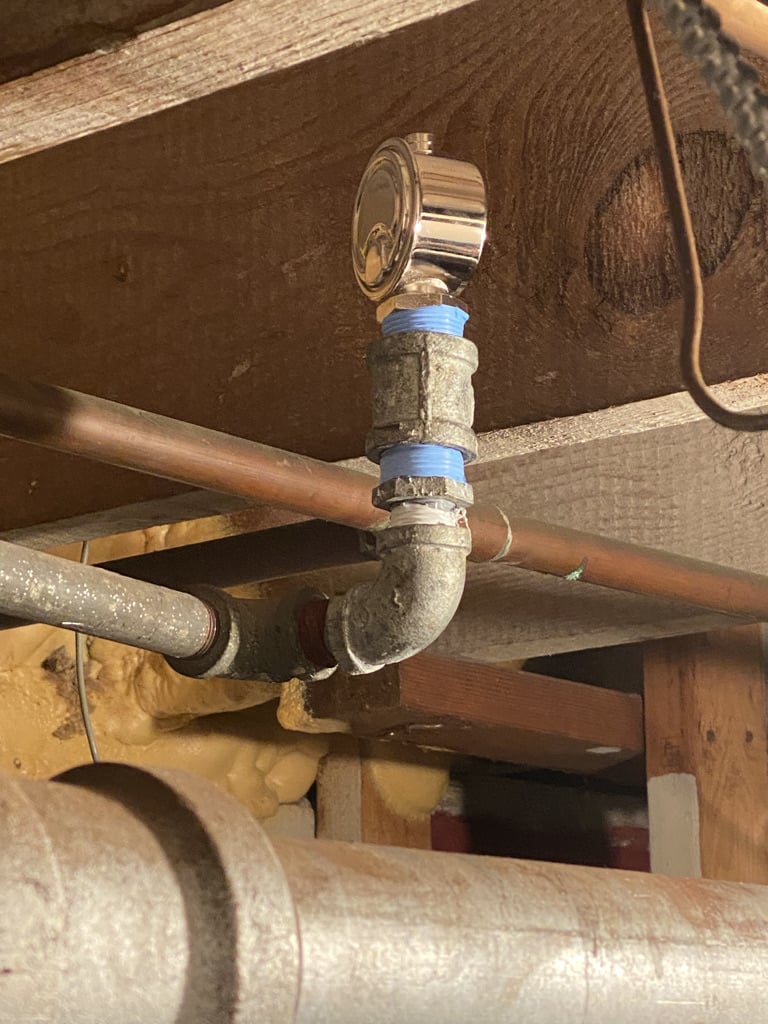

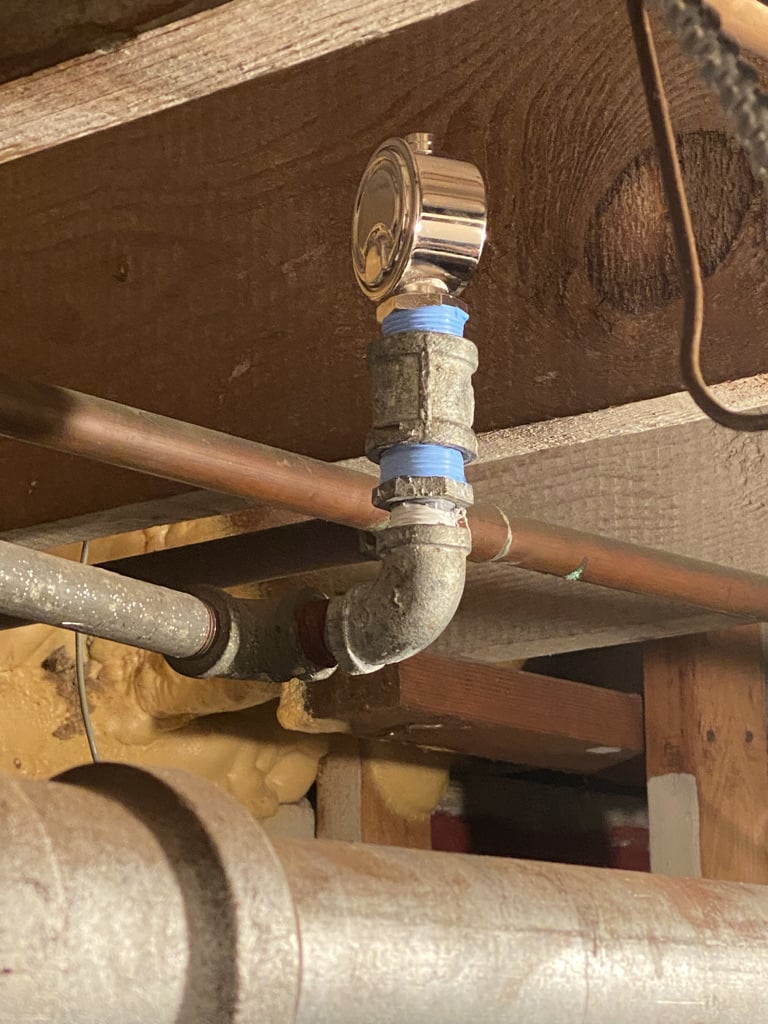

New system included new thermostat and vaporstat. Contractor has been out three times adjusting vaporstat - same problem. Third visit replaced Hoffman with straight vent. System is not a vapor system now. same problem. Question - should a drop header near piping been used?

All original steam header piping, radiators, feed and return lines are still the same. Radiators have no traps - only standard 90 elbow. Only one Hoffman pressure/vacuum valve.

Comments

-

Unless you added steam traps to everything that is counting on a low differential pressure between the mains and the returns, you still have a vapor system.

Where is the hoffman differential loop? It should be near the one and only vent in the system.

0 -

are all the vapor valves still on the radiators?

0 -

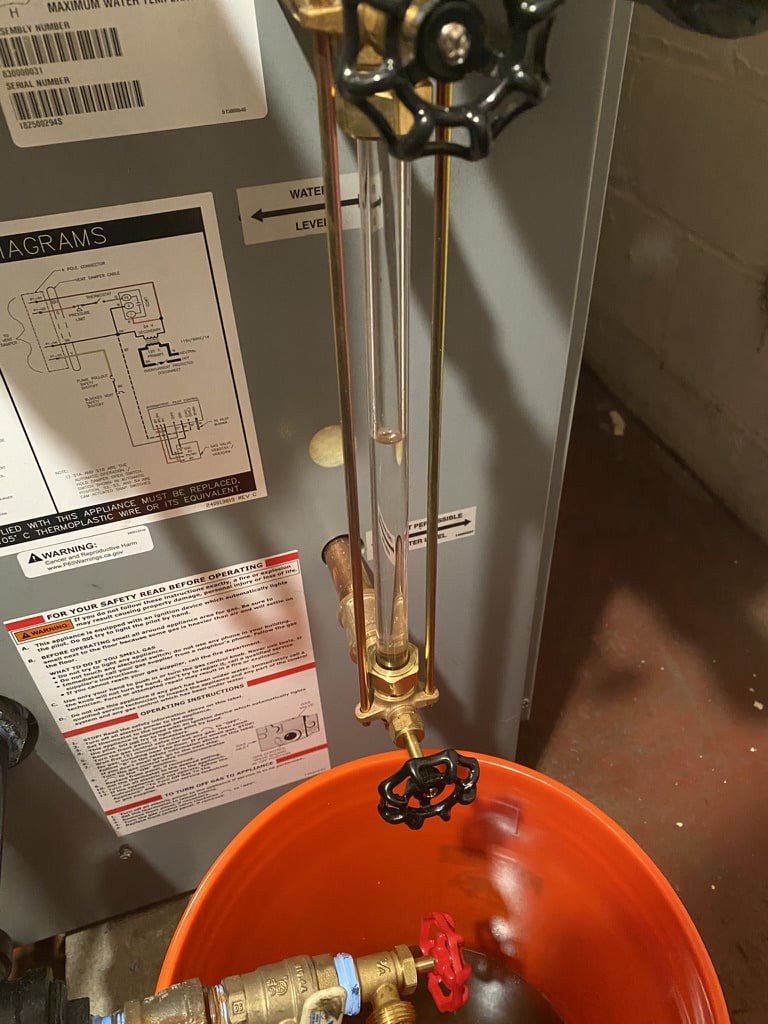

Where is the water level? I don't see it in the sight glass.

0 -

Looks like he piped it right and the sizes are correct. The only thig you should drop the equalizer below the water line before using 90 degree elbows.

How it the water level when it is steaming? Fairly steady or bouncing a lot?

Did the contractor shim the boiler?

Did he measure the radiators when sizing the boiler?

Why did he go up 30,000 btus with the new boiler?

1 -

Since it is a vapor system if anything undersizing the boiler a little bit would probably work out best. The boiler is sized by measuring the equivalent direct radiation of the radiators connected to it.

But that isn't your problem, that will just cause it to cycle on the vaporstat if it is oversized.

What is the vaporstat set to? The cutout should be somewhere around 8-12 oz/in^2.

0 -

the radiators have never had any traps or vapor valves. The Hoffman 76 is the only vent on the return line to the boiler. The 76 is a pressure and vacuum vent. That vent is mandatory for a vapor system. Using a straight vent turns the system to non vacuum.

The system has no hoffman differential loop

THe issue - the old systems worked fine - only change was new boiler and near piping. - same two pipe system, radiators and returns - New system passed inspection of new boiler install.

water level

0 -

The vacuum vent makes it a vacuum system. It is still a vapor system with a regular vent. The radiators have to either have metering valves on the inlet or orifice plates. I think the Hoffman metering vapor valves look like ordinary radiator valves. The hoffman differential loop is just a fancy loop of pipe that lets steam in to the returns if the differential between the mains and the returns gets to high. Without the differential loop or controlling the differential some other way like keeping the pressure very low with a vaporstat, steam will blow through the radiators and into the returns and keep other radiators from being able to vent and heat.

In a vapor system the inlet to the radiator either has a special metering valve or an orifice plate that combined with a regulated pressure in the mains limits the amount of steam to less than the amount that the radiator can condense so all of the steam condenses before it gets to the returns. That is how vapor systems can work without radiator traps. The mains will have some sort of return connection and crossover traps to allow air to vent out of the mains through the vent in the return.

0 -

Simplified version:

Removed old boiler - had to replace cracked boiler

Installed new boiler

connected new boiler to header

new system not heating radiators like old system did.

no changes were made to above piping or radiators

0 -

I'm trying to explain to you how the system works and what to look at. The near boiler piping is part of the system. There originally was a hoffman differential loop at the boiler that regulated the pressure so that the controls built in to the radiators worked correctly. I'm trying to figure out if that is still there or if it is relying on the vaporstat to provide that function and to find out what the vaporstat is set to.

The way the mains connect to the boiler isn't quite correct either but it might need to be that way for the differential loop to work which may or may not still be there, i can't see everything that is going on to the left of the boiler.

0 -

Absolutely critical. The vapourstat MUST be set to cutout at no more than 7 OUNCES per square inch (0.42 psig). Differential set at 4 OUNCEES. You should add a low pressure gauge (0 to 3 psig) to verify the pressure settings.

Anything more than that and the system will not work properly, if it works at all.

I don't seem to see any evidence of a Hoffman Differential Loop, and it quite possible that it never had one; only Hoffman Equipped Systems did. Or it may have been removed in some previous "improvement". in any case since neither it nor any other similar device is there, you are entirely dependent on the correct vapourstat settings.

Everything else is secondary at this point. You seem to have main vents in odd spots; Odds are the only vent you need is that big Hoffman, unless someone removed the crossover traps — in which case you probably need more main venting, but we can fix that later.

The oversize boiler isn't going to help, but what's done is done as far as that goes.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

Upsizing the boiler like they did isn't helping anything. The vent on the main is inadequate to vent for the entire system, and that is being amplified by the too big boiler. The original was quite possibly oversized and they went even bigger. Unless every one of those radiators is huge, the boiler is too big. We would need you to run the EDR calculations to be sure. That would be an academic exercise at this point unless you think the contractor would swap out the entire boiler.

You may be able to get it to work acceptably by increasing the main venting dramatically, best guess by a factor of 6 since the vent is trying to vent the entire system rads and all. We would need to know length of the mains and possibly system EDR to give better input on the vent sizing.

My best guess based on given information. The anemic venting is restricting steam flow, that restriction causes the pressure to rise, the vaporstat trips on pressure before everything is heated, when it restarts it keeps moving slowly, but the lower floor radiators are already heating. The thermostat then kicks it off because the first floor is satisfied, but the second hasn't really heated acceptably yet.

To be very clear on system pressure. Pressure is a function of boiler size, to system size, with venting mixed in. Get one of those out of balance and the system will fail to perform. Boiler sizing is extremely critical because of this. Too much boiler and things get out of hand in a hurry. I've experimented with my own system and I can tell you 25,000 BTU's one way or another changes my entire system dramatically. A huge system can act as a better shock absorber for bad boiler sizing, but a typical residential system is relatively small and sensitive to sizing.

1 -

Proposal Notes from contractor: From the radiation survey I performed and factoring in your homes size, windows, etc. I calculated your home can handle around 375 square feet of steam which puts that in the range of a 150,000 BTU/HR steam boiler that puts out 383 square feet of steam. I believe the Utica Heating UH1605HSID steam boiler will be a great fit to properly heat your home. This is roughly the size of your existing boiler.

The above radiator survey was short one radiator of 65 sq ft. New total is 440 sq tf

The main is uninsulated - 68 ft

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements