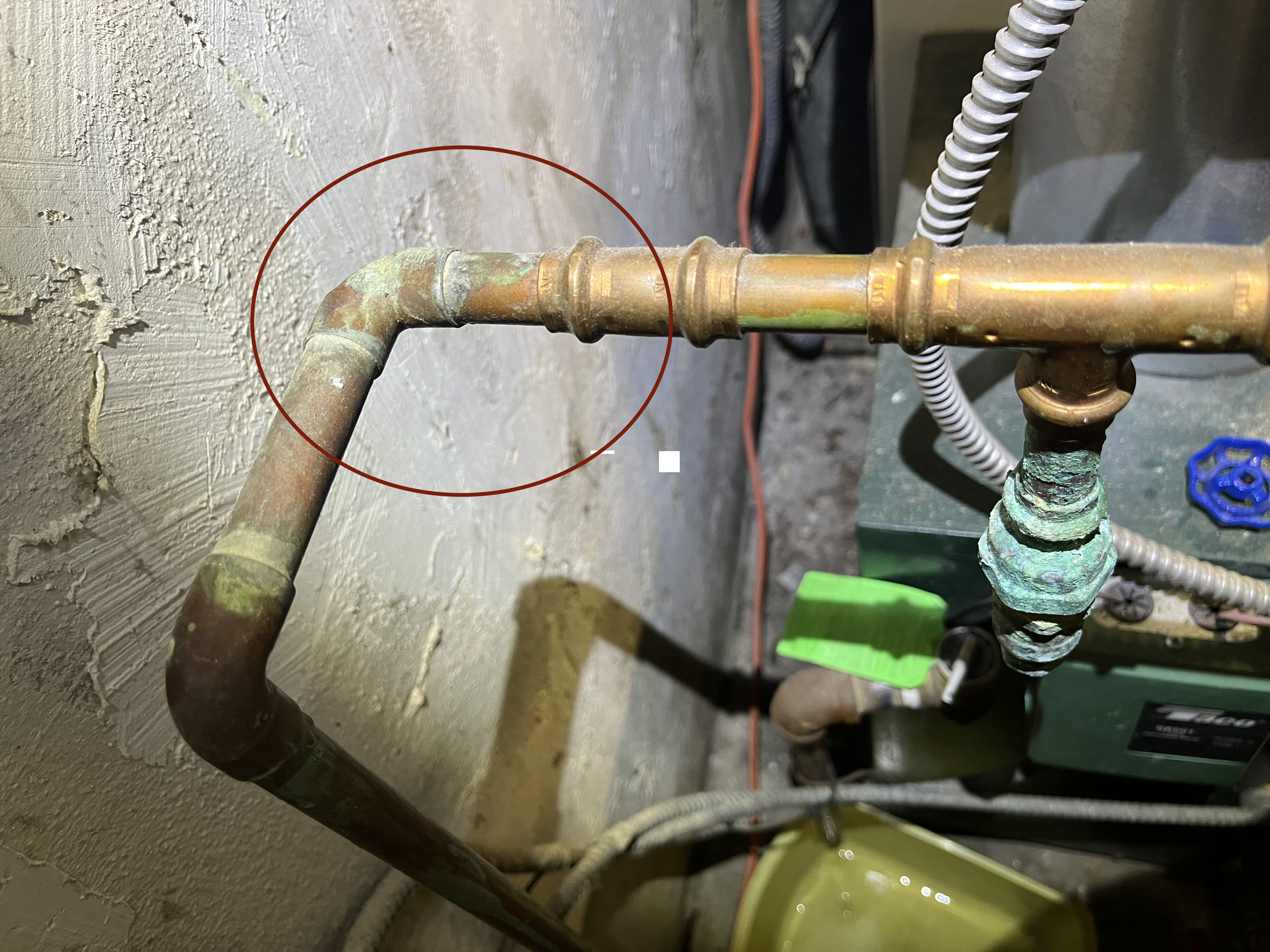

Soldering close to soldered fitting

I have a situation where a pro-press tee fitting on my gas boiler's return line is leaking. It's 1" from an adjacent press fitting, which is 1/2" less than the minimum distance specified by Viega to do any soldering.

Since I don't own a press tool, my first thought was to cut out the section just past the adjacent press fitting and solder replacement copper pipe with a new tee. I have some experience soldering copper, but I'll admit I've never soldered new fittings that close to existing soldered fittings, and I'm a little concerned the old fitting might get borked in the process of doing the new soldering.

What do you guys think?

Comments

-

-

that’s close

You can try but be prepared to replace the T.

0 -

-

"Since I don't own a press tool, my first thought was to cut out the section just past the adjacent press fitting and solder replacement copper pipe with a new tee."

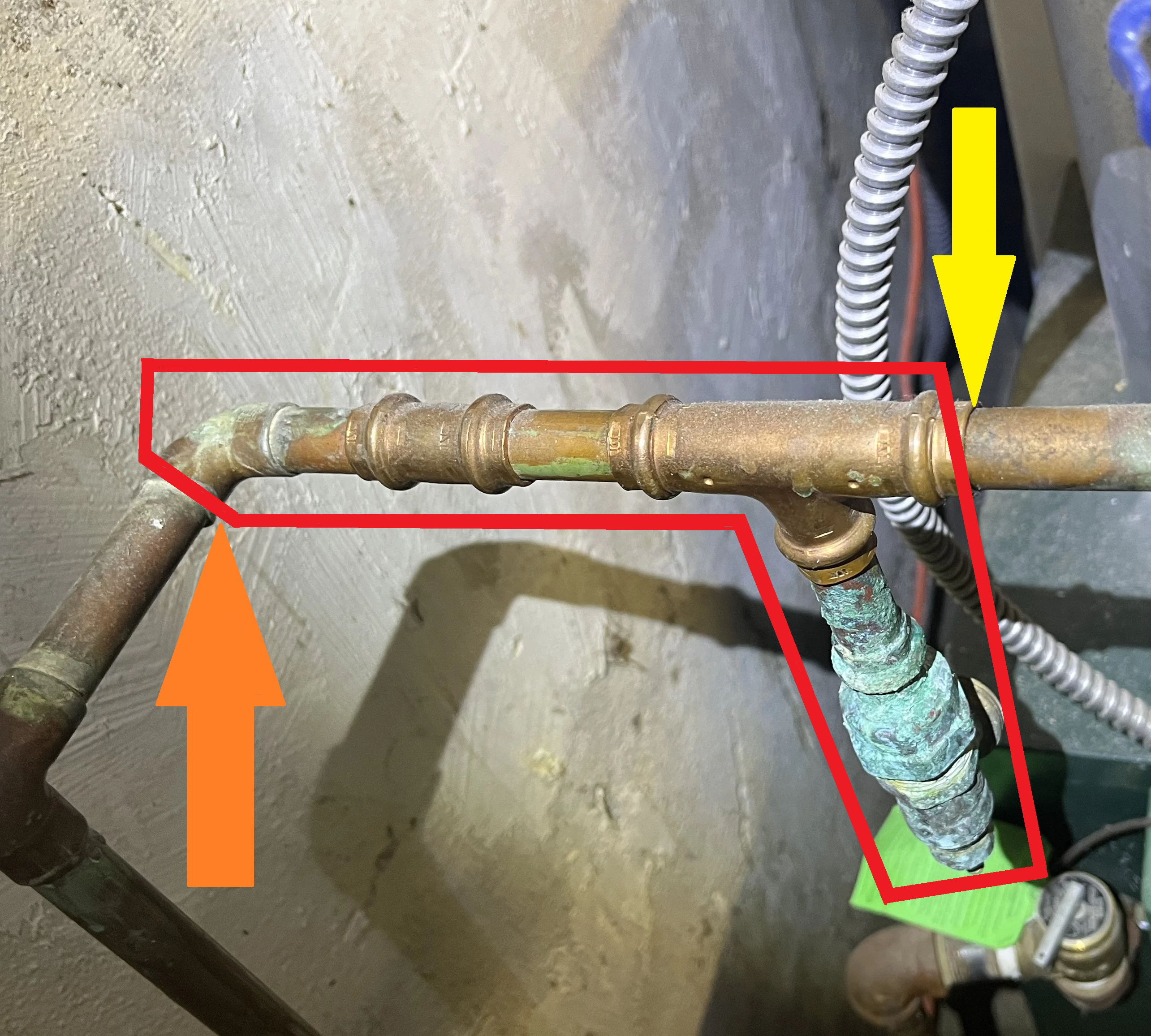

If the tee is the press fitting that needs replacement I'd cut out both press fittings and replace the whole section with solder.

Maybe even take off the solder elbow and go fresh from there.

1 -

-

-

Thanks, gents. I should have been clearer. I’m not worried about any of the press fittings, I was concerned that soldering too close to soldered elbow on the left of the assembly might compromise it.

Removing the whole enchilada and just sweating a new assembly is an approach that’s so simple I’m a little ashamed I didn’t think of it in the first place. But you guys are pros and I’m not!

Thanks again everyone

0 -

that other half inch copper 90? You’d have to roast that fitting to come close to melting solder on that other fitting. All the pros are worried about that pro press fitting, you’re gonna heat up that rubber O-ring.

1 -

I'd cut on the left side of the press coupling and on the right of the press tee, then piece it back together with 2 repair couplings (maybe even a union?). Start with the left side of the tee and work your way outward, minimizing the heat on the existing sweat fittings. As long as you have everything fluxed properly and can control the heat, there shouldn't be any concern with the existing sweat joints.

1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements