Calling Peerless 63-series Owners: A Venting Mystery

Comments

-

This is really making me question whether I want to get a Peerless to replace my old Peerless. I was thinking of getting either a 63-04 or 63-04L and either upfiring or downfiring if I needed to, but if this is how they treat their customers, they can pound salt.

Just another DIYer | King of Prussia, PA

1983(?) Peerless G-561-W-S | 3" drop header, CG400-1090, VXT-240 -

They have a strict "only professionals" communication policy which obviously isn't great for the three of us, but it's their business to manage as they see fit. I can understand it even if I'm not a fan. Dwyer, for example, returns my emailed questions politely and competently and that is very nice.

Peerless → Sales Reps → Supply Houses & Installers → end users & home owners

Or something like that

It is very surprising to me that their parts fulfillment knows about the 63-X series but their sales reps don't. And it is also confusing to me how they can replace the whole 63 series with like 3 or 4 sizes that they currently show.

I'm sure it will become more clear in time.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Even at 5" wc you will compress some air and get some steam in especially the larger radiators even if you had no venting so you can't stop it form heating completely with venting.

For @ethicalpaul for an addition I would probably run hot water off of the water in the boiler rather than extend the steam for many reasons, the biggest being that you can zone it separately and the new construction will never heat the same as the original structure.

0 -

I appreciate that Matt, it would be a lot easier to run hot water lines

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

» Even at 5" wc you will compress some air and get some steam in especially the larger radiators even if you had no venting

I disagree.

I've blocked vents and I can feel the first 2-3 feet of riser get hot, but the steam never gets even close to the radiator. That's with most vents unblocked.

Now when I block ALL the vents and let the pressure go towards 1 psi, then the steam at least gets close to the downstairs radiators.2 -

yeah this is what I’ve noticed too.

And I don’t know if it’s from compression of the air allowing steam in, or just the steam rising up through the denser air and/or convection in the pipe

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

I owe y'all an update.

There will be no downfiring of my 63-03, because I cannot get the parts. They are not in stock anywhere, and Parts-To-Your-Door, which is part of Peerless, has deemed my approach unsafe.

First, I had to explain myself:

» what is the reason for replacing this and what caused it?Upon confessing that I wanted to downfire my boiler, I was sternly warned off the project:

» We heard back from our engineering department and the consensus is that the changes you are looking to do for this boiler is a safety hazard and will completely change the boiler itself. Doing so will not only void warranty but will remove all liability from Peerless Boilers.My argument that this change results in a unit that i already for sale cut no ice:

»The 63-03 and the 63-03L are two completely different units because of the ratings, etc. The unit you have is a 63-03, not the L.So I saved myself fifty bucks and some aggravation. Maybe when @ethicalpual UP-fires his 63-03, we'll swap parts. Just so long as we do it in the summer :)

Or maybe I'll fabricate a bracket; I do have the gas manifold.

I've watched Paul's videos where he argues that the manufacturer's minimum piping is just fine. I can't quarrel with his observations, but I will say that a four-burner 63-03 will significantly increase the roiling and throwing up of water in the boiler vs. his three-burner unit. When skimming, I made the mistake of leaving the burners on a tad too long… I turned them off when I saw the first twitch in the sight glass, but there was a lot of heat already in the iron and the water boiled for bit. The skim tap was already open, and I had quite the deluge shooting out of it — thank goodness I had a metal container to catch it, and was wearing gloves so I didn't get scalded. That tap is about four inches above the water line, indicating how violent it gets in there.

I think I'll stop posting here and return to my original DIY thread for the next steps, which involve water treeatment. I only opened this extra can of worms to attract fellow Peerless owners regarding the vent piping. I'm grateful for the responses I received.

cheers -matt

0 -

Weird, so converting to or from a 6x to a 6x-L is not supported? And maybe has never been supported? Wild.

Keep in mind the skim port is lower than the top of the boiler where the steam supplies are. My skim port will also spit water if I leave it open while boiling.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

If I got to do the experiment, we wouldn't have to do so much guessing. I haven't ruled out making my own bracket yet, I'm fighting with surging after adding 8way… that's for the other discussion.

There may be a legal issue that I can guess at without understanding it.. they did say "All data labels and serial numbers would have to be removed from the unit if these changes are made against PB Heat’s recommendations."Heck if all this federal belt-tightening leads to me working less (or zero 😎) i'll have all sorts of time for boiler games.

I DO have experience jury-rigging burner supports.. this piece of artwork got me through four months of last winter…

0 -

Peerless is strange. They make an awesome gas steam boiler, but they got some really strange stuff going on behind their desks. I am not saying whether or not you should rig something up. But if the only thing stopping you is warranty or liability, I would not be particularly concerned. Especially since it's your own boiler. Your boiler will almost certainly have to live with the warranty. And if it doesn't, don't expect them to honor the warranty anyway.

3 -

These warranties aren't worth very much anyway that I can tell.

"All data labels and serial numbers would have to be removed from the unit if these changes are made against PB Heat’s recommendations."

Who exactly do they think they are? Do they think they still own your boiler?

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el2 -

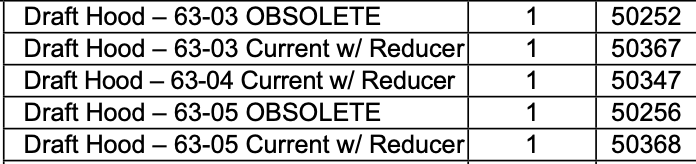

Hey @mattmich I was looking at some Peerless part lists and did you ever see that they apparently didn't used to use a vent reducer which may explain why mine doesn't seem to have one, but in current (well current as of some months ago before they discontinued the line) models, they have the reducer that apparently you misplaced:

Didn't they tell you that they had no knowledge of a reducer in their draft hood? It may be that by then they had already let go the engineers or other people who actually know about their now-defunct 63 line

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

I think the air would only decrease in volume to about 93.5% of it's original volume when pressurized by 1psi over atmospheric. Therefore, steam making it to a radiator with vents closed I might presume is more likely due to air leaks in the system or vents, perhaps more notable at 1 psi than at 5" WC.

0 -

Hi @dabrakeman I think the reply above got put onto a different thread than intended

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

Atmospheric pressure is about 15 psia so a 1 psi change would be about a 6% change in volume. The volume of the radiators vs the main may be such that reducing the volume by 6% may be enough to get in to the radiators. Usually when people start cranking up the pressure to try to fix venting issues it is more like 5 psig to 10 psig which would be a significant reduction in volume.

No idea what the original question was.

0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements