Can someone explain this hydronic loop heating.

Moved into a new house in NY. The heat is hydronic gas boiler. The bottom piece im assuming comes in on one side and out on the other. Why does the top do?? Doesn't seem to have a flow path.

Comments

-

I can see no purpose to that extension from the location where there should be a vent of some kind of vent to expel air from the convector. You may find it in a circa 1950s popular mechanics magazine, when there were many innovative ideas. But I can see no benefit.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

Is it known where the third pipe goes to ? Could the slight internal pressure change of heating the upper part modulate the water flow through the lower part ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

Thanks all!

0 -

-

-

-

Weird. The 3 pipes were originally put there for some reason. Is there another tapping on the right-hand side of the original convector?

0 -

I don't even see where much of any water is going to get in that contraption

0 -

-

-

Does this unit not heat ?

Maybe when the tapped air in the upper part expands it adds air to the convector coil, so the heat output is self limited. I'd leave it alone if it is not leaking.

If you need more heat from that unit you could remove upper part and and add a manual air bleeder. You may get more heat from it since you can get more air out.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

It does heat when I tested it, not sure how well. I checked out rest of the house and found all upstairs to have the same set up except that some have manual bleeders in addition to the non circulating loop, and some dont. Some have manual bleeders, some have saddle valves installed for bleeding , and some have none. Im going to remove them all and just stall manual bleeders.

1 -

If they have a way to bleed them, they will heat some through convection of the water but they will do little to add to the output of the convector.

0 -

There's enough room to pipe in a 3/4 ball valve, then a 3/4 x 1/8 coupling, and an 1/8" Hy-vent.

0 -

-

Agree with @JUGHNE

I wouldn't do anything until you find out what the third pipe does. It seems to me there could be more to the story

0 -

-

For a finned tube or coil like that you need an enclosure to enable some convection currents. Colder air enters the bottom, warmed air exits the top

What type of cover goes over that opening?

It needs a slot along the bottom and top to enable convection currents

A blank cover or grill or some sort will not allow good output.

Another option to increase output is a small fan to force some convection.

Vacuum and brush the fins to increase output also

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

The third pipe is connectconnected to the convector, meant for bleeding im sure. The boiler is about 10 years old, Williamson 105k. Its a typical setup , expansion tank , hy vent , coming off the boiler. Pretty sure someone, definitely not an expert, at one point attempted to get more heat out of convectors. Out of the 10 units , 2 have saddle valves piecered in the pipe for venting , 3 have coin bleeders , and the rewt dont have a way to bleed at all.

The the cover is slotted at the bottom and the top to allow for air movement.

I Ordered the fittings and manual bleeders , so arrive tomorrow.

1 -

The OP confirmed the 3rd pipe is the vent. How many times do you see a vent that big? All it needs is an 1/8" coin vent.

0 -

I think that convector element has tapings to feed it from the top or bottom or connect in a loop or feed as 1 or 2 pipe steam so it has several taping that can be used different ways for feed or reduced for a bleeder or steam vent.

0 -

Since the unique tapping is only at one end and on top and the supply and return is from underneath I still think it is a self metering method. It seems deliberately made that way.

It's not like trapped air that needs bleeding like with a typical vertical CI radiator.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

There are thousands of homes on Long Island with that type of convector on mono flo systems that have a 3/4 tap for bleeding. I don't remember who made the original bleeders, but they looked like brass rockets. About 4 or 5 inches tall.

I have to admit, I never saw one where the tap was on a vertical, so it is deceiving. A pic from another angle would show it better.

1 -

Yes, saddle valve located at that exact location for air bleeding.

0 -

Ummm " Yes, saddle valve located at that exact location for air bleeding. "

A bleed valve here seems like knucklehead maneuver.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

maybe it was to drain it

0 -

Yes, that would make more sense to drain water out of an assembly that should be air bound, not for bleeding air out.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

water will get in to that bottom part over time and it will freeze if you have the house shut down for some reason.

0 -

As I alluded to before, I believe it was an attempt to reduce or limit the heat output, not enhance the heat output. Did the home have gravity or coal fired heat at one time ?

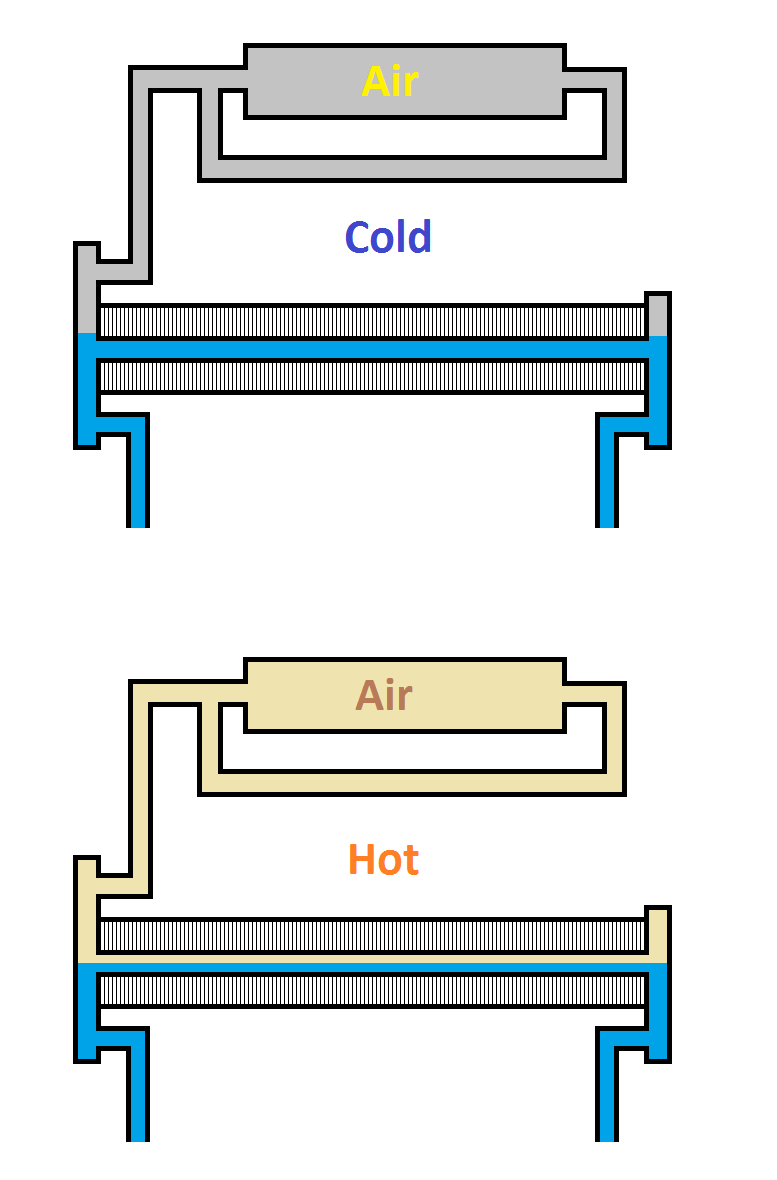

As illustrated below when the upper air chamber is cold the convector has full flow, when heated up the air expands entering the convector coil, thus reducing the volume of water that could pass through the convector coil, limiting the heat. Whether this worked well or not, I have no idea, apparently the concept never gained any traction.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

If it actually works as I illustrated I would have built it so it could not trap water like it would now. The Copper pipe over the aluminum finned air bound section.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

the water will absorb some air when it cools and some of that water with more dissolved air will find its way back to the boiler where it will be heated and the air will come out of solution then that water will circulate as hot water to the convector and cool and absorb more air. over time at least some of that loop will fill with water.

0 -

All 11 convector heaters had their top section removed and replaced with just an 1/8 coin bleeder. I was able to bleed air from all of them and they all heated up nicely.

Again , out of the 11 of them. Some had coin bleeders on the top loop, some had saddle valves installed, and some had neither. Very very strange.

2 -

Might want to seal up those holes in the floor so it pulls air from the room instead of from under the floor. Use foam or something around the pipes so they can move.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements