Old Winkler for you oil folks

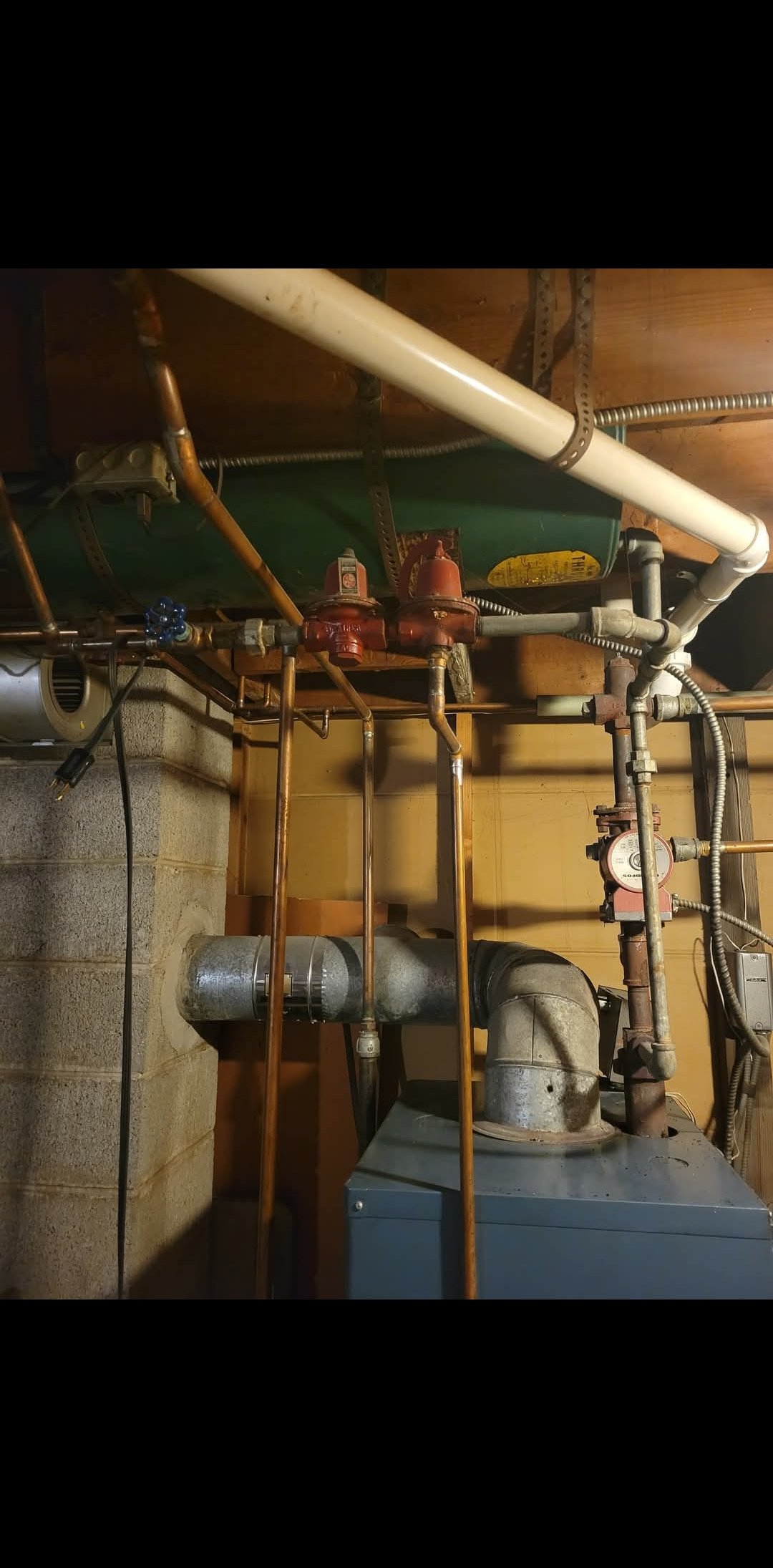

Let me start by saying that I am new here and to heating a home with water. We purchased a home in WI earlier this year and with the market the way it is, I had some fear on the heating system in the house due to unknowns and replacement costs. Once established, we found the prior owner used the wood burner for majority of the heating of the basement and warm air was pushed up the shoot via 2 fans to warm the house and the oil burner was back up for cold days or when they were away from the house. Looking at the oil burner, I found out it was an old Winkler and there are a few guys on FB that seem to know of these. Heating oil is not that popular in Wisconsin as it seems to be on the East coast. Natural gas and LP are what we have here. Natural gas is available at the road too, just have to trench a few hundred feet of line to the house that costs some good amount... When talking to the owner, it is original as far as he knows or damn near so that puts it in the 60's. He never messed with it or cleaned it or anything according to him, just cleaned the chimney. Talking with some folks that reside on the East coast, the older ones that are in the service trade seem to like these ol girls. I was waiting for winter to be over and this summer, I want to pull some stuff apart and give it a cleaning and look over now. It may not be efficient but she fires right up when needed. I'm still looking for how to drain air in the system, air vents for other air, things like that to keep it going. I realize I'll need an upgrade soon but was suggested even a Beckett AF/AFG burner head will help with efficiency of oil usuage until one day it needs to go. Anyways, I just thought I would make this post and include some pictures since who doesn't like to see an old antique still working, right? That's how our family is with antique tractors, except today, everything is made with very little money, costs stupid money and you throw it away and hope to finance another system…. Anyways, suggestions or ideas are welcome.

Any information or suggestions are welcome.

Comments

-

Older system looks to be late 50s early 60s.

Not farmalier with Winklers. I know Winkler made low pressure burners, don't know if they made high pressure burners.

The Pressure has to do with the oil pressure used to atomize the oil. Parts could be an issue. You also could just change the burner. If you could get pics from the other side of the burner I know it looks tight. Can't see the oil line.

0 -

That's one of the later Winkler low-pressure burners. In its day it was one of the most efficient burners out there, and the fuel metering setup is a marvel of engineering. It pre-mixed some air with the oil before sending it to the nozzle. I think it ran at 4 pounds pressure, and it would burn heavier oil than the usual #2.

Unfortunately, these were very expensive to produce, so they went out of production sometime in the early 1960s IIRC. Fuel was ultra-cheap back then and the higher cost could not be justified. I've often wondered what would happen if someone put a modern flame-retention head on one of these.

I think the boiler itself was actually made by Dunkirk, but that might be wrong. It's a solid unit. The burner, however, is best sent to a collector, since parts are very difficult to find for it. If that were my boiler, I'd change the burner to a Beckett AF, and at the same time get rid of the stack-mounted primary control whose trial for ignition is probably 70 seconds rather than 15, which is current Code.

I've spent some time in WI. What part are you in?

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

Or at least change it to a modern primary control and find the right person to change the burner when something you can't get fails on that one and have that person service it until that time comes.

you could also put a gas power burner on it.

0 -

You also need to understand about maintaining the air in the compression tank.

is one circulator for the heating loop and a second for an indirect water heater?

0 -

-

She is an old dinosaur for sure. I was down looking at the system last night and I don't even see how the get air out or flush water/air really. I have no idea on that pump below but I have to give it a better look when I get down there and check the routing. Looks like top pump does upstairs and the branch off is for the heaters in the basement. No indirect waterheater. I don't know if there was at one time but not anymore but the bottom one is plumbed in somehow. I've never seen a tank like that. Not a normal expansion tank for sure. We are located around Richfield, WI. Was already suggested to install a S2000, Buderus G115, Utica Trifire or a WM WGO-2. Just just hoping not to have to yet. Also trying to figure out the NG or oil part.

0 -

Really cool and Really nice, but it really needs replacement.

0 -

They are neat. Has to be a good 85lbs

0 -

More intersting, The pump assembly and air adj

0 -

Thanks for the really great photographs of your old “classic 60s” boiler system. That is the way I was taught to install boilers in the 1970s. Really brings back memories.

I want to ask one question about "Two Circulators". How many thermostats do you have?

As others have suggested, ditching the burner for a new Beckett AF/AFG replacement is a “minimum to do” ASAP, if you are going to depend on that boiler for the majority of your heating needs.

If there is Natural Gas in the future, then you can opt for a Gas Conversion Burner like the Carlin Carlin EZ Gas Pro or the Wayne P250 along with other brands like RW Beckett and Riello. But know that if you go that route ,and your boiler fails (water leak) and needs to be replaced that burner will not fit your new gas boiler.

Since you are probably not going to pay got the natural gas line anytime soon, then the replacement oil burner is the way to go. Beckett is more common and you have a better chance of getting someone that knows how to clean and tune them up properly.

As I look closer to your system, I will be able to answer more and more of your questions. Start with finding someone to replace the Winkler burner with a Beckett. Try your fuel supplier for starters! I'm not familiar with WI, but i find that plumbers that advertise themselves as "Plumbing and Heating" are more likely to know about boilers and oil burners, Than those that advertise themselves as just "Plumbing" or "Plumbing and Drain cleaning". A good oil burner Tech will be hard to find but keep looking, there is one near you that can help you out. If the fuel company wants you to burn their oil, they will find someone that can help you do that.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

@mamuel I can help tp answer many of your queries. I will take them one at a time after I study your system photos. Can you answer two questions for me.

- How many thermostats do you have?

- What do your Radiators or Heat Emitters look like?

- If assembled in the 1960s you may have baseboard hot water radiators with copper tube /aluminum fin elements

- You may have convectors that are connected to a one pipe MonoFlo® tee design system, or you may even have cast iron radiators.

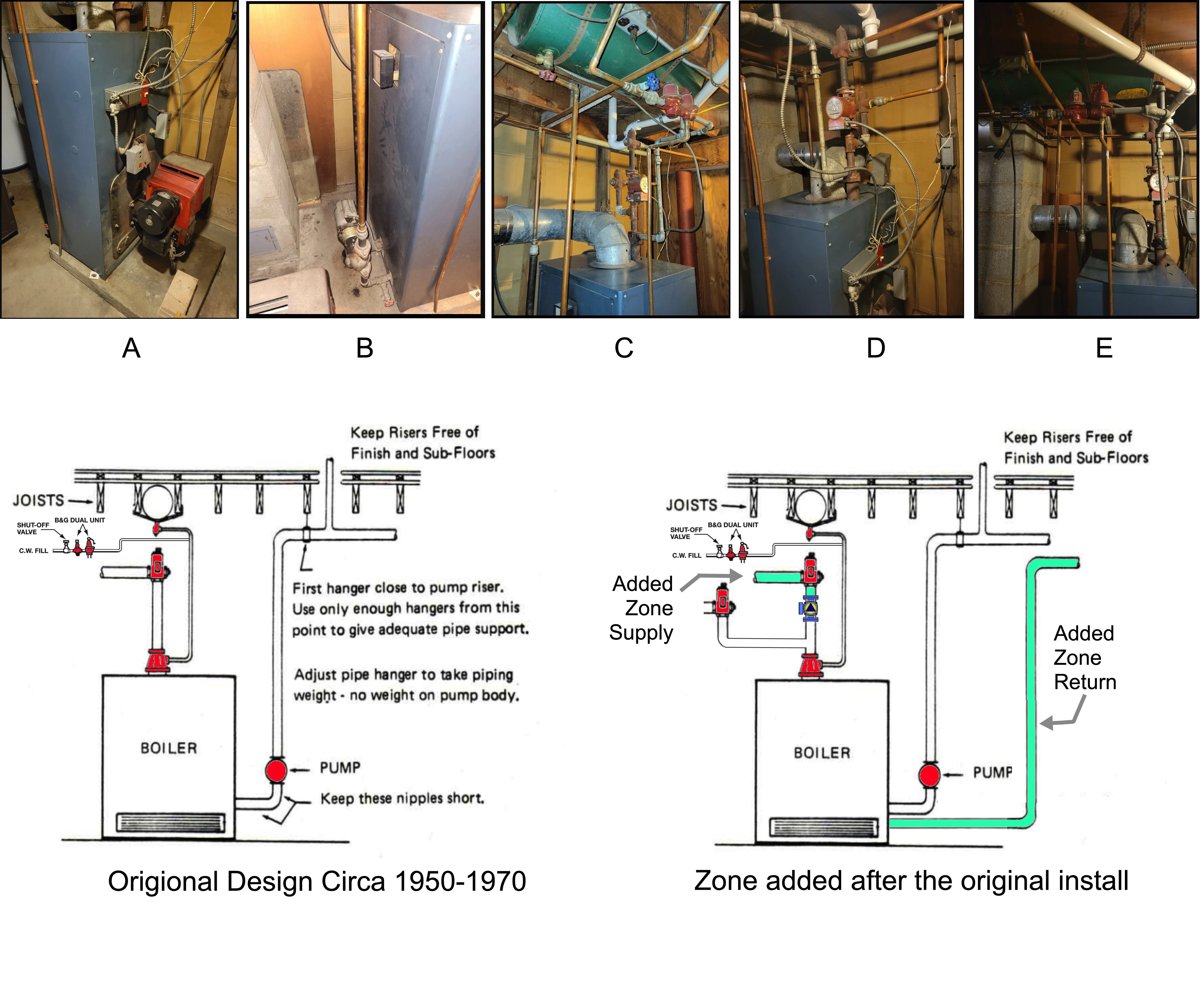

- Since there is a circulator added after the fact, you may have two different radiator/heat emitter designs. One that is original and another that is newer the the original.

Answering these questions will help me help you with how to eliminate Air from your system.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I want to save this info because there are so many times I want to show someone a photo of an old system but have difficulty finding just the right Photo online.

This is just conjecture, but I see your system being built in at least 2 stages. Perhaps there was an addition built some time after the original house was completed. You have a classic design that was used when that home was build as illustrated on the left diagram. There are some classic Air Elimination devices on this original boiler. those parts were needed to remove air from the radiators and channel it to the expansion tank. Once your system is up and operating, you should not need to remove air, EVER!

The green expansion tank is self maintaining, when it comes to draining water and adding the proper amount of air as a result of the AirTrol® boiler fitting and the AirTrol® tank fitting. With the system you currently have, you must not add any automatic air vents anywhere in the piping, radiators or on the boiler. The AirTrol® system controls the air in the system automatically, without human intervention.

The only time you may need to remove water or add water or bleed the radiators is when the closed system is opened up for service like replacing a valve, circulator pimp of other fitting that requires draining the boiler system.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

-

-

Where is the airtrol fitting in the tank? I only see a nipple going into the tank. Also the airtrol tank fittings I have seen mount vertically in the bottom of the tank. The airtrol separator in the supply piping works excellent, but I don't believe it prevents air migration from the tank.

0 -

The Airtrol fitting is just where it should be. It's not there to prevent air migration from the tank — it's there to ensure that any and all air in the system for some reason gets into the tank in the first place.

It's exceptionally rare for a compression tank to get too much air in it! It's not at all that uncommon, though, for a compression tank to get too much water — become waterlogged — if by some evil chance someone has added another air removal device to the system.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

I don't see an airtrol fitting, i just see it teed directly in to the boiler outlet. I don't see the airtol air scoop that encourages the air to migrate to the tank, i don't see the airtrol trap that stops gravity circulation in the connection to the tank from bringing dissolved air out of the tank.

0 -

When you said Winkler I thought you had a coal stoker at first.

You have a perfectly intact Thrush compression tank that creates the point of no pressure change in your heating system to allow your circulators to work and push hot water through your home.

DONT let anyone rip it out!!!!! It is fine where it is and has been working since it was installed and you can use it with the new boiler with no issues as long as the plumbing is done correctly WITH NO AUTOMATIC AIR VENTS ANYWHERE.

You need to ask the former homeowner who takes care of this boiler as they will know what is required for maintaining the air to water ratio(air charge) in the tank which is 1/3 air 2/3 water.

If and when you have to change the boiler out the only thing you will need for the steel compression tank is to remove the boiler drain valve and replace it with a Drain-O-Tank valve that will allow you or the plumber to add the correct amount of water to the tank and the same time eliminate the excess air in the tank to provide the correct 1/3 air to 2/3 water ration in the steel compression tank.

You have a perfectly good US Stove Console heater that will last you for years of home heating with wood.

0 -

I have not been on here in a while so just stumbled back on. To answer a few questions, there are 2 old thermostats, 1 on main floor and 1 in the basement. Upstairs is all fin tube baseboard and half of the basement is the same. 2 rooms in the back are unfinished are cabinet types, I'm not sure what they are called but can get pictures. I can get more pictures of anything if needed. I did notice that its a Thrush tank. Just tapping on it, there is no water or anything in it. From what I gathered from the old owner, he said he's never done anything with it or had it cleaned but I could of sworn he said it was tuned up but I doubt it. Probably just tank filter changed. I do have a guy that is going to do heat loss calc and stuff like that very soon after cleaning up Milwaukee flood area. Otherwise, I'm pretty sure he just said he burned wood and used that for when there were gone or needed extra heat. Not sure if he even put oil in the oil ports of the motors. But it worked last spring and we'll see how it does this winter maybe since I haven't gotten around to gas and replacement yet until that guy comes over for calc and take a look. The worst part is wondering how heavy it is and I'm sure its old enough to have asbestos… Anyways, let me know if you are wondering anything else. I thought about changing the head but it's just not worth the hassle I guess since I won't have a need for it when it goes. I wonder if it's one of the last still running in the state or country?!

0 -

Like mentioned, I don't think they guy may of even oiled it. He was a tinkerer like the rest of us but I don't know if he did on that. It didn't sound like it. Just threw wood in burner for those 2, if the boiler kicked on when too cold or away on weekends, then cool. I almost want to pull burner to check and clean but almost don't want to touch anything now. Replacement head not worth it now as I don't know what I'm doing yet but haven't pulled gas up yet but a guy i know is going to come check out other stuff. Wanted to replace wood throwing window to seal up house better and pellet stoves are big in my area. Wood is easy as locals have plenty of decent priced cords. not enough on our property to rely on but damn, I wanted to close up that single pain, window and not carry down the stairs. Not sure how I'll move the Winkler and I'm guessing it has asbestos in it…

0 -

Just remember that you will be using two tons of wood pellets versus one ton of coal if you decide you need to change.

You can always put a coal stoker boiler sized for your home in a shed with a concrete slab for the stoker boiler and to store bagged or bulk coal and keep the mess of dealing with coal ashes outside.

0 -

The Winkler's were pretty common here in New England. The boiler looks like a Utica from the 50's probably made by them but labeled Stewart Warner.

If you don't have the $$$ to replace the boiler. I suggest some short term changes that will get you some more "worry free years" out of it.

- Change the burner someone suggested a Beckett AF (AFG) good move and if you contact your local oil company they might install a used one.

- Get rid of the stack switch primary control

- I couldn't tell from the pictures but it looks like a thermal vent damper on the flue pipe. If so rip that out as well. They are no longer made and can be quite dangerous. They were not recommended for oil and not recommended to be installed horizontally. Regardless of what else you do I'd get rid of that and install a CO detector.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements