Small Delta-T hydronic system

Morning!

I’m having an issue with very small heat transfer on a hydronic unit. The unit is a weil-mclain gas boiler, two zone valves and a Taco 007e pump. Confused as I am getting only a 3-4 degree difference in temperatures between the supply & return piping and I can’t figure out why. It is also my understanding that if I were to try and throttle down a zone via a manual valve, that the 007e would account for this and defeat the purpose?

Needless to say, the baseboard radiators are warm but the house is very slow to heat up.

Any thoughts appreciated!

Comments

-

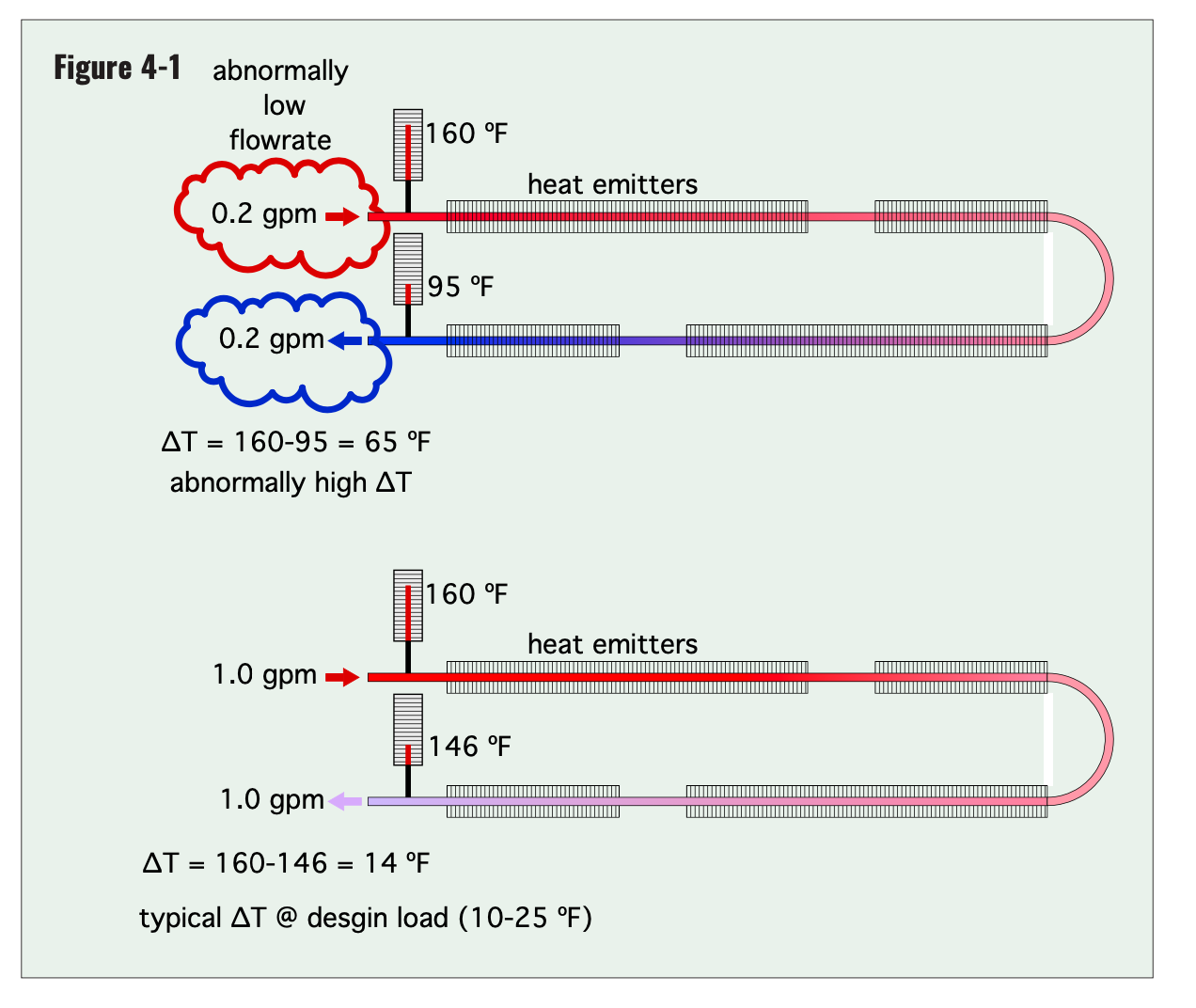

The delta T on a system is a moving number. We choose a ∆ for a design but a system may never operate at the exact number. The delta varies based on the load of the space. In a cold room expect to see a wide delta on start up.

As the room warms the ∆ will tighten up.

The determine the actual operating delta the system needs to get to thermal equilibrium. This is the point where the supply and return temperature have stabilized. 10- 25° is a typical fin tube design ∆.

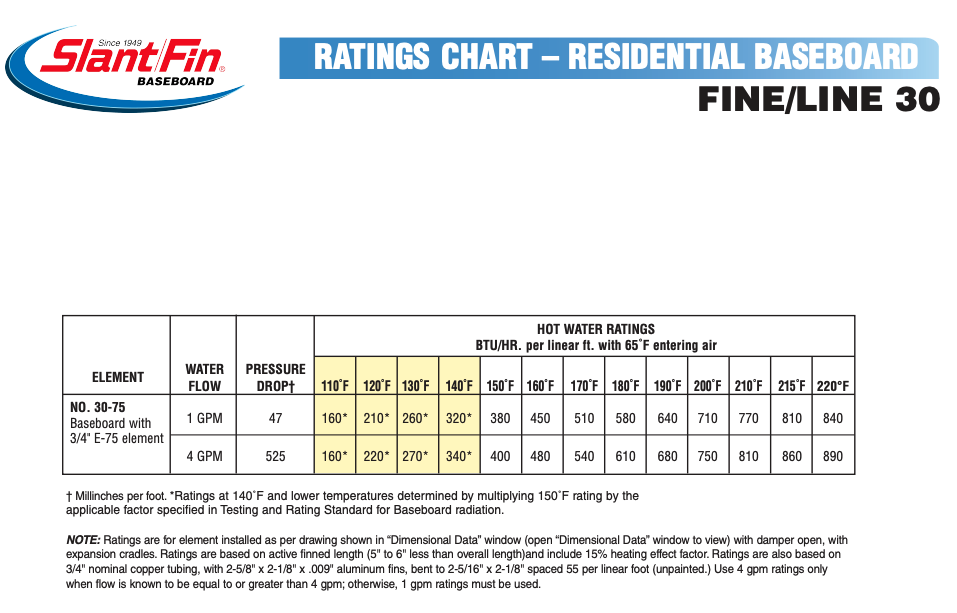

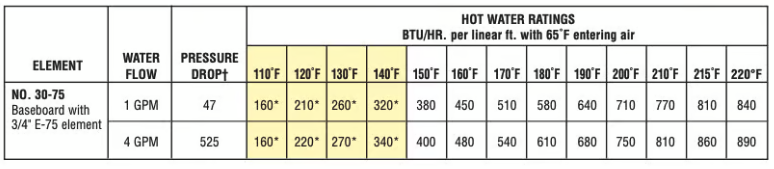

Fin tube spec sheets usually show BTU output at two different flow rates. Slantfin shows a 1 and 4 gpm.

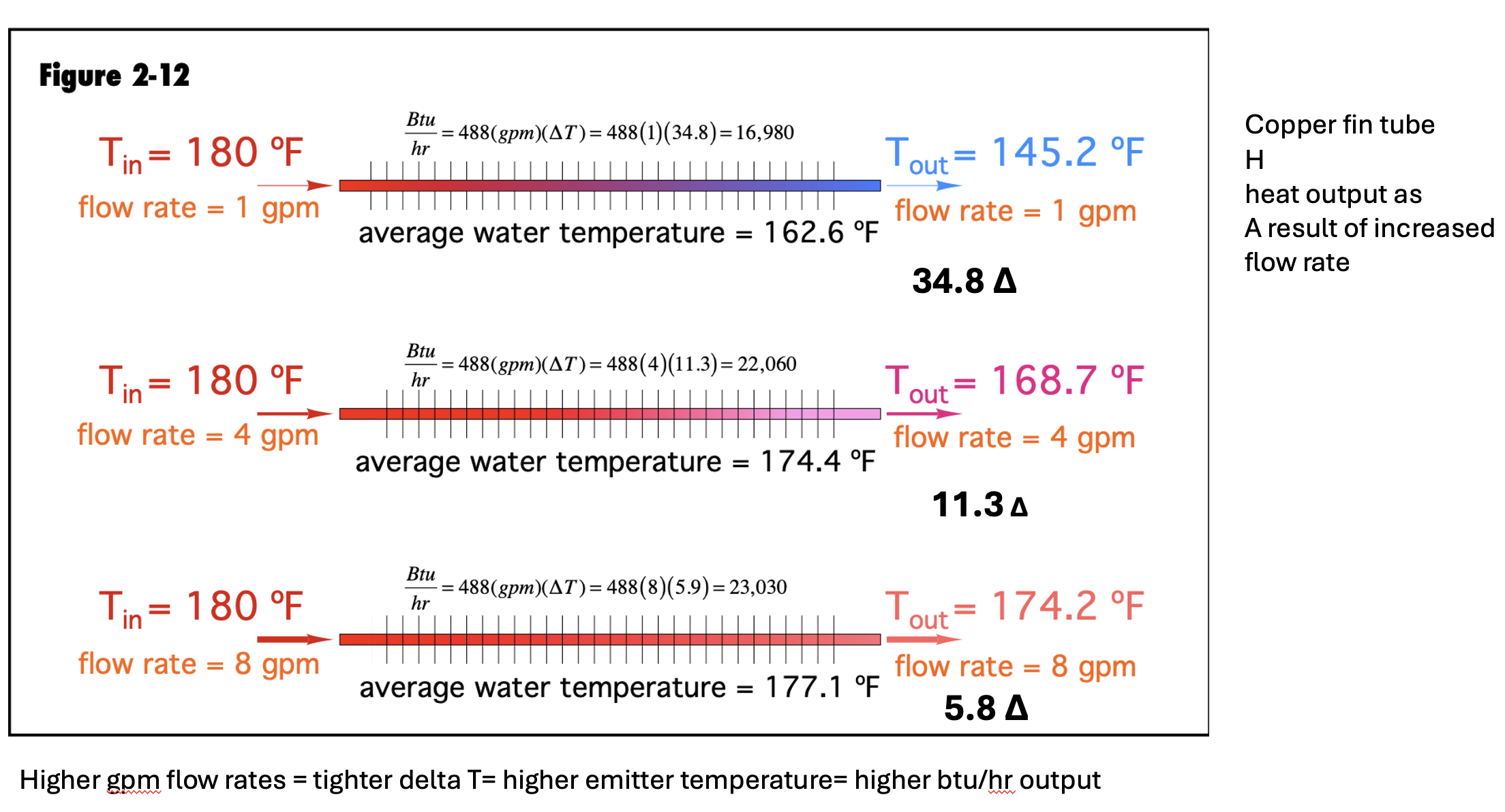

Here are some graphic of how various ∆s effect the heat output of a strip of fin tube. As flow increased the ∆ closes up. That equates to a higher AWT average water temperature across the heat emitter, higher BTU output. For 3/4" fin tube, 4 gpm is about the max, without getting velocity noise.

What is the temperature at the first fin tube on the loop? Two ways to increase heat output are to raise the supply temperature, or increase the flow rate.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks for data, love that stuff. The first emitter was around 150 degrees. I could increase supply temp for sure… My main concern was that there was a high demand — the house was at about 56 degrees at the time of startup. The circulator would run for a long period without the burner on because the water was still coming back so warm… it was taking an extraordinary amount of time to increase the temp of the space a few degrees.

0 -

Various brands of residential fin tube will have similar out put. 150 SWT isn't giving you much BTU output. and that temperature drops along the series. Most fin tube designs are, were, based on 180 SWT

You are sure the pump is actually circulating when you take measurements? The tight number you observed could bve the pump has just turned off, no water is moving?

I don't believe that 007E is a ∆T function? Maybe a ∆P function for zone valves?

Bottom line you need temperature differential and flow to transfer heat hydronically.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

It sounds like water is moving and I can see small variations in the pressure gauge when it is on vs. off. So yes, the circulator was running when I recorded temps. (Note, this system is not/could not be set up pumping away as it has an indirect DHW coil and install instructions limited the location of the circulator to the return side).

It seems the 007E pump makes adjustments based on inferred head pressure (inferences made via electrical draw on how difficult it is for the impeller to move water) so no, it does not directly adjust baed on delta T.

I will crank up the SWT to 180. I experimented with restricting some flow on the zones and was able to get up to about a 10 degree differential, despite other info suggesting that the 007E pump would account for this…

0 -

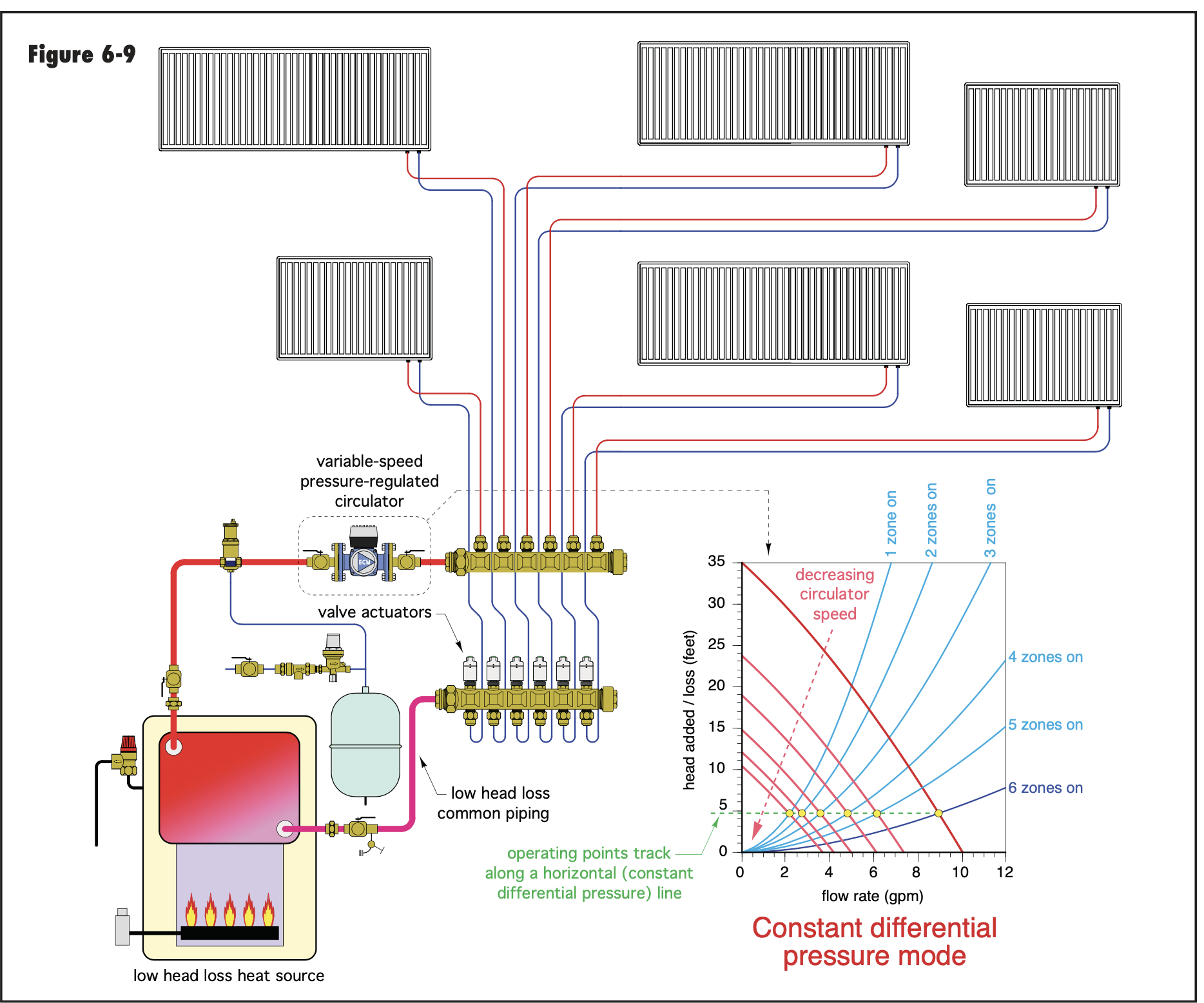

The ∆P circulators that adjust flow do so based on zone valves opening and closing, so a multi-zoned system, is that what you have?

It will not make any flow adjustments on a single loop circuit.

Here is an example of how delta P circs looks/ works

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

yes, two zone system controlled by Taco zone valves

0 -

If the pump is programmed properly you should see, hear it modulate as the valves open and close. Some pumps have a display that shows you the change in W or gpm.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Also Check the orientation of the finned elements within the baseboard enclosure. I recently ran into a job where we did a boiler replacement and the initial installer had positioned the fins incorrectly and there was poor convection across all the baseboards with very low delta T.

0 -

The question I would start with is, has it ever worked satisfactorily? If the answer is yes, let's focus on what has changed since it last worked. If no, that's a little trickier, we're looking at some sort of design issue.

The heat output of a radiator is given by the flow times the temperature drop. If the heat output is less than what is wanted, either the flow or the temperature drop has to increase. Generally, to increase the temperature drop you have to increase the water temperature.

If it worked at one time, my first suspicion would be flow has become diverted or obstructed. I would make sure the system was free of air before checking anything else.

1 -

Plugged strainers is another common flow blockage that sneaks up on you slowly. Any Y strainers in the piping?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks — more great suggestions. Will definitely start simple and conduct a thorough air purge to rule that out…

This is the first time diagnosing and checking the delta T on this system, so I can't answer whether it is a new problem or not.

0 -

Flow is not your issue here, if the delta t is low, the flow is high and more than enough.

It looks like you had a very deep setback of the air temp in the house and with the boiler only making 150F, the response time was slow. If your boiler is running with an outdoor reset controller, deep air temp setback is not what you want to do with the boiler operating at lower temps. you can do air setback, just not 15 degree setbacks.

So what you experienced is normal for a not normal situation.

Dave Holdorf

Technical Training Manager - East

Taco, Inc

2 -

That was my understanding from the beginning (that I was dealing with too much flow, not a restriction).

The setback was not intentional; the boiler was down due to a bad flame sensor. Once replaced and the boiler was back in service, I was just checking overall function and noticed the very small delta and long heating time.

0 -

Delta T is actually the answer to an equation . Hot Rod's chart along with the Slant Fin chart are being used out of context and dare I say , nefariously here as they are many times by some . One thing that they do clearly show for those who would listen is that higher average water temp does NOT deliver more BTUs to the space being heated . It's really very simple , If an emitter with an AWT of 162.6* had a Delta of 34.8 and the same emitter had an AWT of 174.4 had a Delta of 11.3 the lower AWT emitter CLEARLY delivered more heat to the space having a lower AWT . This cannot be intelligently argued without me asking anyone who reads it , WHERE did the twenty three and a half DEGREES go ? Before anyone attempts to dispute this remember that Hot Rod also said , "

Bottom line you need temperature differential and flow to transfer heat hydronically.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dreamGood luck .

You didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38331 -

@Dave H_2 : "Flow is not your issue here, if the delta t is low, the flow is high and more than enough."

That's assuming the flow is getting to the radiators. If you have primary-secondary piping, or radiators in parallel, you can have plenty of flow circulating but little of it reaching the radiators. If the flow isn't reaching the radiators there's going to be little heat loss and a small delta t.

0 -

Heat transfer is flow times delta T times 500 (for BTU/hr). At the same time, the heat output of a radiator is determined by the difference between the radiator temperature and the room temperature. And those two things have to balance — the heat transfer has to be the same either way you calculate it.

Going to your example, let's say in the first example there is a flow of 1GPM. With a delta of 34.8F, the heat output is 17,400 BTU/hr. Let's say the room is 70F, the AWT is 162.6F, or 92.6F above room temperature.

In the second example, the AWT is 174.4F, or 104.4F above room temperature. The heat output has to be 104.4/92.6 times as great, or 1.127 times as great, or 19,617 BTU/hr. With a temperature delta of 11.3, the flow has to be 3.47 GPM.

That's the only way the two calculations balance. You can put in any flow number for the first situation, the flow in the second is always going to be 3.47 times as great.

0 -

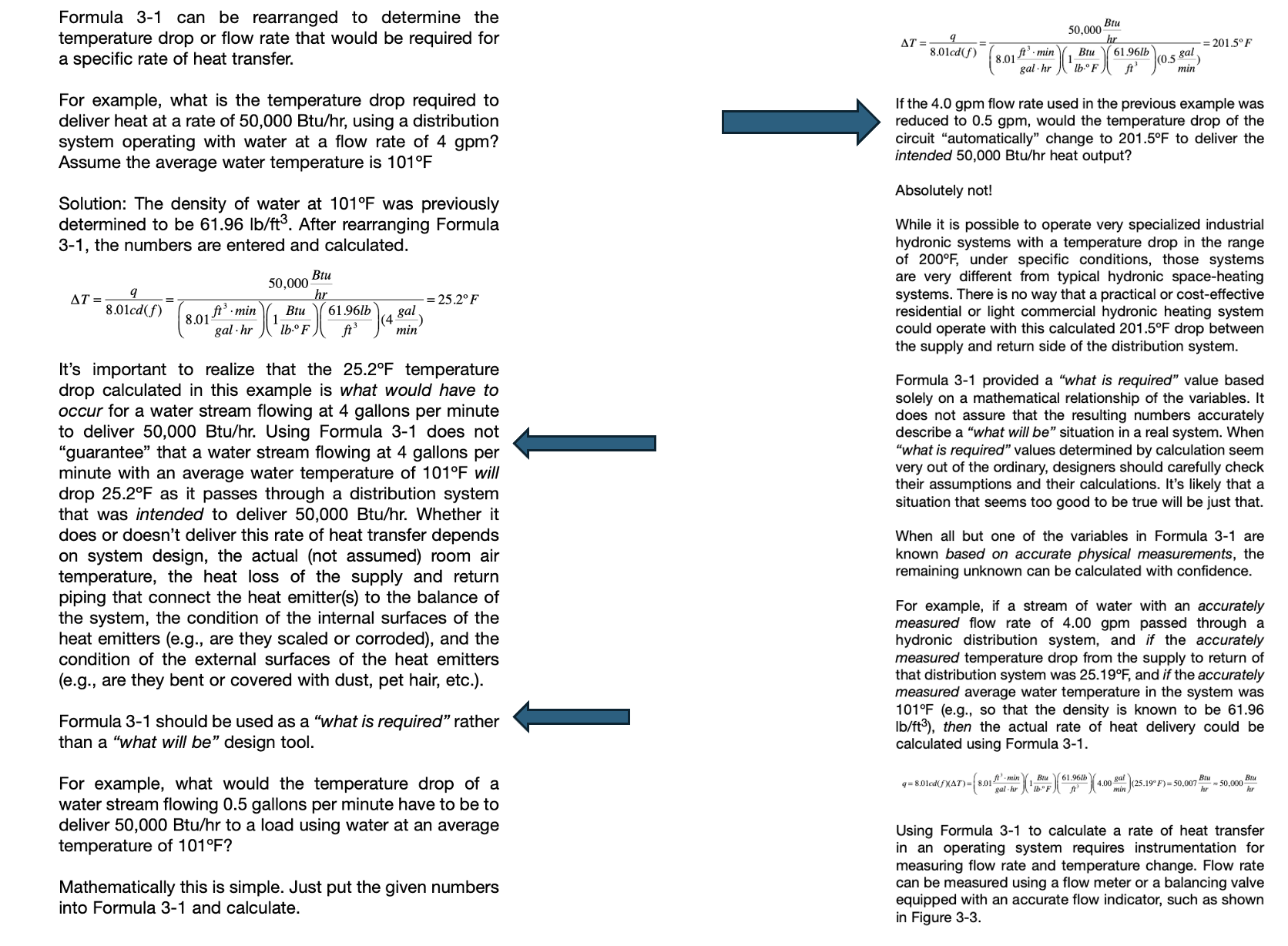

Conveniently leaving the "f" out of an example is always suspect :) Sounds like something a member of the alternate reality ∆T club would say:)

No you cannot just raise the SWT and cause the ∆ in a loop to increase.

The ∆ that a system operates under is driven directly by the load at any given point. Further the operating condition of the boiler is driven by the load on the system. You cannot force the delta to be what you want it to be with a basic fixed speed circulator.

Archimedes allegedly said " give me a lever long enough and I can move the earth". Sounds good, could probably even put some numbers to it, but.

While the universal hydronic formula can predict most any possibility, not all will be attainable.

500 X 2 gpm X 5∆= 5000 btu/hr

500 X .01 gpm X 1000∆= 5000 btu/hr

Anyone care to build a working model of the .01 gpm flow example?

A wise man told me

The “danger” with the [ Btu/hr = 500 x gpm x ∆T ] formula is that people think that anything the makes the math work to the desired result can actually physically take place. For example, if someone just thinks I’ll make the ∆T 40 instead of 20, and cut the flow rate in half, and get the same heat output (which is true mathematically) but this math absolutely doesn’t imply that the circuit will physically operate under those conditions to give the same heat output.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@hot_rod : "Conveniently leaving the "f" out of an example is always suspect :) "

I'm not sure what you're getting at.

"No you cannot just raise the SWT and cause the ∆ in a loop to increase.

The ∆ that a system operates under is driven directly by the load at any given point. Further the operating condition of the boiler is driven by the load on the system. "

True, but be careful about what you think of as the load. The load is what the radiators are putting out. That's not driven by the outside temperature, it's driven by how hot the radiators are. If you make the radiators hotter, they put out more. Always true — so long as the room temperature stays the same. If the radiators are putting out more, and the flow is the same, the temperature delta has to be greater.

"You cannot force the delta to be what you want it to be with a basic fixed speed circulator."

This is absolutely true.

0 -

-

Some easily proven facts tend to be overlooked by certain "professionals" because it simply doesn't fit their narrative. I proved this "higher SWT equals higher BTU/SF" theory with video using my own radiant floor heating system in my shop to a certain someone very active here last week in another forum and instead of an intelligent discussion using basic elementary math, that person chose to tell me that I was an idiot and then left the group.

The example was an 80* SWT with a 3.0 GPM flow rate and a 60* RWT, obviously transferring 30,000 BTU into the slab. I then cranked the SWT up to 140* with the same 3.0 GPM flow rate and the same 60* RWT (because a high mass slab obviously can't just ignore absorption) and using the exact same formula that we (including the "professional" in question) all use every day, that transfer was then 120,000 BTU simply by raising the SWT. Obviously that delta would shrink as time goes on and temps begin to equalize, but the fact remains that a higher SWT does indeed yield a higher delta and therefore a higher BTU output when all else remains the same.

0 -

What you want and what you get. The load of the building, not you or the pump, or you buddies determine the actual operating conditions.

Your change of SWT without any other changes, absolutely will not guarntee the system is operating at the 80∆ you calculated. Granted the increased SWT from 80- 140 is where extra output comes from.

However if this is the 1500 sq ft shop discussed on another site? 120,000 btu ÷1500sq ft. = 80 btu/sq.ft seems like an awful high load you are trying to cover?

For those with open minds tuned in today, more data here

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

In the long run, the load is the heat loss. But in any given moment, the radiator can only be on or off*. When it's off the load is zero, when it's on the load is whatever the radiator is emitting in that moment, which is determined by the temperature difference between the radiator and the room. If the thermostat is doing its job the room temperature is pretty constant, so the load seen by the boiler for that loop is entirely determined by the radiator temperature, which is going to be determined by the water temperature.

What I do agree with is the general sentiment that you can't force all three of send temperature, return temperature and flow rate. You can set two, the third is going to be determined by what the radiator puts out given the other two. And of course not every combination is possible, it's going to be determined by the physical capacity of the system.

*(I'm assuming this is a system with just an on/off thermostat, no temperature modulation. But the logic doesn't really change.)

0 -

@hot_rod yes it is that building, and no the load is nowhere near 80 BTU/SF although that would be attainable. As was discussed then, the load is 27 BTU/SF but you argued tooth and nail that it was impossible to attain with only 1200LF of tubing because raising the SWT into a high mass radiant floor while maintaining everything else the same would not raise the delta or the BTU output. I showed you two videos as explained above to explain why you were wrong and that raising the SWT absolutely 100% DOES raise the delta and therefore the BTU output, but instead of trying to have an intelligent conversation about it, you got defensive and called me names before leaving the group entirely rather than admitting that you were wrong. As you were told then and still stands, you are welcome to share all the charts and opinionated snippets that you wish but none of them supersede the mathematical equation of DT x GPM x 500 = BTU. I very clearly stated that the delta in the extreme above example would dwindle as the temps reach an equilibrium, but that does not negate the fact that your deflections and opinions do not supersede mathematics and facts. I tried to give you the benefit of the doubt that there was simply a reading comprehension issue on your end, but then you doubled down with the insults and went so far as to remove yourself from the group to avoid being wrong. The reason this is being brought up again, is because it looks as though you're trying to preach the same falsities here and I want to make sure the others know not to trust everything they read- even if it comes from somebody like the almighty Hot Rod.

1 -

on first start of a cold radiant, or coming out of a deep set back, expect to see high deltas, aka transient conditions. As the slab warms and room temperature increases, I’d suspect the delta to close to 20 or less at a stable operating, thermal equilibrium, condition.

The delta through the loops will drop as the space reaches setpoint. And of course to 0 when the load satisfies.

This is the point of the delta moving with the load. You cannot force the system to stay at the 80 delta. That is how I’m understand groundup read on this system.

On the earlier run 80 SWT, 60 return, that delta too would close as the slab and space warms. Assuming it was the same cold start condition?

These are actual measured deltas I refer to, not the ones the formula produces.

I think I made the point about what the formula predicts and reality at the jobsite?

A data logger on the system for a day would record all this, the actual system changes, time frame, btu outputs along the line, RWT changes, delta changes, and the moving transient to stable operation delta numbers.

If a design was done indicating all the input numbers, and the predicted operating condition, loops, flows, temperatures, glycol%, etc, the system may still never work at that exact designed condition.

Assuming the system and building was assembled, insulated, tubed as the design specified. This would be in the assumption report that some radiant designs spit out.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

You said multiple times, and I quote, "Raising SWT and not changing flow rate does not change the delta", among several other avenues saying the same thing to imply that a given BTU output is impossible without a ridiculous amount of flow. That is false. You were/are wrong. Period. Now back to our scheduled program- sorry bauer, did not mean to get off topic.

2 -

Unfortunately you have done what many do using 500 for one factor of the equation . That 500 number is basically only a number for 60* water and changes along with the viscosity and temperature of the fluid . Maybe we should use the AWT of each and every example discussed to be dealing with facts . Alpha numbers matter !

You didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38330 -

Please, I welcome you to repeat my calculations using whatever numbers you think are more appropriate than the 500 I used. I think you'll find it doesn't change the conclusion in any material way.

0 -

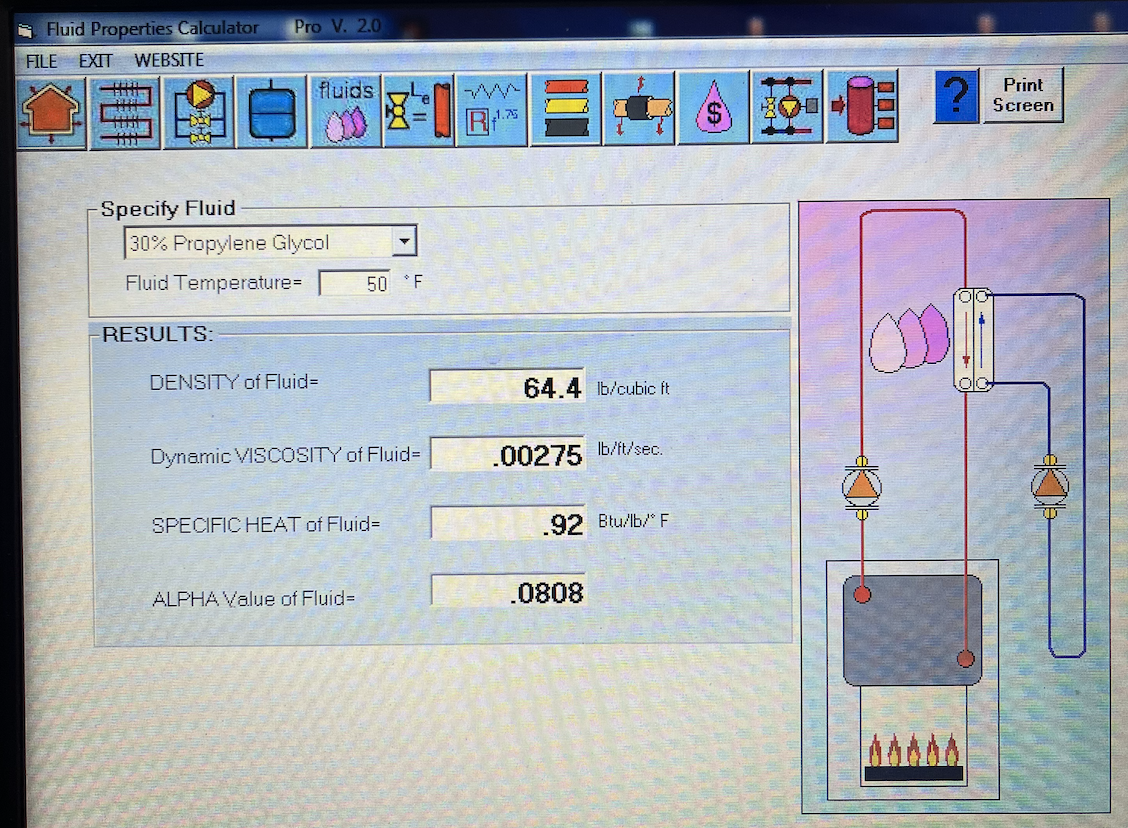

477 for 30% PG glycol, and that changes a small amount based on the glycol temperature

temperature of the glycol effects heat transfer and pumping capacity

water 500 X 3 X 20= 30,000 btu/hr

30% PG 477 x 3 X 20= 28,620 btu/hr

The HDS software has a fluid calculator if you want to drill down to exact numbers.

This is why very transient conditions exist until the system reaches equilibrium

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements