KBR 42 3 Bosch Greenstar

KBR 42 3 Bosch running on propane for radiant heat application and domestic hot water.

Over the past couple months I started to occasionally get the boiler to shut down with an EA error code and a flashing reset light.

Bosch rep wouldn’t give me much info on the phone because I’m not licensed, and finding anyone in the area (north central Illinois) that works on boilers has been a surprising challenge.

I found that my condensate line which is about 10’ in length and simply drains into my lower garage floor drain (no risk of freezing), had sagged in the middle, making water have to flow a bit uphill before hitting the floor drain. With that fixed, I was still running into the same problem.

I did find one YouTube video on how to clean a Bosch boiler - similar model.

I purchased the Bosch cleaning tool to clean out the heat exchanger and started to take the boiler apart.

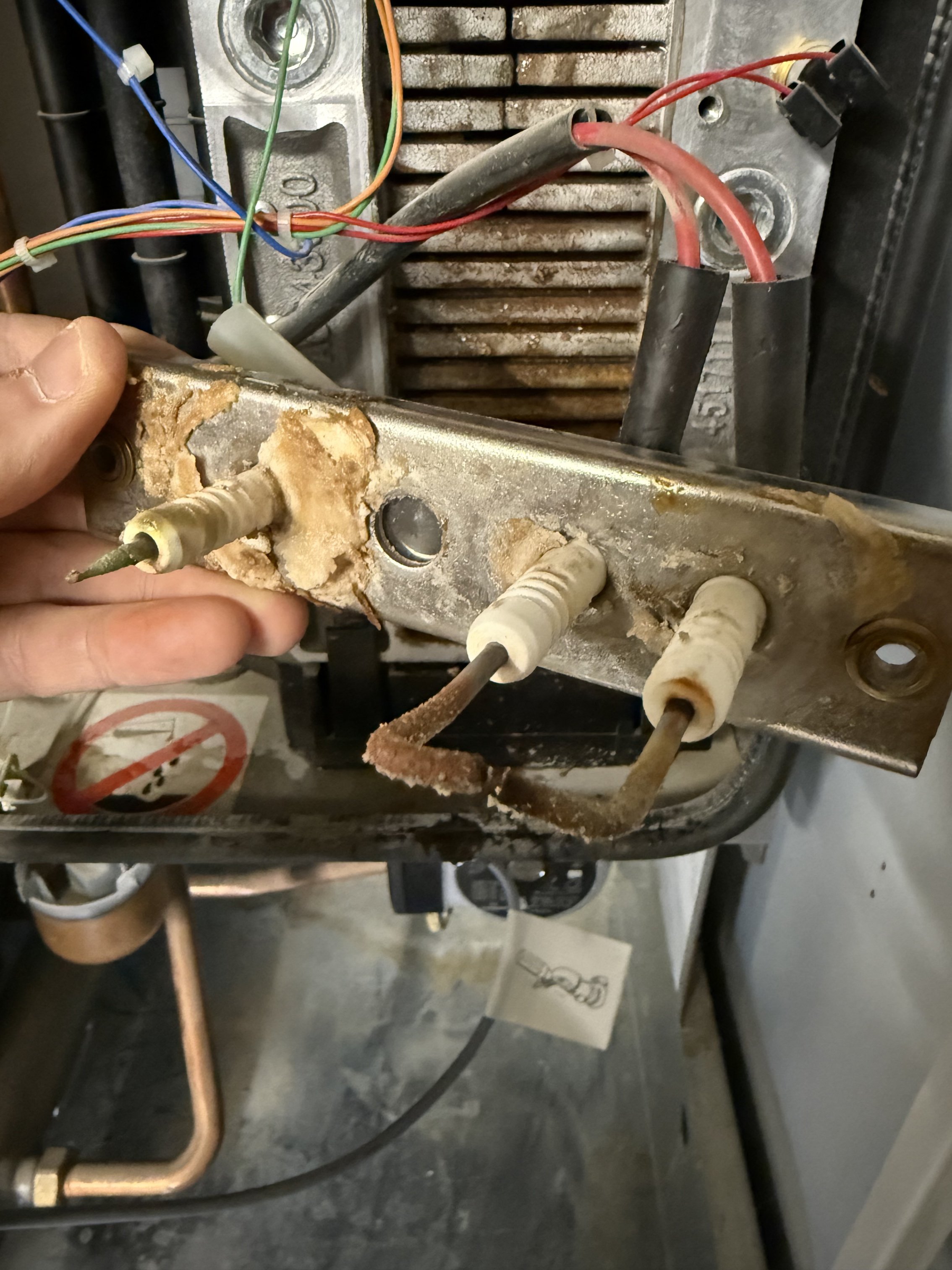

The igniters look horrible. I have a new set arriving this afternoon, but mine were in much worse shape than his in the video, so I was able to find a set at supply house.

I’m confident this is the problem and should fix the boiler. Spoke with one guy about an hour away that works on Canadian boilers (not much Bosch) and he said these igniters are advertised to be good for about five years but should be checked every year and if you have the boiler running year round like I do for domestic hot water as well as radiant heat, they will probably need replaced every two years or so.

Mainly posting this for others that run into same issue - I had a tough time finding info on this and it was frustrating I couldn’t get Bosch rep to give me info because I’m not licensed- and I’d probably need to venture into Chicago to find anyone that works on these things.

Comments

-

it's the first thing that comes up googling that error code, no flame detected on ignition. For any failed ignition on modern condensing boilers the procedure is relatively the same. Clean and check burner/heat exchanger, clean/replace electrodes, check gas supply and combustion analysis to correct any underlying issues. Fouled electrodes are typically a symptom not a cause!.

Once the new parts are installed and heat exchanger cleaned I would want to set up the burner properly. gas pressure, gas valve adjustment, check for flue recirc etc. those parts will foul up over time, but in my opinion if its happening before the 5 year point I would be looking into why.

1 -

thanks for response. I did find the error code online but was unsure of the reason (and still not sure why they fouled up like that).

I was having flow issues with the radiant heating system for quite awhile. There was a call for heat at the manifolds but Taco three way valve strainers weren’t allowing sufficient water through. So I was getting hot water at the manifolds, but not nearly enough volume. The system wasn’t running efficiently at all. I removed the strainers completely and this past year it was running nicely.

To your point ; I’m not certain that the installers did a combustion analysis and set this boiler up properly. I have a bit to learn before I’m confident that I can get it set myself, as I’m contemplating if it’s worth the cost to purchase a combustion analyzer vs finding and hiring someone who has one and can set this thing up the way it’s supposed to be running.

0 -

Unfortunately replacing the electrodes did not solve the issue. I’ve managed to get the boiler to fire since then, but sometimes it takes multiple attempts / resets. Results in same error code. Outside of a combustion analysis, is there anything else I should check outside of your aforementioned?

I plan to call Bosch again in the morning and let them know what I’ve accomplished thus far and see if the next guy might be a little more willing to provide some potential solutions.

- Edit : Condensate trap looked pretty bad. Sludge at bottom. Wasn’t in video but as directed in manual I cleaned it out. Tomorrow I will put vinegar solution through entire line - I think the copper pipe that the condensate line ties into might be blocked

0 -

depending on the exact situation I might look at a blocked vent, or just swap electrodes if its an after hours call in the dead of winter. but typically I would do the following, while also visually inspecting the inside of the cabinet and looking for anything out of place.

I always start off no flame signal type codes by checking gas pressure, static and dynamic. specifically what is the pressure while the unit is off, when it lights (or tries to ignite) at high fire (if you can get it there) and then what does it lock up at on shutdown. I'm looking for the pressure drop from static here. Next I would pull the burner and inspect and clean the heat exchanger, condensate trap/line, and electrodes (generally replace the electrodes if they are fouled) The fire side of the heat exchanger should be able to freely drain water, if the condensate backs up too much it can mess with the burner operation (it looks pretty wet from your photos, and you said there was sludge in the trap) now thats the tricky part because I have never cleaned one of those style heat exchangers, maybe someone else here has some advice on that. Once the heat exchanger is cleaned, drains freely, gas pressure is in spec with acceptable pressure drop, and the electrodes are in good shape I would put the analyzer on the unit (at this point assuming gas is good, burner is good, electrodes are good it should fire) and tune combustion into spec for this model.

Separately I would also be inspecting the boiler pressure, not strictly an ignition related issue but it always gets checked. Given how wet it looks where the igniters are, and the sludge I would want to rule out a leak in the heat exchanger as an underlying cause, especially if my gas pressures were within range the whole time, and the burner wasn't too far out of range once everything was cleaned etc.

0 -

Thank you very much for reply,

Recently with the very hot weather I was suspicious that residual hot water from boiler was finding its way into my floors, so I shut a lot of the valves off manually preventing any water from having the chance at doing so. A couple days later I noticed the boiler pressure operating in the red (up near 40) when the top of the green is 30. I wouldn’t have expected that to happen by me closing off the valves to the floors, I have expansion tank hooked up etc.

Anyway, if there was to be a leak caused by over pressure , would that occur in the heat exchanger ? You’re correct it was very wet in there.

0 -

There should be a pressure relief valve piped somewhere near the boiler that would open up when it sees a set PSI. Usually 30PSI for residential boilers. The expansion tank should be attached to the system and valves left open in such a way that there is always an open water path from the burner to the tank. It's possible overpressure could damage a heat exchanger but I would expect if that happened this conversation wouldn't be possible. If there was already a leak or pinhole etc higher pressure would make those issues much worse and alot more noticeable. It's possible your relief valve is a higher pressure one, if this is residential it should almost definitely be changed for a 30PSI version, and if it already is 30PSI you need a new one. I can't see any relief valve in the photos, it's possible it is just hidden or I'm missing it. It's very important that you have that installed correctly on the system

0 -

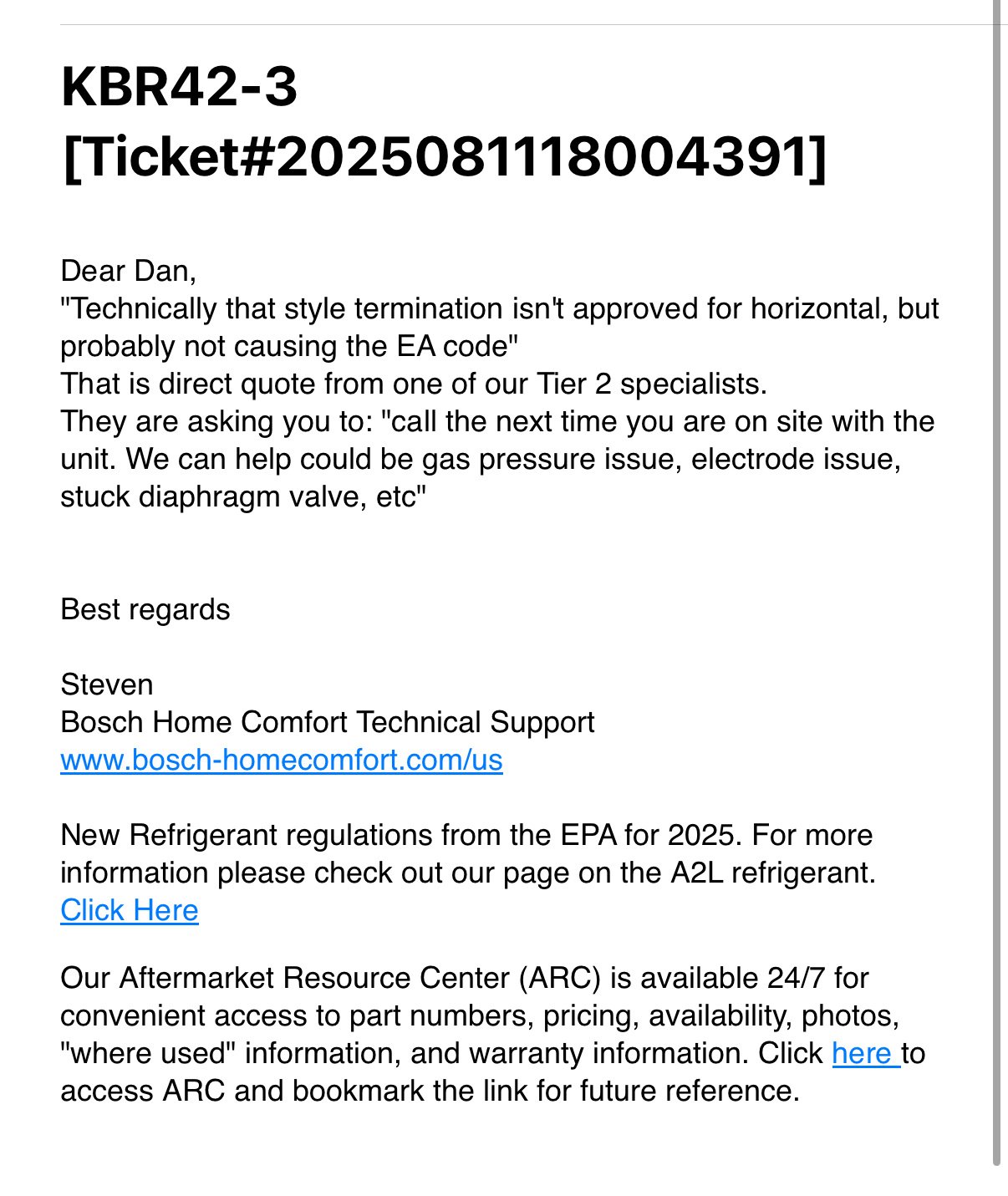

@GGrossI spoke with Bosch this morning and after explaining to the rep everything I’ve done - he said I need to get a licensed tech out here with proper tools to diagnose further.

Water quality has been a problem since the first installers opened this system to a well with a brand new pump that introduced unfiltered water with debris from the bottom of the well into new components.One thing I plan to talk to the reps about tomorrow is getting the system flushed , cleaned , filled with filtered water and brought to correct ph with inhibitor. The amount of sludge in the boiler’s condensate trap is concerning.

I cut the condensate line from the 1/2” copper and put temporarily into steel pipe so there’s no chance for restriction.

When the boiler was fired up I went outside to make sure it is venting properly. Doesn’t appear to be any issues there, it seemed to be venting fine.

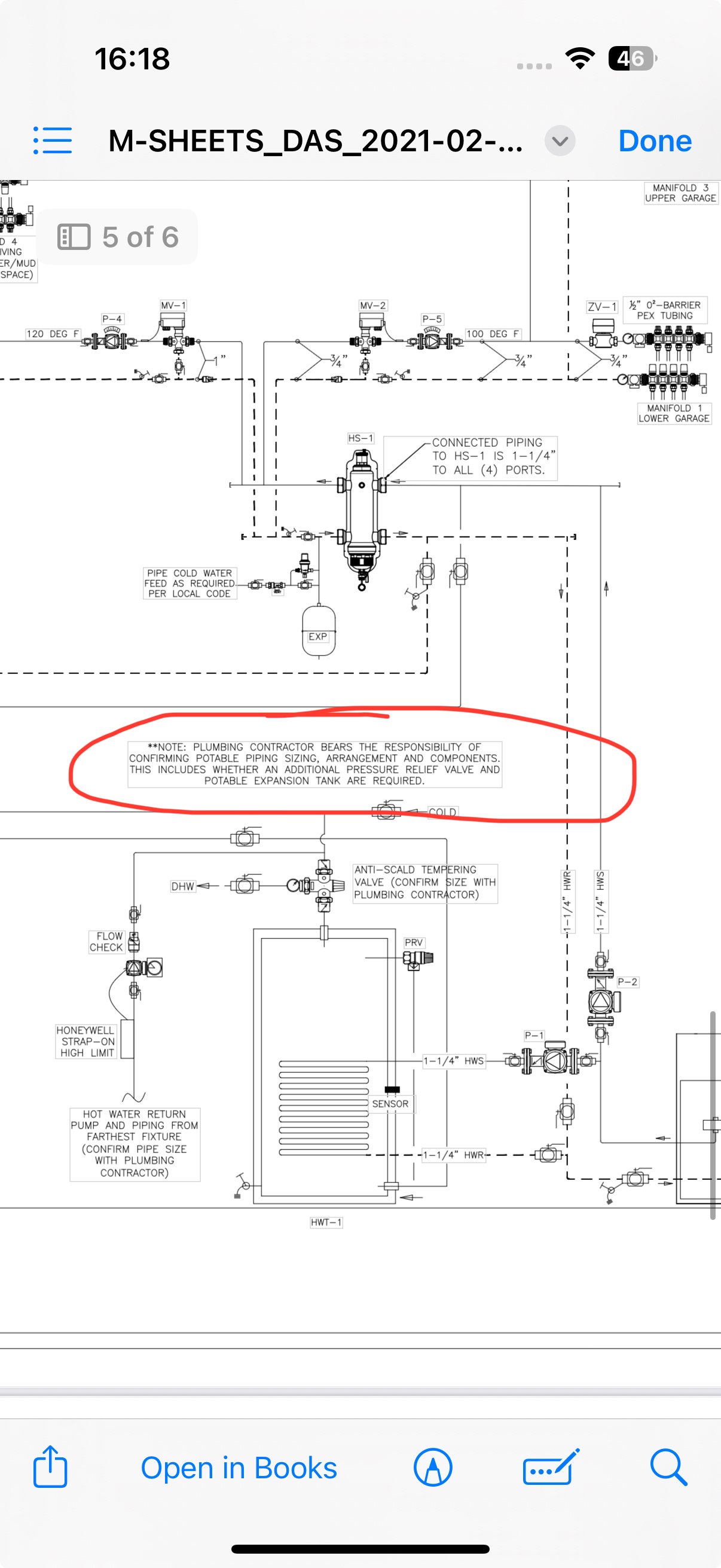

I attached the plans and some pictures of the full system (minus the manifolds). The water comes in from the well through a constant pressure system set at 70psi. There is a 100psi pressure relief valve and I’ve been down here a couple times when for some reason that pressure is high and that valve opens up and dumps water into the floor, right near the drain.

The water goes through that cap looking thing (pardon my ignorance) which restricts / reduces the pressure, and passes by the expansion tank, through the caleffi hydro sep and then into the boiler. After closing some of the valves to the floors manually, I did witness the boiler operating in the red around 40psi , though. I noticed in the design that the designer said its onus on the installer to determine whether another relief valve is necessary.

I wish I had a few more tools and more knowledge. This definitely isn’t my trade, but I am learning.

hopefully these guys that show up tomorrow know what they’re doing and I’ll definitely be providing them with the advice you’ve laid out here. Thanks again!0 -

You have the right idea here. The safeties are piped and thats the important part!

The system is piped a little funny, that big green device with 4 ports on it is a caleffi hydraulic separator, your boiler has a simplified version of this inside the bottom of the cabinet. so you kind of have a primary/secondary/tertiary piped system, not really necessary. If the system works as intended other than the ignition issues I would leave that as is, it will make any future changeout easier if the contractor has the caleffi separator there.

you do have a fill valve on the system in your photo, and it is open. This would be the standard "set it and forget it" approach so the boiler doesn't go off on a low water fault. Personally I like to close them to be able to control the makeup water a system is getting. One thing I might recommend, if there are leaks in the system and you can't find them. You can hook up a controlled filling station to that fill line, so rather than just putting new well water with new minerals to destroy the system to replace the leaking fluid, you can use a controlled demineralized fluid as makeup water. Depending on how bad the leaks are you may need to service the filling unit regularly. always best practice to fix leaks. I would bet the sludge you see is a result of the makeup water, I would have a contractor check to make sure the heat exchanger on the boiler is not leaking, it seems like a very possible culprit here.

0 -

yes sir, the designer had a reason for utilizing both the boiler low loss header as well as the caleffi hyd separator but I can’t recall what he said, now.

The system will eventually be hooked up to a wood gasification boiler as primary heat source and the propane boiler as a secondary, that might be the reason…

hope to find something later today, boiler continues to shut down. I just really hope I didn’t cause any damage/leaks with the boiler operating at a high pressure for awhile.

0 -

This has been a frustrating ordeal. Technician showed up a few days ago to diagnose issue. Unfamiliar with Bosch boilers. Didn’t do much of anything but said he’d come back with combustion analyzer a couple days later. Yesterday he came back and did a combustion analysis. At the time he was here boiler was firing normally without issue. But overnight it failed again with the same EA code. Boiler doesn’t seem to be failing as often as a couple of weeks ago, but still has an obvious problem with occasional EA error codes and flashing red reset button. Fires back up within a couple attempts of reset. Huff and puff sound occasionally as it attempts to fire.

to date since the errors started occurring, I cleaned heat exchanger, replaced electrodes, cleaned out condensate trap, verified it’s venting ok, took leaf blower and blew air back through air intake to ensure no clogs, and tech did a combustion analysis yesterday.Couple tech visits and $ down the tube in labor and still dealing with same issue (although not as consistent as before).

Any other possible ideas here? I think I’ll need to get another tech back out here and on the phone with Bosch.

Thanks in advance

0 -

For curiosity sake take a picture of the outside venting terminations. I am guessing either concentric kit or close piped.

I would check the diaphragm on the air and get somebody to test the gas valve to check those off your list

0 -

Thank you; First picture is taken from outside. When boiler is running it seems to be adequate venting, but I guess I could put a snake down there to confirm no clogs…

Concentric venting - second pic is just before piping exits wall.

0 -

The install manual says not to use that specific concentric vent unless you are going thru the roof.

0 -

@yellowdog thank you , I’ll ask Bosch about this. I agree that it doesn’t show a picture with that used in a horizontal application - I just don’t see anywhere that says it can’t be. The boiler ran for about a year and a half with this venting application with no issues… but it might be something to look into. The guy that I installed the vent with said they use these in horizontal applications often. Going through roof wasn’t an option (I have a garage above this room) and drilling a single hole through the 10” concrete wall was much easier than drilling two.

appreciate you pointing this out - I’ll ask the reps at Bosch !0 -

0

-

-

I guess it’s a little over two years old. I’ve gone through two full winters with it. This year (during the summer when the boiler is firing up for DHW) is the first I’ve ran into this problem.

I’ll start paying attention to the winds outside and see if perhaps I’m getting more failures when the wind is out of the east which would push the exhaust back against the house.

If I were to have had this problem periodically since I first started using the boiler I would have been more suspect of the exhaust application, but since I just started having this problem recently and the venting has been the same the entire time, I was more thinking that the exhaust might have gotten restricted somehow. But that doesn’t appear to be the case, either.0 -

2 years is a very short amount of time for a boiler. Look at those pics you posted, you are having these ignition issues after only 2 years. Thats typically when a boiler gets serviced for the first time with no failures. Issues with poor combustion, recirc, water quality etc take time to manifest. usually a couple of years. I would not write off anything at this point, 2 years and it looks like THAT in the heat exchanger tells me that a whole lot of problems have existed since install. I'm still more concerned that there may be a heat exchanger issue given it looks awfully wet in the fire side.

to be clear flue recirc is NOT going to cause an immediate failure, It will slowly destroy everything the flue gas comes into contact with. you would need to sample the intake air with a meter, or look at tell tale signs in the cabinet, the venturi etc to confirm this is happening. wind load in the exhaust can cause issues, and can cause more flue gas recirc.

Poor water quality and too much makeup water will kill your heat exchanger, but it will NOT happen immediately. The amount of time this takes depends on several factors. How hard the makeup water is, the exact chemistry of the boiler fluid, how much makeup water is going in, and even flow rates and supply temp can affect this.

Poor combustion will destroy igniters, door seals, plug the fire side of your heat exchanger etc. it will NOT immediately shut down your boiler

all of these issues need to be looked at, a boiler firing and doing its job on install is not indicative of there being no problems. The majority of boiler issues take a couple years to do their damage. That's where you are now.

1 -

It should be fine, those Concentrics do their job.

0 -

You probably need someone with a combustion analyzer. Those Greenstars need to be dialed in on low and high fire. It's semi odd it fired all that time with that super bugged out Ignitor and ionization rod, and a fresh one isn't lighting things up. You're 100% sure you fuel is good? Nat or LP?

Eliminate the question on the drain, divert to a bucket if you have to. A blocked drain is a no go. Blow on the tube to make sure is open if you have to.

IF the concentric is recircing its own gas, that isn't normal for that type of concentric. Need to figure that one out.

1 -

thank all of you for the responses.

I was out of town for work this past week and during that time my wife said she never had to reset the boiler. I did have a tech come out and do a combustion analysis on the boiler prior. The boiler did fail a couple times since that happened, but has been running ok for the past four - five days with no issue. I don’t get it.

it’s on propane - I can’t get natural gas out in the woods where I am.

@GGross mentioned water quality. I’ve been dealing with water quality issues from the beginning, when the installer opened up the water valves to the newly installed system and a freshly installed well pump put unfiltered water into the system - picking up debris from the bottom of well and allowing it in. I’ve put inhibitor in the water before but I was dealing with so many flow issues from the strainers getting clogged that I think that water has been flushed out.

My plan is to get the system flushed out and cleaned , filtered water put in with fernox f1 inhibitor.

The heat exchanger was dripping wet inside, but I did clean it with the Bosch tool and it didn’t seem to be all that clogged up or anything… how would incorrect ph water effect the heat exhanger?

Finding anyone in the area who works on residential boilers and understands radiant heat systems has been a big challenge. I think I may end up needing to purchase some hydronic system cleaner, a pump, filtering system and a combustion analyzer so I can do everything myself.

0 -

cool

if it 'didn't light' at all, it definitely wasn't water quality.

There's another old tale that is the lp co overfills the tank by a smidge, you'll struggle to light off.

Glad its back on

1 -

I'm not telling any "old tales" lol. Gary is right that poor water quality won't stop a unit from firing, I never made that claim and if you actually read what I wrote you will see that. Poor water quality can destroy the heat exchanger though, and that can stop the unit from firing. there is evidence that happened and I would be ruling that out before proceeding. introducing new demineralized water won't fix an ignition issue, and will be a waste so long as there are still leaks present.

1 -

@GGross do you think poor water quality could cause a leak in two years time? I’m not exactly sure how to test for a leak in the heat exchanger without taking it completely out…

I will say that the boiler has been firing up consistently for over a week now- we haven’t had it shut down. I can’t figure out what it was.

I have an ejector put in the lower level that the drains feed into. At one time there was an issue with the float and the drains overflowed with the ejector pit full. This would have prevented condensate from draining. My suspicion is that I started having issues around this time… the Condenstate trap was full of sludge when I cleaned it. Perhaps it just took awhile for everything to get cleaned out and running normally again, with a few instances of that error code even after it was cleaned. It appears to be back to normal now.

I appreciate everyone’s responses and help.1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements