Top draw Roth problem

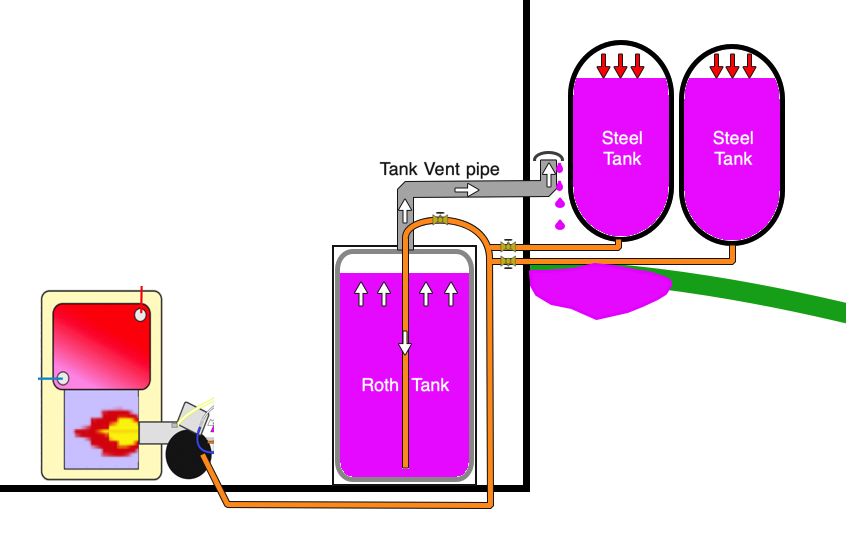

New Roth. And two old outside 275 tanks with great gravity feed to a tiger loop. That's three tanks. Furnace fires up fine with the two older tanks. But never when the two older tanks are shut off. And the new Roth on. All three on /off valves in basement. Roth has one new line flared each end. No no feed from Roth. Gotta figure it out and use that oil as it's been in that tank for 2 years. Air lock? Will try disconnecting both ends and push air for clean out. Did a pebble slip in when the dog bumped my arm? Will find out when it stops raining. In the mean time, air lock? And if yes how too fix? Thx….thoughts?

Comments

-

-

Start off by turning off the two outside tanks. Make sure they are really and truly off. Now. Can you prime the burner pump from the Roth? If not, you have a vacuum leak somewhere in that line and that needs to be found and fixed.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

Chances are you have a bad flare between the Roth and where it connects to the new system.

But you may have another issue. With 3 tanks connected and the two old tanks being gravity feed and all tanks turned on the burner is probably going to pull from the old tanks as they are gravity feed and not from the Roth that needs a vacuum to get the flow started. Oil like electricity will take the path of least resistance

1 -

-

Not nice. This is called HeatingHelp.com. I don't see how your statement helps

Tom indicated that there are some different possibilities …and some others.

- Dirt fell into the fuel line during assembly

- Leaking flare connection

- Leaking pipe thread connection

- The draw tube inside the Roth tank is not below the liquid and is just drawing air.

- There is no draw tube inside the Roth tank

- The Roth tank valve (that looks like a miniature hand pump handle) is in the off position.

- There is a pinhole in the copper tubing between the tank and the tigerloop.

I have a concern about your three tank descriptions. This could be a recipe for disaster. You may have it under control, but some day you may be on vacation, or in the hospital or just too old, and someone will “do you a favor” that does not understand how you have the tanks arranged. They will open a valve and you will have all the oil from the outside tanks siphon into the roth tank. Please tell me “that all the tanks are at the same level” otherwise you may have this condition:

Of course if you have this setup, you are smart enough to never have all three fuel line valves open so the oil in the higher tanks can gravity flow into the lower tank then spill out thru the vent onto the ground. I just wonder if your helpers will know that if you are not there for some reason when they do you a big favor and order two full tanks of oil so your pipes don't freeze while you are hospitalized …. you know what they say about no good deed

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

2 -

Not sure about this one. Obviously if the tanks are at different elevations as you drew it it will be a disaster.

If the tanks are on the same level, I can't make up my mind.

The burner pump runs and creates a pressure lower than atmospheric. All 3 tanks are under the same higher atmospheric pressure.

So does it make any difference if one is top fed?

Think I made up my mind, if the top feed line is full of oil and air tight I guess it makes no difference

1 -

The Roth tank is new but the fuel in it is 2 years old? And why three tanks? The two outside aren't even twinned? Got a Push/Pull Pump?

0 -

-

Why is anyone entertaining tanks at different levels? But will draw the line with sarcasm.

0 -

In appreciation I'll say thx as that's a bunch of commentary and I'm listening. Thank you . Response …..all three tanks are above ground same height. Boiler in basement. Each tank has a new shut off. All three valves are visible and in close proximity to each other. Reason for three tanks? I'll be eliminating in time the other two. Good point made on the what if I'm in a nursing home and someone opens all three valves simultaneously. I'll put up a big sign. For now. Good point thx. My new question is if the line needs a longer priming process, how long? I've already bled a half of soda bottles worth of oil out. And seeing no air in that process. Keep going? Keep bleeding. Get a 5 gallon container? Keep going? Keep searching for some air pocket in a copper line only 15 ft long? Or move on to potential flair issue? Thx

0 -

Oops for Tom. Correction.…..how long bleeding the AIR out, not the fuel oil ! ! Mental mistake caught. The question, how long on the possible AIR? As the issue? 5 min or 15 min worth? Of waiting. Bleeding air? The Mrs. keeps interrupting. Something about the butterflies hatching outside today.

0 -

If you are bleeding at the pump bleed port and the oil is clear, steady stream with no bubbles than I don't think it is an air issue

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 19 Recall Announcements