DIY Boiler Monitor Project -- Useful?

Hi everyone!

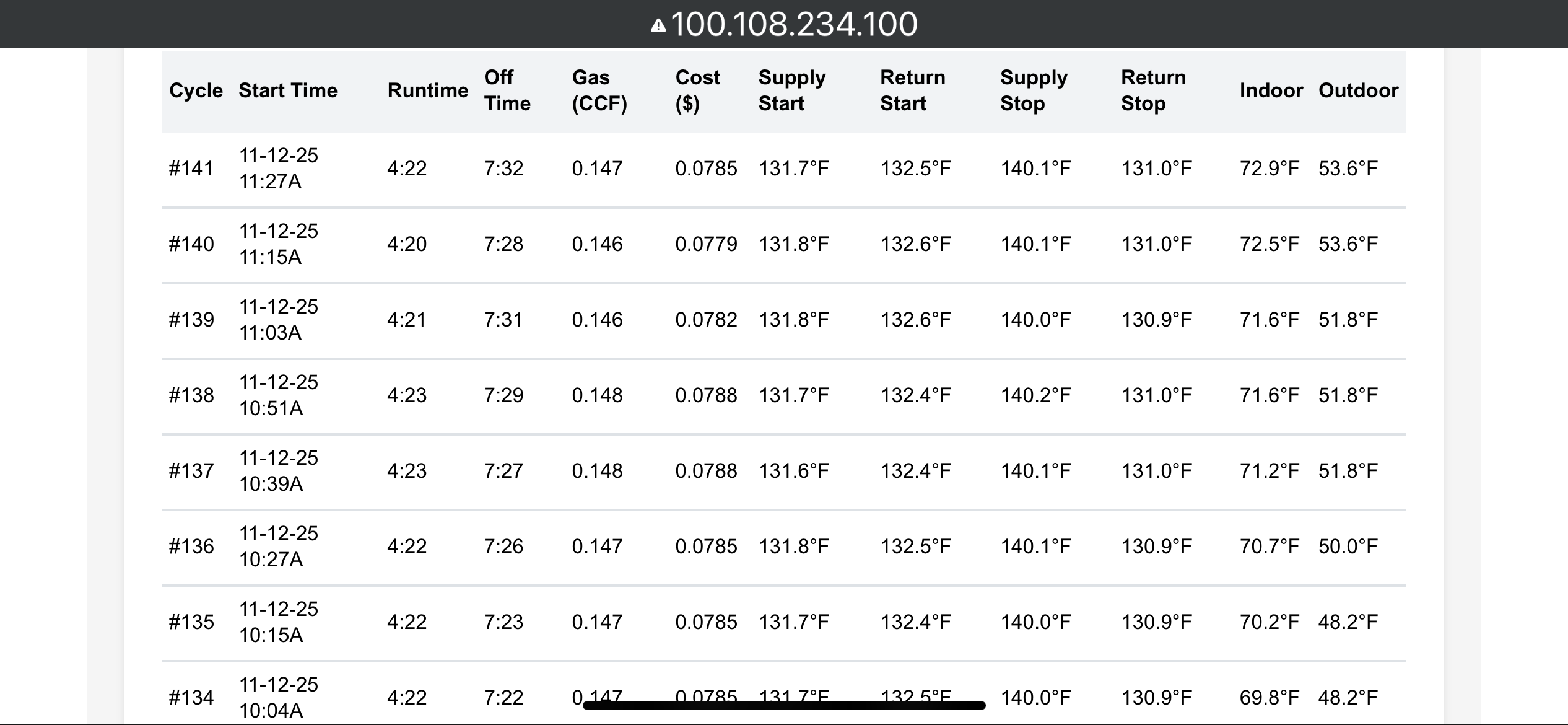

On my journey to increase my understanding of hydronic heating (thank you @EdTheHeaterMan and many others), I put my "nerd hat" on and developed a little project to show me the boiler statistics via a simple webpage.

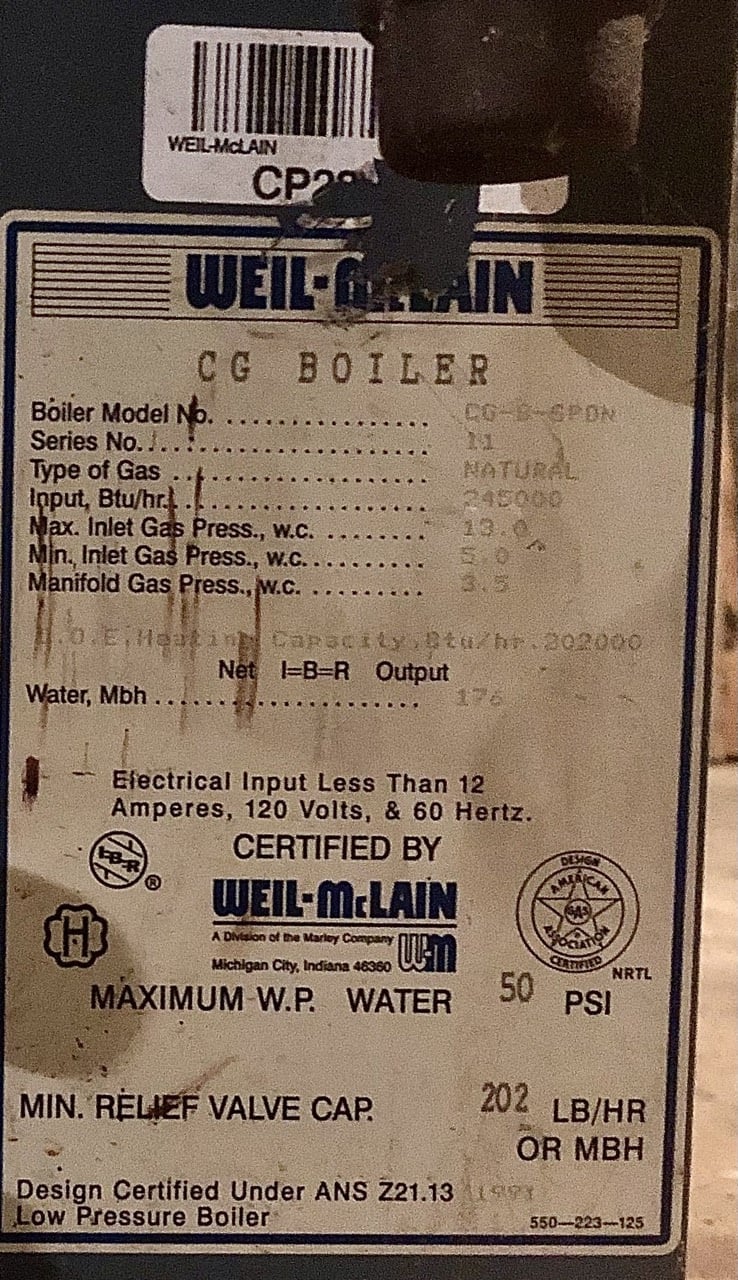

I have a older WM CG8 and a TekMar 256.

I didn't want to touch any of the wiring and instead use simple sensors safely attached to various parts of the boiler to capture when the flu damper opens, supply and return temps, outside and inside temps. I used a small camera to capture a pic of the Tridicator, also.

I had fun developing this and learned a bunch about what is actually happening during the heating cycle.

Comments

-

Here is something that will surely increase your journey of learning hydronic heating.

Look up the book or booklet by Bell & Gossett titled "Zoning Made Easy."

This book, in my humble opinion, is the best explanation of hydronics. It covers pretty much all of the bases and was written by the founder of this website @DanHolohan long before websites or personal computers were a thing.

I used this book when I was a Vocational Education Instructor years ago, and it was very well received as an addition to the curriculum. I still use it today as a reference guide. So, check it out. I'm sure you will be as pleased as I am. The book is excellent. Not to mention the many books offered on this website.

2 -

-

Thank you @Mad Dog_2 and @Intplm. !

Yes, @DanHolohan books have been teaching me quite a bit! Much more to read of his!

0 -

Great info! Clever data collection methods

6 minute run times are fairly short. Probably mild season loads?

With run time and off time.

6 minutes on, 11 minutes off, total elapsed time= 17 minutes

6/17= .352 run fraction 35.2%

So running about 80% cycle efficiency

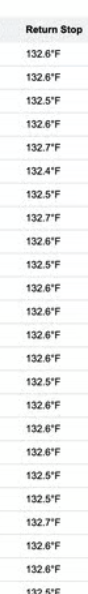

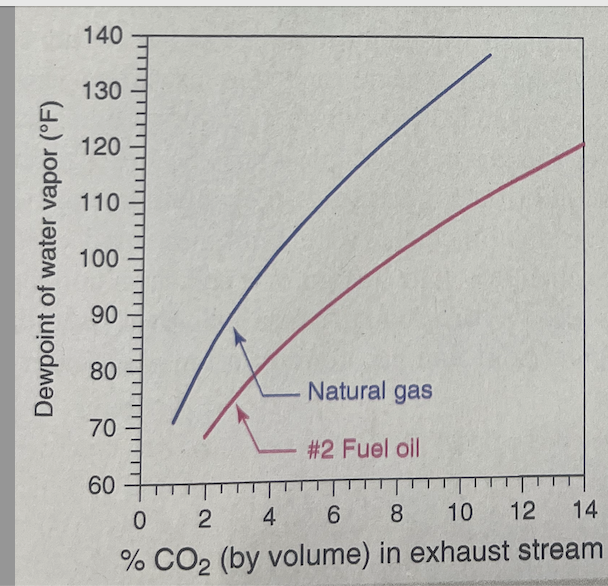

I'd like to see the return up around 140F at shutdown. If you could get a CO2 reading you could determine if the boiler is still condensing when it shuts off. Or the flue is still sweating?

\

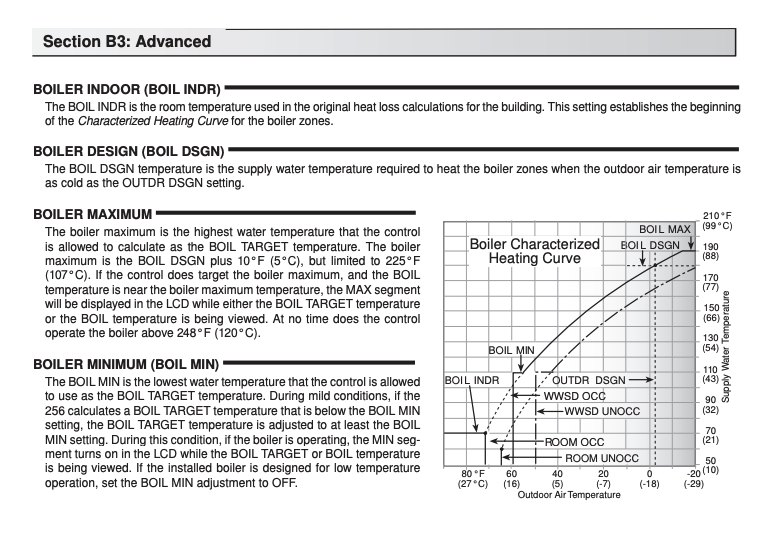

With a cast boiler you might bump the min. on the tekmar. Are you using a return sensor? You are limited on reset temperatures with a cast boiler might not do a wide reset with a cast boiler

Graphs from Modern Hydronic Heating & Cooling 4th edition

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

I agree the cycles are a little short.

0 -

Thank you, @hot_rod ! This is very helpful! The tridicator guage and the supply/return sensors from my project differ. Not sure which one to believe. Need to test more. Curious if you all know if the tridicator guage on this model boiler is a easy swap or does the boiler have to be drained?

The TekMar uses the pipe sensor and is reading similar to the project sensors.

As far as the run cycles, I agree. I initially had the TekMar 256 in the auto-differential mode but the cycles were very short. I changed the differential to 15 and this is the result. Based on recommendations here, I should be considering a 20 degree delta. If I did indeed change the differential to 20 instead of 15 and bumped up the min from 140 to 145 this would equal better results?

I've not noticed any condensation. Not able to test the CO. It's quite cold yesterday and today. I would think these results are a good representation of the current conditions.

Thank you!

0 -

Here is the link to Zoning Made Easy. I believe I have sent it to you before. After reading this book a few times, you can try to answer these questions from the Zoning Made Easy Workbook. This reinforces what you have learned by reading this book.

I used it as the textbook for the one day seminar I used to teach for the Eastern Heating Cooling Council.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

2 -

-

The scale is course and the accuracy is not great on most tridicator.

. A good 30 psi pressure gauge at the expansion tank tee is an option. Pressure will be accurate there but moving with heat and cool from, thermal expansion/ contraction

The manual for the Weil GC indicates return 130 or above. I didn’t see a CO2, 8.2- 10.2 is a common range

It takes some time to get a tekmar dialed in, with your data it should be quicker than sitting on a bucket for hours

With those short cycles it may be the thermostat is turning off the boiler before you reach thermal equilibrium

Thermal equilibrium is when the supply and return temperatures stabilize, not moving up or down. That is where you would read the operating delta T. At this point the heat emitters care delivering all the boiler can produce.

Not all systems operate at the designed for delta, some never do. The delta at any given time indicates how much heat is being transferred.

If you know flow, 500x flow X delta t = btu/hr at that point in time

500x 10 gpm X 18 delta= 90,000 btu/hr

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

thank you @hot_rod !

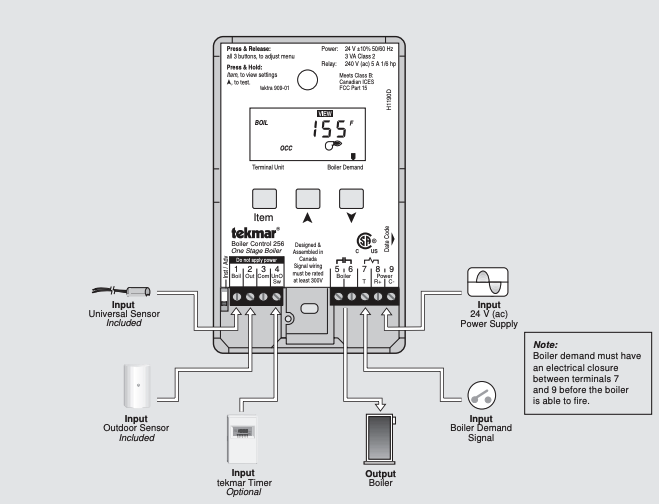

I noticed that there is a jumper between terminals 7(T) and 9 (C-) on the Tekmar 256.

Is this standard practice?

0 -

@24 VAC goes on 8 &9 this powers the control

7 & 9 enables the boiler to fire.

Sometimes zone valves or a relay contact connect to the "input" so the boiler only fires on a heat call. Seems like your boiler is always hot with that jumpered?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Thanks @hot_rod .

No, the boiler is not firing all the time.

The boiler cycles (although as you’ve pointed out, short cycles).Is this something the installer would have chosen in absence of a thermostat?

0 -

There are any number of ways to wire that demand.

On a single zone system the thermostat could wire there. With multiple zones typically a relay on the zone control box would wire there. It could be a seasonal wall switch. An outdoor temperature control. Or it could be jumped for a permanent "call"

The manual refers to a switching "device" the installer makes the determination what the device is.

It's possible another control is calling on the boiler, not the 256? We would need to see the control logic drawing.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks @hot_rod.

I noticed that the boiler cycles are not changing with an increase in the outdoor temp/ODR. Is this suggesting that the ODR is not functioning?0 -

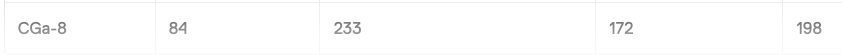

Is this the boiler you have?

Any idea what the heat load is? For the entire building and the individual zones? What zones are calling when that data is collected?

With one zone calling on maybe a mild heating day? , you have a lot of horsepower to tame. With a fixed output boiler, especially if it is oversized, it is not so easy to lengthen run times.

Added to that is the min. temperature that a CI boiler needs to run at.

Great data to show how important condensing and modulation can be to a zoned hydronic system.

You are running 80% maybe less boiler cycle efficiency. A mod con could be running 90% + under your current conditions.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thank you, @hot_rod .

No, I have the older non “a” version.

CG8 series 11 (245,000/202,000).

Just 1 zone. 2 pipe reverse return. 4 family apartment building. I’m working on a heat loss calculation.

Basic facts:

1938 Brick and plaster

Replacement Double pane insulated windows

Slate roof

2 story.

0 -

-

Thanks @hot_rod .

No TRV's. There are manual valves yet haven't been exercised in years.

I do have some wifi temp monitors in each unit.

All hear emmiters are functioning as they should.

0 -

Hi @fentonc ! Thanks! Really have enjoyed your journey, too!

This has really helped me understand what is actually happening!

I'm using some ESP32s, arduino code (thanks Claude/Gemini) and various sensors.

This data is then published to a webpage I can access locally and also remotely with VPN/TailScale.

I've added a few more data points to the table such as cycle efficiency and the indoor/outdoor temps.

None of this connects to the boiler or boiler control wiring.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements