Copper boiler piping in a pool room

Current set up:

Hydronic boiler unknown btu. Gravity vented. Old

Heats a water-water heat exchanger. (Boiler loop-pool water loop)

Probably a 100ft run from boiler room to the pool room. Plumbing is 2 inch copper the whole way until the last 30 ft. Where it switches to PVC.

This morning maintenance back washed the pool and didn't turn off the boiler. Turned the pvc into spaghetti. Though im not sold this wouldn't have happened anyways.

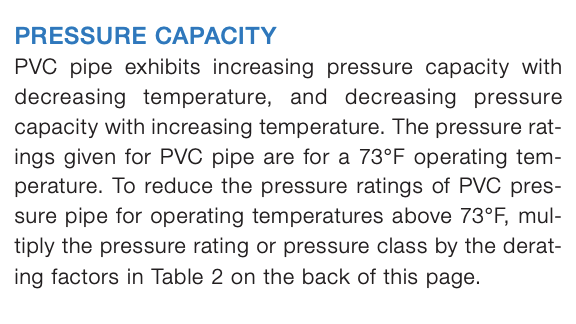

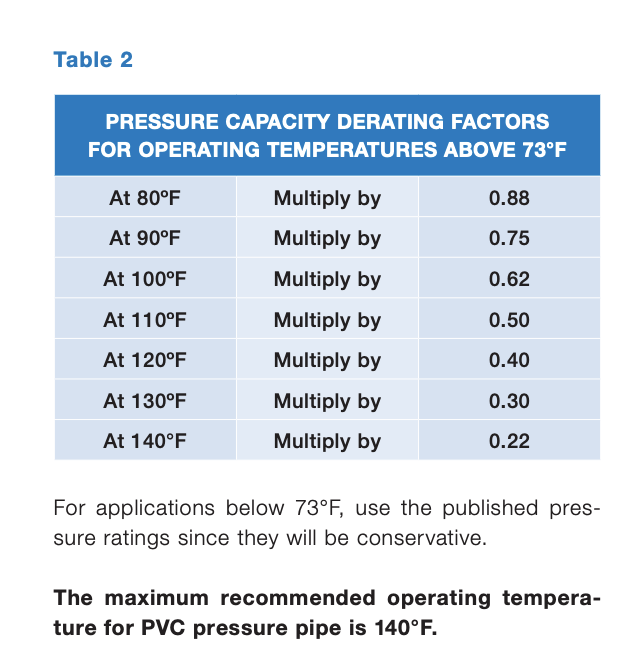

The hot water supply to the pool easily gets around 100 degrees. Maybe 110. PVC shows a rating of no more than 73 degrees so no wonder.

So im going to replumb that pvc in copper tomorrow and go to pvc at the pool plumbing. Likely pvc also but could be cpvc IPS I forget now.

Any issues you can think of besides its definitely going to turn green? Any experience seeing copper fail quickly in a pool room?

Comments

-

Schedule 40 PVC is rated for 140 degrees so I don't know what pvc your using that says 73 degrees. You can't heat a pool with a 73 degree supply temp. it would take forever to heat up if it even heats up.

Why would backwashing the pool turn the PVC into spaghetti? The boiler is on its own boiler side loop and should have its own aquastat to set the temperature of the boiler side loop. the pool side loop of the heat exchanger should have its own set point control.

i would avoid using copper on the pool side of the HX. if the chemicals fall out of balance not only will you degrade the copper but anybody with blonde hair will have green hair. all my hotels customers check there ph balance 3 times a day.

i learned the hard way at my own pool when I removed my flat plate SS heat exchanger (too restrictive, lack of flow) for a copper heat exchanger and let the balance of my pool water get out of whack. my kids and I are all blondes , not too mention my ex-wife, and Green hair turn into the color of the day lol.

0 -

I'm not sure if this is Celsius or Fahrenheit

0 -

Mattmia its farenhieht

I got 73 degrees from the print on the pipe. Most of this run is copper already.

The way the piping is laid out, the supply feeds into pool plumbing right before it heads to the pool. The return is about 6 inches upstream during normal flow but if reversed it could easily go from supply to return very quickly. The return is much more melted than the supply.

I dont think I mentioned this but the aquastat I found was also wired close on rise. So when it got hit it just never shut off. Have already corrected the controls. Not sure why the boiler never shut down but it was set to 185 anyways so there's lots to go over before I start it back up.

While I have you....ive wired controls to go

24v source>flow sw>boiler aquastat,hi limit, ICM>Pool aquastat>wrote terminal on ICM. Do you agree this is how you would want the order of operation? Also setting the boiler to 150 and safety to 200.

Pool stat the customer wants at 85.

Would value your thoughts. Thanks for the response

0 -

73 is commonly seen on PVC. There is a pressure temperature correlation

. Sounds like a temperature control or high limit failed causing the excessive temperature? If temperature at the boiler was set to 150°?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Copper won't last long in a pool room.

0 -

I think the key to keeping copper happy is controlling the chemical outgassing in the boiler room.

Many pool boilers are actually copper tube and they last a long time, if the pool water chemistry is kept in line..

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thank you for this

0 -

This is in the pool room. Separate from the boiler room. I know the copper will be green before long. I passed along if he keeps the chemistry im check it'll extend the lifespan. We shall see

0 -

pex

0 -

Resolved:

The backwash had nothing to do with it. Controls were a mess. I tidied it up and put a boiler kill switch in the pool room. Straitened out the pool temp controller, brought that boiler loop down from 180 to 150. Limit to 200. And pool temp at 80.

Replumbed in copper and tested all the stats and safeties. Running good.

Thanks all

1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements