Monoflow System

Hi all, Our monoflow heating system doesn't seem to be working very well. we have a 120000 Pennco boiler with 100 ft of 1.25 iron pipe with 16 mono flow tees single loop 130 ft of baseboard on a taco 1.25 zone valve on one zone. other two zones are on 3/4 zone valves and about 38 ft of base board on a loop, one taco circulator 007 f5. I feel the taco 007 is too small I don't know how to calculate the head per monoflow tee. any help would be helpful.

Comments

-

Is this a new problem or has it always existed? If it used to work what changed? Do you get domestic hot water off the boiler?

Can you post a picture of the piping around the boiler and a picture of a Monoflow tee.

does the house not heat at all or is it sluggish? Was the 007 changed?

Are all the zones monoflow or just the main zone?

1 -

exactly what brand and model of zone valves? most zone valves are generally too restrictive for monoflo.

0 -

This is an existing problem, no domestic hot water. B&G monoflow tee 1.25, House does heat sluggish. the 007 was on the boiler. Just the main zone is a monoflow.

0 -

taco 572 1.25

0 -

a 572 is a 1" zone valve with a Cv of 7. Ideally you would zone that zone with a separate circulator and flow check but there are some zone valves with a much higher Cv. 7 gpm is probably not what someone using 1.25" pipe had in mind.

0 -

Something like this has a Cv of 42

https://www.supplyhouse.com/White-Rodgers-1361-104-1-1-4-Sweat-Zone-Valve-Two-Wire

0 -

sorry it is a taco 573 zone valve. I was thinking of taking the zone valve out and use circulators instead, my problems is how to size the right circulator with so many monoflow tees?

0 -

someone else will have to help you with the head calculations. from that and the heating load you cna figure out the flow you need and look at the pump curves and select the circulator.

0 -

16 monoflow tees is a lot of tees. I would definitely bump up to a larger pump.

I had 8 monoflow tees with 1 1/4" pipe at my house and an 007 with the same 1"

zone valve and it barely did the job.

A taco 008 has the same dimensions and will bolt right in.

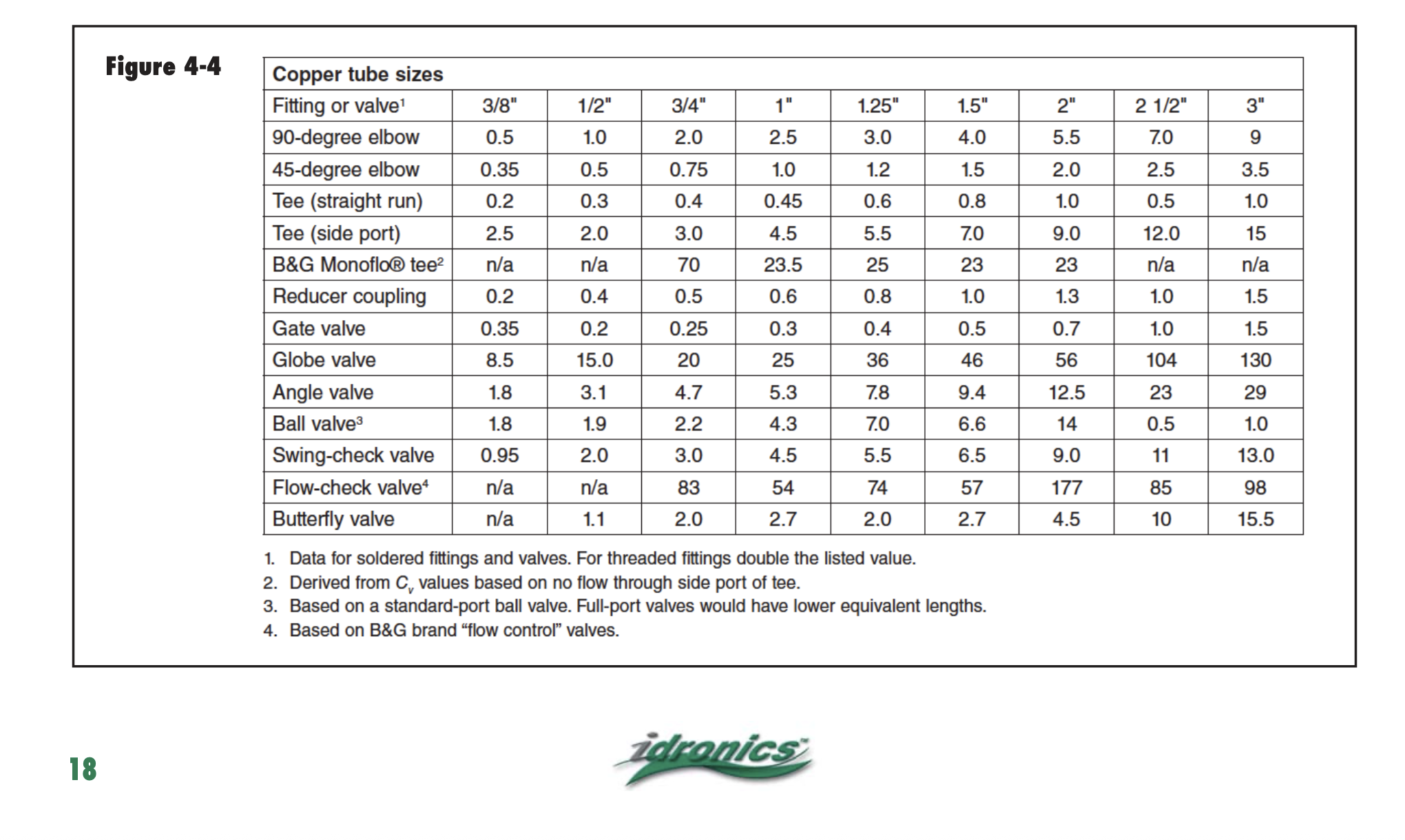

See the attached

0 -

Did you take out the zone valve in you system? Do you know what the head is for each 1.25 monoflow tee?

0 -

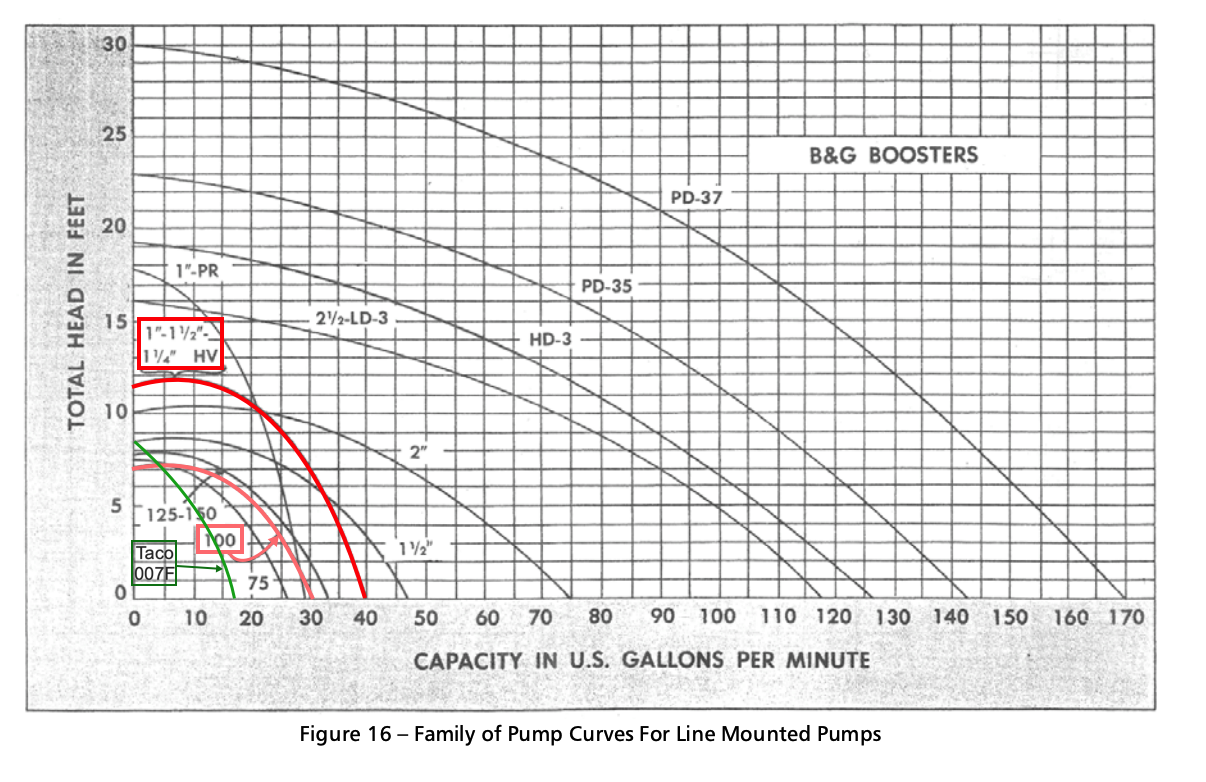

I am hearing "this has always been a problem since the replacement boiler (that came with the Taco 007F) was installed, but it probably worked fine when the original boiler was there". The original circulator pump may have been a B&G HV. I have added the pump curve for the Taco 007F pump to a B&G pump curve that has the most popular B&G 100 pump and the also popular B&G HV Pump highlighted in Red so you can see the difference. Do you know what pump was on the original boiler when those MonoFlo® tees were originally installed? Click on the graph and zoom in on the lower left corner to see the difference

Even if you can't understand pump curves, You can clearly see that the old standard B&G 100 and HV pumps are more powerful than the Taco 007F. I can do the math for 16 MonoFlo® tees on one 1-1/4 main pipe, but I would feel more comfortable if @hot_rod took a stab at it.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

No. The 1" zone valve remained. I don't know the head on each monoflow tee. To calculate the head you would need to know the flow in the main and the flow through the branch piping. Its kind of like a catch 22.

My system worked ok for years with an 007. It had no zone valves. When I installed a new boiler I added an indirect water tank off the boiler so now I needed 2 zone valve and 1 circ. I used Honeywell zone valves which are more restrictive than the Taco you have.

When I started it up the house wouldn't heat, very, very sluggish and this was with the zone valve to the indirect off.

I finally took out the 1" Honeywell and put in a Taco the same as you have.

After that it was OK. .

I ahd a n 1 1/4" copper monoflow system with 8 tees. The 007

The oo7 runs out of gas at 10' of head which is only 4.3psi. If you had places to stick a couple of pressure gauges on your suction and discharge you might be able to see something but gauges are not vary accurate at low pressures. Based on my experience with the 007 and other posts we have seen here I think you don't have enough pump. I had about 95 feet of 3/4 baseboard and about 130' of 1 1/4" main

0 -

-

but it isn't adding significant head to the system….

0 -

I don’t have hands on experience with diverter tees. All design info I have read cautions about pressure drop in the tees and radiators in series. And that they don’t like piping modifications from the original design.

130’ of fin tube seems excessive on one loop? Is it 1-1/4 fin tube?

I think Modern Hydronics has a chapter on designing a diverter tees system. That you could reverse engineer it.

I think more pump may be the answer?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

if it is 130' of baseboard on the monoflo loop it is a series-parallel combination so the flow splits between each section of the fin tube and the main at each section of fin tube so the fin tube only has to carry a fraction of the total flow. if the baseboard is about 500 btu/hr/ft then that is 65,000 btu/hr and you need somewhere in the ballpark of 6.5 gpm through the 1.25" pipe.

the monoflo book from b&g is out there as a .pdf in numerous places that describes the design.

the monoflo tees simply have a circular partition in them that divides the flow between the branch and run. you could get the same effect with a reducing tee.

0 -

Does the monoflow book give the head for the 1.25 tees? I did check the pressure before and after the pump which was 8.74 on the suction side and 12.68 on the discharge side, will that give me the head pressure of the system?

0 -

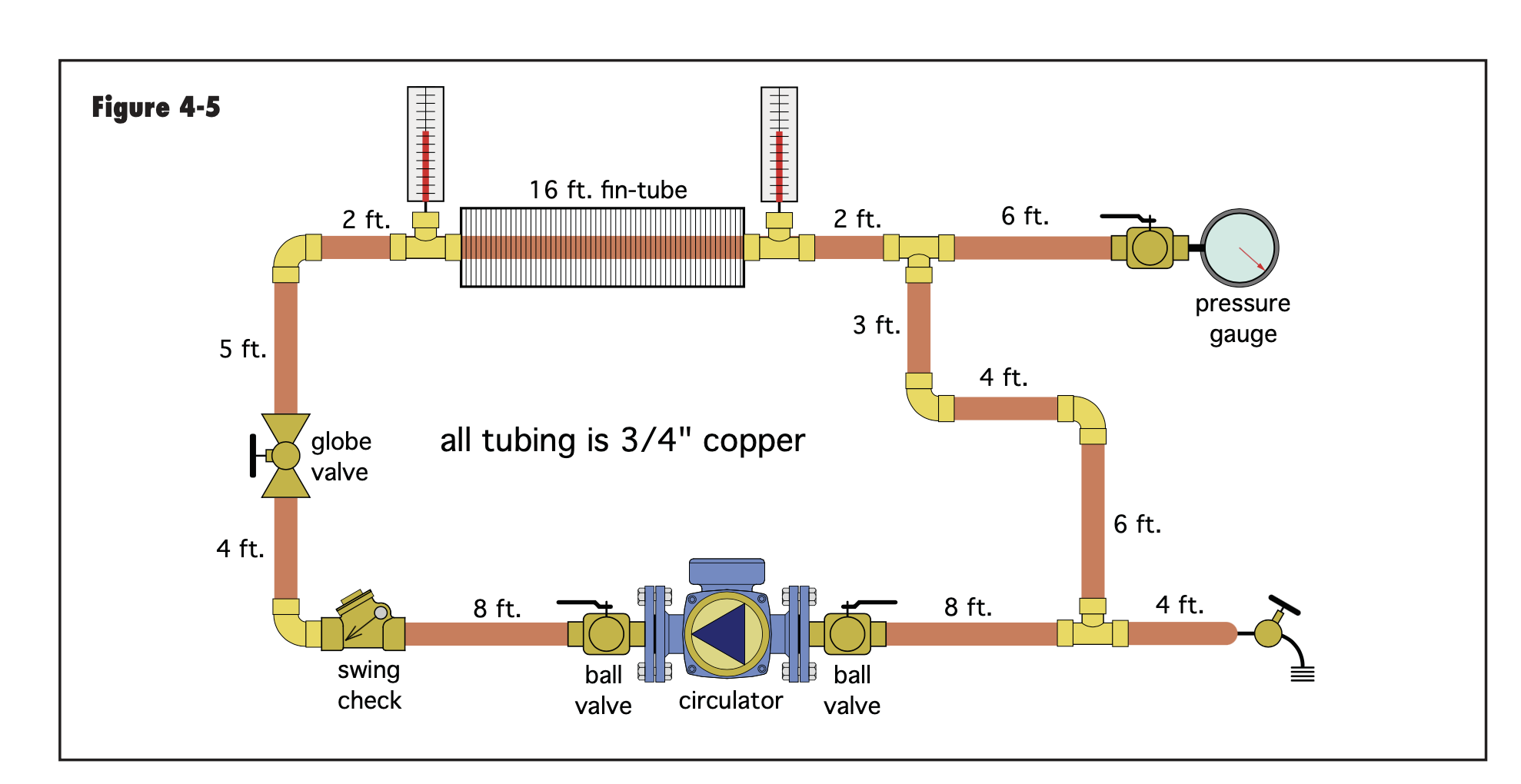

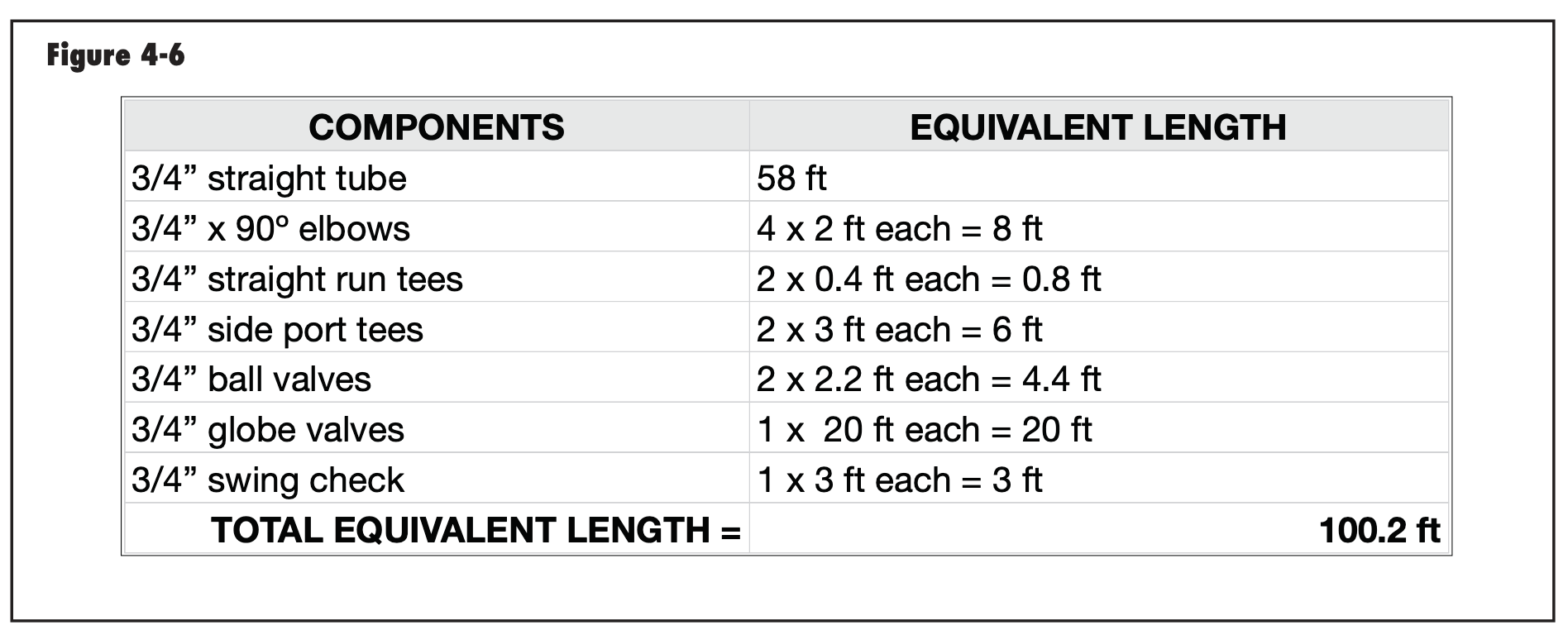

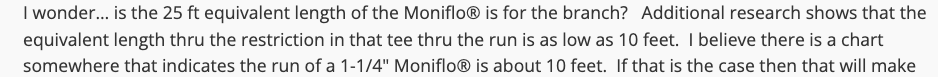

Generally when defining or determining the pressure drop of a circuit you convert pipe and fittings to EL, equivalent length. An example and chart with common fitting conversions. A 1-1/4" monoflo® tee =24' of tube

\

Head pressure really isn't an accurate term. Head is the mechanical energy added to the circuit by the circulator. Feet of head is the unit. Pressure is a measurement of force.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

B & G sizing chart is attached

I have the original "Taco guide for Hydronic Engineers " which tells exactly how to design a monoflow or venturi system. Thats what I used to do. We were taught how to design them in school. never did one after that because tey ar not installing monoflow any more.

But you need all the information to do this. The flow needed in the branches depends on branch tube size which is usually 3/8" od-5/8" od copper. the length of the baseboards on each branch etc etc. You would need all the info to do this. Pressure drop through the branch. It is a long tedious procedure as I posted above.

I don't see any possibility of an 007 pumping this job after what I went through.

@skip143727. You have 3.94 psi across the pump. that equals that equals 9.10 feet of head. At 10' of head the 007 is flat on its face and hardly moving any water.

As I explained above the monoflow tees the head from each tee is dependent on the flow in the main the flow in the branch etc.

Your short on pump

Your pressure drop measurements tell the story.

If you want to gather all the information and post a sketch of the piping I can calculate the head and gpm you need.

Your going to need"

Feet of baseboard on each branch

size of branch pipes and approximate length, fittings on branch pipes etc

size of venturi tees 1 1/4 x 1/2" , 1 1/4 x 3/4" etc

Sketch and length of 1 1/4 main

Flow check valve/, zone valve etc and sizes

Pictures will help.

0 -

I will definitely get the info for your review! Thanks

0 -

So if I make the following assumptions about the 16 monoflo® tees on a 1-1/4" main pipe that wraps around the basement using 100 feet of 1-¼ pipe.

- At some point that system operated properly and was designed properly on some old boiler system with a more powerful pump

- Then add another 40 feet for a branch feeding and returning from the farthest radiator from the main that would be about 20 feet. Off the main (maybe on another floor)

- That would be a total of 140 feet for the rule of thumb calculation of the longest run.

- Then you add another 50% to account for the fittings for a total of 210 feet of equivalent length

- Since this does not account for the equivalent of 16 Moniflo® tees

- The equivalent length of a 1-¼” Moniflo®, according to the chart provided by Bob @hot_rod Rohr, is 25 feet.

- Then we need to add to the 210 feet the EL of 16 Moniflo® tees @ 25 feet or another 400 feet .

- Now you have a total equivalent length of 610 feet. Then multiply that by 0.04 to get your total pump head of 24 feet.

- Match a pump that will deliver the necessary GPM at 24 ft head and you might be close to selecting the proper pump for the Moniflo® loop only.

- If you want to add the GPM of the other zones then you may need an even larger pump. but still only need 24 Ft Pump Head

That is how the longest run rule of thumb works. If the pump is powerful enough to work on the longest run, then it will be strong enough for all the shorter runs.

I wonder… is the 25 ft equivalent length of the Moniflo® is for the branch? Additional research shows that the equivalent length thru the restriction in that tee thru the run is as low as 10 feet. I believe there is a chart somewhere that indicates the run of a 1-1/4" Moniflo® is about 10 feet. If that is the case then that will make the needed pump head only 15 feet. That makes the B&G 1/6 HP model PR pump more likely to be the pump that was on the original boiler. But this is all speculation at this point.

I might try a Taco 0014F or a Taco 0011F as was suggested earlier.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

We will see what the calculations come out to if I get the info from the OP.

I doubt he needs 24' of head unless he needed to run the 1 1/4 to full capacity. He has 130 ' of baseboard that would be 130 x 550btu/foot or 71500 btu/10000=7.15 gpm.

He has 3.94psi deltaP across the pump which is 9.14 feet of head. The Taco 007 moves very little at that head. The 007 at just over 7 gpm dies at 8' of head. Given the inaccuracy of using pressure gauges that is pretty close.

If he needed a pump that did 24' he would not be getting any heat at all instead of it being just sluggish as it is

1 -

The foot note 2 at the bottom explains the flow path for that Cv number.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

oh…well that isn't actually what happens, now is it… I suppose if you were solving for the case where someone is shutting off radiator valves that would come in to play.

0 -

B & G likes to keep secrets. I have been searching for the pressure drop of 1 1/4" B & G Monoflow tees and couldn't find it. I only found the 24' @hotrod @EdTheHeaterMan mentioned. But as HR pointed out it says with no flow on the branch.

I did find something in my old B & G Handbook second edition 1949. Page 43 has a chart for Monoflow fittings. an 1 1/4 Monoflow tee with a flow of 14 gpm on the main is 4500 milliinches. Chart 7 "Pressure drop Curves B & G Monoflow tees". This manual or one like it is probably on this site. 12000 millinches=1' so

.375 feet/tee or a delta P of .162. 16 tees x .375=6 feet of head The op does not need that much flow however.

I have a 1964 Ashrae "applications" says to use 3000 millinches if you can't find the MFG data.

Taco has Standard or Super Venturi tees. The standard is 5000 MI the super is 14000MI both 1 1/4 " and both at 14gpm

so the standard would be 6.6 7 feet for 16 tees

super would be 18.66 feet for 16 tees.

The 1949 B& G manual is the same one that is on this site.

0 -

After thinking like water and asking "where would I go if I was entering a Monoflo® Tee?” I might be divided at the first tee, however if that branch were closed off then I may act as though it was equivalent to 24 feet of straight pipe on that first tee. After that first tee, I might not react identically on the second tee since I was already restricted by the first tee with no branch. What percentage of that first 24 feet of equivalent length (EL) would the second tee result in? Might it be something less? Then the third would be that same percentage of that second tee’s EL. Then the 4 would be tthe same percentage less than the third tee. The law of diminishing returns takes effect here so by the time you get to the 9th tee, (

you are ready for a beerOops that golf) the EL is down to that of a regular 1-¼“ tee fitting’s run.As mentioned by @EBEBRATT-Ed that information is not well published by the B&G folks in easy to understand terms like you might find in a @DanHolohan epistle on the subject. You need to understand Millinches and other engineering terminology, then translate that into Plumber speak. (That is a language taught to plumbers from their first day in apprentice training. Right after you get sent to the supply house for a left handed pipe wrench or a bucket of steam.)

I believe that the Taco 0011 should work for our original poster, but it is not my money being spent on this test. I can only hope that it will work for them.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Hope this helps a bit

0 -

Here s what i always did when i have been faced mono flow system which had been added to and which the original mono system performance became sluggish or when asked to start zoning a mono flow system . In your case i would separate the 1/2 baseboard loop and any other zones off of the original mono flow system and add a seperate pump w check valve and zone valves if required for them and install a seperate pump just for the mono flow . I have found it much easier and in the long run cheaper then trying to make what is there work correctly,balancing valve or better flow setter and time $ . Some may argue to fiddle around a bit but when not wanting to go back or have a unsatisfied and unhappy customer on a cold snap i ll stick to what has worked for me on a lot of butched mono flows which at some point might have just been the easiest and cheapest thing to do at the time or they didn't know and figured it just pipes and it will get hot sooner or later .

It's pretty common being where i grew up there where a ton of homes w them and a lot of them suffered bad spacing for second floor convectors so some one figured they remove and add baseboard get more heat not such the case . A few i increase the spacing of the tees and got them working and some w a lot of baseboard where converted to a separate zone ,

hope this helps peace and good luck clammy

R.A. Calmbacher L.L.C. HVAC

NJ Master HVAC Lic.

Mahwah, NJ

Specializing in steam and hydronic heating0 -

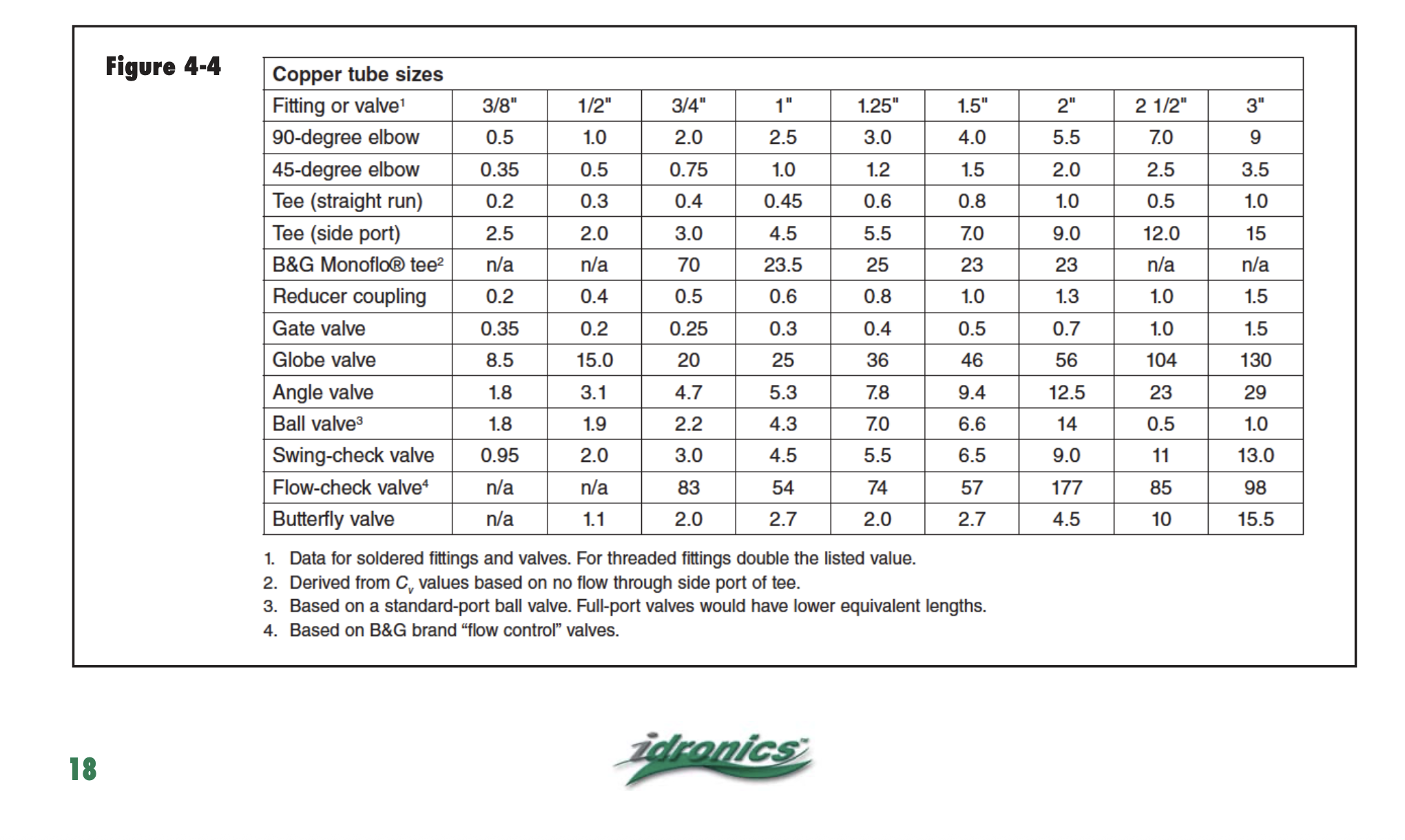

So most of the radiation loop have monoflow tees on the supply and return? I count 6 loops with monoflow tees on the supply and return and 3 short loops with 1 tee.

How do your other zones with 38 feet of baseboard tie into this. Do they have their own pump and work fine so they can be ignored? Or are they on the same 007 pump?

I will work on this tonight.

0 -

Thanks for the info, The house was built in 1952 and I'm sure it went thru many projects that had changes to the system. It may have never worked right? What I hear so far is the 007 won't cut it, I think if I know what pump should be on it hopefully it would improve. What I have read is remove the zones and use circulators with IFC and switching relay on the supply side! Bleeding the air out is very time consuming.

0 -

7 loops, 4 loops have tees on the supply and return, the upstairs loop that has 29 ft of baseboard has 1 regulator tee on the supply with what I assume is a 1/2 check valve and the return has the 1.25 x1/2 MFT which is all in 1/2 copper with a air vent and is terrible! Two locations are just piped in with 3/4 Pex I found they were just capped off. Spacing on one is 18 inches and the other is about 6 inches. There is a 6 ft convector in the kitchen that is piped in 3/4 black iron about 10` of piping , works good. The basement zones have there own taco 3/4 zone valves with a taco zone controller they won't come on if the main floor calls for heat so I didn't add that in. Hopefully that's okay they are on the same 007 and seams to work fine. The boiler is a Pennco gas 120000 btus. hopefully I didn't miss anything. Your help is greatly appreciated!!!

0 -

You can't put other emitters between the monoflo tees for one emitter, it will reduce the flow in the main for all those emitters.

Since it divides the flow, the flow has to recombine before the next emitter. That baseboard loop has to either reconnect at the same spot on the main or be made a separate zone.

0 -

One location has 1 monoflow tee on the supply as the first zone and a regulator tee last on the return end. Could this be done with a regular tee. The 2nd location has a zone in between another zone with 2 monoflow tees? 1/2 copper. The upstairs zone is split right in the middle of all the zones in 1/2 copper?

0 -

one regular and one monoflo tee is ok as long as the monoflo tee is pointed the right way.

i don't understand the 2nd and 3rd questions.

0 -

So the emitters in between different monoflow tees will need to be changed so it doesn't reduce the flow to all other emitters? There's 3 locations like that? Or is okay if using only one monoflow tee with a regular tee? 1 monoflow tee says supply/return on the tag?

0 -

I can figure out the main with what you posted. If you could repost the drawing with the baseboard on it it would help.

I can tell you that the second floor (is the 29' of baseboard all the baseboard on the second floor?) you have a load of about 16,000 btu and the flow needs to be 1.6 gpm. Since it is all done in 1/2" copper it is maxed out.

0 -

I needed to make some changes hope this helps

0 -

@Skip143727 K. I will see what I can do.

0 -

So the 1/2" monoflow loop to the second floor is that the only radiation on the 2d floor?

What is the lay out of the house. Is this typical boiler in the basememt? Your existing basement zones heat the basement are not part of the drawing correct?

All the radiation shown on the drawing is above the boiler and is on the first floor except the 1/2" loop to the upper floor correct?

0 -

Yes the 1/2 inch is the only radiation on the 2nd floor. yes the boiler is in the basement, and the other two zone controls a bathroom and a living area.they work fine. Yes the first floor is the real problem. And then I have this, I think this is what's killing the flow to the far side of the house? The middle tee feeds the upstairs on the supply side of the 1.25 main pipe. the first tee says supply, the third tee says supply/return with the arrow pointing to the supply on the 1.25 main pipe.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements