1933 Burnham Boiler - Questions and Potential Replacement

I recently purchased a house that has quite a history. Original house was built in 1820, but redone in 1933. A newer section was constructed in the 80's. The older section (approximately 3800 sq feet is currently heated by a Series G-1 Number 2708 (Included pictures of the boiler and the data plate in this message). I've been attempting to find out more information on the unit without success. I found a post with a catalog https://www.heatinghelp.com/assets/documents/185.pdf

but I can't correlate what I see on the data plate with what is in the catalog. Can anyone assist me in finding information on the unit / understanding the spec sheet? I am seriously considering replacing it with a modern unit as my heating bill was quite large. I'd like to know more information about how it is currently sized to compare it with my notes for selecting / deciding about a replacement.

The system is a 1 pipe setup with two feeds and two returns, one for the back of the house and one for the front. The burner has a 2 GPH nozzle on it.

Some thoughts that I had that I would like to double check if my logic is sound

When the heat was running during the winter, standing in the boiler room, it must have been 100 degrees. Seems to me that if the boiler is outputting that much heat into the room, its heat that's not heating my house (while a basement shouldn't be freezing, I don't need it to be a sauna).

I am aware that the boiler and pipes are asbestos covered and that would need to be remediated for any replacement plan. I am also understanding that getting the old boiler out of the basement is going to be fun (but its something I have accounted for).

The boiler must have at least a hundred galloons of water its heating up before it can make steam, it seems as if the newer boilers have significantly less water capacity which means they spend less money heating water mass before they make steam.

My main purpose right now is to decrease my oil usage and increase the temperature that the house can be set to.

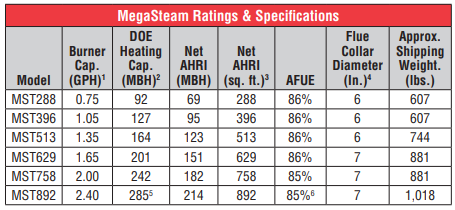

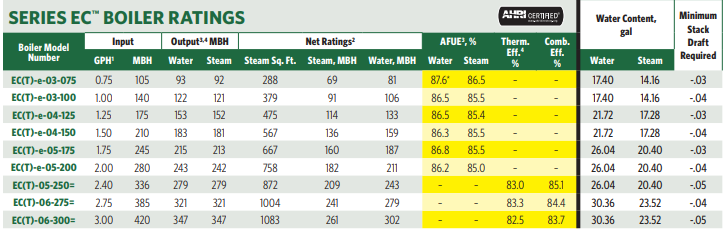

Did a radiator steam calculation and came up with 634 sq ft of steam. Seems like a Megasteam or a Peerless would be an appropriate replacement (Pasted the specs below). Does this seem logical. The boilers seems significantly smaller then what I have and I just want a sanity check on what I am selecting before I pull the trigger on a purchase.

Thank you very much,

Jim

Comments

-

You don't need to know anything about that old boiler to replace it with a new boiler. You need to find out how much equivalent direct radiation is connected to that old burnham. With that info, you can select the proper replacement boiler

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

3 -

Totally agree, my local HVAC Company who currently services my boiler helped me do a steam calc and came up with 634 sq feet, so that makes sense, but I would like to understand from a financial perspective how close what I have is. I have a feeling that its over sized, which would lend myself to replacing it being worth it. I would hate to spend a significant amount of time and money to wind up with a newer boiler and the same or close to it annual heating cost. That money and time might be better spent elsewhere (like maybe windows).

0 -

That Burnham 2708 is rated 1550 square feet. Double-check your radiation- also see if any rads have been removed over the years.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting2 -

As @EdTheHeaterMan said there is no information about the old boiler that will be useful.

If you double check the load calculation (radiation) and its right that is the # to use.

The biggest question is how does the house heat? just trying to find out if you need any work on the system such as venting which can save fuel.

If the boiler works and is not leaking, you may want to do insulation and windows first.

1 -

the actual input and out put will be set by how the oil burner is set up. coal boilers typically weren't fired at their full capacity for a number of reasons. it looks like that is a multi pass boiler so if all the baffles are in place and the oil conversion was done well the efficiency might not be terrible.

1 -

The actual combustion efficiency is probably good but the seasonal efficency not so much as you are heating a lot of water up and have larger stand by losses.

0 -

. this is picture proof that you don't need the old boiler specifications. Uncanny about the picture in this article is SOOoooo close to the boiler in @os2man4's post

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

Is this one pipe or 2 pipe? You can undersize 2 pipe a far bit to get closer to the actual heat loss with a reasonably well functioning system. It can be done with 1 pipe as well but everything has to be perfect to not end up with parts that won't heat.

0 -

@mattmia2 it is a 1 pipe system, and its split into the front and back of the house with two main steam lines splitting at the boiler and two returns that come back from the front and back and then join back up at the boiler

How close does it need to be?

I measured a requirement of 634, but the closest boilers between MegaSteam and Peerless are 629, 667, and 758

I was leaning towards the megasteam boiler, but it makes me round up to a higher btu output then the peerless, not sure if that means that the megasteam would just significantly higher or if it would just run for slightly shorter and heat up faster (which would make the additional btu a wash)

and what do you mean by perfect? or are you saying that there is more margin with a 2 pipe and a 1 pipe has to be sized correctly as an undersized system will no heat the end radiators

I am planning on insulating the steam lines and removing / improving the radiator covers but other then that I'm not sure what else I can change with the steam system itself to improve it

0 -

Always, always round down

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el2 -

the number on the boiler has an extra 30% "pickup factor" subtracted from it. normal systems don't have that much pickup factor so you'd be bettoer off rounding down.

what i mean by perfect is if the balance isn't perfect or you have some small amount of condensate pooling or some of the piping is wrong and you don't make enough steam to fill all of the radiators, you might fil some before some heat very much but that combination is consuming all the steam the boiler produces so the unbalanced radiators may never heat. with 2 pipe you can fix that by closing the radiator valve some on the radiators that are the first to heat.

that being said, i wouldn't worry about it until your connected edr is over 30% more than the boiler rating plate.

0 -

Ok, so it seems like an MST 629 with 629 square feet of steam to fill 634 would work (my math says it would be 898 square feet without the pickup factor)

Does anyone have any recommendations between the peerless and the megasteam? The megasteam seemed to be a newer design which is why I was leaning towards it, but that opinion isn't really informed by very much.

Also if I have an third story that is finished, but I am currently using as more of an attic. Could I turn off some of the radiators in that space to gain some cost back? I don't want to heat that space to the same degree so I was hoping I could shut off one or two of the radiators. No idea if that would accomplish anything. If I am reading how a 1 pipe system works shutting off radiators would lower the total volume of steam and should decrease the time the boiler is on (even if only by a little).

Thanks for all the help

0 -

Just write down the radiators:

STyler, height, tubes, and sections. So people can verify your radiation.

0 -

-

If that were my house, I'd go with the MegaSteam.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

If it were my house I would go with Steamhead.😄

Do be 100% sure of your EDR calculations. If you have any doubt send example photos and measurements of some of your radiators. I would still personally account for the radiators up on the third floor unless they are being physically removed. You may or the next owner may come up with some other uses for that space. I'd just put some slow vents on them.

1 -

Hello again to everyone. My grand plans for replacing the boiler this year… well… did not happen. So I am running this beast for this winter.

I've already made one decent change (At least it seems to have been for the positive), I verified and then reconfigured the thermostat so its not the default forced air setting and is now running the boiler in longer spurts with larger setback.

As I do more research I am curious as I don't think the boiler is setup optimally.

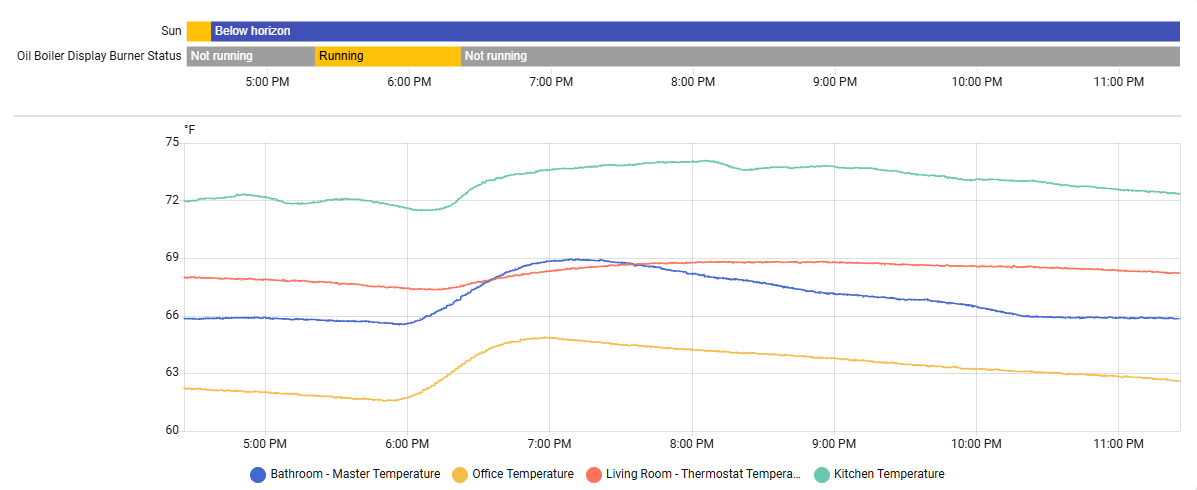

From my research the boiler is designed to output 1500 sq feet of steam, which with the pickup factor is 2000 sq ft and ~ 480,000 btu/hr. That corresponds to ~4 gph nozzle burner. It is currently setup for a 2.0 gph burner, which only works out to be about 242,000 btu/hr and 752 EDR or 977 with the pickup factor. From the data I am collecting it takes about 40 minutes from when the boiler kicks on to when the radiators start to react. See the below chart. The thermostat is in the Living Room and is currently set to 68.

I'm wondering if the boiler is underfired? It never shuts off, the pressuretrol is set at the lowest possible setting, but the boiler will only shutoff with the thermostat. I took the pigtail apart, verified it is clear and using an air compressor verified that the pressure gauge is working and reading accurately. I would expect a boiler this large to easily fill the system, but this seems to struggle. The house heats ok, but not great. I suspect that either I have a major leak somewhere that I have yet to find, or the 2 gph burner is just enough to make steam, but the mass of the boiler is too large to ever get really going and build pressure.

My full radiator calculations and measurements can be found at

Radiator Calculations - Google Sheets

From the radiator calculations is seems like I should have more then enough boiler (only have 628 sq feet of radiation) , but with it being underfired, it doesn't seem to ever be getting any pressure.

I have two mains, one is about 60 feet in length of 2.5" and the other is 50 feet and is 2". There is a Gorton #1 and a Hoffman of a type I can't identify (it has an adjustment dial on top an a 3/4 thread). Those seem undersized from what I was reading. I think going with Gorton #2 would be a better idea, but am not sure how much of a difference it would make. The best price I have found them for is $144, which seems very expensive to me. Does anyone know if that price seems normal or know of a better place to grab them? From the information I see I should be using 3 Gorton #2s on the 2.5" and 2 Gorton #2s on the 2" line. That equates to 750 dollars worth of venting and I just want to make before I spend it that it makes sense to do so. (I'm ok spending that much if its worth it, just don't want to spend that much and then find out I should not have)

0 -

typically coal boilers were oversized and fired at a lower rate for more coal capacity and longer burn times before they needed to be stoked.

that old boiler has a lot of mass to heat so it may take a while before it begins steaming.

is 2.0gph the nozzle or the actual firing rate? typically nozzles are run at a higher pressure which increases the firing rate.

if the boiler output matches the edr it will never build pressure. you don't want it to build pressure, the boiler is oversized if it does.

1 -

2 GPH is about right for a load of 628 ft.² EDR. An oversized, high mass boiler like that will certainly take a long time to make steam from a cold start, but the time should be much less on a hot start. Your system should ideally not build pressure.

When you say the house does not heat well, what do you mean?

—

Bburd0 -

So there was this steam boiler in a catering hall that was taking 6 hours to make steam from the time the burner was started to the time the unit heaters in the hall would blow hot air and satisfy the thermostat. I sold the owner a new oil burner modernization and fired the burner thru the fire door (not at the bottom like yours). I also changed the firing rate from 4 GPM to 3 GPM. With the oil flame closer to the location of the original coal fire location and the hotter flame design by the type of oil burner compared to the old burner, I was able to get the boiler to make steam in 20 minutes, the unit heater fans came on in 30 minutes and the thermostat was satisfied within the hour.

So the bottom line was that I took a 4 GPH fire for 6 hours, and changed that same boiler to work with 3 GPH in one hour. That saved the owner a ton of oil and paid for itself within the first year. This is an unusual situation. Usually the payback on energy saving jobs takes 3 to10 years. and if it takes longer than that then you should spend your $$$ elseware

I believe with some experienced oil burner dinosaur helping an oil heat rookie, you may be able to get your oil usage to drop significantly. You just need to find the right mechanic. finding the right mechanic is easier said than done!

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

I do too but if I was using oil I'd be buying a Mega steam. No reason to cut off your nose to spite your face.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

@ChrisJ If it was just steam Burnhams that failed that would be one issue. Around here they (Burnham) took over the New England market back in the 90s & 2000s. They mostly all failed. Even their HW boiler wouldn't last and would start leaking in 10-15 years. Their excuse is chlorides in the water and steam on one side of the HX and flue gas on the other side. No other brand boilers had as many failures around here.

@EdTheHeaterMan I agree firing through the door puts more heat to the boiler but I wouldn't recommend doing it to an old boiler which could have a lot of mud in the lower part of the sections. JMHO. We did many of those installations with commercial burners.

0 -

When I said doesn't heat well, most of the rooms hold temperature for about an hour, in which time the boiler has cooled down enough where it takes 30 to 40 minutes to make steam. If I ran it to keep those room perfect, it would be running about half the day.

The room where the thermostat is holds heat much better, so it doesn't turn the boiler on very often.

The rooms holding heat better is clearly not the boilers fault, but if the boiler heated up more quickly then I would be spending less oil to get heat to the rooms. So I'm attacking it from two angles, I would like to get the boiler better and I need to fix the rooms to reduce the heat loss.

I was wondering if I might have a main venting issue, as the vents seem undersized. Is there a recommend method for testing to see how well the mains are vented?

As for the other stuff, I'm open to trying pretty much anything. I would say that I'm pretty mechanically inclined, but am new to steam.

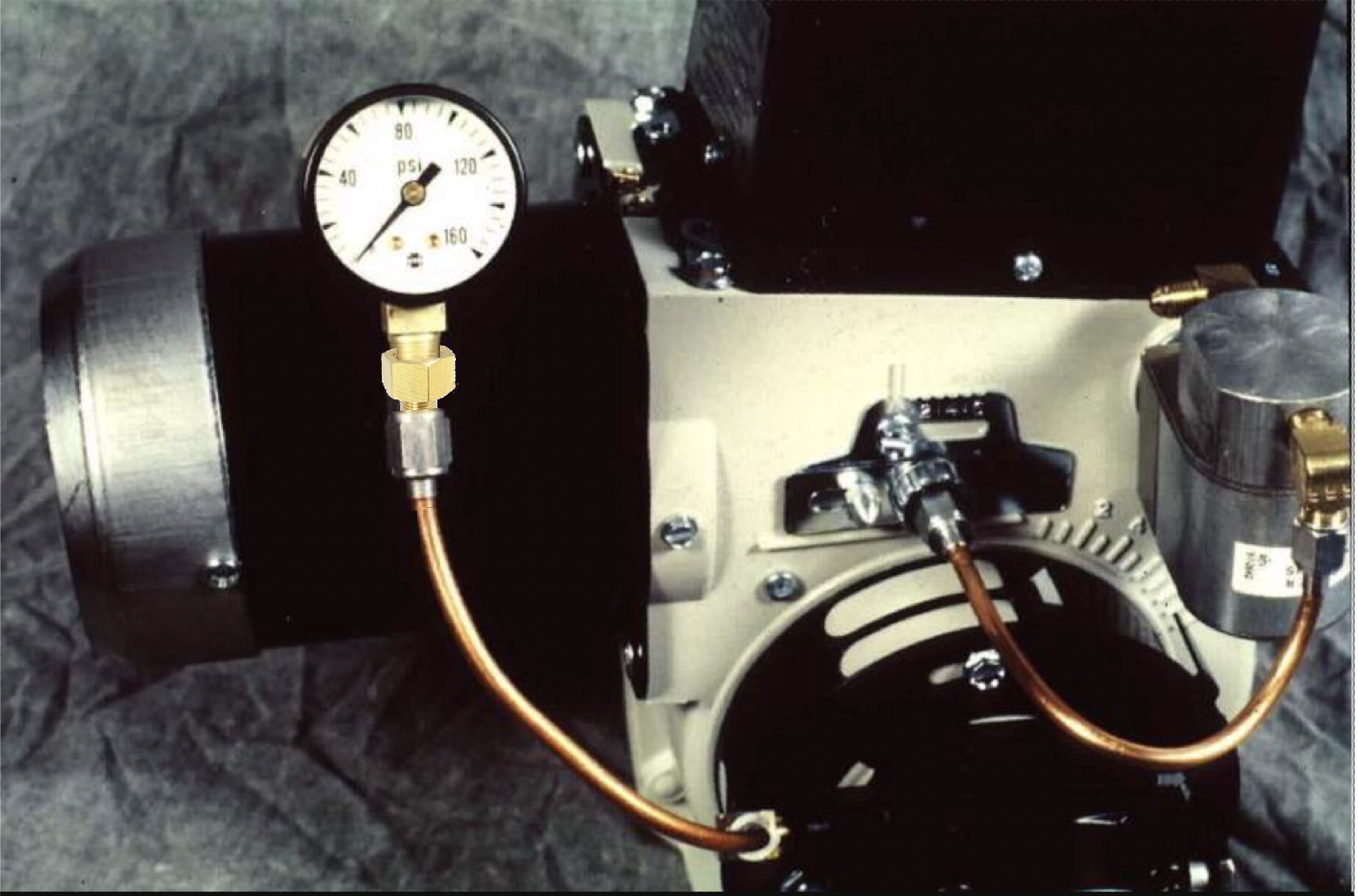

How do I know what pressure the nozzle is getting to know if its a 2 gph at a higher pressure?

Thanks for all the help

0 -

@os2man4 asked: "How do I know what pressure the nozzle is getting to know if its a 2 gph at a higher pressure?"

A zero to 200 (or 300) pressure gauge in connected to the high pressure line of the fuel pump. Operate the pump and adjust the pressure adjusting screw on the fuel pump as needed.

Gauge must be equipped with flare adaptor to do this test.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Might be a good idea to move the thermostat, or, switch to one that allows a wireless sensor, to a cooler room that doesn't hold heat well. Then install a TRV in the current thermostat room that does stay warm, as well as any other rooms that tend to stay warm. This will get the boiler running more often, and hold back the rooms that don't need heat.

The Honeywell Prestige allows wireless sensors, as well as running 2 and 3 CPH, which will make it run more often. I'd recommend 2 CPH for you, 3 will probably be a little too touchy. The more often the boiler runs, the faster it'll make steam each time.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Sounds more like you need to balance the system better. Faster vents on the slower to heat rooms, slower vents on the fast heating rooms.

How long does it take from when the boiler starts making steam to when the ends of the mains get hot and does it happen within a few minutes of each other? You need to vent the mains as fast as possible but also balanced before you can balance the radiators.

The speed the mains can heat is limited by the mass of the mains, the steam needs to get the main steam hot where the steam currently is before the steam can move further along the main.

0 -

Different vents do work, to an extent.

The problem is, the colder it gets out and the longer the system runs the more the slower vented radiators catch up. On really cold days they will typically completely catch up and still grossly overheat the rooms if they're well insulated etc vs others that aren't.

That's where TRV's really start to help because they won't let the radiator heat at all, or, they'll hold it back a lot.

You can balance a system as far as timing with vents, but you can't hold back an oversized radiator. It just doesn't work.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

1 -

You could also try changing the heat anticipator or CPH setting on your stat if it has one. An extra shorter cycle might smooth things out a little.

0 -

Please visit the heating help bookstore and purchase copies of WE GOT STEAM HEAT and GREENING STEAM, these well written books about Steam Heat by Mr. Holohan will help you a great deal in solving your heating issues.

0 -

but if it is just a balance problem, that can be fixed with venting. if the rad next to the t-stat is mostly hot 20 minutes before the rads at the end of the long main just start heating, that is going to shut off the boiler before the far rooms ever get hot no matter how cold it is out. it might be better as it gets cold out but balancing venting would even that out.

there is also the possibility of a big puddle in the main that has to be heated before the steam gets past that point too.

0 -

All good points.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements