Advice for replacing a Bell & Gossett 2-1/2" with a Grundfos

Long story short, I want to DIY replace a Bell & Gossett 2-1/2" circ pump with something much quieter. I'm thinking a Grundfos since that's what the rest of the system is using. Grundfos have equivalency charts that suggest the UP 53-45 F, but that's discontinued and they suggest the UP 53-46 F instead. Though comparing the specs with the B&G, that's quite a more powerful pump, and I wonder if I can get by with a UPS 50-44 F. But I have to admit I don't know how to size a pump, I'm just assuming what we currently have is probably a bit oversized and went down a notch. The building has 15+1 units, is 3 stories high with a partially sunken basement (where the pump is), and about 35ft high in total.

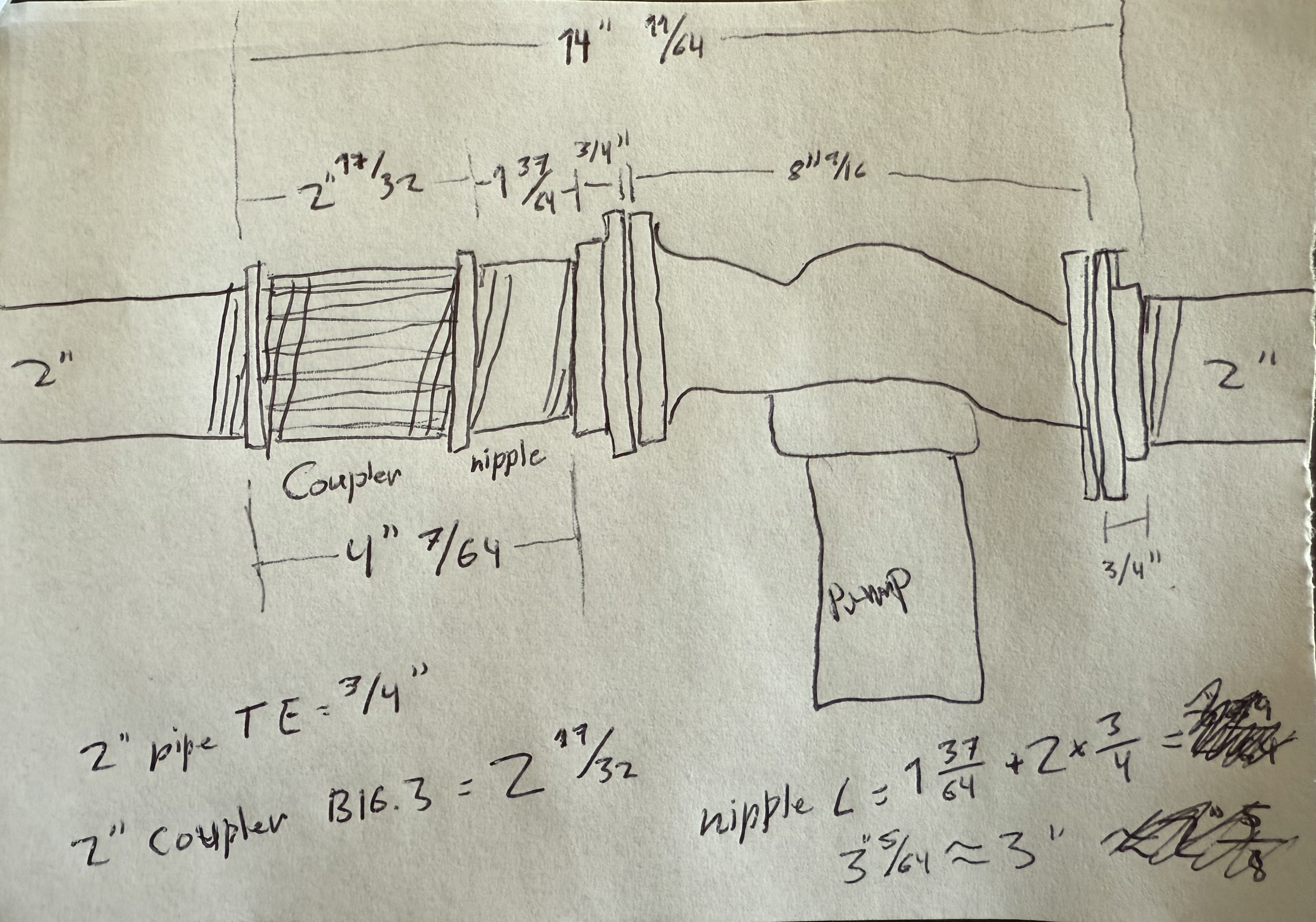

If I go with this pump then I also need to shorten the pipe. I've done plumbing and have changed a pump before, but I've only worked with copper and PVC, so this black iron stuff is new to me. I don't have NPT thread cutting tools, so I'm hoping to get by with a coupler and nipple. I did my research and based on all the measurements I have, a 3" nipple is just about right.

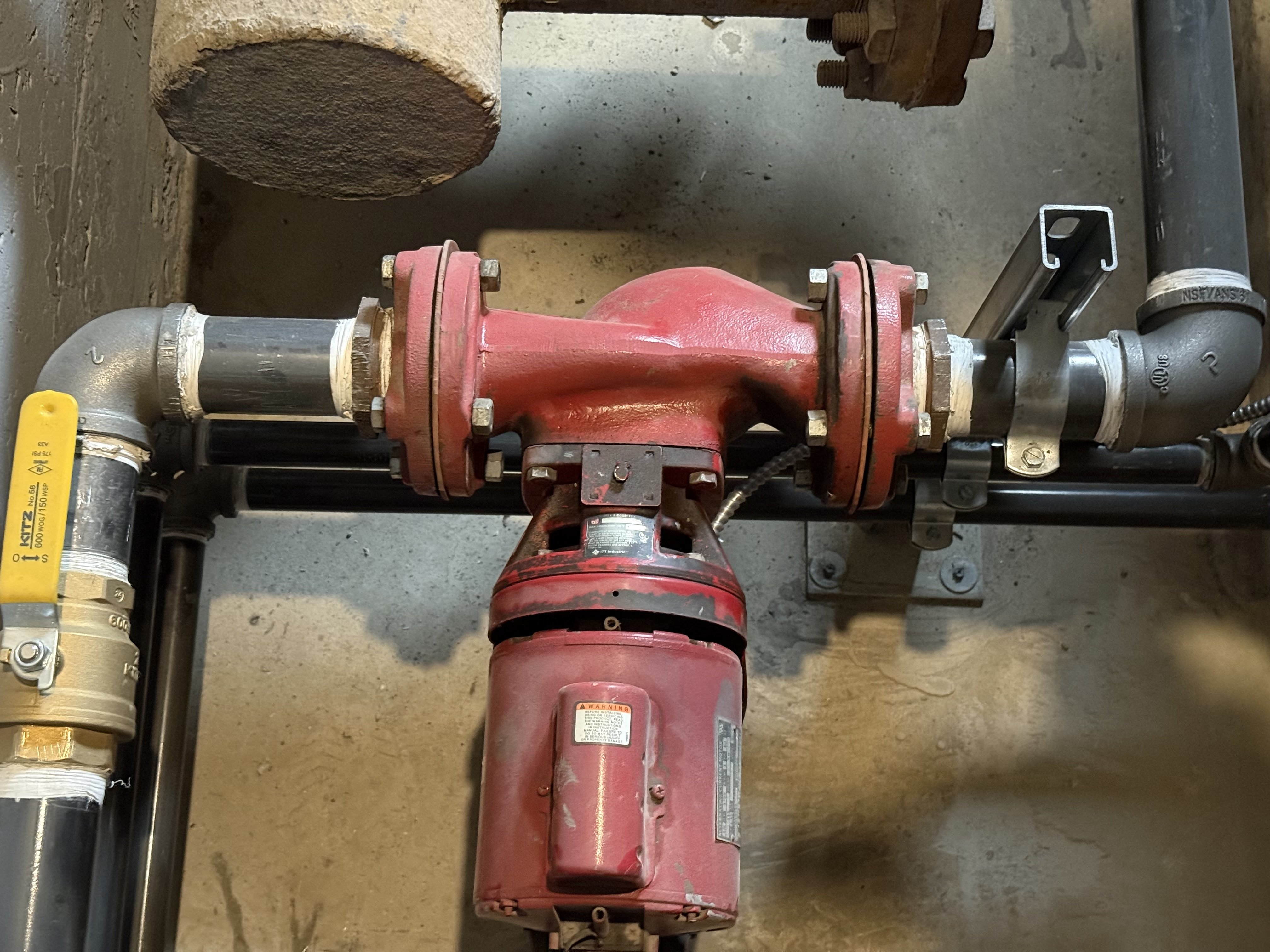

Here's the current setup: I plan on removing the 2" 1/2 thread adapters and lengthening the left pipe for the shorter port-to-port length of the Grundfos.

And the math (sorry for the bad handwriting):

If I understand correctly, couplers have a standard length, and for 2" pipe I need 3/4" of thread engagement. I also did the math in metric since most spec sheets gave metric values and I don't trust my knowledge of imperial measurements, and arrived bang on at 3" (7.62 cm).

I found a domestic supplier for the pump, coupler and nipple. I think all I need is two 18" pipe wrenches, which should be suitable for 2" pipe?

Will this work? I don't want residents angry at me because they don't have heating…

Comments

-

What kind of noise are you getting from the existing pump? Motor noise, cavitation (like marbles rattling in a coffee can), water flow (velocity) noise in the pipes and emitters?

If it's velocity noise, that pump might be oversized for the job. If so a more powerful pump will make things worse.

—

Bburd0 -

It's a clearly audible hum on the first floor. It's not rattling, and it seems to travel through the pipes.

0 -

Unless the noise is new, that sounds like a need for acoustical isolation of the pump rather than a new pump. Above my pay grade I'm afraid, but others may have suggestions.

—

Bburd0 -

It's hard to tell if it's new because there was another much louder B&G pump (same model IIRC) that got replaced professionally this year, and that got rid of a louder and much me annoying whiny noise. It's possible the hum was there all along just not as noticeable. I'm hoping that by replacing the second pump I can finally get rid of all the noise.

How does acoustic isolation work for a pump?

0 -

Acoustical isolation generally applies to larger base mounted pumps rather than the smaller ones supported by the piping like you have.

Usually it's a combination of flexible connections (like braided stainless steel over synthetic rubber) between the pump and the system, and acoustical isolators at the pump base, generally springs or rubber or both. This is not simple though, the isolators have to be selected for the load in order to work.

—

Bburd0 -

-

You may want some extra nipples one size longer and 1 size shorter on both sides of the pump.

You can look up the "correct" make in allowance for fittings but in the real world that sometimes doesn't work out do to manufacturing tolerances and China made fittings.

0 -

Should I extend both ends or just one? Seems like only one end would be easier. Fewer parts.

But yeah I should buy the next size up and down to be safe.

0 -

what type of radiators in they it’s? How are they controlled, by zone valves?

If you have zone valves or TRVs in the units consider a Grundfos Magna. It is an electronic pump that varies its speed based on the building load. They are whisper quiet and use 50% less electricity. They completely eliminate velocity noise as they modulate their speed. Think of a cruse control on a vehicle, same concept.

The pump you have tries to move X amount of gpm always, so it may be over-pumping as units turn on and off.

In some areas the state or power utility have incentives to change to high efficiency circulators. Www.dsireusa.org to check you area.

In a few years those PSC style pumps will no longer be sold, as they do not meet the energy standard updates

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

They're old cast iron radiators. It's all one zone, but some radiators have been retrofitted with control valves (3/6 in my unit have a valve for example).

I'm in Canada and I couldn't find any subsidies for high efficiency circulator pumps (only for pool pumps), but the MAGNA pumps are still interesting. It might be overkill though since we don't really have zones. The other pump I was looking at is a manual three speed so I should be able to dial it in somewhat. But what model of the MAGNA line would you suggest?

0 -

In the middle of the night I can still hear the micro relay on me T-stat and the 007 circulator ever so faintly.

0 -

3 things you should know or determine to properly size a circulator

GPM, head, and type of fluid.

Most often pumps get swapped with same or similar size, be it right or wrong.

You want to size as close as possibly, with the new ECMs they adjust and modulate on their own

When you say control valve in your unit, are these just manual wheel handle valves? Or thermostatic?

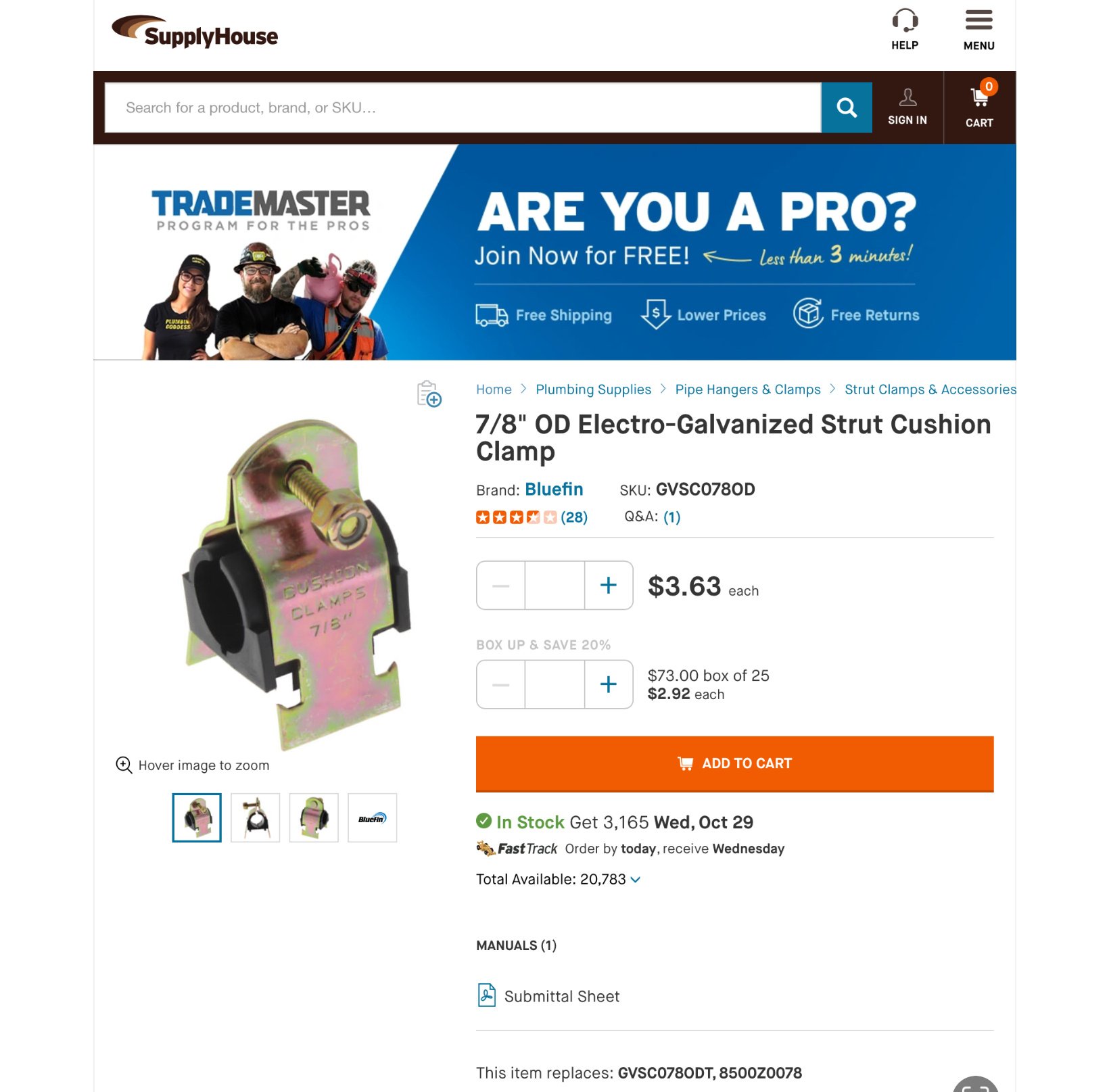

This type of strut clamp may be all you need, they make a big difference for noise and vibration dampening

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Fluid is water, but for head and GPM I don't know what they need to be.

The MAGNA pumps are way more expensive than the regular ones, so sizing the same would just be a waste of money if we don't need that power.

The valves are just plain manual wheels.

Thanks for the advice about the struts, should be easy to swap.

0 -

My thinking is you haven't got a lot of room for a coupling. It may fit it may not fit. You may find that if you shorten the nipple on 1 side and slide the pump over you will have more room for the coupling on the other side.

Also changing two nipples and installing the coupling will then give you 6 threads to work with which will make getting the space between the two flanges you need easier

0 -

I see, but I checked the measurements and I don't have room for two couplers.

0 -

-

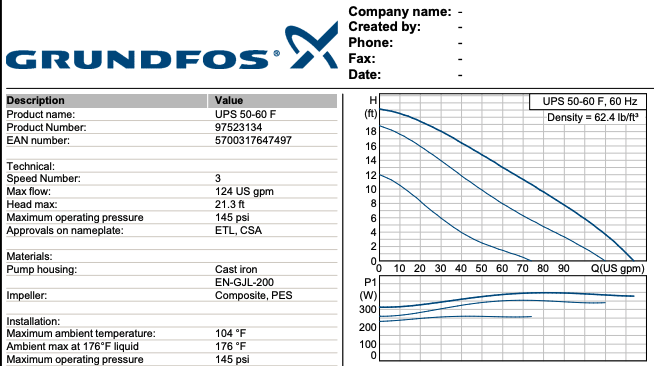

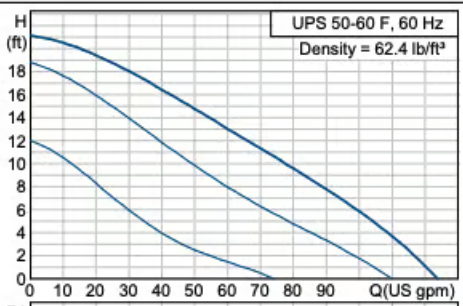

After some more research, I think a Grundfos UPS 50-60 F is maybe a closer match? If I don't want to undersize. Looks like it's a 3 speed equivalent to the discontinued UP 53-45 F in the equivalency chart.

0 -

If you don't have the gpom or head data, look at the boiler. Say it is a 250,000 divide by 10,000 and you need around 25 gpm to move the heat around at a 20∆. So you need a pump that can at least move 25 gpm. Head is a bit trickier to guesstimate.

Unless you have small coil, high pressure drop fan coils you probably do not need a real high head version.

Ideally the gpm number is in the middle of the pump curve.

So depending on the speed the 50-60 wants to flow 30-70 gpm to run mid.

On speed 1, 30- 50 is mid curve.What size is the boiler?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

A cushion clamp is what you need for this and perhaps a rubber cushion at the base to absorb more vibration.

Generally, when you have vibration like this the bearings are going bad and all you may need is a new circulator assembly.

You will know if the motor end bearing is bad if the shaft can be pushed/moved too as the outer race will be bad as well.

If you have an engine stethescope you can quickly identify bearing noise and cavitation/air bubbles being generated in the circulator housing too indicating a severely worn volute.

Before you waste your money, invest in an engine stethescope to listen to the noises being made as you will quickly find the cause.

1 -

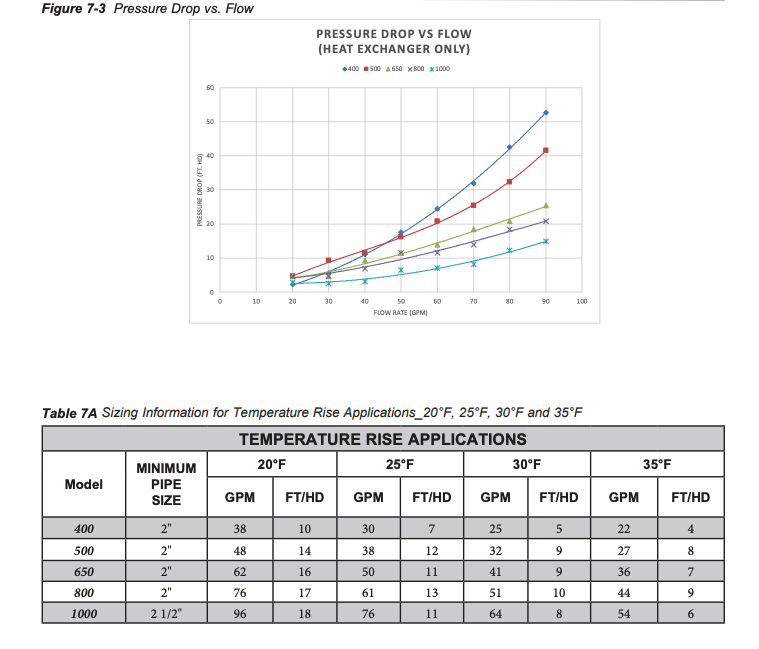

The boiler is 650,000 btu/h. For head I have no clue, this is an old building and I have no official information about piping.

Digging up a previous tender, they suggested a Grundfos UPS53-55/57F, which is quite a bit more powerful than the B&G.

0 -

Avoid over-pumping, it leads to noise ad pipe ad component wear. If the boiler is a 650K input X 82% efficiency then the boiler output is 533,000 BTU/hr so around 50- 53 gpm.

My guess with the info we have is this circ is a close choice. The 3 speeds give you some wiggle room.

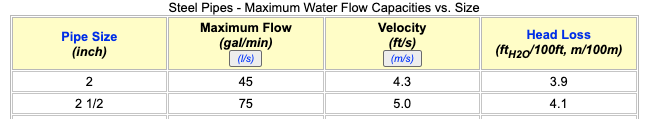

2" schedule 40 pipe accepted flow rate typically 45- 50 gpm

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

It's 97% efficient (brand new), but I think the pump is still a good fit.

Thanks a lot for the advice.

0 -

Buy the engine stethescope and use to listen to the noise if any before you wander down the circulator replacement rabbit hole.

0 -

I'd appreciate any product recommendations.

0 -

-

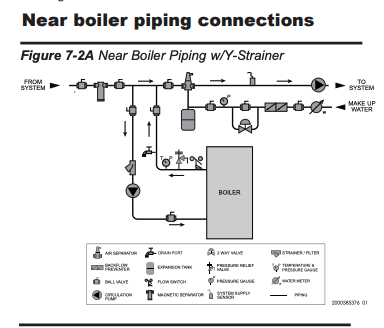

if you have a 97% high efficiency boiler, you need to check the pump spec for that also. Some of the high efficiency boilers have high pressure drop heat exchangers and need to be primary secondary piping

Got a pic or brand and model?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

If the vibration is from the 60hz line frequency (very likely since it is a big single phase motor), putting the pipes on soft mounts won't help. To isolate the pump you need a length of flex hose before and after the pump with the pump itself hard mounted to the concrete. I had similar issue with a smaller pump and 4' of pex on either side cured it.

Modcon generally means that pump is running 24/7, on a such a big pump the electricity costs are not small. Usually an ECM pump will be about 1/2 the cost to operate with typical ROI in a couple of years. If you are replacing it, I would go for ECM just for that.

The only thing to watch is if is an older system with a lot of sludge, you need a magnetic separator before the pump. The big bonus in your case with ECM pump is they are WAY quieter and free of usual 60hz hum.

Also try to mount the new pump with a horizontal shaft. Puts less load on the seals and generally bad idea to put potential leak points above electrical wiring.

1 -

It's a Lochinvar Knight XL KBX650N.

Unfortunately the budget remaining for the year is tight and convincing the residents that the savings are worth the costs can be an ordeal.

Looks like I might get it professionally installed since I got a quote that's competitive with the price of DIY and it's less of a hassle in many ways (mostly I'm not responsible if things go poorly), so I'll discuss noise mitigation with the contractor.

0 -

I think the 650 is a discontinued model?

It should have a dedicated pump, and be piped primary secondary as the manual shows. So you should have a two pump system?

Here is the pump spec for the boiler depending on the delta you are running. At a common 20 delta it needs 62 gpm!

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Yeah it's two pumps, sorry if that wasn't clear enough. The boiler feed pump is fine, it's a brand new Grundfos UPS43-100F.

It's the main loop pump that needs to be replaced.

Edit: I don't think it's discontinued, this is what we have:

0 -

when I looked for the manual, this is what Lochinvar shows, although the manual is still available

I think they have a Knight 600 and 700 now.

Good idea getting a pro to do the work and cover the liability.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Important bit with a modcon is make sure the outdoor sensor is installed and a reasonable reset curve set in the boiler. This increases the efficiency and reduces the cycling on the unit so it is a win win in terms of operating cost and boiler life.

With PS piping and a modcon boiler, the secondary pump should be sized for your load not the boiler. You can look at your heat load if you have a man J estimate or fuel use during previous heat season. From there you can figure out how much water you actually need to flow. If you are not replacing with an ECM at least go for a 3 speed unit so it can be adjusted once running. Getting the rad delta T dialed in gets you a couple more precent efficiency as well. With older gravity conversions you do have to watch low flow rate though as some rads might end up getting starved.

1 -

You have three parallel pipelines stacked on top of each other with a solid wall on the left side and three clamped pipes to the right of the circulator.

If after you find the circulator is not going bad the next thing would be to invest in rubber isolation clamps for the steel leg and a rail mounted on the wall for three more rubber isolation clamps to further absorb any vibration as circulator/pump vibration can travel for long distances in unsecured piping.

0 -

Do you have any more news on your vibration or circulator issues?

Did you purchase a mechanics stethoscope to identify and isolate the vibration???

0 -

There was a vibration issue with the old pump, responsible for most of the noise, but since the pipes are mounted right against the struts there's no place to insert a clamp cushion. We opted to replace the pump entirely since it also meant no maintenance and less power consumption. We had the extra budget allocated anyway.

There's still some noise, which gets worse as the pressure drops, and I think it's cavitation or trapped air somewhere in the pipes (tried purging various radiators around my unit but no change). But since it's a three speed pump I can just drop the speed and it mostly goes away. I guess an ECM pump would've handled this automatically, but it was too expensive.

Thanks everyone for the help.

0 -

I am glad you were able to isolate and remedy the problem to a great extent.

Perhaps looking at a circulator fed top fed hot water tank to gravity feed all the radiation and have more thermal mass to make use of since the entire building consists of one zone for heating would be worth looking at?

A top fed gravity hot water heating system should be looked at as the heat is slow and even at all times and the circulator would work even less as the float switch would control the water level.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements