Need help balancing steam system

Introduction

I am a new home owner (~1800 sqft 4 bed/1.5 bath 1936 home w/ a fair amount of draftiness from the basement) in the Detroit MI area and I need help balancing my system. The info below is to the best of my knowledge (a lot of the piping is in the walls and/or covered with asbestos insulation). I have listed my questions below in the final section. If further questions arise, I will edit the original post and increment the question number so it is easier to track.

Please let me know if further info, pictures, or clarification is needed. Please feel free to answer some or all questions. There is no obligation to answer all the questions.

Boiler

Utica PEG112EID @ (1/2 cut-in + 1 diff = 1 1/2 psig)

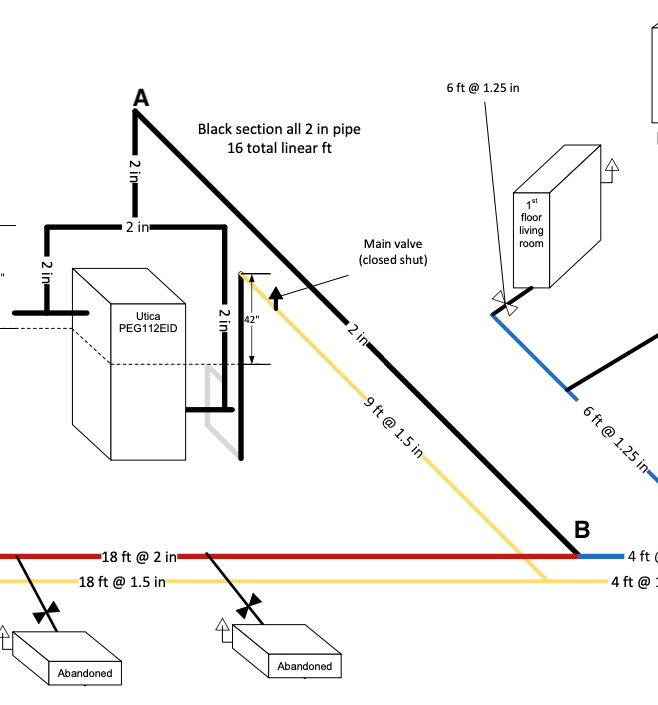

System Diagram

Calculations

Radiators

Room | Leg | Room size (sqft) | Radiator (all thin tube) Columns x Sections x height | Radiator E.D.R. (sqft) | Riser air (cu ft) | Radiator air (cu ft) | Total air (cu ft) |

|---|---|---|---|---|---|---|---|

1st floor entry | Blue | 3'x'3 (9) | 3 x 3 x 39" | 10.5 | 6*0.01=0.06 | 10.5*0.013=0.1365 | 0.1965 |

1st floor Living Room | Blue | 13'x16' (208) | 5 x 16 x 25" | 56 | 6*0.01=0.06 | 56*0.013=0.728 | 0.788 |

2nd bed | Blue | 13 x 14 (158) | 5 x 6 x 37" | 30 | 15*0.01=0.15 | 30*0.013=0.39 | 0.54 |

Dining Room |

| 11'3" x 13'8" (154) | None | 0 |

|

|

|

Kitchen |

| ~20' x 13' (~250) | None | 0 |

|

|

|

1st floor bath | Red | ~8' x 6' (~36) | 3 x 4 x 37" | 14 | 12*0.01=0.12 | 14*0.013=0.182 | 0.302 |

1st floor den | Red | 11'x11'(121) | 5 x 11 x 20" | 30 | 10*0.014=0.14 | 30*0.013=0.39 | 0.56 |

2nd floor bed | Red | 11'6" x 17'6" (201) | 5 x 13 x 21" | 35 | 25*0.01=0.25 | 35*0.013=0.455 | 0.705 |

2nd floor den | Red | 9'x'12 (108) | 5 x 9 x 26" | 31 | 25*0.01=0.25 | 31*0.013=0.403 | 0.653 |

2nd floor bath | Red | 8 'x 7' (56) | 3 x 6 x 30" | 18 | 25*0.01=0.25 | 18*0.013=0.234 | 0.484 |

Totals |

|

|

| 224.5 |

|

| Blue: 0.1965+.788+.54=1.5245

Red: .302+.56+.705+.653+.484=2.704 |

Mains and Dry Return

- Black : 16 ft @ 2 in = 0.368 cu ft

- Red : 18 ft @ 2 in + 4 ft @ 1.5 in + 2 ft @ 1.25 in = 0.49 cu ft

- Blue: 4 ft @ 1.5 in + 12 ft @ 1.25 in = 0.176 cu ft

- Yellow (Dry Return) = 31 ft @ 1.5 in = 0.434 cu ft

- TOTAL: 1.468 cu ft

Load

- Total radiator EDR = 224.5 sqft

- Total load for existing radiators = 224.5 * 240 = 53,880 btuh

- Total load for existing radiators * 1.5 pick up factor (per Holohan) = 80,820 btuh

Questions

- Is a single Gorton # 2 acceptable to replace the broken and improperly installed main vent at the end of my dry return?

- Is it acceptable to remove and cap the purple section? A knucklehead thought a random run of pipe in a laundry room with a small Maid O Mist at the end would be an acceptable 'main' vent. This pipe run is back pitched and does basically nothing.

- Have I calculated my total load correctly and is my boiler over-sized or within an acceptable range?

- Basically all of my radiator air valves hiss or wheeze/pant and need replacing (2nd floor bath is the worst offender as I assume it's trying to vent a crazy amount of air). Is it acceptable to reference the radiator venting charts and apply the following rule of thumb?

- Small radiator = Gorton # 4

- Medium radiator = Gorton # 5/6

- Large radiator = Gorton # C/D

Thank you!

Comments

-

Question 1. Yes, that will help a good deal — but… you have a built-in problem. Someone gave you two "dry returns" (they aren't really, but we'll let that go…) from different steam mains (the red main and the blue main) which join before they reach the boiler and the vent. This may make it almost impossible to get even heating, as steam from the blue main — which is much shorter — will happily whip around into its part of the "dry return" and close it long before the steam from the red main gets there — and having steam at that location will trap air in the red main. Don't feel bad — this is a classic error. There are several ways to attack the problem, but it will depend on how the pipes run in the basement. I'd need to know which way the pipes pitch to get further…

Question 2. Um… probably, This is actually related to the piping problem noted in the answer to question 1. If you notice that the radiators off the red main heat slowly or otherwise poorly, you might try putting a big vent — another big Gorton — at ;that location and see if it helps. Otherwise, that vent isn't doing much for you and it could be eliminated.

3. Your boiler is slightly oversized — 292 square feet rating vs. 225 square feet of load — but isn't outrageous. The smaller boiler might have been a bit small. Not to worry about.

4. If the pressure settings you quote are what's really there, it may be that the pigtail connecting the pressuretrol to the boiler is clogged. What you are describing very much suggests that the pressure is a bit high Your contemplated sizes are a reasonable start, but with any one pipe steam system balancing is a matter of try it and see. It may be very hard to get good results with the "dry return" piping as it is.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

There are a few things not to like here. You should discuss and address them one at a time and see how far you have to go to be satisfied with the system's performance.

A #2 Gorton vent should be sufficient for the system. I do not like that the two dry returns connect to each other above the water line. This can permit steam to back-feed to the longer return, interfering with condensate handling. Ideally, the two returns should return to the boiler separately, each with a main vent and tie together below the water line, or one can be replaced with a wet return.

Remove the purple main or most of it and use the stump of the pipe to add another main vent.

A quick look shows the boiler sufficiently sized for the radiation.

If you have trouble heating the 2nd floor bath radiator, consider either venting the end of that radiator riser or adding a second vent to that radiator.

Main venting can be improved with a vent at the "abandoned run of blue main" and at the stub of the "purple main" after removing the extra unused piping.

Splitting the end of the black main with a tee isn't best practice. The two separate mains would be better served if piped separately from the boiler header or if separated with a different piping arrangement.

By venting the mains quickly, you should get steam at all the radiators within a couple of minutes. Then you can size radiator vents based on the size of the radiator and the lengths of their runouts.

Congratulations on your new home.

1 -

@Jamie Hall please see the updated original post with reference pictures

- What points in the basement do you need pitch information?

- I might have a few inches of room to add a vent at the red/purple junction but I fear that I can only raise it up perhaps an inch before I hit the floor boards. I'd rather cap at the tee and try and vent the h*ll out of the 2nd floor bathroom radiator.

- Thanks

- The pressuretrol is almost certainly clogged. My plan is to do a full flush and maintenance routine at the end of the season. I fear if I unclog the pressuretrol it won't even run for more than 10 mins.

Thanks!

0 -

-

@Long Beach Ed please see the updated original post with reference pictures

- I don't have much inclination to repipe so I'm hoping either 1 x Gorton # 2 or 2 x Gorton # 1's on a tee for redundancy / eliminate single point failure can get me through the next few seasons. Unfortunately the abandoned run on the blue leg is capped and inaccessible. It used to service the dining room, but the dining room radiator was removed.

- I might have a few inches of room to add a vent at the red/purple junction but I fear that I can only raise it up perhaps an inch before I hit the floor boards. I'd rather cap at the tee and try and vent the h*ll out of the 2nd floor bathroom radiator.

- Thanks

- There isn't room to move the 2nd floor bath radiator riser to add a tee and a vent unfortunately.

Thanks!

0 -

On the pressuretrol and the pigtail. You don't have to drain the boiler to check that. If you can get the pressuretrol off the pigtail you can blow through it…

The reason I asked about pitch information is trying to get some idea as to how the condensate gets back to the boiler. As we have implied, it's going to be really tough to get the system working properly so long as the two "dry returns" join together before they drop to the boiler return, and what I'm hoping is that it might be possible to run a new return from where they join independently to the boiler, vent both the new return and the old one, and then drop them. How well that will work depends on how the condensate flows.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

@Jamie Hall thanks for the response.

I'll try and clean the pig tail out in the next few days.

My best guess is that the black mains pitches slightly up leaving the boiler until it hits the black/red/blue tee junction, which it then drops down (see the picture in my reference section of my original post that I have updated). From the black/red/blue tee junction the blue and red legs pitch away from the boiler and the yellow 'dry' return pitches back towards the boiler. A classic wet/dry return :facepalm:

I think B is slightly higher than A. I can get my laser level or bubble level to confirm if needed.

EDIT: The pitch from A to B is completely level

0 -

Figures. That is a fairly common way to arrange the mains and returns, and works just fine — provided the returns don't join before they drop independently to the boiler. Any chance of adding a new return beside the old one from that junction to the boiler drop and deleting the junction?

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

Excellent mapping!

The common return is a problem since the steam could shut the vent at its end before the red main and its return leg are filled. Not saying it can't work but will be very hard to predict. Ideally you would split those returns dedicating one to one main and the other to the other main and joining them back at the boiler below the water line. Then balancing could be more easily predicted on radiator size and takeoff lengths. Alternatively the main vents could be back at the boiler at the end of each return before they drop below the water line and join. Starting point that I would use would be similar to the this. 2 Gorton #1's on the red main and 1 Gorton #1 on the blue should be quite sufficient.

Otherwise you could just put a #2 where the vent is today with no other changes but then I would suggest MoM vents with a bunch of extra orifices and lots of trial and error.

1 -

@Jamie Hall The returns join before it drops to the boiler. The return for the red leg comes back at an elbow and heads straight to the boiler, picking up the blue leg at a tee. I took a bit of liberty in the simplification in my diagram. You can see a picture in the reference section of my original post. Please let me know if that picture is insufficient.

Honestly, it's all copper piping for the returns in my boiler room until it switching back to black pipe for the near piping, so I assume it wouldn't be difficult. If it will really help the system I would consider it. I just need to know the costs I suppose, I'm 8 months into this money pit house so I have to weight this out.

0 -

@dabrakeman thank you for the information.

The picture in the reference section of my original post shows the boiler room where my 2 returns meet and return to the boiler. It's 1.5 in copper.

I could try and place maybe 1 Gorton # 1 at the purple/red junction. It's very tight clearance wise. I'd have to angle out from the tee to avoid the joist and from there I have maybe 4-6 inches before I hit the floor boards.

Knowing this, what would you choose?

- Cap purple/red junction and repipe boiler area for dedicated returns and mains

- Keep the dual return and place mains at the purple/red junction and find a spot on along the blue main to vent?

Thanks!

0 -

It's that dual return that's the problem — as several of us have mentioned. I don't think it would be all that hard to cut out the T where the return from the red side and the blue side joing, then run them both separately to the boiler, put a nice big main vent on each one, then drop them separately again to the floor level and join them there and go to the boiler from there.

Splitting the steam mains at the boiler is ideal — but not necessary in the this situation. Splitting the returns is.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England4 -

@Jamie Hall thank you for the response.

It sounds like splitting and repiping the return is the way to go. I will clear the pig tail ASAP. After that, should I wait until the return is repiped to try and address the radiator vents? For the most part the heating is fine except for the 2nd floor bath because that air vent is probably old and clogged while also trying to be the main vent for the red main.

0 -

Just so. Changing that return will make quite a difference in the balance — so get that done and run it for a bit, then see what happens.

I'm sure that bath radiator will need a new vent…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

Venting back at the boiler on each return will be fine. Just marginally better at the ends of the mains but inability to find a suitable location often is the driver for putting them back at the boiler. Would still do one Gorton #1 on blue and two Gorton #1's on red. These are both more than sufficient but you do have more than double the main and main extension volume to vent on the red.

I guess if you don't have any banging then no problem but normally no pitch in a 16' length of main is asking for a sag somewhere. You should have at least 3/4" of pitch over that length down from the boiler to the T. Maybe just hard to measure.

0 -

-

Optimist. That probably works well enough in houses and buildings less than a few decades old, but… in older houses. there's no substitute for a level — or, better yet, one of those wonderful rotating laser level gadgets.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

- Before i sink a bunch of money into adding an independent dry return, I'm going to attempt to repipe the dry return main vent with a #2, and add a secondary #1 vent to help the longer red leg vent. Space is very tight above the red/purple junction. I have my new vents, pipes, and fittings. There are a few remaining issues.

- The tee at the main vent (pic 1) and the tee/bushing (pic 2) in the laundry room are very rusty. After I remove the old broken main vent, how do I address the rust so my new piping is solid?

- I have pipe tape but no dope. Should I err on the side of caution and fit everything with tape + dope?

- I plan to cut the galvanized pipe in the laundry room and add my vent as mocked up in pic 2. The elbow on the purple leg is back pitched and the vent at the end is shut closed and extremely hard to reach. Air and condensate are always trapped there and I get massive water hammer. Any concern with this approach?

@Jamie Hall @Long Beach Ed @dabrakeman

Pic1: Main Vent

Pic 2: Secondary vent on red leg at purple/red junction

Pic 3: Purple length full angle

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements