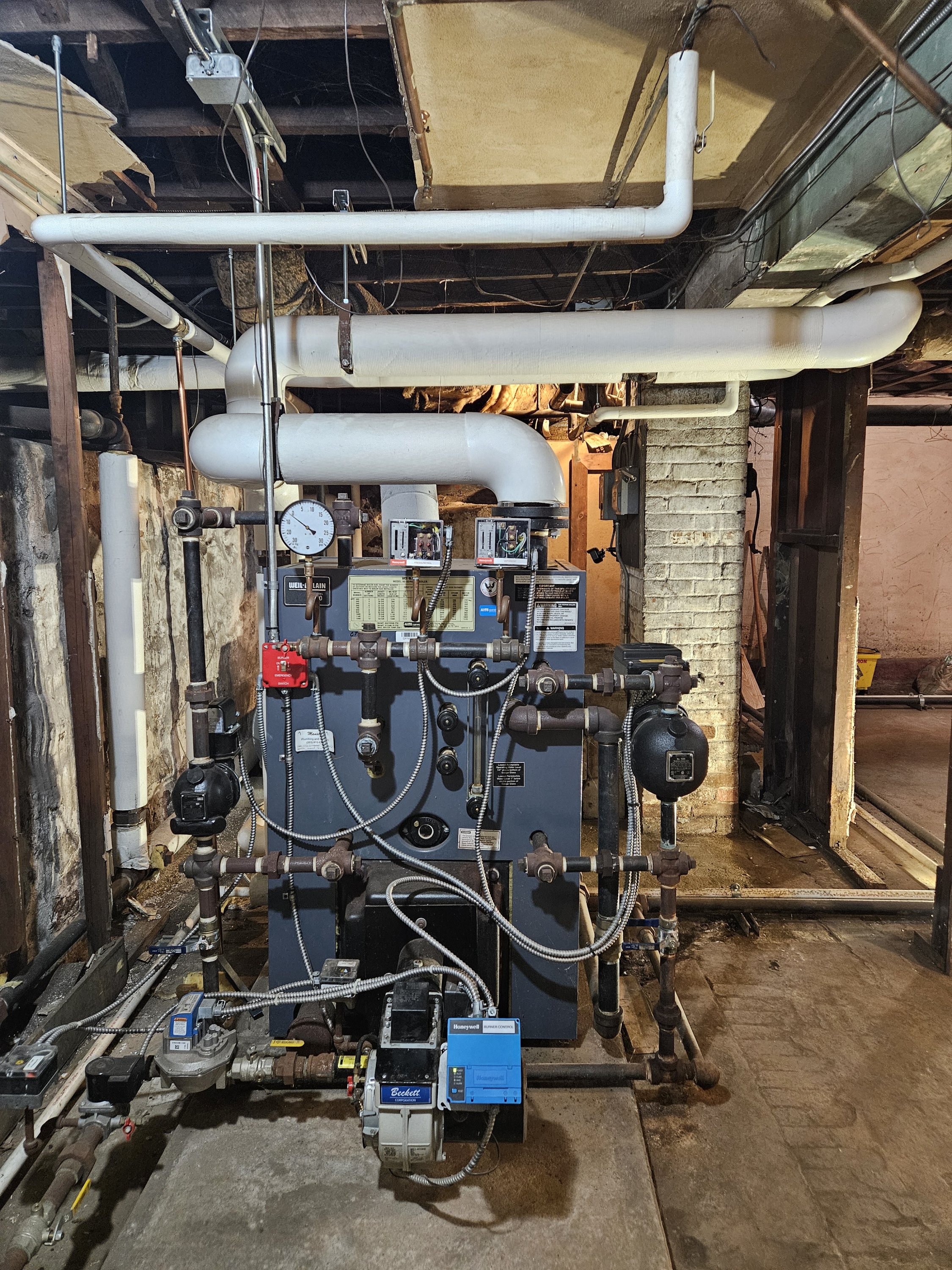

Flooding Commercial Boiler

I have a Weil Mclain 380 steam boiler boiler thats 15 years old. Recently it started to flood and even shoot steamfrom the condensate tank. I replaced the 150s pump switch/LWC. I also replaced the check valve on the boiler fill supply from the condensate tank. It' a 2 pipe atmospheric system. It has 15 radiators with good air valves on the second and third floor that heat up pretty good. The boiler starts great but really starts flipping the float fill on pretty consistently. As soon as the boiler shut off for more than 5 minutes 30 gallons drops in from the supply? I turned down the vaporstat from 1 1/2 to 1/2 which didn't help reduce the flooding. There are 4 condensate returns above the boiler they all connect to a wet return around the perimeter of the basement which traps the condensate 4 ft. high before it goes into the tank. The trap is lower than equalizer and the dry returns. 2 condensate returns are from the base of the steam supply risers. The other 2 from the 2nd and 3rd floor returns i the basement crawl spaces. The have air valves just before the drop I nto the wet return. No steam traps! It has been running like a champ without a hiccup. Wha am I missing?

Comments

-

-

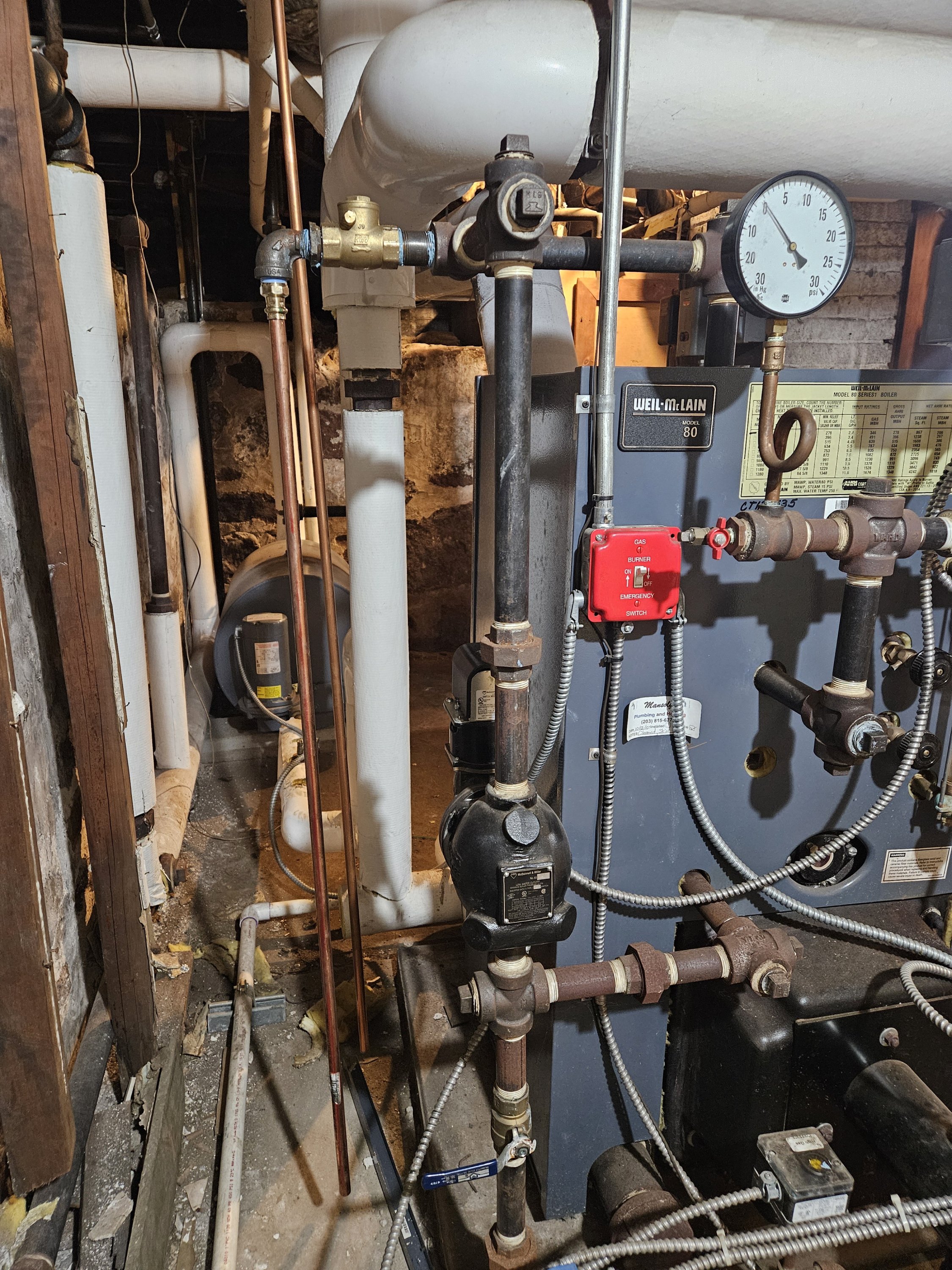

It appears to be a vacuum lock between the tank and the boiler. Replacing the check valve seems to have eliminated the steam blowing up in the condensate tank. But there is nothing preventing water to be pulled into the boiler. The vacuum is so strong that the condensate tank (pump off) will drain as I drain the boiler down to the operating level. The tank is vented. I'm considering installing a anti siphon valve or an air valve on the boiler. Not sure where and how to pipe it into the boiler. I was under the impression that the equalizer would prevent this but that's not what I'm seeing.

0 -

The equalizer will equalize the pressure between the header and the top of the Hartford Loop or the inlet to the boiler — but if the header drops into a vacuum, so will the boiler as a whole and the inlet.

So I might ask… is the header dropping into a vacuum? And if so, why? Unless all your vents are vacuum type vents, it should never go below atmospheric.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Pull the plug on the right side of the inspection cross tee above the feed control (preferred location) - install a check valve (1/2 is fine so get a 1 x1/2 bushing, 1/2x6 and a 1/2 IPS swing check) - see if this stops your vacuum pull. You can add it under the pop safety (on the run of the tee) in the back as well- the check valve orientation should be pointed toward the boiler -the arrow into the boiler - - FYI Please shut off boiler prior to install - check that/this first - ****you may get some discharge from the valve * -

$20 investment-before you go further

0 -

Here is a small radiator, most of the other ones are bigger with covers. Non of the system has been redesigned or added. General maintenance and 150s and check valve. Definitely a negative vacuum in the boiler. Not seeing a pressure increase on the gauge. It shuts down and fires right back up. Once it shuts down for five minutes 10 gallons dumps into the boiler and flood it

0 -

Thanks jimma Sounds like a plan. I need to start somewhere

0 -

so those are vacuum vents on the radiators?

seems like the tank should vent to the return instead of the atmosphere, if the tank can handle vacuum.

0 -

The vacuum is only in the boiler which is pulling the water from the bottom of the tank. There is no pressure inside the condensate tank. Trust me I would have never believed it until I seen/hear it. I can't pinpoint what is causing the negative vacuum. I'll see how it goes after I add the check valve

0 -

Not sure why it just started happening? Might want to try a spring check valve instead of a swing check valve for the boiler feed line. Was there a lot of debris in the piping next to the check valve? Was the old check valve in poor condition?

I agree with @EBEBRATT-Ed that there may be some sort of blockage one or more of the returns. Any chance one or more of the returns is missing a hanger that was there in the past, allowing the condensate to puddle in the piping?

0 -

You can put a check valve on the boiler to serve as a vacuum breaker or Tunstall sells steam vacuum breakers.

Get it above the water line. Coming off the top of the 150 I would not do that it might cause the float to rattle around.

I would use a good quality swing check valve with the flapper on a 45. 1/2 or 3/4" should be fine.

1 -

When I open the condensate feed line to replace the swing check there was very little debris. I used a 1" 45 degree soft seal check valve. ($180). I had this cheaper 1" check valve on the shelf for this fix project which is hanging in there so far. The true tet will be cold weather and time. As far as the return lines go I have the kid in the crawl spaces checking for broken hangers and leaks. Hopefully this is works. Thanks everyone

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements