Loss of pressure in closed system...

20 year old floor heat system gets heat from heat exchanger from 130k BTU water heater. When I went to start it up this year the pressure was between 0 and 5 PSI. From a bit of reading the issue is likely leaking expansion tank or air purge vents. Life of bladder tanks is said to be 10 - 25 years. Given the age I am thinking I should just replace the tank regardless of if it is the actual problem. The expansion tank Schrader valve vented some air but low pressure. Think I would need to remove it to check if that's the leak. Should I drain and flush the system before refilling? It's 50% food safe antifreeze now since it heats a garage floor. Thinking I should run some vinegar or other cleaner through the water heater side since our water is hard (have a softener) and lots of calcium and such. I looked at the vents but didn't see anything obvious showing leaking. I suppose I need to pressurize it to find out. Any suggestions on how to proceed?

Comments

-

-

Don't know why I would see water. The valve stem is at the top and there is nothing to add water. So the tank may have a bit more water in it but nothing to fill it all the way up.

0 -

Tap the Schrader and see if air comes out. If so, the tank is probably okay and you just need to add a little water. If there is fluid at the Schrader, the tank is shot.

0 -

I get some low pressure air out the Schrader. Still don't see how I am going to get water even if the diaphragm is shot. The tank is above most of the system and water is not compressible so isn't going to expand to fill the tank.

My real question is how do I track down the leak? If the diaphragm is bad the air in the tank would slowly dissolve into the water and might give low pressure. Think I need to pressurize the system and look for leaks. Hopefully not a really really slow leak that isn't obvious…

0 -

where did the water go?

0 -

regardless of the diaphragm being rupture and the tank waterlogged the system should still hold pressure, and pressure would increase as it heats.

Unless there is a rust hole in the tank, sir or water cannot get out. Where would it go?

Pressurize the system to 20 psi and observe for a few hours or over night.

It is not always easy finding leaks in radiant systems

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

if you're running antifreeze in the system, how is the system getting makeup water? is there a prv off of the domestic water? is there a glycol tank with pump? is there a manual valve from the domestic water supply? most systems have some very small leaks at valve packings and things like that so if there is no makeup water it will eventually lose pressure over months or years.

0 -

I did think the system should still hold pressure with a ruptured diaphragm although perhaps some air would dissolve in the water and loose some pressure. I did find some stains around an air vent that is likely at least part of the issue.

The system does not have any way to get makeup water (other than me manually doing it somehow). The water heater has a TPR valve but handles potable water for the house so any leaks on that would have totally different results. The floor heat system is isolated by a heat exchanger. It has kept pressure for 20 years but I can see how it would be difficult to avoid very small leaks. I figured it would be good to use distilled water due to the amount of minerals in our domestic water and used a small pump to initially charge the system. How is recharge handled in such systems?

Also have some questions about cleaning the heat exchanger, especially the domestic water side. I recall reading something about that when I set things up. Something about running vinegar or some other cleaning solution through it.

I will try to charge the system and see if I can see leaking anywhere.

0 -

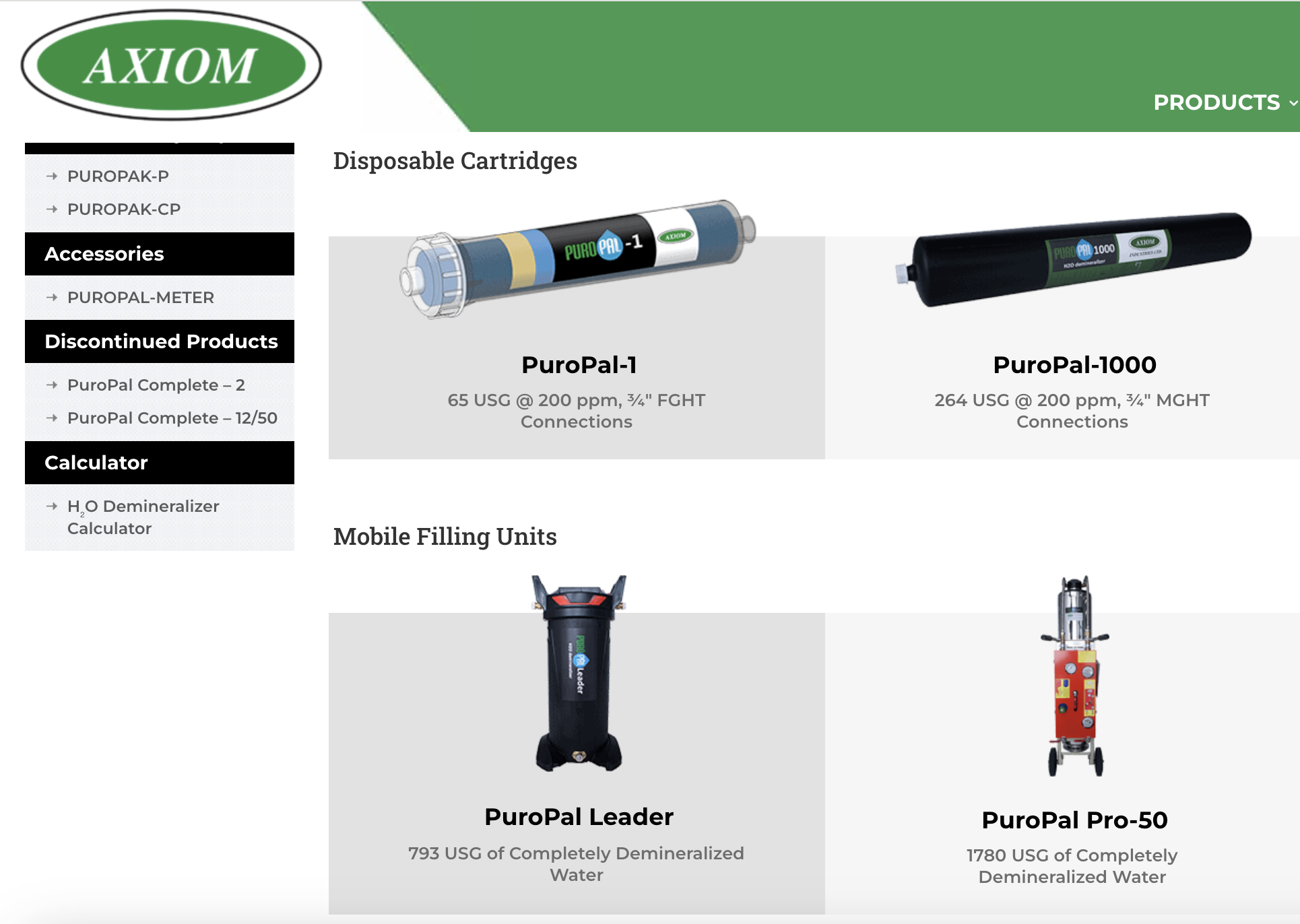

I found some evidence of leakage on one of the air vents. I see some air vent specs state they can be taken apart for cleaning - is this a maintenance item that needs to be done periodically? Should I be getting better ones? If so I see some brass ones such as Taco 400-4 and Watts FV-4M. I have a similar looking Amtrol device near my pump but don't see a model number.

Should I be using distilled water if my domestic water has high mineral content?

Here is a pic of the vent.

0 -

There are a few brands of auto vents that cannot be disassembled, the top is crimped on.

Most of the forged brass type can be disassembled and cleaned or rebuilt. Often a speck of debris is in the small needle valve inside. Clean ad reassemble.

If your water is over maybe 10-12 grains hard or high TDS, it is good to get some filteted water. Boiler manuals give you water quality specs. IO'll attach a few.

True distilled water is hard to find and expensive. most filtered water you see in the stores is either run through a RO unit or a media for DI deionized, or DE demineralized water.

For small amounts 5 gallons or so, places like Walmart have water machines that you can fill your own container.

Water treatment companies will generally fill a 55 gallon drum for you.

Another option is to buy a demineralizer cartridge and connect to a hose to filter water on site

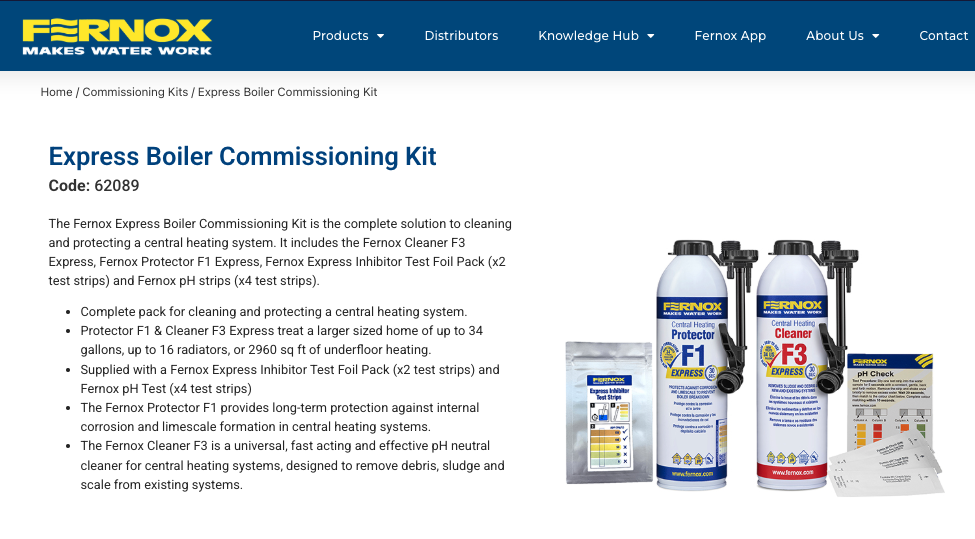

A 3 step process. Run a cleaner first to dissolve any oil, flux, pipe dope etc. Flush that out, add good water, then add a hydronic conditioner.

The conditioner adds a thin film over the cleaned bare metals, has an oxygen scavenger and ph buffer to protect all the metals.

There are easy to use kits for this now. They screw onto a hose thread, like a boiler drain to squirt in.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements