Gas boiler heating house without call for heat

I just finished replacing/repairing stuff in the boiler room in preparation for heating season. With your help, I cut out a leaking press section of pipe on the supply side near the boiler and sweated a new section to replace it.

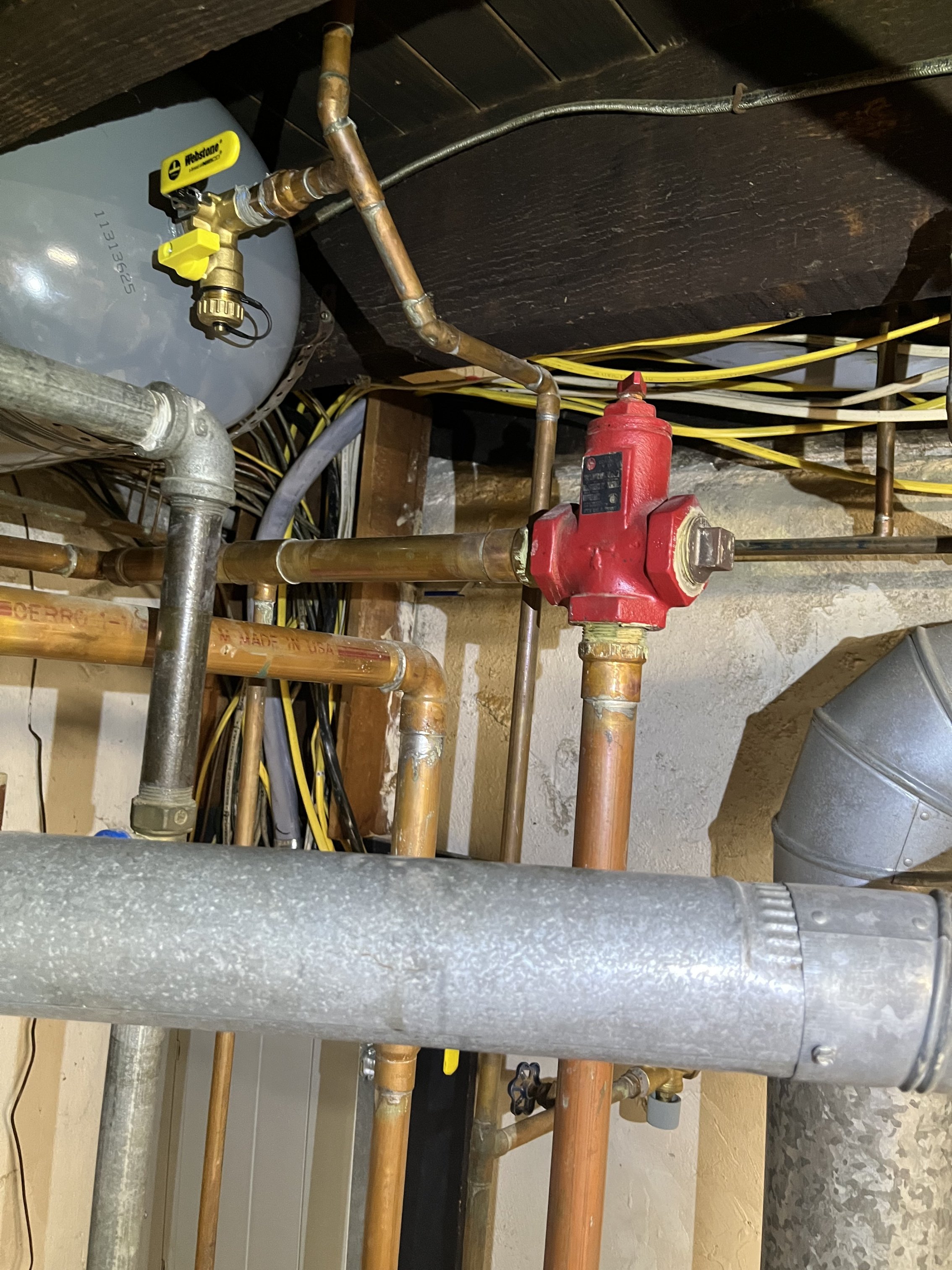

I also replaced an old Watts reducing valve with a new Caleffi autofill valve, replaced an old dripping relief valve, and replaced the old Extrol 60 tank with a new one, and added a Webstone shutoff valve.

The system is single zone with baseboard in the basement and convectors throughout the rest of the house. It runs off a 140K BTU Williamson gas boiler.

Boiler is in the basement and the highest convector is on the 3rd floor. I set the new Caleffi autofill valve for 18 psi and precharged the extrol for 18 psi.

After refilling, purging, then powering back up, the burner came on as normal and I left to head to the grocery store assuming it would heat up to 180 as usual. The boiler, that is, not the house, since the thermostat is off and there is no call for heat.

When I came home, however, the house was a sweat box with heat radiating nice and toasty from the convectors. It’s in the low 70s here in Philadelphia. My wife gave me the business for turning on the heat in September, then leaving. I told her I didn’t turn on the heat.

Here’s what I’m wondering: the system is single zone but has a B&G flow control valve installed from when it had a second zone running out to the garage. That zone was removed and half of the flow control valve was capped.

During refilling and purging, I manually opened the flow control valve. I forgot to close the handle clockwise to return it to automatic operation.

Is this maybe why the house is a sweat box despite no call for heat from the thermostat?

Comments

-

gravity flow or a circulator?

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

"During refilling and purging, I manually opened the flow control valve. I forgot to close the handle clockwise to return it to automatic operation."

Possibly and probably, if your boiler is warm start, i.e. always hot.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab1 -

-

circulator—Taco 007

0 -

It is warm start. I turn it down to 140 from April—October when there’s no call for heat. It was drained and powered off for several days while I was working on it.

0 -

From the other thread;

" We have a three story duplex right outside Philadelphia thats heated by a gas boiler and convectors. Separate gas water heater and gas boiler (Williamson GWA 140N-S, 140K BTU) "

Why is it warm start ?

Also…

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

-

-

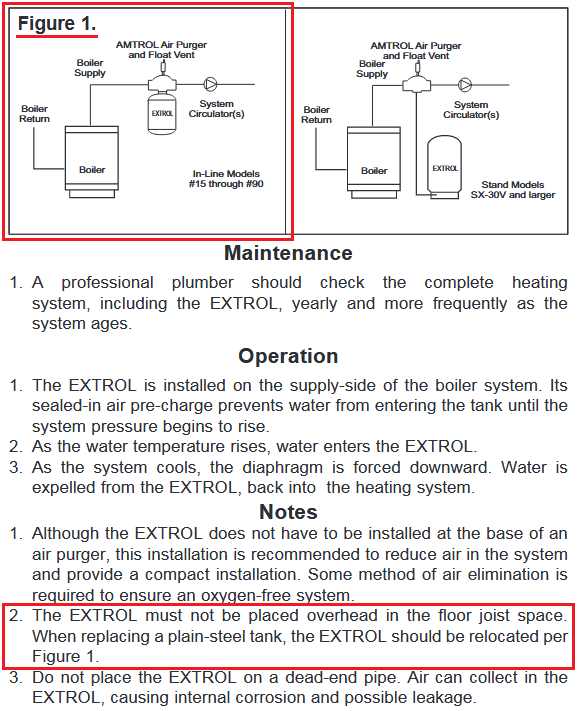

Yeah, I don't like installing stuff other than per manufacturer's rec. The tank has been installed in that spot/orientation I assume since 1997 since that's year of manufacture for the old tank, so I just swapped the tanks in place.

If I'm being charitable to whoever originally installed it that way, maybe it replaced an old bladderless tank that was installed in that same spot, IDK. Not sure how a tank of that size could be installed there threads-up. Presumably would require significant repiping if its possible. The hot water heater, boiler, and circuit panel are all crammed into a corner of the laundry room.

0 -

-

When there's time and you have someone who knows what they're doing, the thermostat/pump/boiler can be wired in series so that the boiler will only come on when the thermostat calls for heat. As it is currently wired, only the pump responds to the thermostat.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab1 -

-

-

-

Your fuel bills may go down (even during the heating season) if the warm start is disabled.

IMO Extrol wants the vertical position so air is not trapped on the water side of the diaphragm. Air on the water side of the diaphragm against the steel housing may lead to premature failure and property damage.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

Why is your boiler maintaining a temperature if there is no call for heat? You should have a control system that allows the boiler to get cold if there is no call for heat. How do I know this? There is a gas water heater next to your boiler.

Your home probably had a oil fired Boiler with a tankless coil for your DHW in the past. This guess is based on the red flow control valve that was not removed when the replacement gas boiler was installed. You do not need to maintain a minimum boiler temperature and you do not need a flow control valve if you are not making hot water with the boiler.

Anyone that tells you otherwise is not being very helpful and is causing you to use more fuel that you need to.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

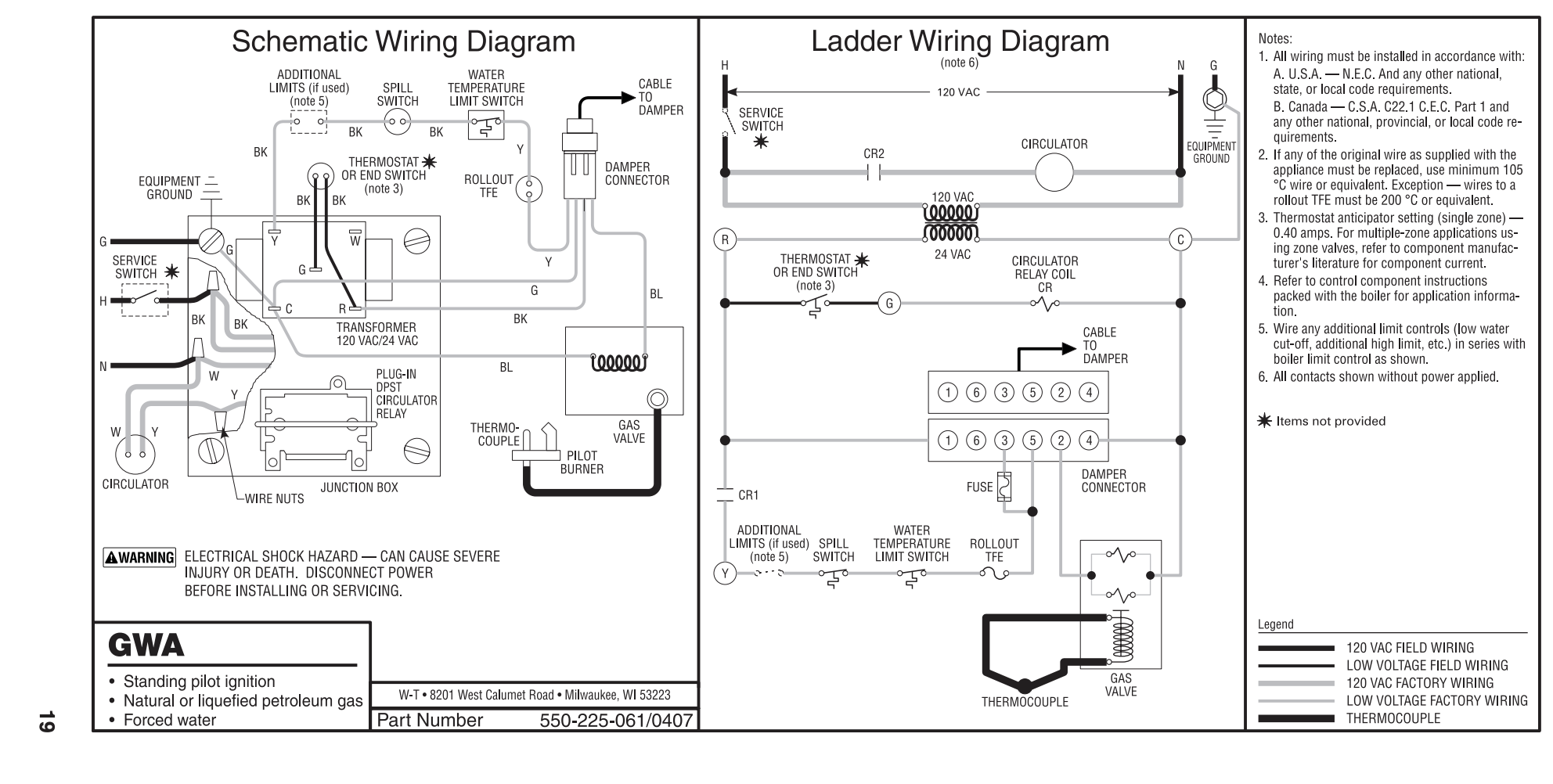

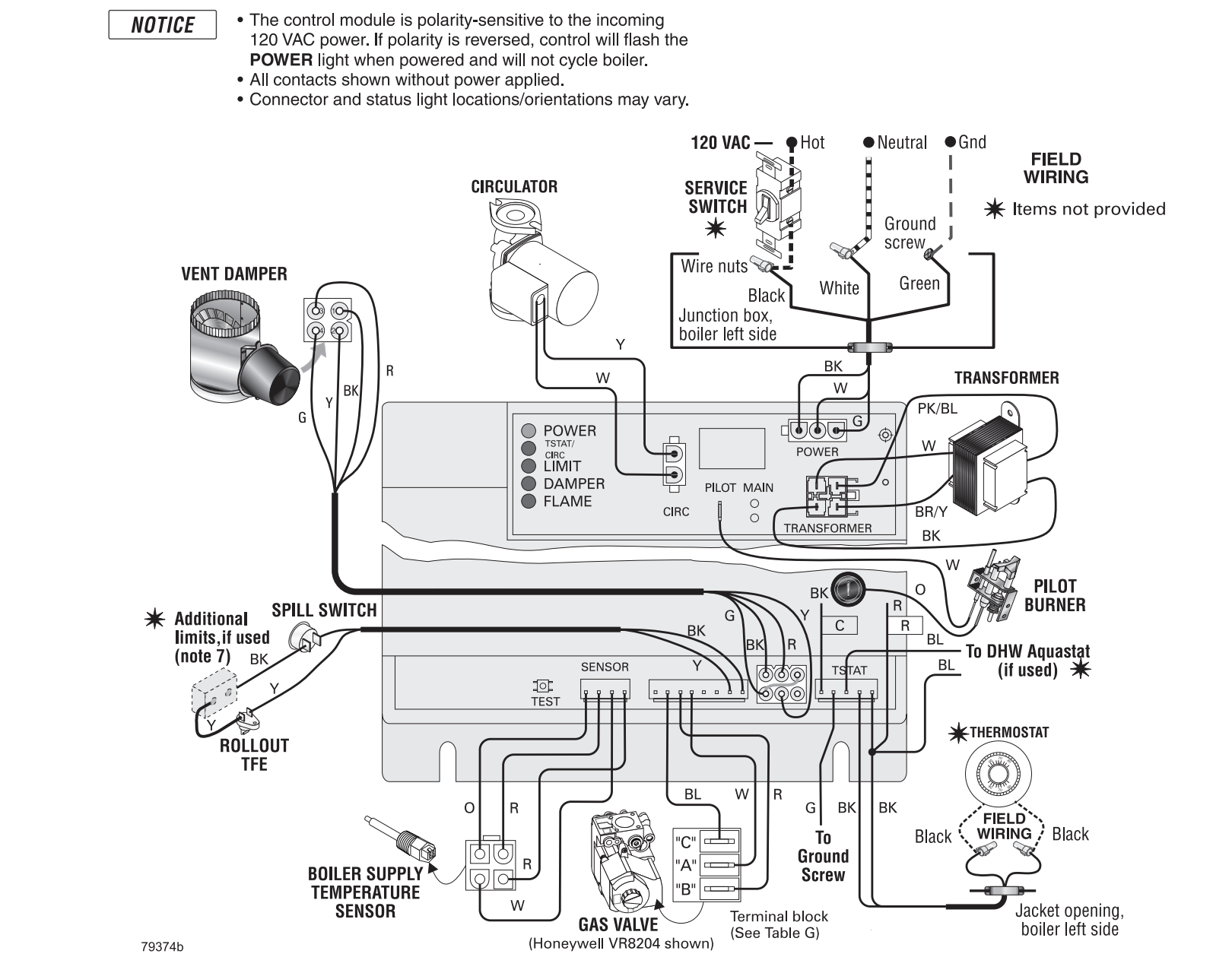

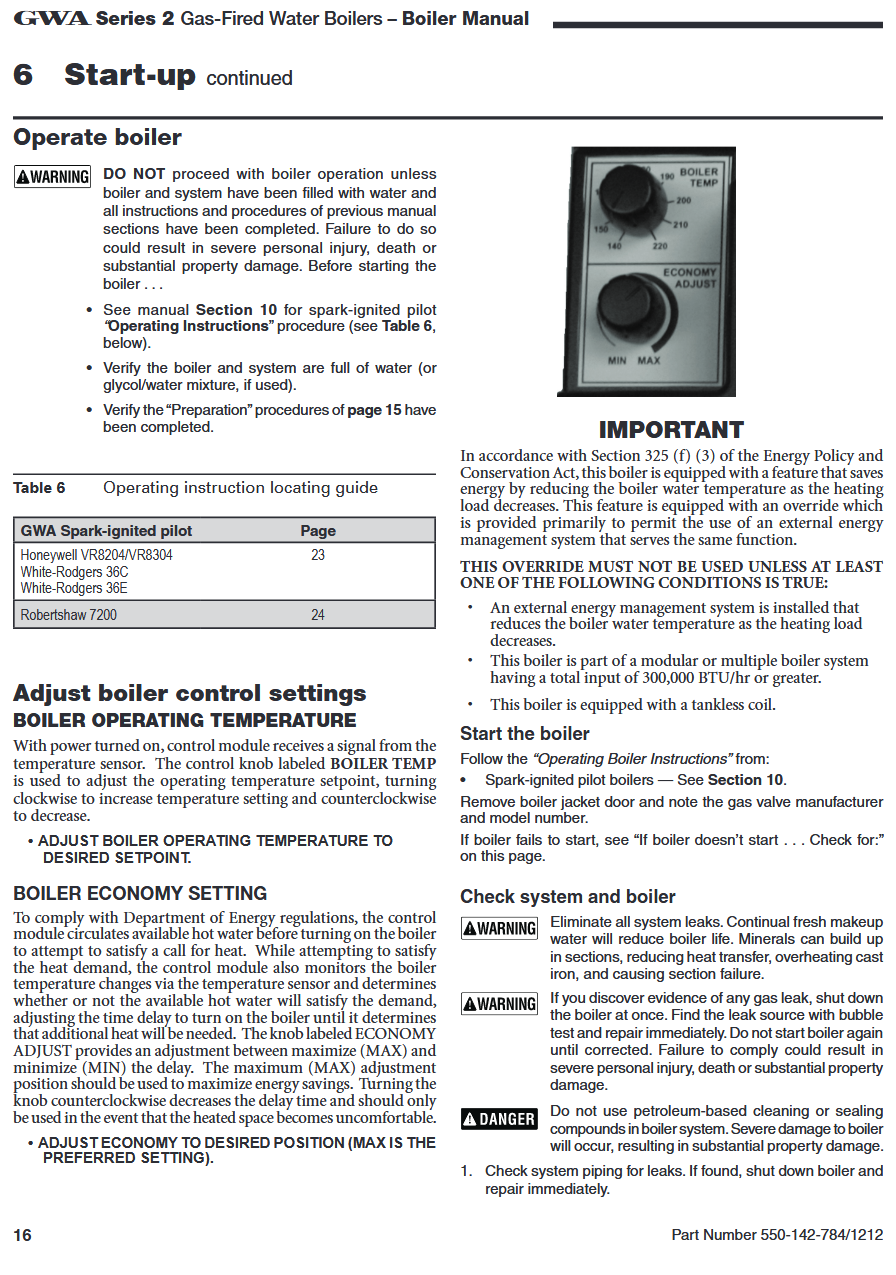

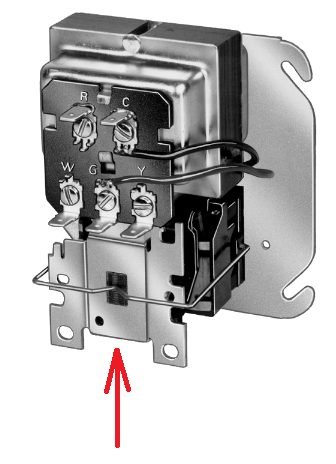

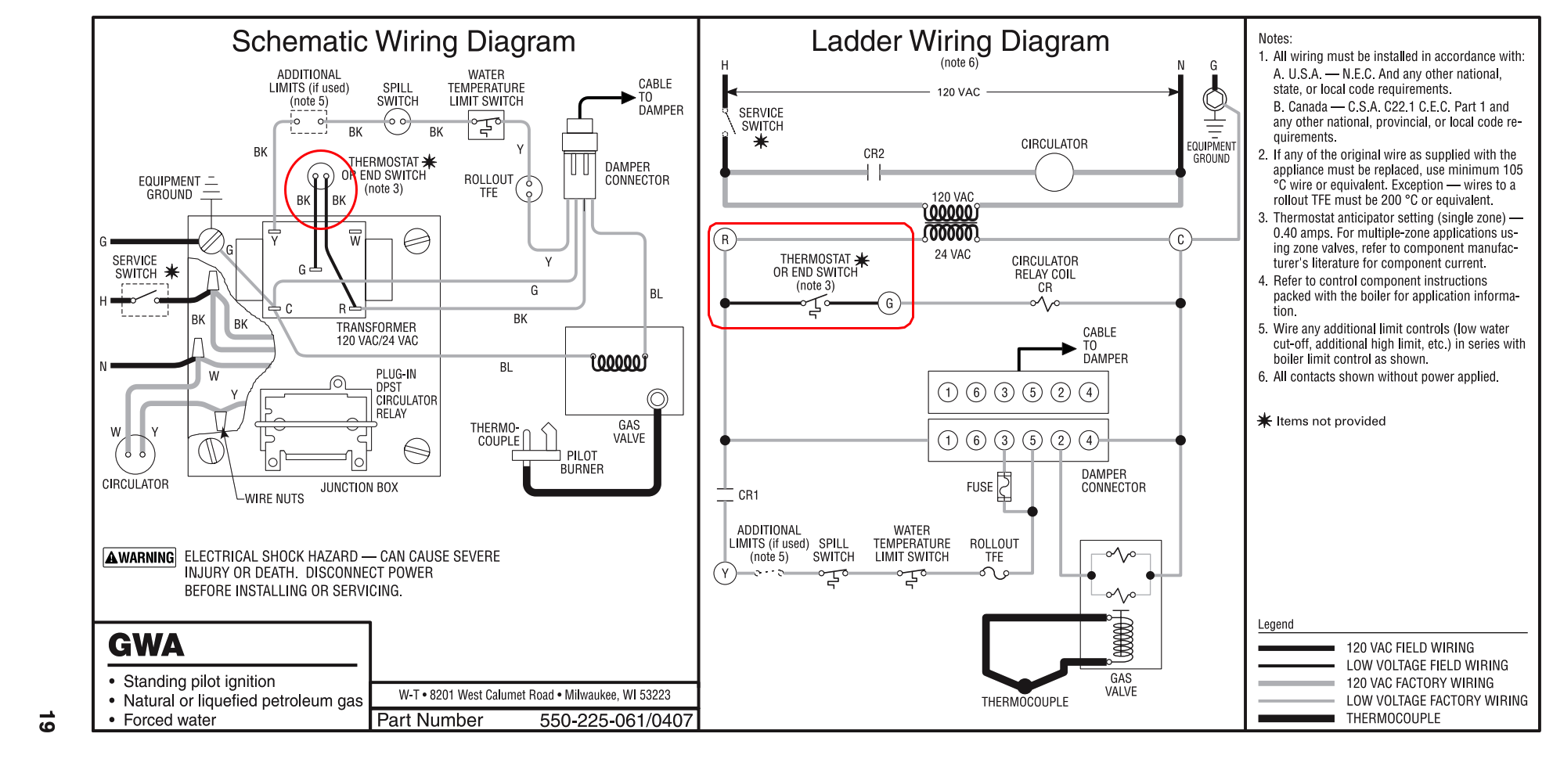

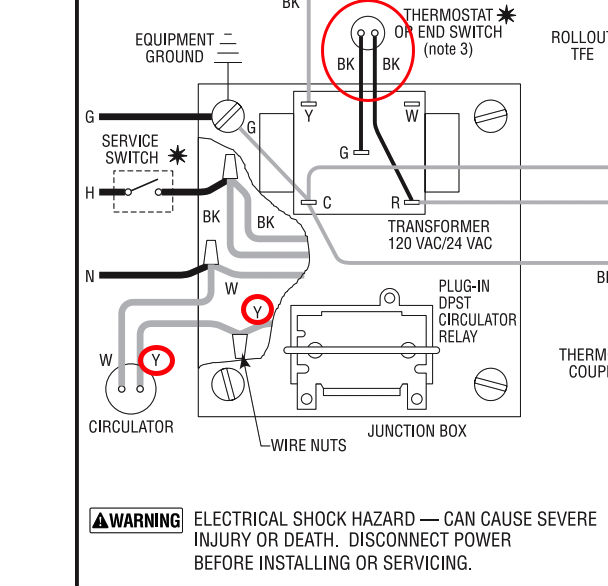

@FrankMaraschino, So, I just looked at the wiring diagram for the Williamson GWA series 1

and the GWA series 2 boilers

There is no provision for maintaining any temperature, 140° or 180° or any other temperature, in either diagram. I think it is a good thing that you found your home like a sauna and that caused you to come here for some advise. You would not have found out that you are wasting fuel by maintaining 180° in the heating season. During the fringe seasons when the call for heat may only last a few minutes, your burner may not even allow the water temperature to reach 150° before being satisfied.

Every minute your boiler is operating at 180° without a call for heat, you are venting lots of heat up the chimney… even with a vent damper closed while the burner is off by the high limit, because that damper does not have a 100% closure. there is always some leakage past the closed damper, and the damper is open more that it is closed whet the weather outside is very cold.

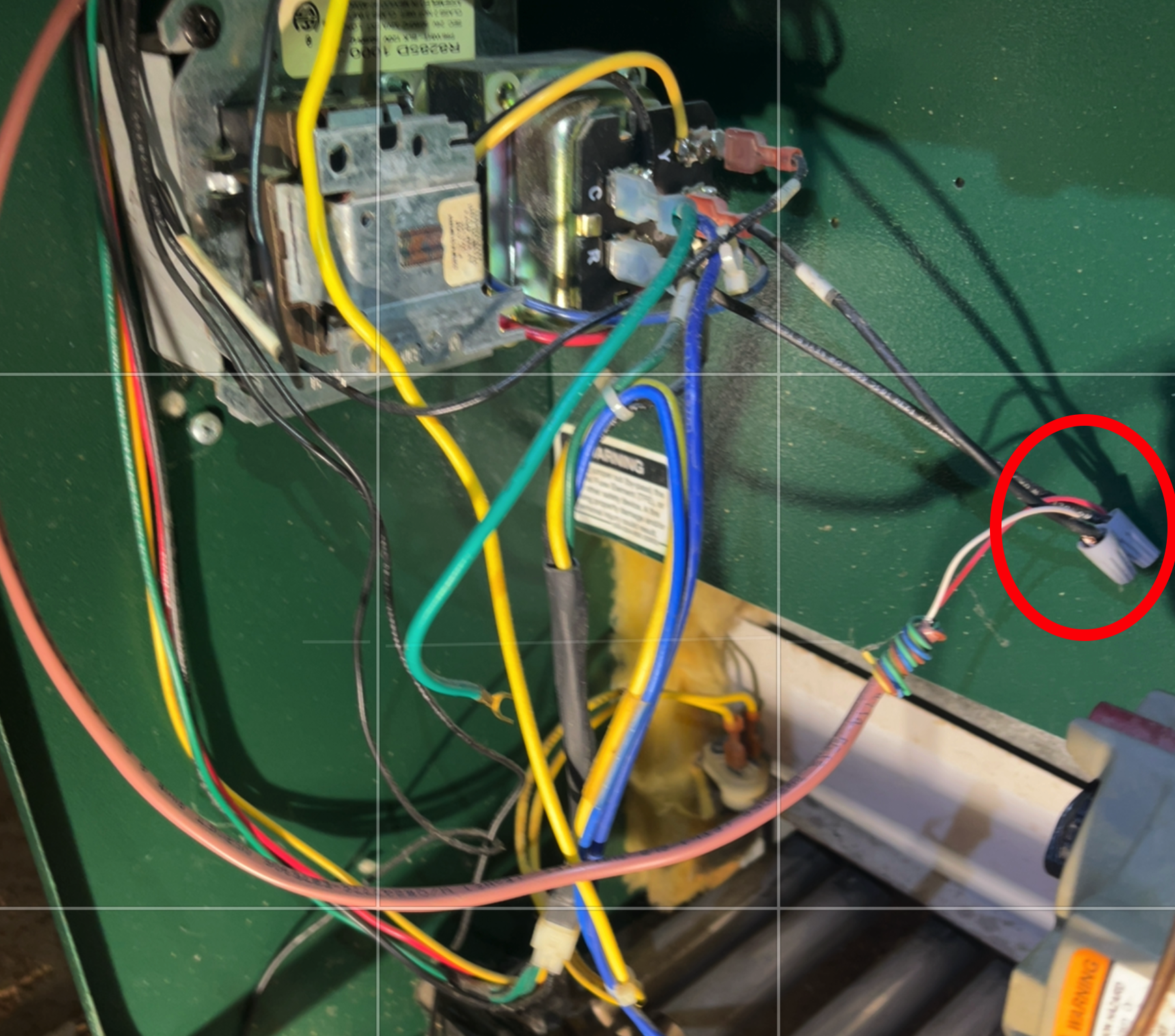

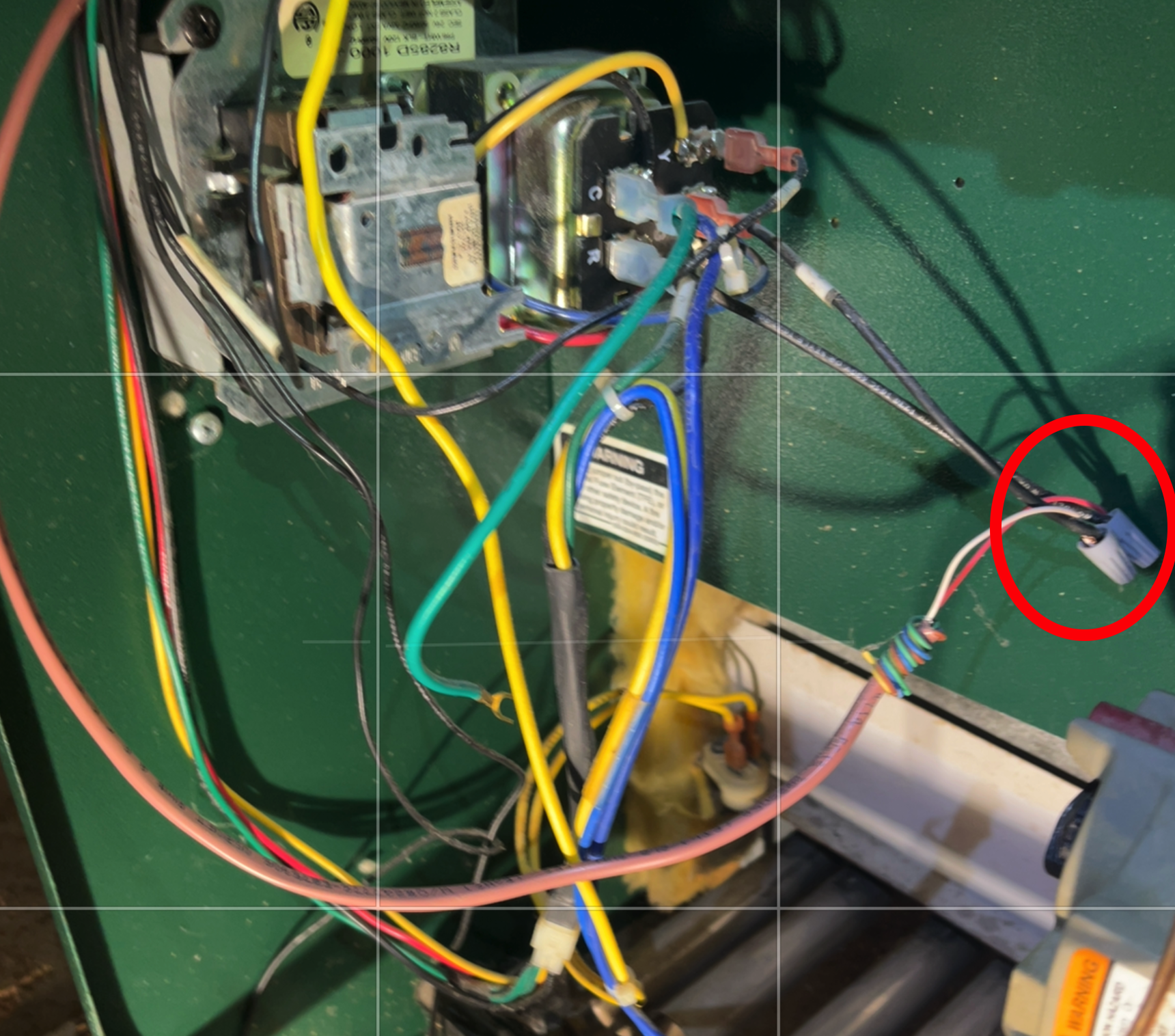

Can you find out why the boiler is maintaining 180° all the time? If you open up the control compartment and post some pictures of the wires inside there, like this:

I can usually see what was done incorrectly and maybe even get you back to a more efficient cold start design as the manufacturer intended. Please try to make the photo as clear as possible by not moving the camera when taking still photos. A video can also help however, there is more involved to post a video and not everyone has the ability to do so.

Also, tank more than one angle so I can see behind stuff that may be blocked in the first pic you take

I understand that wiring diagram can be intimidating to a layman. (and some of the professionals too) But take my word for it, you can fix this with just a minor adjustment and your utility bill will drop by 15% or more.

Yours Truly,

Mr.ED

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

2 -

Series GWA-1 maybe the CR relay is stuck closed

GWA-2 they could have wire nutted the DHW blue wires together

0 -

Other than what was mentioned above, with no demand I would think with the temp setting at minimum and the Economy at Max the burner may never run.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Hi Ed, yes, based on the advice I’ve gotten in this thread I have shut the boiler down until heating season.

I’m not sure if the home ever had oil heat. We’ve lived here 10 years. There is no sign of an oil tank or a fill valve anywhere on the property.Most of the homes in this area were built in the 1920s and 30s and originally featured central plant steam heat. Steam was pumped into homes through underground mains from the Overbrook plant in West Philly. It was supposed to have been a great selling point back then (“You don’t have to buy or operate a boiler or a furnace!”).

Fast forward to the early 70s and the steam mains were deteriorating badly and the company responsible for running the steam plant wanted out of the business. There was a front page photo in the Philadelphia Inquirer of an enormous geyser of steam that shot up from a busted main through City Avenue as commuters were driving to work in the morning.When the steam plant ceased operations thousands of customers were without heat as the winter approached. It was a mess.

Anyway, as I said upthread, our system used to have two zones: one for our totally uninsulated brick garage and one for the the house. The supply pipe for the garage exited from the side of the red B&G flow valve that’s now capped in the photo.I had the piping for the garage zone removed after a couple of eye-watering PECO bills the first winter we lived here. I stupidly thought I could prevent the giant cast iron radiator that used to live in the garage from running by turning the thermostat out there down as far as it would go: 50 degrees. Not sure why it didn’t occur to me that an uninsulated brick garage with a concrete floor in suburban Philadelphia gets a hell of a lot colder than 50 degrees in the winter. Probably a blessing in disguise since if I’d known how to completely turn the zone off I might’ve cracked the pipes out there.

0 -

-

I used to deliver fuel oil the the Olney, Logan and West Oak Lane sections of Philadelphia… Go Birds 🦅!!!

I remember that steam main in the news when I was much younger. There was a rush on boiler installs in that area and many plumbing inspectors allowed some nasty code violations to slip by. But that is a story for another day.

It appears that your convectors were either converted from steam to Hot water back then, or you had a complete new system installed and someone removed all the CI radiators. That would be the reason to have a heat exchanger for DHW and the Flo Valve on your "1970s new boiler" install that also made DHW.

A 1930 home without a coal boiler was like having a gold plated toilet with your "indoor plumbing". Grandmom would tell all her friends in the other parts of town that she doesn't shovel coal or put out ashes once a week. That was before my time and maybe yours too.

I like to know the history of the different heating systems I used to work on.

Now if you understand enough about electricity and you feel that you are a pretty good DIYer, this should be pretty easy for you.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I’m a Steelers fan myself but I can root for the Iggles in a pinch.

Yes the code violations were galore. Many of the remnants are extant; inspectors and building dept guys hate them but they’re grandfathered in.

Anyway, the convectors are old Tranes, I matched them up to a service catalogue from the 1930s. They’re installed inside wall cavities with cover plates. They also all have pot-belly valves except one on the third floor that’s been replaced with a run of the mill gate valve. The brand on the knob of the old valves is Milwaukee. Some of the mains running in the basement are relatively large and old-looking and are either steel or cast iron.

I love building and architecture history. A great site is the Building Technology Heritage Library. It’s an online catalogue of various trade books and product catalogues going back to the 19th Century. Really fascinating. Check it out:

Working on those pics and video1 -

If it is a 3 story duplex it will be very obvious if it was converted from 1 pipe steam to hot water, the returns will be crammed in somewhere. 2 pipe steam converted to hot water could be less kludgey. It could have been gravity hot water heated through a heat exchanger from the district steam. If it was 1 pipe or 2 pipe steam converted to hot water it will be obvious that some new work was done at the emitters to do the conversion.

1 -

0

-

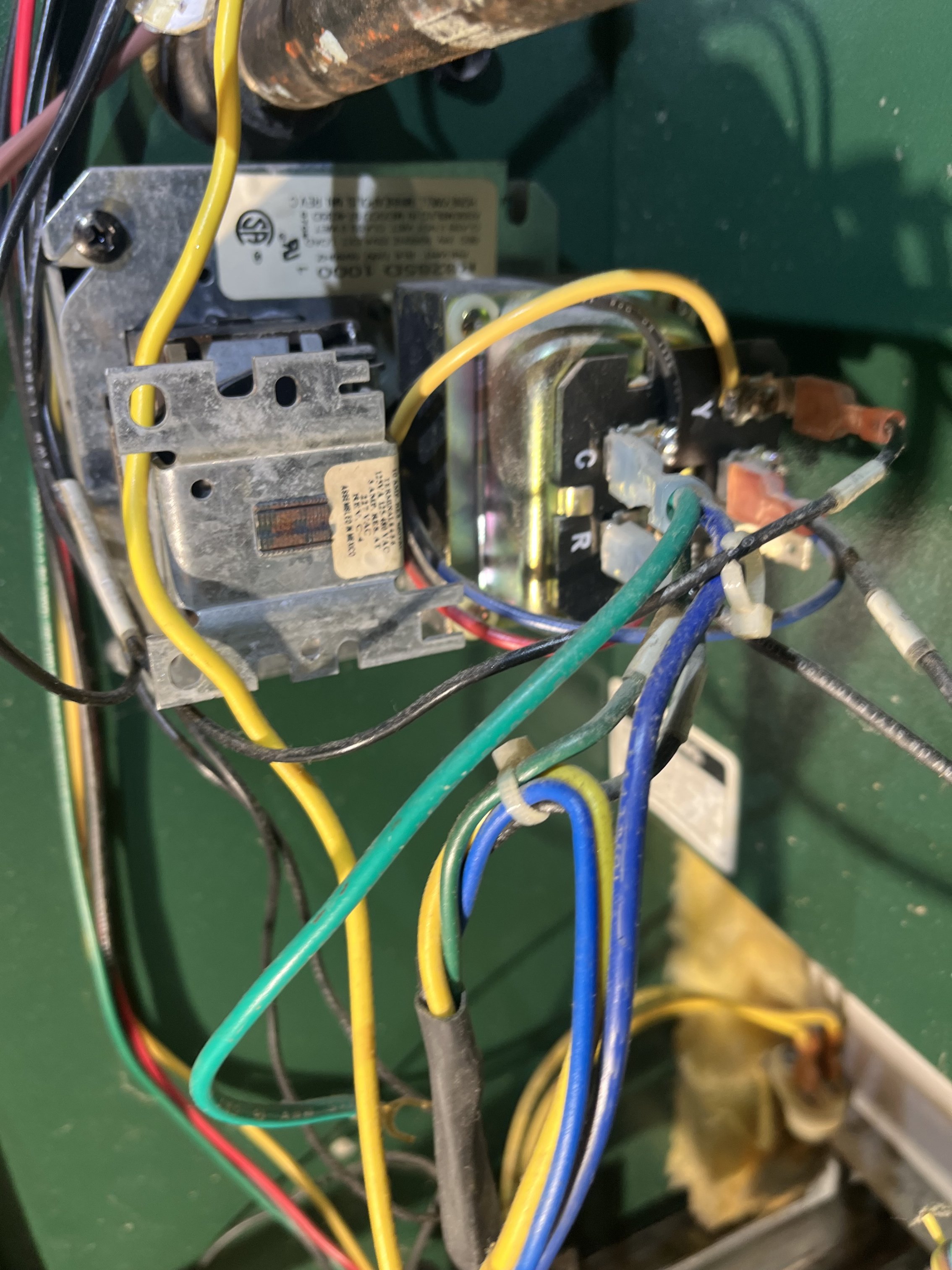

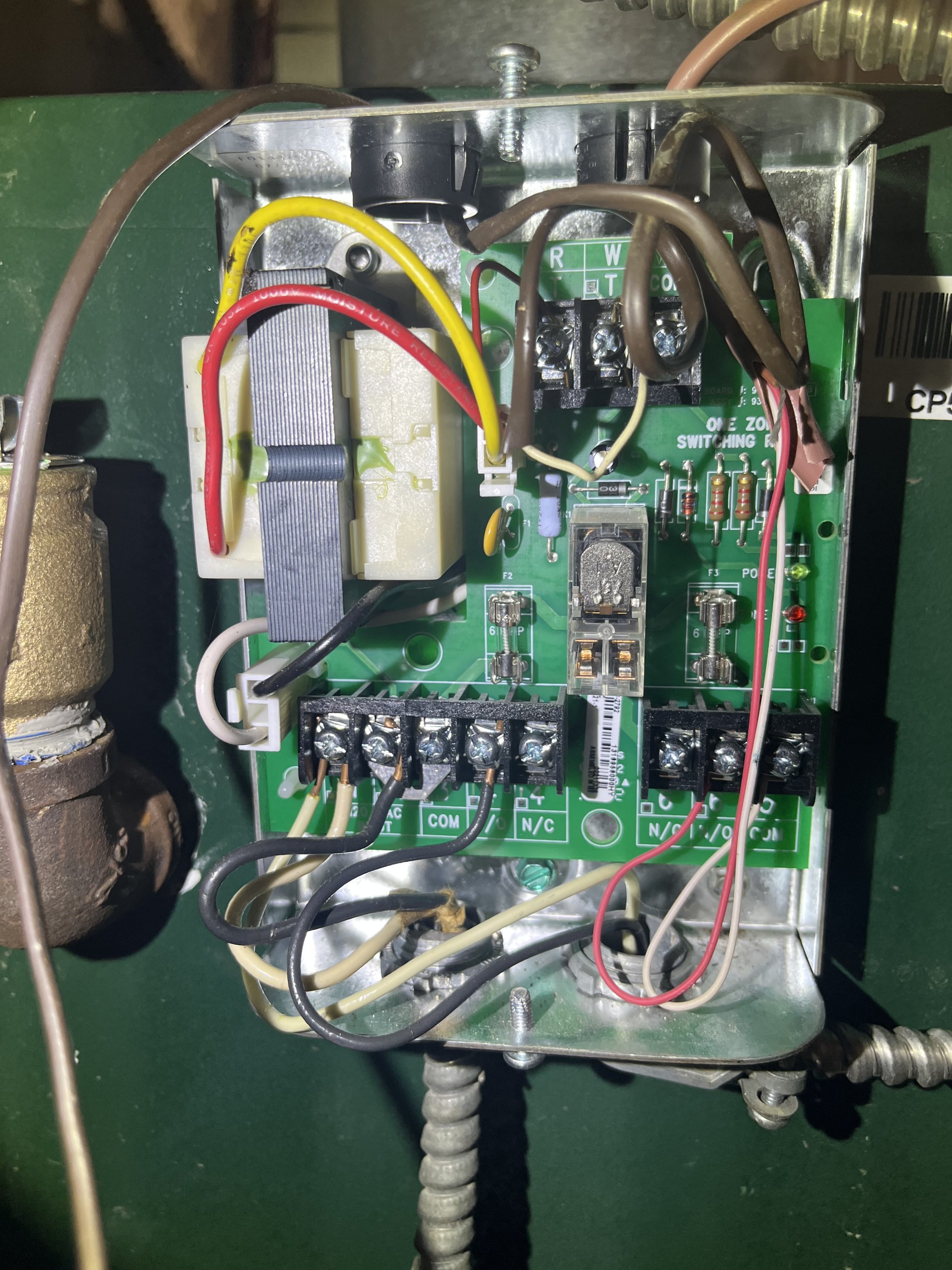

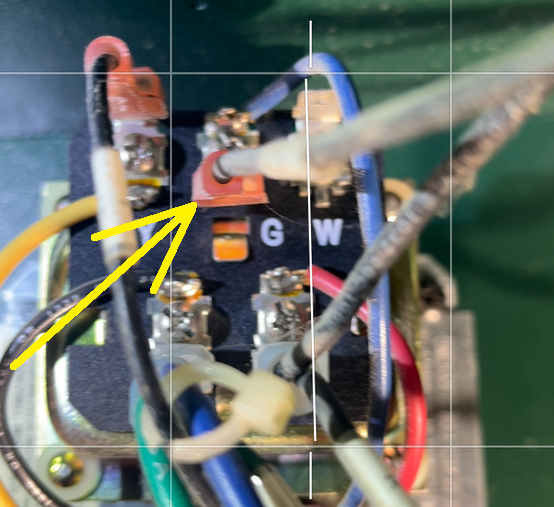

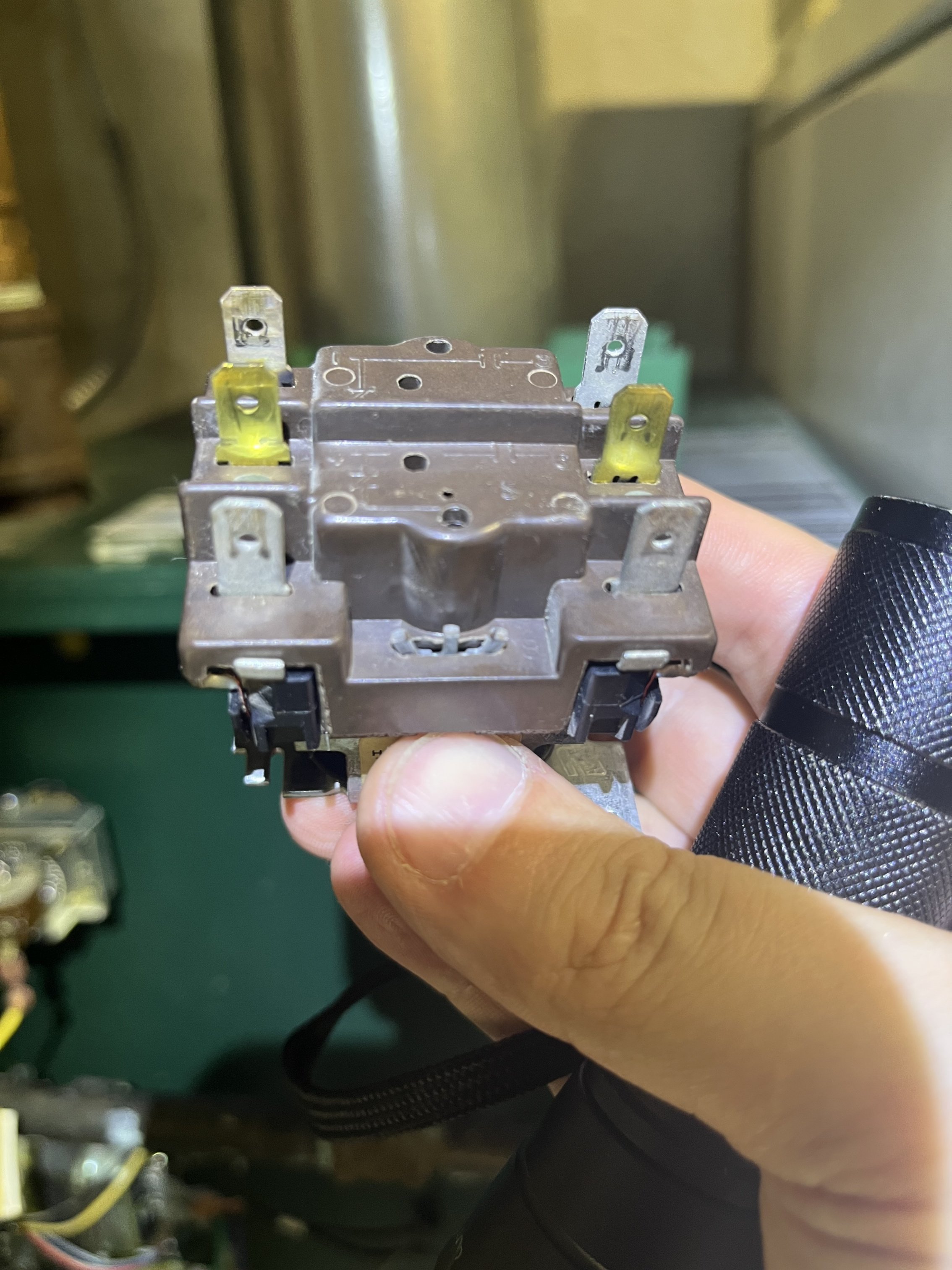

Taco SR501-4 Relay

0 -

0

-

-

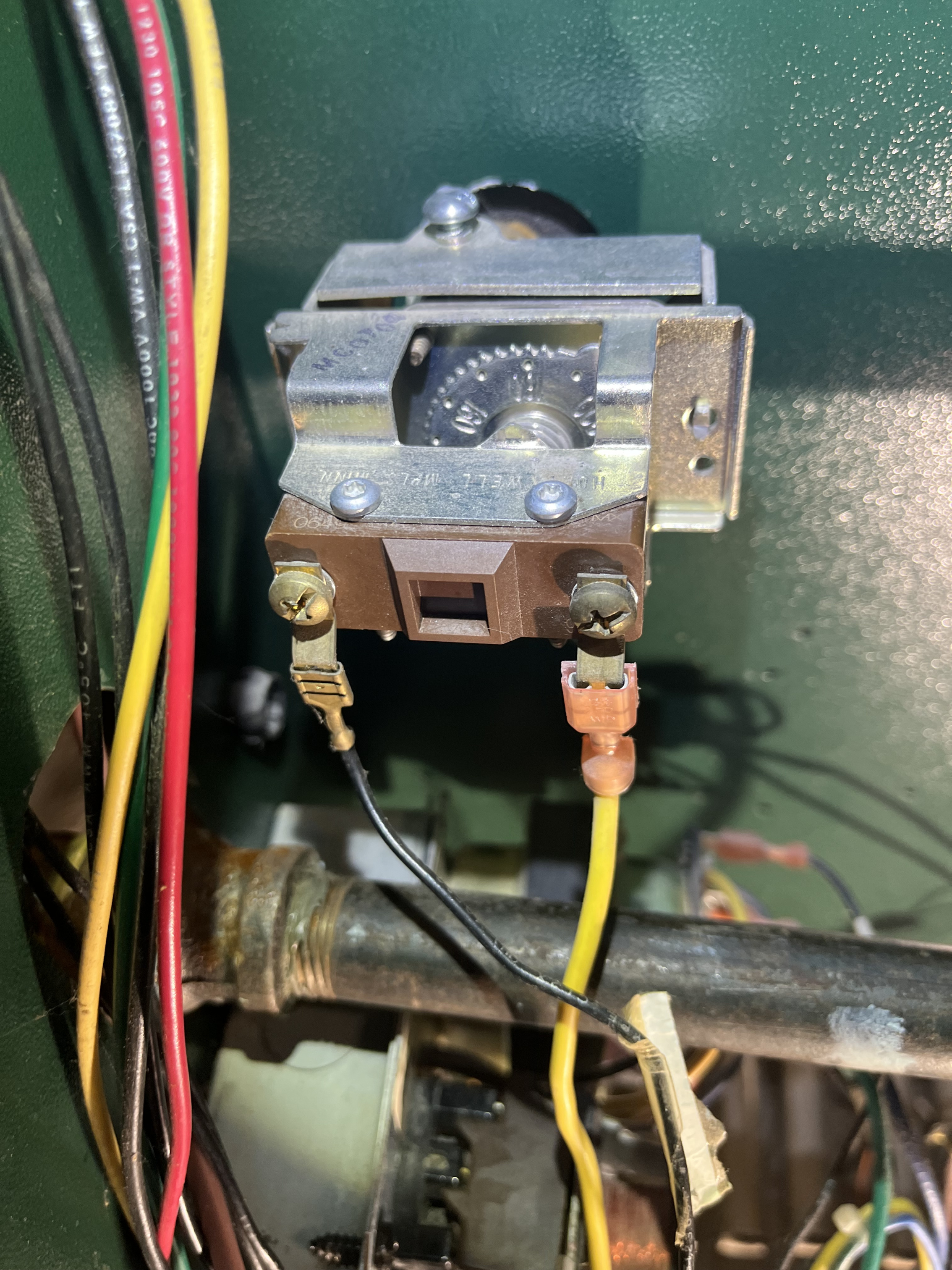

Looks like your boiler is the Williamson GWA series 1 and it should not behave as it does (similar to a warm start configuration). The boiler and the circulator should follow the thermostats command.

Looks like the Taco SR501 is wired correctly.

To start to determine troubleshooting direction start where @mattmia2 stated.

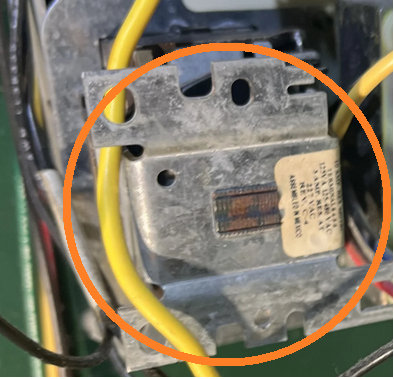

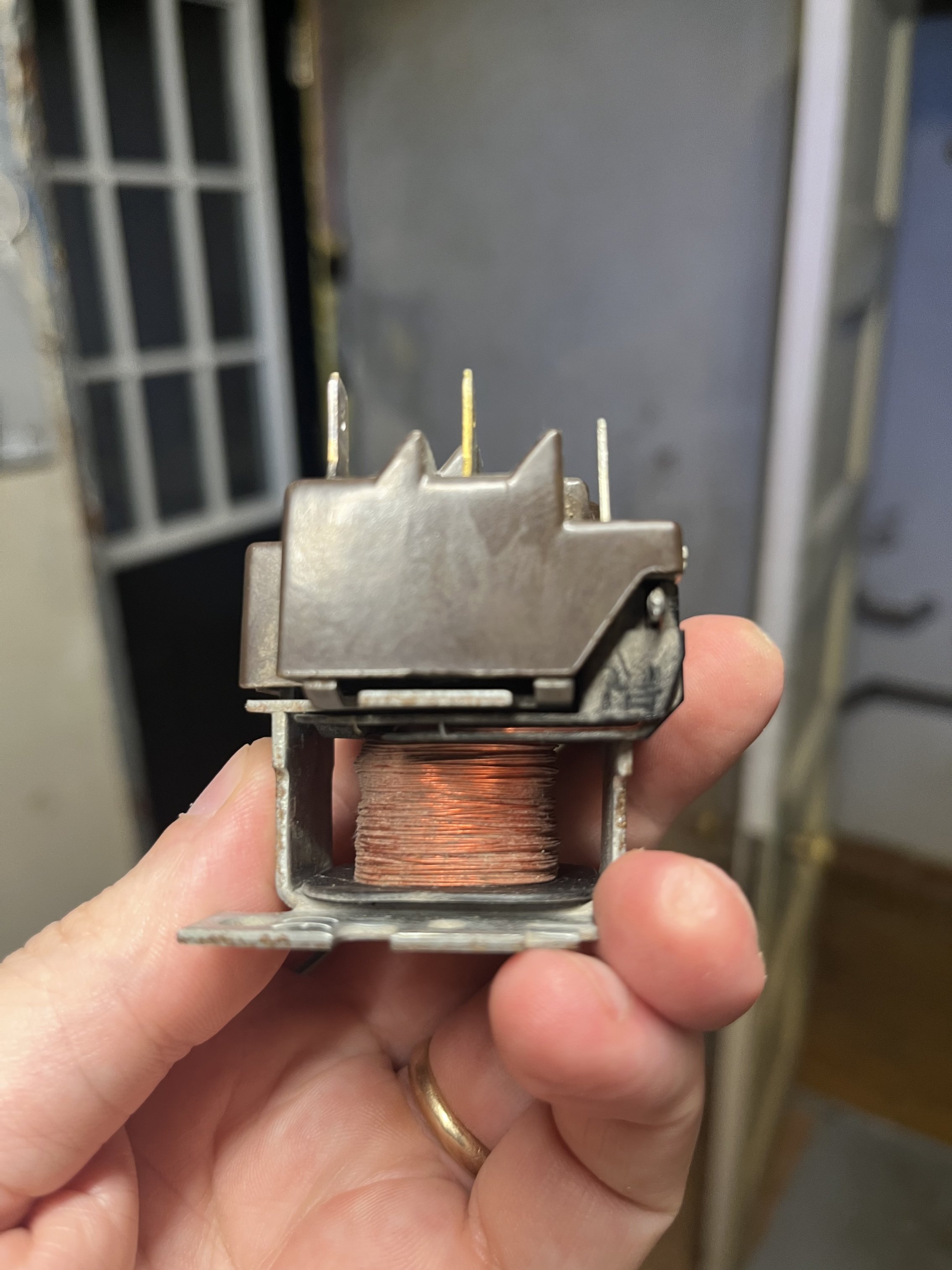

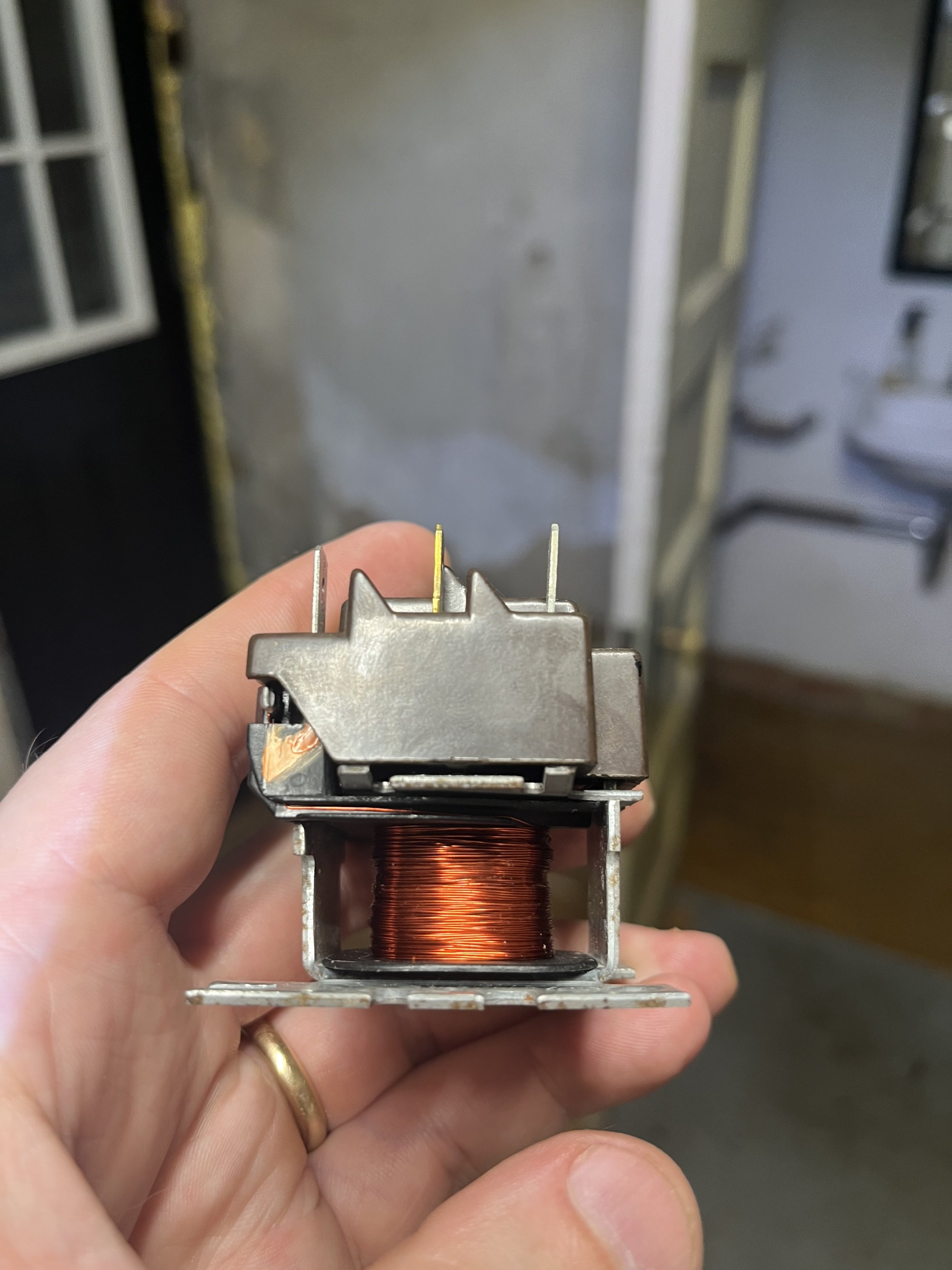

As @EBEBRATT-Ed stated the relay inside the boiler "CR" (Red Arrow) could be stuck, contacts welded, coil energized, or other mechanical defect. Note on your unit the connection plate on the transformer is spun 180 degrees compared to this image.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

As @109A_5 indicated, you have a series 1 boiler with standing pilot so this is your wiring diagram

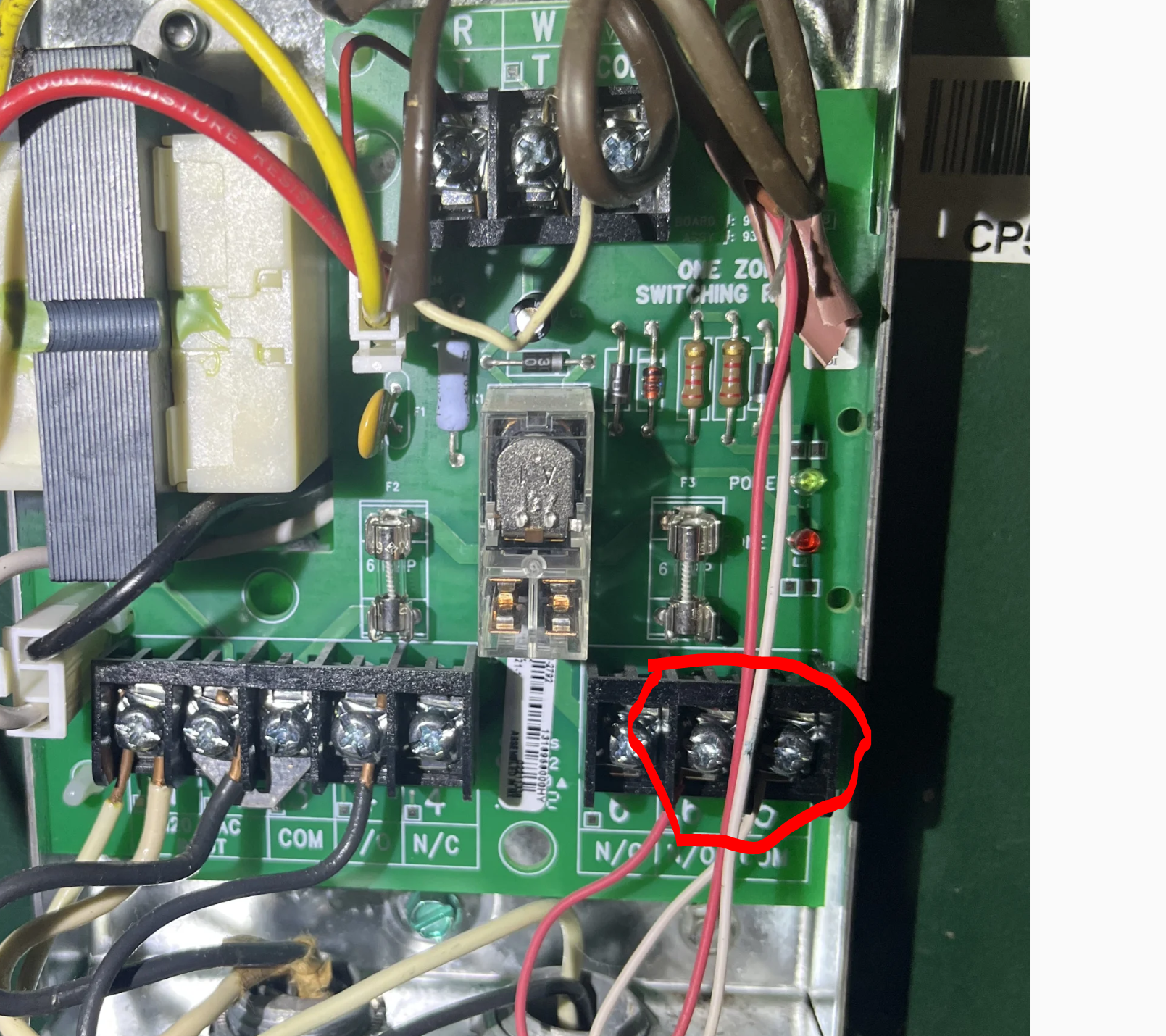

I wouldn't be surprised if that is not posted on your boiler somewhere. I have a red circle on this diagram where the thermostat is supposed to be connected on the diagram. Here is that connection on your boiler.

In your case that is not the thermostat wire. Possibly because there were 2 zones at one time and each zone had a switching relay to operate each separate circulator. Since you no longer have two zones that control is not needed. The fact that it is still there means that you have more than one place to look for your problem. That thermostat wire has 5 or 6 conductors. Only the red and the white are used and they connect to the switching relay where @109A_5 indicated in this picture.

- The place to start looking for the problem is in the TACO SR501 switching relay.

- With the power off to the boiler and the boiler cold, remove both the red and the white wire from the SR501 in the red circle.

- Power up the boiler. The burner should not operate.

- If the burner operates then the problem is not in the SR501.

- If the burner stays off, then the problem is in the SR 501.

Based on your findings, we can take the proper steps to solve the problem.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

Interesting. The boiler buzzes pretty loudly during heating season when the thermostat is set to Heat. I don't recall if the buzzing is continuous or if it only buzzes when there's an actual call for heat.

0 -

I'm on it. Will report back.

0 -

EDIT:

Since this did not stop the burner from firing, then this is not your problem but I will leave it here for others with similar problems to see in the future

Move on to diagnosing the boiler CR relay problem.

- - - - - - - - Original Text - - - - - -

If you power the boiler with the Red and White wired removed from 5 and 6NO on the SR501, and the burners stay off, then your SR 501 is defective. Since you do not need that control, it can be eliminated easily.

- With the power on, touch the red and the white wire together and the burner relay should click and the burners will start. This indicates that boiler is operating properly.

- Turn the power off to the boiler

- Disconnect the red and white wire from the thermostat to the SR 501 relay and connect it to the red and white wire to the boiler as indicated by the blue wire connectors. OR, If the thermostat wire is long enough you can connect directly to the boiler wires indicated in this photo: Both will accomplish the same result.

- The next step is to connect the circulator wire to the boiler relay as it was originally connected at the factory indicated by the wiring diagram.

- That is done by removing the wires from the Taco SR501 N and 4NO terminals that go the the circulator motor

- Now remove the transformer relay from the mounting box

- Locating the two places to connect the circulator wires. If the diagram is correct then that should be a yellow wire inside that junction box and a white wire that already is connected to other stuff inside that box

- Connecting the wires from the circulator

- Replacing the transformer relay back on the mounting box.

- Now you can power the boiler on and see if the burner and circulator are off.

- if they are off, then set the thermostat higher than the room temperature and the burner and circulator will start.

- If the burner and circulator are on then set the room thermostat lower than the room temperature and the burner and circulator will turn off.

This is easy and does not require any additional parts to solve the problem.

If the problem is in the boiler controls, because the burner stays on with the thermostat wires from 5 and 6NO disconnected, then you may need to replace some defective parts. We can go over that if needed.

IMPORTANT

Make sure that the boiler is Safe to Operate by testing that the limit control shuts off the burner. To test this, disconnecting the circulator and operating the burner until the boiler water temperature reaches the limit setting of 180°. With the circulator pump off, the water should get to 180° within 5 to 10 minutes.

If the boiler water temperature rises above 180° and the burner does not shut down, then you need to check the wiring connections to be sure that the limit control is properly wired in the burner circuit or call a professional boiler mechanic to see what the problem is.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

2 -

I removed red and white wires from 5 and 6 N/O on the Taco relay, then restored power. Damper opened and burners fired up until the 180 temperature limit was reached

0 -

It is starting to look like the relay "CR" in the boiler has an issue (could be stuck, contacts welded, coil energized, or other mechanical defect). Power down the boiler, remove the Red push on connector (Yellow arrow), restore power to the boiler and see if it still fires. This just eliminates all the wiring that goes to the SR501.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

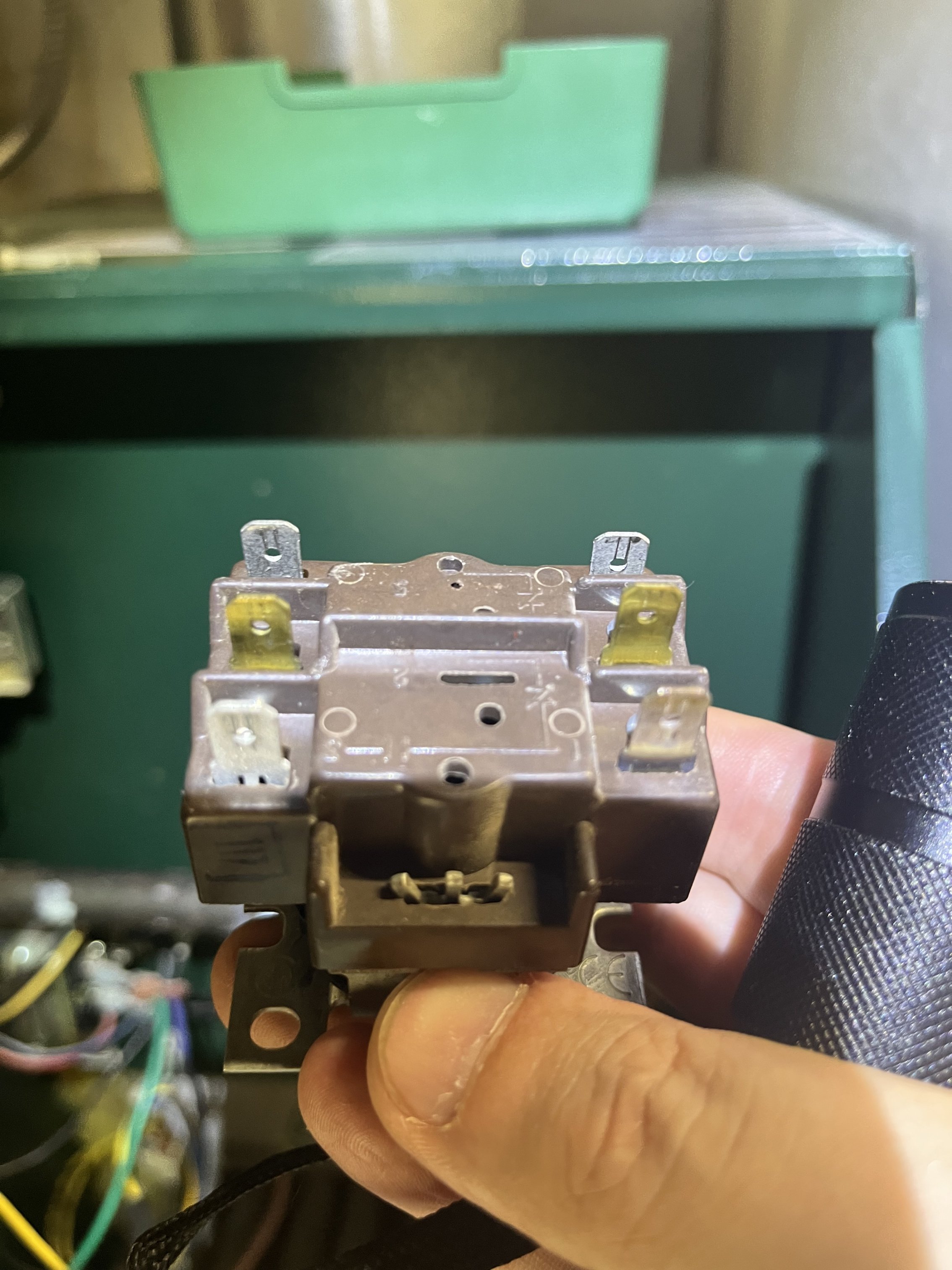

If the boiler still fires I would next power down the boiler, remove the relay "CR" (Orange Circle), restore power to the boiler and see if it still fires up. While the relay is out I would inspect it for welded contacts or other mechanical defect that would keep the armature in the active state.

If the boiler still fires with the relay removed you have a wiring issue.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

@109A_5 I removed the red push-on connector from the G tab as you indicated, then powered up the boiler. Damper opened and burner fired until the 180 temperature limit. I’ll move on to the next step you laid out and report what I find.

0 -

I removed the CR relay and inspected it. I didn’t see any evidence of arcing, etc. though to be fair I don’t really know what I’m looking for. I’m very familiar with home wiring but relatively unfamiliar with boiler wiring.

I did notice that there are no ground wires connected to the Taco relay or the boiler power switch box from the armored cable coming from the circuit panel. I know the armored cable does have ground wires since it’s connected to the neutral/ground bus bars inside the circuit panel. Not sure if that’s relevant to anything or not.

Anyway, I’ll let the boiler cool down a little and then try to fire it up with the CR relay removed.

0 -

When you had the wire on the G tab removed and the boiler fired up was the buzzing you mentioned there still ?

BTW with these tests you don't have to wait for the boiler to get to 180, just does it fire up or not.

Do you have a multi-meter ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements