Wiring relay to cut heat call during DHW (combi boiler)

Comments

-

SR502 control makes more sense. The zone valve relay threw me for a loop.

Your new boiler has the ability to do what the SR502 is doing. You can eliminate it. the diagram I offered you will do a better job to shut down the Central Heat CH pumps and the relay without the time delay will stop the air handler from blowing cold air. The feature of the TAM7 water temperature sensor for the hydro coil will be beneficial because after each DHW use(especially the short ones) the sensor will start the fan faster than the time delay for the fan. That BAYWACC11SC1AA control works when either the time delay is timed out of the water temperature reaches 100°. Since the water will already be hot the temperature will bring the fan on sooner than the time delay. You can eliminate the SR502 and wire the pumps to zone 2 and zone 3 of the Navien and wire the end switch from the BAYWACC11SC1AA P4 to the appropriate zone thermostat location on the Navien

I would not worry about the short DHW demands as the system will be able to handle it just fine. The TAM7 with the Navien connected this way will be able to keep up with the CH needs. That is built into the design of the software of the Navien logic control.

If it does present a problem in the future, than we can get a 30 second delay timer that delays on start. The one you have is probably a delay on finish, to keep a fan operating after the call for heat (or cool) is finished to purge excess temperature after the furnace or compressor shuts down.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Sorta both… I want air handlers (both upstairs and downstairs) to terminate heat calls during DHW calls by the boiler. This is because the boiler will prioritize DHW and will not supply heating water, but the circs keep circ'ing and the fans keep fanning :D. The delay is to allow a small pause before the heat calls terminate, to avoid instant on-off every time someone runs DHW for only a couple of seconds, vs a long shower)

0 -

Exactly right.. it's delay on finish (or in this setup, always on until it's cut by DHW). I have searched long and far for one which does the OPPOSITE of this one, but no luck yet. I even wondered if somehow removing the board and jumping it backwards would somehow help, but the next guess was that a $10 time can do it fine. THANK YOU for the detail… I did have some idea that the modern Naviens could control this much, but was hoping to avoid a lot of rewiring (the ZC is very close to the circulators which are far enough away from the boiler to make it a pain.

Anyway… I finished my diagram before I read your reply… here is the setup in all its glory. I suspect the only way to really make it work as is, is to remove the timing board on the relay like you said, and get a cheap timer between it and the DHW call.

0 -

" Sorta both… I want air handlers (both upstairs and downstairs) to terminate heat calls during DHW calls by the boiler. "

The A/H contacts should do that. Actually you don't want the living space heating call terminated. With the ST82D it adds an off delay to the relay. The ST82D relay needs to open the air handler control circuits to both air handlers. Not interrupt the heating call to the boiler. So during a shower (long DHW call) the air handlers shut down but the call for heat still exists (if needed). That way when the DHW call ends the A/H re-closes energizing the living space heat air handlers, since the heat call never went away, or came back during the shower.

" The delay is to allow a small pause before the heat calls terminate, to avoid instant on-off every time someone runs DHW for only a couple of seconds, vs a long shower) "

You would have to monitor (use a multi-meter) the A/H contacts to see if when there is a brief DHW call the A/H contacts open and then re-close in less time than the ST82D delay duration provides. Assuming the living space call is still present or active.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

You can print several copies of this diagram and put it with your equipment.

The time delay relay you want to use is this one Packard PDT102 and must be connected from the transformer to the relay coil as shown (Red and White wires). You can connect the AH contacts from the Navien on the wire from the other side of the relay to the other side of the transformer (blue wires) then set the adjustable time delay to about 40 to 60 seconds. That is enough time to get the water to wash your hands without setting off the DHW Priority relay

Please don't throw any more curve balls at me. I'm a lousy hitter.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

I THINK in this application that breaking any control to the air handler kills everything downstream… since the boiler is the last in the chain it will just shut off and never turn back on again in this configuration. Like Ed pointed out above, this relay simply will not work to do what I want here. My bad for assuming that because I got it to work with the last boiler (probably more from dumb luck than anything) that it would also work w/ the newer boiler.

0 -

Hey as far as I'm concerned you guys are batting .1000! Sorry for all the confusion… I should have just mapped it out properly from the get-go, but was so hyperfocused on getting it to work "like it used to". Of course the answer was always right there… it never had a chance w/ this config and that relay. Sincere thanks for the work esp the diagrams which is above and beyond. I'm sure it will help many folks… let me know if you have a Patreon or something set up!

1 -

This will sound unbelievable (and not sure it counts as a curveball :D)… Got the time delay today, and IT works great. On the other hand, there is no way I can find to energize this relay so that it properly stays pulled in, when wired through the boiler. When wired directly (without switching through the boiler ie touch the two wires on AH together, it stays in fine. Even weirder, when I attach the wires to the boiler and test for voiltage at the terminals, it also reads 24-25v just fine, no fluctuations. So in short

- relay works fine when wired direct to 24v

- dry contacts appear to be working fine (opening and closing as expected)

- relay will NOT work fine when wired through the dry contacts

The last thing I will try is an alternate 24v power source (like from the zone controller). Maybe the boiler 24V power terminals are not stable when other things are switching on and off.

0 -

No… any 24v source switched through the Navien terminal blocks will cause the relay to pull in and then pull out after 2-3 seconds. They seem to be closing ok, but maybe voltage run through those terminals is not stable.

0 -

that does not count as a curve ball. LOL

the time delay must be connected to a 24 VAC source and a LOAD. In this case the LOAD is the 24 VAC relay coil. and that is connected to the #1 terminal on the Packard PTD102. the #3 terminal on the PDT102 must be connected to the R terminal on the transformer (R terminal will not be connected the the chassis ground) For some reason this works best. to complete the circuit you need to connect the C terminal of the transformer to the other side of the relay coil. This is where you can use the switch that activates the coil.

If i have the function of the Navien AH terminals incorrect, then they open on a call for DHW, then the diagram just needs to have the red wires on the relay changed from the #3 terminal to the #2 terminal and from the #6 to the #5 terminal

Here is the updated diagram. with that change. If this does not work, then we need a delay on stop time delay and you already have that one. I will just need to take some time to process the information. Do the AH contacts in the Navien open when there is a DHW demand or do they close when there is a DHW demand. we will need to do a little trial and error testing to find out. Try this change first.

Here I have Zoomed in on the change.

I will read the Navien manual on this set of AH contacts again to be more clear.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

Thank you x1000. So for clarity's sake… the new PDT 102 time delay arrived today and tested ok (delay function), but is not wired in yet while I was testing the relay functions.

I am using the same relay as before (the ST82, but with the time delay board removed). Which is good for the purposes of the below drawings as it's the same relay :)

The Navien A/H terminals close during a heat call but open in certain conditions, one of which is a DHW call.

The two below it (DHW PRI) ONLY close upon a DHW call and open all other times. I tested off the NC terminals which open when the relay is energized (breaking W)

THIS WORKS (RELAY STAYS PULLED IN):

THIS DOES NOT WORK (RELAY CYCLES IN AND OUT EVERY 2-3 SECONDS):

To be fair, I have only tried it breaking 24v hot, have not tried breaking ground, but I did fiddle w/ different combinations trying to make it work, and the showstopper seemed to be routing it through the Navien terminals (I also DID try A/H to see if it would work while it was closed…. same cycling)

I ordered a few different types of relays from Amazon to see if it will make any difference. Really a headscratcher as to how the Navien terminal relays are affecting this…too much current? Not enough? Causes voltage fluctuation? who knows!

Good luck with the Navien manual lol… I think it was written in Korean, translated to hieroglyphics, re-translated to Korean, then to morse code, then to English :D

1 -

" Got the time delay today " Did you replace the ST82D delay timer relay with a PDT102 ?

If I understand the original way it was connected to the original boiler. This method with the new boiler you are opening the thermostat wiring for the zones with the air handlers. If you are still doing it this way the A/H contacts would open since you are removing the call for heat to the boiler.

If I understand your system the thermostat calls for heat, this call goes to the air handler, the air handler then calls the boiler.

If your ST82D delay timer relay interrupts the call to the air handler, I would think the blower would stop.

If the water temperature to the air handler drops below 100 F the blower may stop. Boiler control of where the water goes.

If you just want to keep the air handlers blower to remain on during brief DHW calls, I'm thinking the ST82D delay timer relay would be triggered by the DHW contacts and the ST82D delay timer relay contacts would close the R to G terminals at the thermostat connection terminals. Thus providing a brief continuous fan mode.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

I kept the ST82 relay coil and physically removed the timing board that came with it (the one which is meant to keep the fan running after eq stops). However I am NOT trying to keep the fan running, rather I want the entire heating call to stop during a long DHW call (like a shower - otherwise it will blow cold air).

Correct that I am effectively cutting the heat call to the air handler (there are a couple things inline w/ the thermostats like a zone controller on one handler, but same general idea). Also correct that handler calls boiler, but it's really handlers each call Taco circulator controller which calls the boiler. Finally also correct that cutting the heat call opens A/H which was the original issue.

The NEW issue is that I removed the time delay board from the relay (making it work like a regular DPDT relay). When the circuit is directly connected (24v to relay), the relay pulls in. When the same circuit is directly connected THROUGH A/H CONTACTS, the relay pulls in then drops out every 2-3 sec.

The mystery is what difference the Navien contacts are making to the relay. If I can solve this, the system will work as I want it to. Naviens work pretty well… but they sure do have a long history of fighting me!

0 -

Yeah, what I stated before (last post) would also keep the blower going during a shower, so forget that part.

" When the same circuit is directly connected THROUGH A/H CONTACTS, the relay pulls in then drops out every 2-3 sec. "

I would expect that since I believe it is killing the heating call from the thermostat and the whole control chain is dropping out, ending with the A/H contacts opening. Then the relay drops out enabling the thermostat again and that process keeps repeating.

It almost seems like the boiler A/H should control the air handler and not the thermostats directly. So for heating the thermostats calls the SR 502 the SR 502 isolated end switch calls the boiler, the boiler closes the A/H energizing the ST82D and that calls the air handler. During a brief DHW use the delay of the ST82D delay timer relay keeps the air handler blowing, but during a long DHW call the ST82D delay timer relay drops out and the air handler blower stops.

One problem with this is there is two air handlers and only one A/H on the boiler. Also this seems like it would have been lot of rewiring with for just a boiler change and possible transformer phasing issues, do you have A/C ?

So when the boiler was changed, no other control wiring was changed just the ST82D hookup ?

I'll think about it some more.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I just figured out that this wiring design will not work because the the A/H contacts are open (OFF) when there is no thermostat call for heat from a thermostat. Without a call for heat from the thermostat then the contacts can not close (turn on). If the contacts are not closed then the thermostat signal can not get sent to the TAM 7 because the R8222 relay contacts are open and will not allow the TAM 7 to close the end switch from (P4) from the Hydronic Heat Control. That in turn will not activate the SR502 zone thermostat to start the pump and send the signal to the Navien.

Basically this approach needs the Navien to call for heat before the A/H contacts close and the A/H contacts need to be closed before the Navien can call for heat. "Catch 22"

This must be resolved by a series of additional relays that will allow the TAM 7 to start the boiler. This will take some time to resolve.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I just got off the phone with Navien Tech Support and it is an easy fix. use the DHW Pri contacts that are right next to the A/H contacts. They do the same thing but start out Closed and they start out open and stay open until there is a call for DHW, unlike the A/H which close on a a call for heat and Open on a DHW demand.

Here is the closeup of the change (Red Arrow)

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Catch 22 indeed… that is the problem I was describing throughout and why we ended up abandoning the "delay on off" relay for the Packard delay timer (delay to turn on lol).

I have already switched to leveraging the DHW contacts within this circuit. When the ST82 relay (with time delay board removed) is energized THROUGH the DHW contacts on the Navien board, the relay cycles on and off. If wired directly (always on) the relay does not drop out. Something about that Navien board relay is not playing nice w/ the current.

0 -

Try it with a different transformer that has nothing to do with the zones or the boiler.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

And sorry I just realized I misled you yet again… I stopped testing with the A/H but lazily left them in the drawing…. corrected below. The point is that this particular relay will not stay pulled in when the circuit is closed via the Navien board. If I can solve that, everything will work perfectly.

THIS WORKS (RELAY STAYS PULLED IN):

THIS DOES NOT WORK (RELAY CYCLES IN AND OUT EVERY 2-3 SECONDS):

0 -

I would think this would work. The brief DHW calls would not interrupt the thermostats heating calls until the PTD 102's delay has expired. Be sure to use the NC contacts on the relay.

Unless the minimum current " Output Ratings Min.40 mA " of the PTD 102 is messing with things. How much current does the relay coil draw ? If it is less than 40 mA (0.040 Amps) the PTD 102 may not work as expected or desired.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Today this arrived:

One of three different models I ordered, in hopes that one of them would work well. Tried it with the Navien both in and out of the circuit, and it does not drop out! Considering it's a two pack for 13 bucks (so I have a spare) and come with a nice rail on which to mount them, it looks like a winner!

0 -

Well maybe the ST82D's coil was drawing too much current from the Navien's 24 VAC source. I believe the coil of the JQX-13F draws much less current, about 46.0 mA.

The coil current, 46.0 mA, of a JQX-13F DPDT relay should be enough to satisfy the minimum current requirement of the PTD 102.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I spoke too soon 🤬

First off, the PTD 102 is not even hooked up yet.

When fully hooked up through the Navien, this new relay is doing the same thing. pulling in then dropping out in 2-3 seconds. I no longer have it hooked up to the Navien's 24V source (thinking that might be the problem) so now it is drawing from the zone controller's 24V.

When 24V is run through the Navien DHW contacts, it is pulling about 180 mA. It appears fairly stable (fluctuating by only a few mA tops). This is just testing between terminals on the relay.

I am starting to think you were right above. Cutting the heat call disturbs too much of the controls downstream. Even though it should make NO difference, perhaps the heat call going out resets something in the mix enough to momentarily jolt the Navien relays to open.

As I mentioned earlier, bypassing the Navien and hooking directly up to 24v works as intended. Not sure it makes a bit of difference, but I can try breaking ground instead of hot if anyone thinks it will work.

0 -

Probably should have done this earlier… here's a clip of the system in action (or lack thereof!)

https://youtu.be/fpJSpqqNMeY

0 -

For the reasons posted above I think this should work. The PTD102 makes the rest of the control equipment unaware of brief DHW calls, since the relay should not change state until the PTD102 times out.

I would verify the DHW contacts close (no load or power applied except a continuity tester) and stay closed for the duration of any DHW call.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

Before we do that… some new info:

- To your question on whether the contacts stay closed, they do. This is audible w/ a continuity tester, with no breaks

- By removing the W from the relay and tying them together, then triggering a DHW call, the relay stays powered with NO DROP OUT. I mean when wired like this:

This is telling me that cutting the heat call jostles the Navien enough to make some sort of continuity break, or enough to signal the relay to drop out, then pull in again, over and over. I wish there was a way to detect this with the meter, but either way it is clear when/why it is happening.

Even with the PDT102 installed, I expect it to do the same thing, after the delay kicks off

Someone at Terry Love suggested early on that a water flow switch on the DHW hot outlet might work, but I was focused on the relay and didn't want to go opening up the plumbing. Maybe it really is the only way to make this idea work reliably.

0 -

If the DHW PRI contacts do not stay closed for the duration of the DHW demand, then you will need to install an After market flow switch that will do the job without depending on the Navien circuitry

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

It's really a bummer… I think you guys wanted this to work more than me! Naviens have always been this way with me… everything you need is there, but nothing quite works all the way.

You were/are correct that it could/would have been a better design to run everything through the Navien… still not totally impossible but would take quite a bit of wiring in the attic. The other option is to look into breaking G for the fan only… it kind of stinks that the heat calls would stay on but at least the system would not blow cold air.

Thank you guys so much for sticking with me!

0 -

@giantsean said "You were/are correct that it could/would have been a better design to run everything through the Navien… still not totally impossible but would take quite a bit of wiring in the attic. The other option is to look into breaking G for the fan only… it kind of stinks that the heat calls would stay on but at least the system would not blow cold air."

I was thinking in that direction but you would need to reconfigure the thermostat to do that and sometimes the G wire may not offer you the higher speed you require for the heating speed. Sometimes when you configure the G Wire to operate the fan for heating from the thermostat, it only operates at 10% of the total fan speed. That is because the G wire only is designed for fan on operation to allow the air filters to operate more efficiently using the very low speed. and will only ramp up when there is a corresponding call for cooling or heating.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

What generates the DHW call, the flow sensor in the boiler ?

" This is telling me that cutting the heat call jostles the Navien enough to make some sort of continuity break, or enough to signal the relay to drop out, then pull in again, over and over. I wish there was a way to detect this with the meter, but either way it is clear when/why it is happening. "

To me, the thing is, on short DHW calls the PDT102 should not allow the relay to energize, so nothing should be jostled, right ?

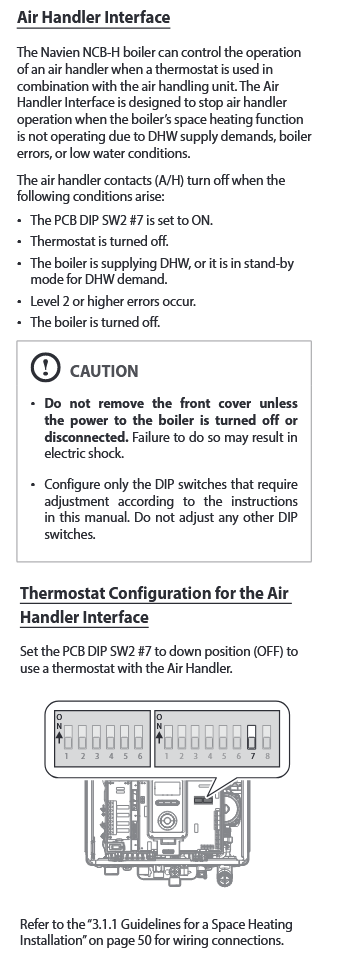

An interesting note: Depending where you look in the manual the terminals for the DHW PRI and the A/H are reversed !!! Are they accurately labeled on the unit ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Yes I believe once the boiler senses an opening of the tap it will activate DHW. I do not know how a call for heat (or lack thereof) affects it though… When the W wires are closed (nutted to each other) the relay works fine and does not cycle on and off, even when passed through the DHW terminals. I kind of wonder two things:

- Maybe the act of turning off the heat call resets something in the boiler, where all the relays that run those terminals reset, even if they start closed (like during a DHW call)

- Also I have found grounding/shorting A/H and DHW to sometimes make the difference, Perhaps the way it's wired they are somehow shorting back to the boiler somewhere unexpected, since it's two W on the same relay?

I get what you are saying about the PDT102 but eventually after the delay it will just start the same process as in the video… the relay will close after the delay which opens W, then will immediately close, which maybe will start the delay again? I have to try it.

I did indeed notice that they are sometimes reversed on the diagrams! Not sure why though. Most times the book has A/H on top and DHW on the bottom, and that is how they are on the board.

0 -

Sorry a squirrel ran by and I was distracted and did not view the video until just now.

What about this…

Since you now have two like relays. The PTD102 should block the short DHW calls from energizing the relay. With the second relay use it to open up the path between the SR502 X-X and the Boiler R-W maybe that will stop the flicker cycling.

The coil of both relays are in parallel so when the PTD102 delay times out it energizes both relays.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

You fellas ready for this? 😂

I went down to test what would happen if the PTD102 was wired in as 109_A5 suggested. As it turns out, I was right about it just delaying the effects I have already been seeing (though oddly, when the delay was set for really long - like 5 minutes - it seemed to keep the relay pulled in longer… might have been a fluke though).

Out of frustration I tried a couple different combinations of hookups… all same result. THEN I remembered this note about DIP SW #7. I figured… what the @#$%… couldn't hurt to try flipping it from OFF to ON… turned on the hot water and BINGO!!!!!!!!!!!!!! THE RELAY STAYS PULLED IN!

I am presuming that turning off A/H Interface mode removes that function from the system, and perhaps it works in conjunction w/ the DHW terminals (see below notes talk about stand-by mode). Maybe cutting W tells the boiler to momentarily flip out of stand-by… don't know don't care… it works! (again lol.. hopefully this time for good!)

0 -

-

-

I'm guessing it at least turns off that relay, and maybe (to my benefit) ignores what is going on in terms of what the DHW call is doing. I'm actually thinking of calling Navien (I can make myself sound like a fairly convincing tradesperson even though I'm not :D) and asking then specifically what might be happening with my…ahem.. my "customer's" setup lol.

0 -

-

-

Boy, that's a whole lot of work to nearly duplicate the functionality of an aquastat on the return pipe. I know the OP said he had trouble with that, but it works so good everywhere else that I think I'd spend some time revisiting it. Maybe an adjustable model, if the SWT is too low to reliably trip the switch.

1 -

That makes sense when you have a PSC blower motor. The TAM7 is equipped with an ECM variable speed blower motor. You just can't open the "Heat Speed" wire with an Aquastat. I would have suggested that much earlier, if that were the case.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements