Unrecognized return vent

Comments

-

just arrange them so any condensate flows back out the inlet.

0 -

If you get the system air tight you probably won't need a vacuum pump. Just a means to let the air out of the system and not back in.

I was curious about the airflow through some of my one pipe vents so I built this interface. Sorry not Hoffmans but you get the idea.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

@Steamhead, @mattmia2 , Nice idea! However, my system doesn't have any steam traps to repurpose. Also, for the vacuum system, I envision a dry air-line return to a discharge pipe (with or without a pump); whatever I use as a valve to hold the vacuum, I don't expect it to see steam, or even more than warm air. So, I expect to use a check-valve or possibly a solenoid valve (depending on the ultimate design).

@109A_5, Excellent! That's a good way for me to quickly setup a vacuum system for testing.

By the way, I am in contact with @PMJ, who very kindly has offered to share his experiences.

0 -

@pacoit , they still make traps. For the long main you'd get a Barnes & Jones "Big Mouth".

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

Thanks, @Steamhead .

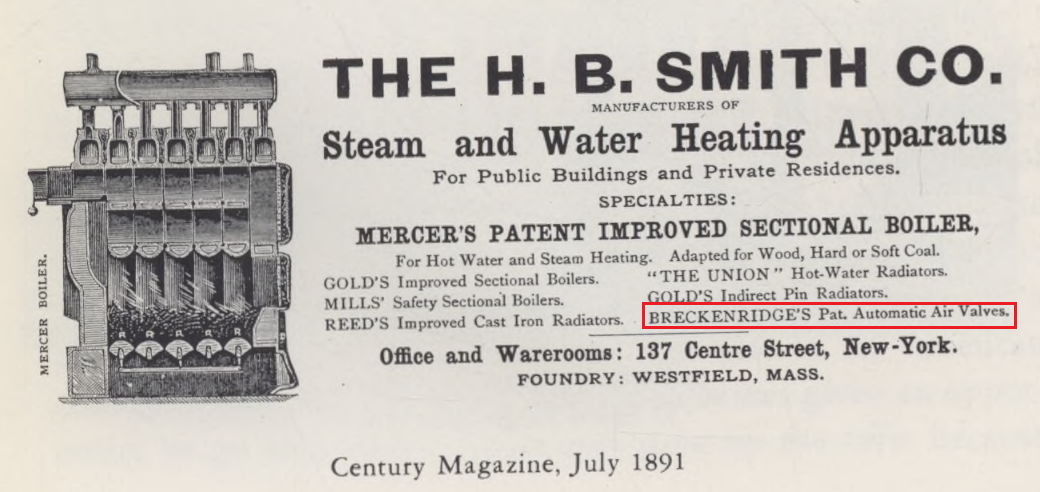

FYI, the threads on the "L" of the Breck are 1/8" NPT.

EDIT: Also, it turns out the first Breck did not have a rusted out adjustment screw hole; it's just that the adjustment screw wasn't screwed in; once I obtained the key, I was able to screw it in without issue.—-Don't want people to think a Breck couldn't last 100+ years!

0 -

This thread is very interesting. Any steam heating system needs to expel air and return condensate to boiler. This system seemed to operate without radiator vents or steam traps which require maintenance.

0 -

@jumper Systems expel the air via the vent(s) (one pipe or two pipe), as you probably already know.

The boiler heats the water, the water expands into steam the air gets pushed out. When the thermostat is satisfied and the steam collapses back to water and a vacuum is formed. The trick is having the system tight enough so the air can't get back into the system (once expelled), to maintain the vacuum from cycle to cycle.

I believe if the system integrity is maintained the benefits are faster steam propagation (less air to push), less air (oxygen) minimizing corrosion and @PMJ's observation of more even, uniform heating.

I also believe with the faster steam propagation you may save some fuel too, since little gains add up over time. You are not burning fuel to push air (as much air) out of the system.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

The breck is a bimetal element air vent. See Dan's article that he linked.

0 -

Update: I put the Breck in 5% acetic acid (vinegar) for 3 days. It de-rusted very nicely. Lots of debris "boiled" out. I re-attempted heating it to see if it would close, but it did not. I also was unable do any further disassembly, nor see how it could be done. (I wonder if the insides were slipped in while the tube was still hot? Heat fit.)

0 -

when iron rusts the scale is bigger than the original metal, even if you get rid of the rust it likely will be bigger than it started out. it also may have additional parts that screw in through the side ports, possibly with some sort of spanner that are holding the internal parts in. they may not have known enough about what would happen after a few years of use or they did know but didn't know how to fix it. This was one of the first steam air vents.

If you ever want to part with one I bet the

would accept a donation.

0 -

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

it would live forever there.

Retired and loving it.0 -

When ever I completely remove rust there was less of the original metal left, since it went away with the rust.

Was the screw removed (Red arrow) ? It would not surprise me if the screw pushed the "D" shaped inner assembly (Yellow arrow) against the other side of the housing.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

is there a patent number on it?

0 -

@109A_5, I removed the screw before de-rusting. I imagined, as you, that the screw held the guts in place. However, de-rusting hasn't loosened things up… yet. Haven't knocked it around much, yet. Also, should check it is fully de-rusted—-another vinegar bath.

I have not found patent numbers or markings of any kind…. Maybe I need to get my eyes checked…

0 -

Hi, Might be good to use some Kroil on it I've had it work on really stubborn stuff. 🤠

Yours, Larry

0 -

This book mentions the ''Automatic Air Vent" and a 1868 patent which I could not find. See pages 71, 111.

http://waterworkshistory.us/DH/1960HBSmith.pdf

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I gave the Breck another vinegar bath. It was quite clean. I then heated it up to see if it would close. But, no such luck; air came out the bottom. I also still don't see a way to disassemble it further. I'll poke around some more.

0 -

I'd probably try something like evaporust. Or heating it to near cherry. Might be worth asking someone that does historic preservation.

I think that screw with the square head needs to be screwed in for it to close, it probably closes at room temp if it is in far enough.

0 -

That screw inside may need proper adjustment for the valve to close properly with heat. Which is why they made it so it could be fine tuned. Also it may not work correctly if the pressure is on the wrong side, since it may be made to let the air in easily. The pressure differential may need to be correct too, higher pressure on the steam side.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

If you intend on possibly using it again I be cautious about using a torch or induction heating as motivation. It may permanently damage the heat sensitive element inside.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I originally used a torch, but only to achieve the equivalent of boiling temperature. Yesterday I tried boiling in water to be more precise. I set the adjustment screw to just a little open. It still did not close on heat.

If I turn the adjustment screw all the way in (i.e., at room temperature), it does close. So, the unit still has the ability to close, but not automatically upon heat.

As to original assembly, I wonder if the guts were set into the tube by shrink-fit?

0 -

The heat and allow to shrink is very unlikely, the type of precision needed for that wasn't common until around wwi or so. it is much more likely that either something unscrews from one of the ports on the side or the corrosion has pitted and raised the surfaces such that they no longer clear each other.

It is very possible whatever held the bimetal element in place has rusted away or the element itself cracked.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements