Air in boiler feed water

Comments

-

I don’t think you can get to the actual needle valve in that sep, that is where the air/ water stops?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

why don't you post pics of the install so we can see what it looks like and find the areas that are not correct.

0 -

@pedmec thanks! I already did this in my other post and we had a lively discussion about it. So this time, let me make some of the changes that have been recommended here and I'll post some new photos.

Now I procured the 20 gallon expansion tank, and it looks like it might be overkill. Easily the size of an elementary school child, I felt confident driving in the HOV lane with it in the passenger seat. I think I do have a spot for it in my small boiler room. I checked the air eliminator, and it was not a spirovent! Although we had specified a spiro, it appears the installer chose to use a honeywell supervent instead. I think I will rebuild the supervent, but I haven't been able to find the core for sale, I suppose I'll have to contact honeywell, or just buy a supervent. They do sell the float unit. However, since the core is accessed from the bottom of the supervent, I'll have to attach some unions or something to make it accessible for cleaning if I install the makeup water supply and floor mounted expansion tank into there. Yes the 20 gallon tank seems a bit excessive, but we are installing steel column radiators, and generally the goal was to oversize the units so we could run the boiler temp lower. Nevertheless, we have been unable to gauge how much water is in the system, and this will help eliminate pressure variation as as the source of our issues keeping the top floor convectors from becoming airlocked.

0 -

Update: Ok so the supervent rebuild kit arrived yesterday. It took a few days to get one, in the mean time I placed a caleffi minical in the top port on my dirtmag on the return side of the primary loop. Newer models don't have this port I believe. It seemed to help a little with the frequency of the boiler shutting down. Yesterday I installed the rebuild kit on the supervent air separator, feeling this could really be the ticket. The kit includes only the float and valve, and does not include the core, which is accessed through the bottom. I did not open the bottom yet, since I plan to install the makeup water and expansion tank there in the future, and the core could not be replaced. At one point I was able to hear the rebuilt supervent releasing a little air, but only once, it was the air that was admitted when I drained that small section to rebuild the vent. I could not find anything obviously wrong with the old component. The float was in good condition, and there was no buildup of muck inside. But as hotrod said, the valve mechanism may have been damaged.

My excitement was somewhat tempered when after a little while I got the glug glug glug, boiler temp spike, e001. One time, before the rebuild, I had the boiler shut down have glugging. Now annoyingly, the boiler seems to kill power to the primary pump when this happens, so it can be tough to get the air out. Some options are using the flush ports, or running the boiler briefly with the gas valve shutoff. One time, I really struggled to get the air out, but after a few minutes of trying things, starting and stopping the pump, purging, etc, the autovent on the top of the boiler hissed for a good 60 seconds or so. That is a lot of air. I'm still confused as to how that much air could be getting in. I have not drained down the system recently and am trying to avoid that another month or so until the weather warms up and mitigates the freeze risk. A leak that big we'd surely see the water somewhere. And keeping the pressure over 20, we really shouldn't be pulling in air. I have not drained down the system recently and am trying to avoid that another month or so until the weather warms up and mitigates the freeze risk. Perhaps I just need to run the system a couple days after the supervent repair vent to clear it out?

0 -

Is there not a way to do some backwards math to find the volume of your radiators by using the sizing charts available in "Every Darn Radiator" After all that's how they originally determined the steam capacity. I think.

Miss Hall's School service mechanic, greenhouse manager, teacher, dog walker and designated driver

0 -

Ok let's take a shot. I have 5 steel column radiators in at the moment. They are on average about 4000 btu at delta T60, so lets round up to 5000. That's about 25kbtu of column rads. We also have four cheaper baseboard convectors, maybe around 15 feet tops, so lets call that 10kbtu a piece. Now let's use this chart on page 41 which I found referenced on this forum:

So we've got maybe 3 gallons per column radiator assuming the largest number from the chart, and then maybe .4 gallons for the non-ferrous baseboards. So 3 gallons/radiator * 5 radiators + .4 gallons per baseboard * 4 baseboards = 15 gallons + 1.6 gallons = 16.6 gallons. Now there's also the piping and components, so lets add what another 10 gallons maybe? 26.6 gallons. Now to the wessel calculator mentioned by hotrod(see below). We see that such a system recommends a tank around 5.8 gallons. With a #30 and a #60 tank, I should be roughly okay with about 6.7 gallons. This is assuming we can only tolerate a 5 psi increase in pressure, so we might have a little room. However if I add more column radiators, it sounds like I'll need a bigger tank. The 20 gallon monster is here just waiting to be installed. But for now, why can't I seem to get the air out?

0 -

No harm is having an over-sized expansion tank. Assuming it is properly adjusted form the intended fill pressure, 20 psi in your case.

Has the pressure relief valve ever discharged? If not you have not hit 30 psi or more.

I wonder if air trapped in all the column rads keeps making it's way back to the boiler and bubbling at the top of the boiler HX.

If you have any ups and downs in the piping it can be a bugger to purge without a high volume purge pump. With large diameter piping, a 1/2" fill valve may not allow enough flow to get an adequate purge.

Most hydronic guys, and gals have at least a 1/2 hp pump for power purging systems. GEO loopers and people that work on large piping systems sometimes build a tank with a 1 or 1-1/2 hp pool pump to blast 20- 30 gpm through large pipes.

Simple homebuilt rigs have a pump on a piece of plywood across the top of a large, heavy duty plastic garbage can.

I built this 24 gpm cart with parts from online, a Grundfos CM-5 120V pump, 1" hoses.

It just feels like you are not getting an adequate purge through all the piping and radiators.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Yeah that makes sense. The radiators do have bleeders, some auto, some manual. I'm not getting a lot of air in at the bleed valve. By the way, I see you're a trainer for caleffi. I'm trying to get some 504401 AERCALS for my radiators, which are sold for the US market by hudson reed. Is there any way I can get them direct, since it doesn't seem they stock them here?

That rig for purging is cool, but it's way over budget for me. Would connecting a hose to a valve closer to my water service line do the trick? My heating system is mostly inch and a quarter. But also keep in mind that I did not have this boiler air issue until relatively recently. The system has been in use about 8 years.

Regarding the tank, yes I did have an issue that I posted about in my other thread a few years back. I was finding my top floor baseboards were often becoming airlocked. If I increased my pressure, I'd get discharge at the relief valve. The installer had only one amtrol #30. I added the #60, and it seemed to improve things, and I added the minicals to the baseboards on the top floor only, and then I didn't have to bleed the radiators all the time. In ret rospect, it's possible the pressure was high enough, but air from somewhere else was migrating up into the top floor radiators. I don't know. It's not like I didn't try to get all the air out, it just never seemed to work without the auto bleeders. With my current setup, the top floor baseboard does not become airlocked, and the relief valve does not open. I do suspect a large expansion tank could help, particularly since I would like to install additional radiators and may want to replace some of the baseboards.

0 -

I have had folk tell me they use online UK sites to order Caleffi Euro products. Altecnic, www.altecnic.co.uk is the official Caleffi rep in the UK, they have a where to buy section.

The 504 is a straight thread with the hemp knurling. I have one and it does go into a NPT, but you would want hemp or Loctite 88 thread to install it. As you see in the pic the threads go all the way into the FIP NPT.

It is a nice radiator air vent fitting, it creates a large chamber up high for air to find. I brought a sample in to try.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Ok so I've had the rebuilt supervent in there over the weekend, so about 3 days, and also the minical on the old dirtmag. I still had about 4 e001s, about 1 per day, but it was less frequent than it used to happen, and just resetting the boiler got it going again, I didn't have to do any purging routines. However I also note that with the warmer weather, the boiler runtime for spaceheating was probably less. Another observation I made is that the problem often happens when the system switches the zone, such as when the DHW indirect tank calls for heat on priority, or when it finishes heating the indirect and switches back on the space heat circulator. The system has only one primary pump, there is a way to pipe it so that a second primary pump feeds the indirect loop, but the installer did not want to do it this way, probably because it would have required customizing the primary loop manifold. I do still hear some air in the pipes with the space heating zone is on.

When the system shuts down for e001, the primary pump shuts off, but I believe the circulator keep running. That's because the boiler controls the primary pump, but a taco zone controller controls the zone circulators. Is there any hope the supervent just needs more time to work?

0 -

A day at the most to get all the air out, assuming all the radiators and indirect have had flow through the separator?

In some cases adding another sep to the indirect circuit can speed up the air removal.

It really should not be this difficult to get a 100% air free system with the parts you have.

Maybe some pics may show something we are missing?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Guess what! I've been running 3 days now, no E001! I can still here air in the pipes, but it's not as bad. Have not drained down the domestic side recently. Boiler runtime has been reduced a bit by the warmer weather, but it's still been running a decent amount, particularly at night. I think hotrod may be right that there is air at high points. It can't be a fully airlocked section, because all my radiators are warm. Need to consider whether to use a purge pump. I'll keep tinkering and come back when I find something. Thanks!

0 -

Hi folks! I'm back, and as suggested I'm attaching photos. Now the weather got a little colder, and I got some E001 boiler high limit temp errors again. Well this time it wouldn't start up. I tried to purge the boiler, but it didn't seem to work. As soon as flame came on, I'd here kettling in the boiler after a few seconds. If I drained the system through a flush port, the kettling stopped, but resumed when I closed the flush port screw. I concluded that the main pump must not be running, and it did not feel like it was running I attempted to bleed the pump, a grundfos ups26-99. There was some spitting coming from the bleed screw when I opened it that did not stop. I went away for a few minutes and got my multimeter. I cut the power and connected my alligator clips to the pump and multimeter. Upon starting the system, I saw the voltage go to 120 on the meter. I shut the power down and closed the pump box. Then I restarted the system, and sure enough the pump ran, the kettling did not occur, and the heat and hot water were restored. I had rebuilt the pump with a new cartridge, around 3 months ago while troubleshooting, but noted no problems with the old cartridge. So I'm confused what could be happening here, I'm thinking maybe one of the following but could it be something else?

- Pump becoming airbound

- Pump becoming stuck and triggering thermal overload protection

- Pump defective and intermittently failing

- Navien control board defective and cutting power to pump intermittently

Thank you very much, all thoughts appreciated, this one is frustrating. I apologize for the photos, it is difficult to get good pictures in such a small space.

0 -

When you remove that large screw slot bolt from the pump, you will see if the pump is spinning, or not. If it steams out, the pump has either been air locked, or jammed up.

follow the wiring to see where the 120v is coming from.

It takes a lot of scale to lock up those medium size circs. There should be not be a lot of scale formation in a closed loop system. Unless you are constantly adding fresh water.

Some boilers have low pressure lock out switches, check that also when the power is not at the pump

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Ok, with the heating season starting up again I finally got around to plumbing in my amtrol 118-78 20 gallon expansion tank. This is a big tank. Over the summer with just the indirect zone running, i still got the occasional e301. While the system was open I charged all three tanks to 25psi. The existing tanks were at about 20psi. I purged the system and fired it up. Starting at about 23.5psi cold on the boiler readout, it goes to 28.5 immediately upon the primary loop pump spinning up. When the water reaches 180 it reads about 29.5. If I turndown the primary loop pump to medium speed, the pressure drops about 1psi. I still remain unsure if the error is caused by air entering the system, or steam forming in the heat exhanger. Water boils at around 240 degrees at 25psi. But I'm not sure why this would happen.

0 -

I think you still have an air bubble in the boiler working its way to the pump causing an air lock

Is there a relief valve on top of the boiler ? I have used that to burp air out

Why such a high fill pressure, 23 psi? What is the highest point in the system, above the expansion tank

Lets say two stories , 20’ x .433 = 8.6 psi Add 5 psi for positive pressure at top, call it 14 psi fill. The tank charges to the same pressure as the fill pressure

The more pressure , precharge you put into a diaphragm expansion tank , the smaller the acceptance capacity. Run 12-15 if you can.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Hi Hotrod, thanks for chiming in. Recall that this is a 4 story building with boiler in the cellar, so it may be as much as 40 feet from the boiler to the top floor radiators. 40' x .433 + 5 = 22.3. There is a minical valve at the top of the boiler, the relief valve is below the boiler in the primarily loop manifold. Since my main conern is the boiler pressure exceeding 30 and triggering the relief valve, I thought 25psi was a good choice. There seems to be an improvement with the new giant 20g expansion tank, but 29.5 in the system is still running very close the 30psi max for the boiler specs.

I think one problematic issue is that regardless of water temp, the primary loop pump increases pressure at the boiler by 5-7psi. Under the best conditions, that means we're running very close to 30 psi hot. Can I do anything to reduce this increase? Would connecting the primarily loop to the expansion tank leg reduce this pressure bump? Can I reduce the speed on the primary loop pump to the middle position? Is there a way to calculate how powerful that pump should be? The system has a space heating zone, and an indirect hot water heater zone. Since the indirect is on priority, both zones cannot run simultaneously. It's not immediately obvious to me why the primary pump is so much larger than the circulator pumps. Perhaps it is oversized?

0 -

Okay folks, I think we have a breakthrough. I did bleed the top of the boiler as hotrod recommended, and all that got me unfortunately was very wet. I think with the new expansion tank, the pressure is pretty stable, the system is nice and quiet, and if I get the PRV set just right, it should keep the boiler under 30 even when pump kicks in but we'll see. However I know longer think this is the root problem. I think the boiler is cutting power to the primary loop pump at certain times without any reason that's obvious to me. My thinking is to replace the control board in the boiler which is where the pump receives power. But I'm curious if there are any other theories, like could there be another fault causing the boiler to cut power to the pump?

I set up my camera in front of the boiler and waited for the E001, and we get it on video. Tea kettle noise, bang bang glub glub, relief valve discharges, E001. So I run the video in slow motion. Pressure is stable at 29.5, temperature is hitting 155. Suddenly pressure drops to 28, then the banging, then the pressure is reading 24 or so and the temperature is rising before the E.001 displays(after that it doesn't display temp and pressure). Why is the pressure dropping? I think the primary loop pump stops running. So my thinking is, the pump suddenly stops, and the water boilers in the heat exchanger until the boiler detects the over temp. Steam then bangs through the boiler.

So the pump was recently rebuilt and I inspected it again finding no flaws, it spins nicely, clean inside, I removed the check valve when I rebuilt it. Still something could be off, but it's an expensive pump. I pigtailed the pump's power cable to a keyless socket and put in an LED lightbulb. Sure enough, when the boiler bangs out, it seems the first thing to happen is the lightbulb turns off. So it seems the boiler is turning off the power to the primary loop pump, perhaps because it hates me so much it just wants to die. I don't know. Do you guys think replacing that board might finally fix it? Or am I missing something else that's wrong with my setup?

Thanks!

DIY

0 -

there are some boilers listed to 45 or 60 psi

Look for the aluminum certification tag fastened to the boiler, it should indicate maximum pressure.

The expansion tables in the Amtrol design manual allow you to calculate pressure increase but you would need an accurate volume

The gauge, if accurate should be a good indicator

Generally a relief valve starts seeping at its relief pressure not full discharge

I would think the boiler pump runs whenever is fired?

There are way to pipe a system for continuous flow so you always pull all the boiler heat out of the exchanger

A bulb wired to the pump would be an easy visual

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks Hotrod, yes the pump should run, it's piped for primary secondary, I think it's a malfunction that the boiler is shutting off the pump while firing. The bulb would appear to confirm this.

If I do replace the boiler I think I will use a 50psi boiler, however I think I've seen on this forum that I need to use an ASME rated expansion tank if I'm running over 30psi? Those are pretty expensive. Not sure if that's true…

0 -

I think the ASME tank requirement would be an inspectors call, or miss.

I've seen some boilers are rated at 45 psi.

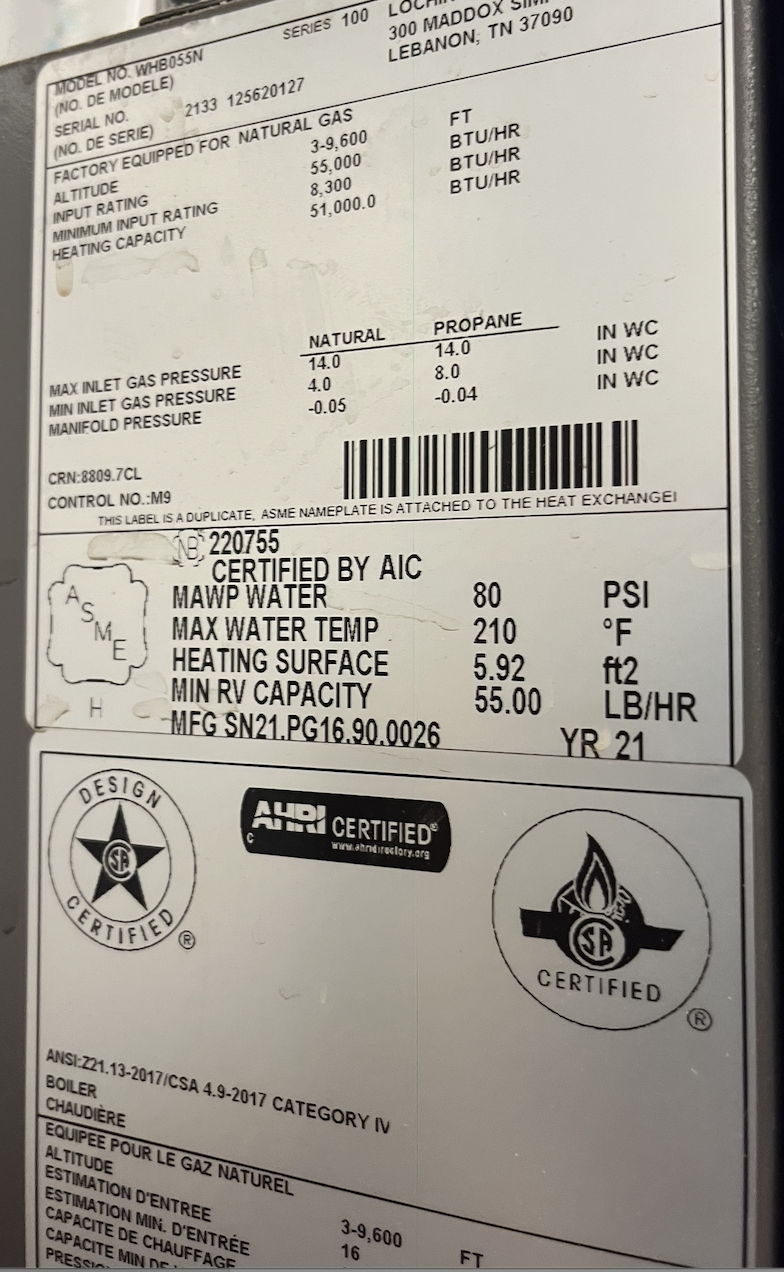

My small Lochinvar Knight 55,000 shows 80 psi max on the ASME tag!

On tall buildings the boilers sometimes get located up top,

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements