Indirect water heater operation sequence

I have noticed the following sequence with both my recently replaced Weilmclain indirect as well as the new one. Both had been set at 135 degrees and use one of my 3 zones. When the indirect is in standby without using the hot water temperature drops normally and the circulator starts and, even with 160 degree water in the boiler, the boiler fires. It runs for maybe for only 1 minutes to bring it up to temperature. It seems to me as a non professional homeowner that it should circulate the water in the boiler until it reaches the point where more heat is needed to satisfy the tank temp setting and then turn on. Is the current operation normal? Thank you.

Comments

-

The operation of the boiler should be controlled by an aquastat on the boiler. Sounds like your boiler is controlled by whatever turns on the circulator…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

What make and model aquastat? Is the indirect on priority?

0 -

My indirect is a Weilmclain Aqua Plus 2. The control on the indirect tank has 3 wires that connect to a Honeywell zone valve. The aquastat is a Resideo L8148A with only a high limit. The zone valve is connected to the aquastat. I do not know if the tank zone has priority. There are no wires from the tank control directly to the aquastat but the wires from the aquastat attach to the same screws on zone vave as the wires from the indirect control so it appears that indirect control does connect w the aquastat.

0 -

From what you're saying, when the aquastat calls for heat, it sends 24 volts to the Honeywell zone valve to open. Once open, the end switch on the Honeywell zone valve closes and turns on the boiler. And there's no priority. If you have plenty of hot water during the heating season, maybe you don't need a priority control scheme.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab1 -

The L8148 has a fixed non adjustable differential of I believe 10°. Firing rate, pipe size, and circulator all contribute. I'm guessing there's one Taco 007 for all three zone valves, and the 007, and possibly the piping isn't correct for the indirect.

0 -

Did you have a tankless heater prior to the indirect? The boiler hooked to an indirect the boiler should not maintain temperature. maybe if you did have a tankless the Low Limit was not disconnected.

0 -

@Miata, You did not have a tankless water heater in your Weil McLain oil fired boiler because you have a Honeywell aquastat model number L8148A. That control will not support a tankless coil for making your hot water. You do not need to answer @EBEBRATT-Ed's question, so don't stress over it, It is not an issue you need to worry about.

You mentioned that the boiler water is already at 160°F when you observe the call for hot water from the indirect tank. This can happen in a few ways. the most obvious is that there was a call for a heating zone that took the boiler up to temperature up (As high as 200°F depending on how your L8148A is configured) then as the boiler was cooling down after that call for heat from a central heating zone, the Water Heater for some reason calls for heat, because the water temperature in the tank has dropped to the "cut in point" of the water heater tank thermostat.

This seems unlikely since it is almost June and you are probably not using the central heat today. The other option is that the original installer added a second optional aquastat to the system designed to maintain a minimum boiler temperature. If that is the case, that is not the "best practice" for your system's design and is probably using more fuel than you need to use to maintain comfort and sufficient DHW. (Domestic Hot Water)

Can you take a Photo of the boiler from far enough away so we can see all the controls, the oil burner, and the pipes that reach the ceiling of the boiler room. Maybe from two different angles. This will reveal a lot of information about your system.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

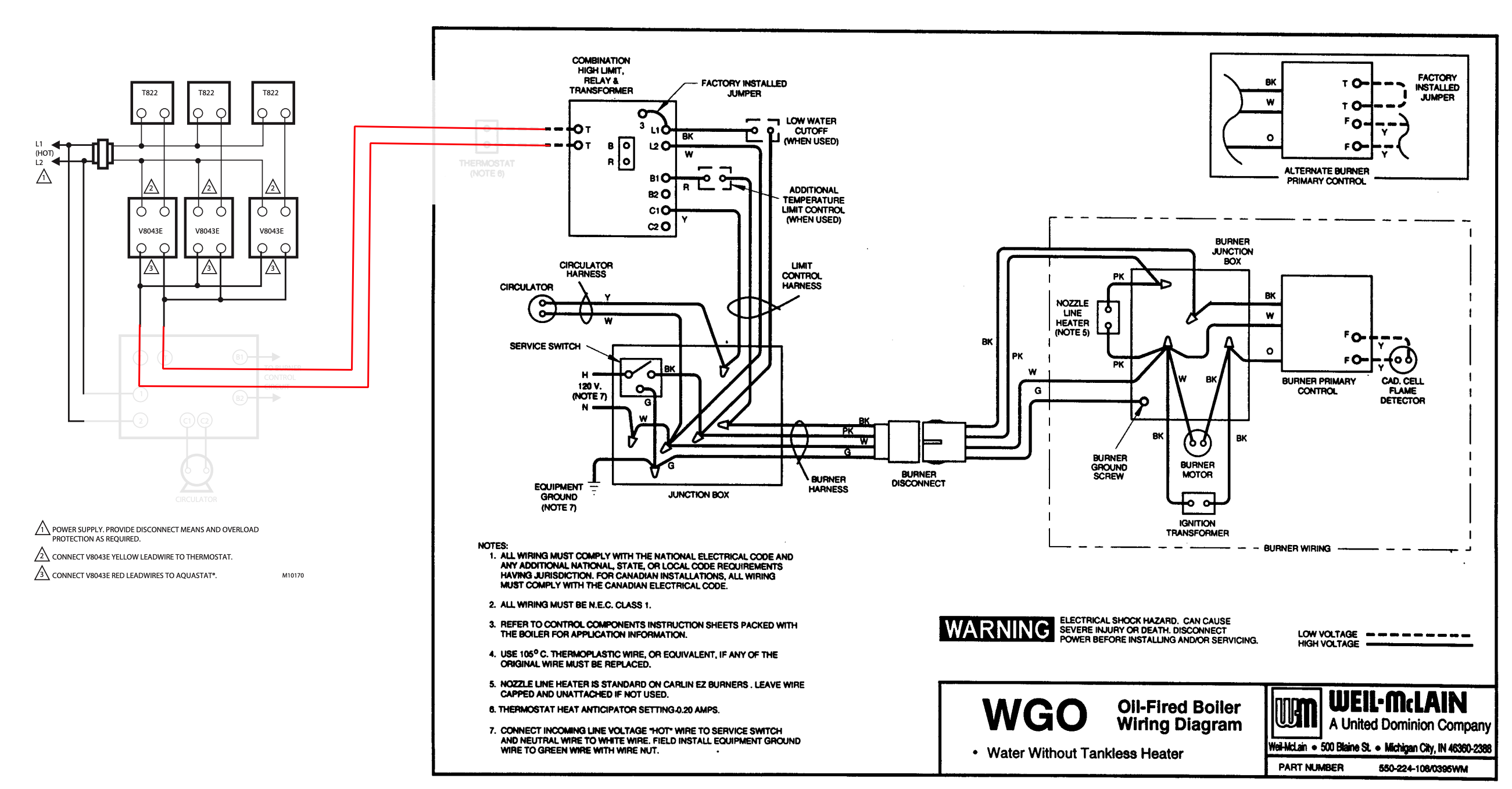

Here is the water heater Sequence Of Operation (SOO) for a Weil McLain WGO series 1 that is using Honeywell zone valves.

- Boiler on stand-by with no call for heat of DHW

- The house needs no heating at this time

- The water heater is up to temperature and is not in need of additional heat at this time.

- Call for heat from the DHW as a result of stand-by loss over several hours of no hot water use.

- DHW zone valve receives the call for heat from the DHW aquastat

- Zone valve opens, the end switch closes (turns on) to signal to the L8148A aquastat that there is a call for heat

- The L8148A relay pulls in and contacts for the oil burner and the circulator are closed (turned on)

- The limit on the L8148A measures the water temperature of the boiler and determines if the water temperature in the boiler is below the limit temperature set point and will power the oil burner primary control.

- if the boiler temperature is below the limit set point, the burner is powered immediately

- If the boiler temperature is above the limit temperature the burner will not start until the boiler temperature drops below the cut in temperature of the limit aquastat

- regardless of when the burner starts, your oil burner may have a time delay in the sequence of operation that prevents it from starting as soon as it gets power from the L8148A

- The circulator will start at the same time as 5 above with no restriction to what the boiler temperature is.

- Once the call for heat is satisfied at the DHW aquastat, the circulator and burner will stop operation as soon as the zone valve closes and the zone valve end switch is open (Turned off).

So as long as the 160° water temperature in the boiler is lower than the limit setting of the L8148A, the burner will start at the same time as the circulator, absent any time delays that result from the oil burner primary control’ Sequence of operation. These oil burner delays may be prepurge timing on the primary control along with power venting devices not normally associated with oil burners that are vented thru a standard chimney.

The above SOO is based on Weil McLain and Honeywell recommended control wiring design.

You may have a wiring design that differs from "best practice" or recommended wiring designs or may have a different Weil McLain boiler. The SOO for Zone Valves and the L8184A is the same regardless of the boiler it is attached to.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 - Boiler on stand-by with no call for heat of DHW

-

Thank you Ed for the detailed explaination as to the sequence. If I understand it correctly , the aquastat is set with an upper limit of 180, there is no lower limit, the indirect is set at 135, and for example sake the boiler is 160 from having heated the tank from a previous draw of water. Now tank drops to 130 and aquastat reads limit of 180, boiler is 160 so it fired until the tank temp is satisfied. So it appears to be a waste of energy if the circulation of 160 water would satisfy need to raise tank temp but the current aquastat is limited in the "choice" it can make. Do I have the correct understanding with a homeowers limited knowledge? Thanks to all for information.

0 -

Once the 160 degree boiler water starts adding heat to the indirect it will fall rapidly in temp, there isn't a whole lot of heat stored in the couple gallons of water stored in the boiler. If the aquastat had multiple setpoints and had a setpoint of say 155 for the indirect call, the boiler temp would drop and it would fire pretty soon after the start of the indirect call anyhow. Since you need the return water temp to get up to 140 pretty quickly after a start of a call for the indirect to prevent condensing of products of combustion in your cast iron boiler there isn't going to be a lot you can do with reducing the setpoint for the DHW call. Energy Kinetics does some dynamic control of the setpoint when they are heating an indirect but it is unlikely you would ever save enough to cover the cost of changing the controls.

1 -

What model indirect?

With the indirect set to 135°, is there a thermostatic mixing valve to temper down to 120°?

The L8148 doesn't state its differential, but we'll assume its 20° since you mentioned the burner came on at 160°.

Knowing what model indirect might help find out what the differential is on the tank controller.

Most smaller WM tanks are piped in 1 inch. The manual for the indirect will describe the piping and circulator size needed. Are they full port zone valves? If the burner is running for only a minute to make up a 20° differential, something isn't right.

There are better aquastats than the L8148, but keep in mind, a demand to satisfy a DHW call should send maximum BTU's to the tank. Recovery rate is key.

0 -

What size tank is the indirect? sounds kind of like it is short cycling.

0 -

You might be interested in "Thermal Purge". The L8148A is an analogue control. there is no "Brain" or "Logic" in that control to "Decide" to leave the burner off. It is as efficient at what it does with the limitations of analogue technology.

Energy Kinetics is a company that understands your idea of "Wasted Energy" as you stated in your original post. They have built into the electronics of the control that replaces the Aquastat Relay, a logic that actually shuts off the oil burner (or Gas burner) early and keeps the zone valve open (in your case) or zone circulator pumping to "Purge" the boiler of that 160° heat into the last zone that calls for heat. That way the boiler won't be left at 180° or 160° at the end of the previous cycle to slowly cool off my letting all the heat from the boiler exit up the chimney. The hot boiler water will be circulated into the water heater or space heat zone for a predetermined amount of time calculated by the control's onboard software. This is only one of the ways that System 2000 and other EK boilers reduce operating cost compared to the boiler brand that you have.

All that said, there is a way to build a holding circuit to purge the left over heat in your Weil McLain into the system, but it can get tricky when you have zones. Some others with single zone systems have had some success with lowering their fuel consumption as much as 5 to 7% using DIY thermal purge. @jesmed1 is one that comes to mind in this post

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

It does seem to me that the boiler is short cycling when it runs to make up the loss of heat from the tank due to standby losses. During those periods it may only run for 1 to 2 minutes since the boiler always seems to start at 160 degrees.To provide some more information the boiler is Weilmclain WGO with 100,000 net btus feeding a Weilmclain Aqua Plus 45 gallion tank set at 135 with no mixing valve. There are two adults in the house

and my wife loves "hot" water. There is 1 inch piping from boiler to tank. Tank was installed last week. Never had a tankless coil in boiler.

0 -

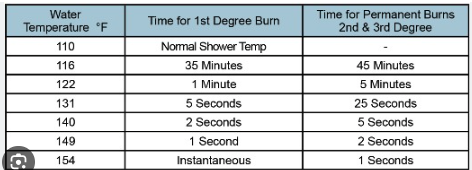

Be careful with DHW set that high, caution guests, especially small children, elderly adults, to the hot water being "hot" It only takes a few seconds to get a burn at 135°

Most single handle tub shower faucets have a temperature function now a days.

Piping looks fine for maximum input from boiler to tank.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

the bigger problem is that the temp can vary a lot depending on what state of stagnation the tank is in and how hot the boiler water reheating it is. even a health adult can't necessarily get out of that fast enough.

0 -

So many variables just looking at it.

0 -

The piping work looks well done, but they should be insulated, the expansion tank should be fully supported and - maybe it's out of the picture - there should be an accessible shutoff valve on the cold supply to the indirect.

Cute the way the low voltage wires are festooned, but they should be strapped to the insulated piping.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab1 -

also way more resistance since they are 3x as long as they need to be

0 -

-

Putting black pipe in the water MU line even after the feeder is just stupid if you ask me. When the feeder stops you have cold water with oxygen in it sitting in black pipe. Once it is tied into the heating system where it mixes with the boiler water then BP is fine.

0 -

Jumping into this conversation rather late. But, you stated there are three wires to the aquastat on the indirect. This aquastat requires four wires, 2 going directly to the transformer, 2 which function as an on and off switch to control the incoming boiler water. I did have the short cycling that you described on one of the indirects that I have installed. I called Weil McClain and I was told that these aquastats absolutely had to be installed on their own individual transformer. That transformer could not be used for anything else.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements