Air in oil lines - potential tank relocation

For the last few months, my oil furnace/boiler (combo unit - we get our hot water and baseboard heat from the same unit) has been failing to light reliably. Initially it would occur once every few days, but had become a daily situation. The indicator light on the control box would illuminate and I would have to hit the reset switch to get it to fire. Over the span of a few weeks, attempts at resetting it would only start the blower with no ignition. I started to purge the air from the line via the bleeder valve. I was getting air and foam. I called a local plumber to come out and service the unit (May 2025). He did a clean out, replaced the electrodes, air vent, filler nozzle, pump screen, and took the burner apart to clean the fan blade.

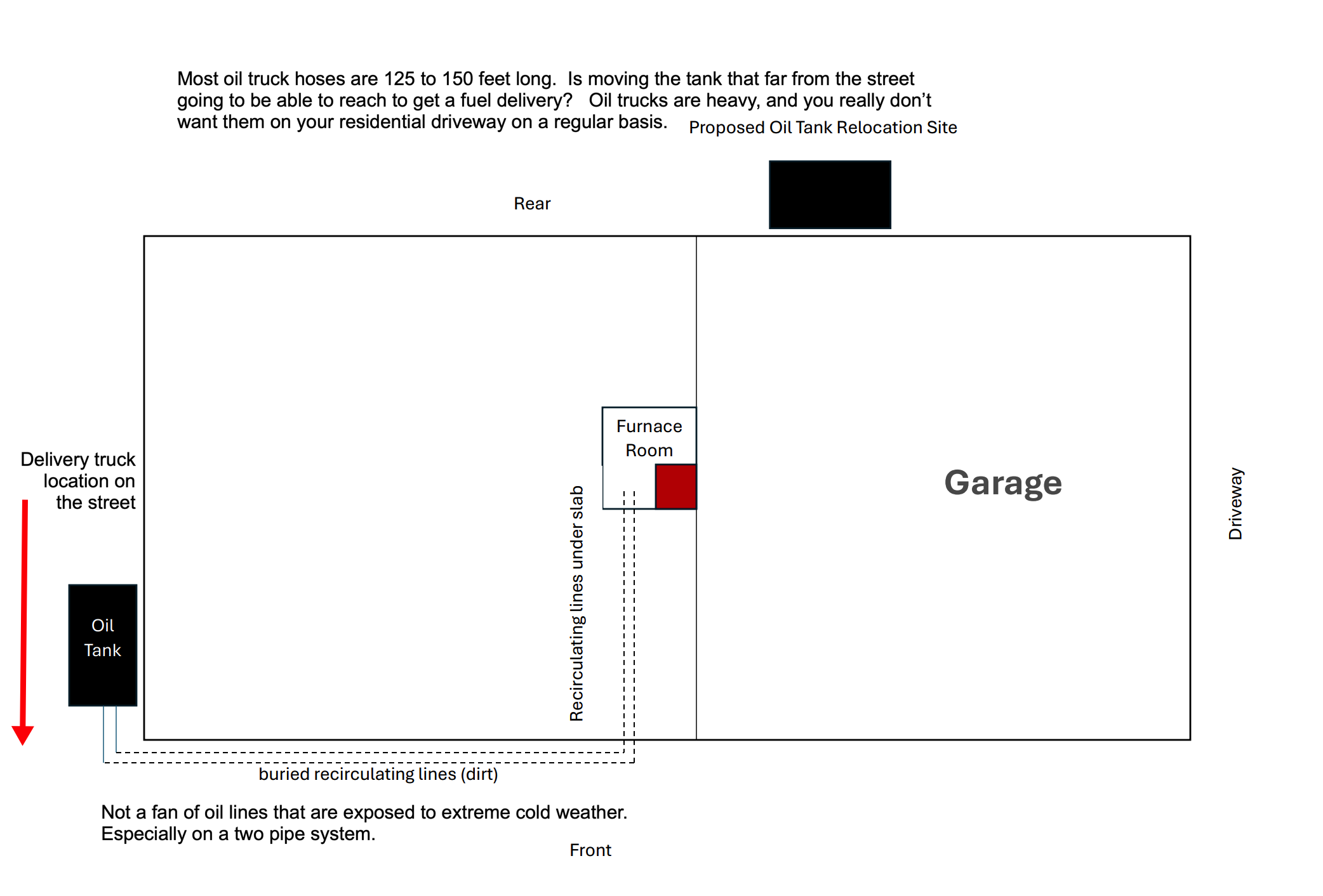

The problem persisted after the service. I tried to get him back out here, but was told that I just needed to purge more air. After 2.5 months of irregular firing, I got him out here again and he bled the lines; got it firing again. When he did this service, he commented that we should replace and relocate our oil tank closer to the closet where the furnace is located. We have 2 recirculating lines that run from the oil tank to the burner; under the dirt in the front of the house, into the slab and come up through the slab in the furnace room (see attached pdf). He assumed that there is probably a pinhole leak along those lines, but did not pinpoint the source (no pun intended).

Before I embark on a huge expensive project… looking for second opinions on the situation.

Is there a pressure test that can be performed to confirm if the oil lines is the source of the air? I'm hoping maybe the pump is at fault or another less expensive fix.

Would those lines need to be removed entirely if we relocate the oil tank to a closer location? Would we have to potentially smash up our slab to remove them or can they be blown out and capped?

For a new oil tank - Roth vs Granby? Current oil tank is a single wall 12G 275 gal. Granby installed 2009. Tank located outside. Is the tank in dire need of replacement at 16y/o?

Any additional input would be greatly appreciated. We would like to get the system back up and running before we have to turn the heat back on. For now cold showers suck, but no heat is a deal breaker.

Comments

-

Is that a flap check valve on the return line?? WHY???

It would be worthwhile to reroute a new single oil line and place it in the ceiling of the basement routing it to the boiler and then have the plumber install a tiger loop air purger in your delivery line near the burner.

I would seriously consider replacing the 2 pipe system with a one pipe system using a tiger loop ultra air purger and a new oil burner.

2 -

Your plumber may very well be right — there may be a pinhole leak in the supply line (one in the return line is not a problem). In fact, if those lines aren't sheathed — and it doesn't appear that they are — I wouldn't be a bit surprised.

Unless this is a seriously cold climate, I expect you could manage very happily with replacing both lines with new ones — sheathed — above ground; if it were ,mine, just below the siding attached to the foundation — for the length outside. Don't bother to move the oil tank. No harm to having it checked for corrosion — you oil company can do that if you are a regular customer, but it at leaks looks pretty good. Now how you go inside is another question; from your plan it looks as though there is a convenient wall from the front of the house to the furnace room. Run the new lines exposed on that wall.

Keep the two line setup. It's fine (though the check valve on the return isn't needed). If it's installed correctly there is no need for a Tiger Loop, although they can be a useful item if the various joints aren't made up properly.

And no need to do anything to the old buried lines. Abandon in place and don't worry about them.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

keep the system 2 pipe. keep the tank where it is. Pressure test the lines, if they leak replace them.

I would be more suspicious of a leak around the burner pump, fittings and oil filter etc.

A pipe in a vacuum like your suction pipe may NOT show a leak because it is pulling oil in.

You need a technician willing to take some time and figure it out. Not easy to find one these days.

This old saying I herd 60 years ago is still true "if the oil can't get from the tank to the burner the burner will not run"

1 -

For pressure testing the lines, is that something a plumber can do or do I need to find someone who specializes in hvac/oil furnaces?

0 -

Its probably a weak Igniter. Or way too much combustion air.

Where are you located? The soot on the front plate is not acceptable. You need an experienced oil burner tech with the tools and instruments to get your boiler running clean.

What brand boiler is that? Trianco? Laars? Whatever it is, its a dry base vertical steel tube boiler that probably has over an 800° gross stack temperature.

Where do you buy oil? Do they have a service department?

You can't just keep hitting the reset button. Especially with that obsolete primary control. One time you're going hit the button and will need to call a restoration company as well.

0 -

I am located in NW NJ. I'm not sure what brand the boiler is. All we know is it came with the house and is the original from 1989. We purchase our oil from a company that does not service equipment.

There is pretty significant smoke that comes from my chimney and out of the front of the unit once it does kick on. Are you saying there is risk of fire?0 -

Risk of fire? Yeah… or more likely explosion.

An oil burner, properly adjusted, produces NO visible smoke. I repeat: NO VISIBLE SMOKE. That burner is very poorly adjusted — to put it mildly. You need to get someone who knows how to maintain oil burners out there and put it right — which will probably take the better part of a day, since it's been out of whack for quite a while from the sound of it.

In the meantime, do not attempt to run it. Just Don't Do It.

There are at least three good men who service your area. You can click on their names to send them a personal message. @EzzyT , @clammy , and I think @JohnNY .

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

There is a problem with your tank piping design.

- Having the fuel lines exposed to extreme cold weather for that long run around the building can lead to frozen fuel lines. If the return line freezes and the supply line does not, then you get a call for the burner to operate, the fuel pump's seal will fail and you will be pumping 16+ gallons per hour thru the pump seal, all over the furnace room floor (because it can't get back to the tank in the ice plugged return pipe).

- I always try to make the fuel lined from an outside tank travel up from the tank until it gets inside the building or crawl space out of range of the freezing weather.

- If my top feed lines must turn down before entering the protected interior or crawl space, then the lines must continue down hill slope until the lines are inside the home or crawl space. This is to avoid making a trap for condensation to get stuck in the ultra cold tubing

- I recommend a one pipe fuel line from outside above ground tanks because the oil moves slower thru the fuel line. When the fuel is very cold the viscosity is greater and the slower the fuel moves, the less friction there is on the moving fuel thru the tubing.

- Also not a fan of the four separate 4" block foundation.

I solved a no heat situation with a fuel piping design just like you have where the fuel lines were buried shallow around the perimeter of the home for about 25 feet, and the friction of the two line system along with the extreme cold fuel from the tank caused the fuel pump to generate so much vacuum that the noise was very noticeable. The vacuum exceeded the fuel pumps specifications and the burner would starve for fuel. The copper lines were so cold, once they entered the basement, frost was forming on the tubing and the fuel pump. I added a tiger loop at the burner and the fuel thru the single line from the tank, went from 17 GPH (the pump gear set capacity) to .75 GPH (the firing rate) and the heater purred like it should.

Now you don't need this set up every day of the year, you only need it in a couple of years when you get that colder than usual winter night and you have no heat when you need it the most. When I install a fuel tank I design the fuel lines for that one day when that unusual cold condition occurs.

In your current situation, I would do a pressure test on the buried fuel lines to determine if there is a leak. If you find one line that is not leaking, then I would use the good copper line with a tiger loop for now. Then when you have the necessary funds that won't break the bank or spoil your nice vacation plans, I would get the new tank and maybe install it inside the garage out of the freezing weather But that would be me. Others might tell you to convert to natural gas.

The pressure test is the same that you would do on a gas pipe or water pipe. You must disconnect the pipe from the fuel pump and procure the necessary fittings to place a gauge on one end and plug the other end of the pipe. Add air pressure to about 20 PSI and watch the gauge for about an hour. It may drop within the first minute or so then hold at some pressure near 20 PSI or 18 PSI. Then it should stay steady for one hour. If you have a leak, check the fittings with soap bubbles to rule out bad flare connections. If there are no leaks at the fittings but the pressure drops, then the buried line is no good.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

IDK about a risk of fire. Its definitely possible. But there's certainly a risk of soot blowing throughout the house. There's really no excuse.

0 -

I contacted a highly recommended local mom & pop company that works primarily with oil heating. They said it sounds like it needs a thorough cleanout and recalibration. The earliest the can get here is the 27th. They suggested I contact another recommended local company to see if their tech can get here sooner. Waiting on a call back.

As for the furnace - I was told by mom & pop company that as long as the smoke dissipates after the delayed firing, I'm okay to use it for hot water. Continuous smoke after lighting the burner, I should shut it down immediately. The trouble is, I'm not able to get it to light consistently even after bleeding the air. After what I know now, I only bleed for no more than 3 cycles (usually the foam subsides mid 2nd cycle). If it doesn't light on the 3rd, I let it rest for some time before attempting to relight.

They were also baffled as to why my plumber didn't do any further diagnosis to the suspected pinhole leak while charging over $600 for not fixing the problem nor finding the root cause. They strongly urged me to call him back, but I'd rather not continue down this path with him since the problem seems to be outside of this expertise.

I'm sure I can contact yet another company to arrive sooner to come and service the unit, but I was told that the larger more corporate organizations in my area try to push replacement with younger less experienced techs versus diagnosing and fixing the problem based on years of experience.

I guess for now I'm just at the mercy of a call back and cold showers.

0 -

If you keep bleeding air and it doesn't clear up, you have an air leak. Or, you are opening up the bleeder too much, which makes it look like an air leak. Make sure you only crack the bleeder no more than a quarter of a turn. Secondly, if you are having to bleed it at all with a two line system, there is something else wrong, such as a fuel pump that did not have a bypass plug installed. I just did a phone fix from 2000 miles away where a former customer did that.

Depending on how the fuel lines are run in to the fuel tank, you could swap the two lines and see if the air goes away. If you do that , make sure there are no check valves in the line, which I don't see in any pictures, but was commented on. If the air does go away, then that would indicate a leaky fuel line. If that is the case, change it to a single line with the good line, and use a tigerloop setup.

Rick

0 -

The truth is no one can tell you what is wrong without proper testing. Pressure testing won’t work with the oil line going into the top.

It could be a restriction, or nothing related to the oil line.

You have to ditch the two pipe and go with a single pipe and an oil deaerator if necessary. It’s a proven modern method and all the reasons have been discussed an agreed upon by competent, knowledgeable techs and industry professionals. Anyone who disagrees is either stuck in their old ways, or lack the proper recent knowledge.

By code the lines need to be protected. By code you cannot have a check valve in the return.

Your tank may or may not need replacing, but based on a top feed and two pipe, It is not hard to imagine that the bottom of the tank has a lot of water, microbes, and sludge, and may be well on its way to failure…or not.However if you decide to go with a Roth tank, you are going to have to pour a concrete pad.

0 -

Its a 2 pipe system. You shouldn't have to bleed anything. Stop believing its an oil delivery problem without a proper diagnosis. It could be electrical. It could be a fouled nozzle and/or coked head. It could be combustion air. The bottom line is, stop hitting the reset button. The Al Jolson routine doesn't fly nowadays.

0 -

I have a tech coming today to do a complete cleaning, run diagnostics, and rule out any leakage at the site of the furnace.

Yesterday after a rain storm, I noticed this nick in the supply line from the tank. I'm hoping this is the source of my leak.

0 -

The tech came out today. Determined the cause was the transformer was bad, the plumber installed the incorrect nozzle size, and the pump wasn't pulling enough. No leak detected in the lines.

0 -

-

See? No leaks. Was the boiler opened up, brushed and vacuumed? Flue pipe and chimney base? Combustion chamber? Did the tech do a combustion test? Smoke test? Draft test? If not, history might repeat itself. Which is typical today anyway.

0 -

Interesting that you found a bad transformer, wrong nozzle and other items that were not related to under slab oil line leak. There are some items that you neglected to tell us about the service performed. Since this tech is qualified as a Oil Heat technician, you should have the results of the combustion analysis performed after the nozzle changes and other "Tune Up" or "heater cleaning" services performed.

Every Oil Heat technician will automatically do the combustion analysis with the properly calibrated instruments. It is the way I was taught over 45 years ago and it is the way I taught all the technicians that worked for me. And I believe it is part of every technical school curriculum when it comes to the oil heat portion of that training program. If that test was not completed, then you do not want to use that technician any more.

I hope this helps you to find the best oil heat tech available in your area.

As far as the existing fuel line that is buried outside the perimeter of your home, I still believe that getting a properly designed fuel line from the tank to the burner is IMPORTANT. It will be less expensive to do it before you have a problem. The customer that I mentioned in my previous post from Aug 12, paid a premium for the repair because it happened at about 11:00 PM on a Saturday night. I find that there are lots of companies that charge extra for overtime emergency repairs. There are also companies that offer discounts on repairs to customers that purchase service or maintenance agreements, when customers allow the company to make scheduled repairs rather that emergency repairs.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements