Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Steam powered saw mill

Options

Big Will

Member Posts: 395

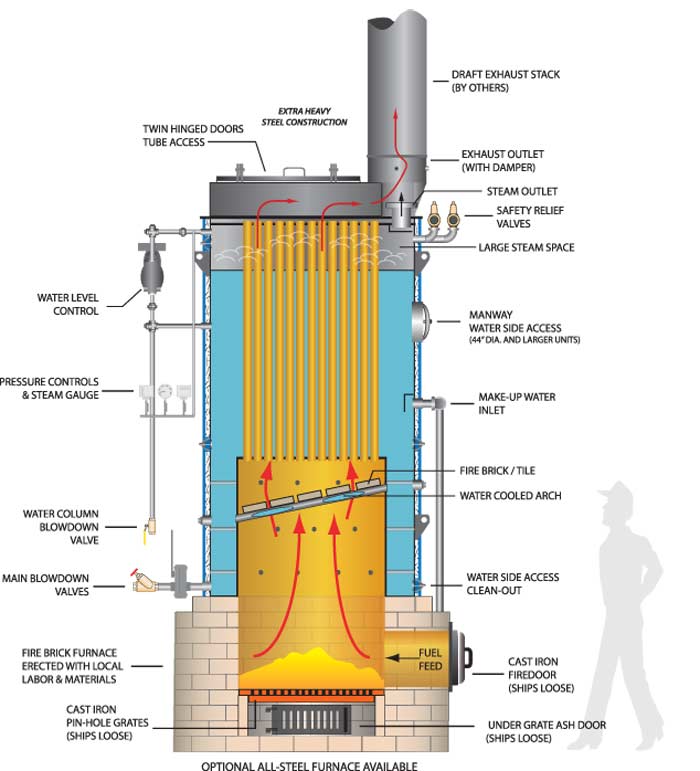

I have been asked to help with a oil fired boiler at a restored steam powered saw mill. I am really looking forward to it but it has me thinking about period accurate equipment. The mill originally had a wood or coal fired boiler. It has long since been abandoned. The oil boiler has been run by the gentleman there for years but they are not boiler guys. They think they have a couple bad tubes and want it looked at in general.

My question is not about the current boiler though. It would be a huge undertaking, but wouldn't it be great if I could set up a new wood fired built in place boiler. Are there any companies selling tube sets for something like that anymore? I doubt it. I am thinking that I might be able to get a boiler from an old traction engine or locomotive and restore it. I helped a power museum restore a Huber steam traction engine years ago. It's coal fired. That was a great time.

I love old stuff and I love a challenge. I just wanted to bounce the idea around with some steam people. I am in Northern California and there are very few steam guys around here to talk to about this kind of thing.

https://www.sturgeonsmill.com/

My question is not about the current boiler though. It would be a huge undertaking, but wouldn't it be great if I could set up a new wood fired built in place boiler. Are there any companies selling tube sets for something like that anymore? I doubt it. I am thinking that I might be able to get a boiler from an old traction engine or locomotive and restore it. I helped a power museum restore a Huber steam traction engine years ago. It's coal fired. That was a great time.

I love old stuff and I love a challenge. I just wanted to bounce the idea around with some steam people. I am in Northern California and there are very few steam guys around here to talk to about this kind of thing.

https://www.sturgeonsmill.com/

0

Comments

-

I'd try over at the coal pail forum

https://coalpail.com/coal-forum/

Mostly coal heating, but there might be a lead to whoever makes engine boilers. I have seen them.

Hurst makes high pressure coal / biomass boilers as well, might be worth calling them

https://hurstboiler.com/boilers/solid_fuel_fired/coal_firedTrying to squeeze the best out of a Weil-McLain JB-5 running a 1912 1 pipe system.1 -

Trying to squeeze the best out of a Weil-McLain JB-5 running a 1912 1 pipe system.0

-

The Northern Illinois Steam Power Club puts on the Sycamore Steam Show every year. Starts second Thursday in August. When my son was younger I would take him to the show. He now makes steam out of rocks that glow.

https://sycamoresteamshow.com/

This Aultman and Taylor sawmill is powered by belt drive from steam tractors.

https://sycamoresteamshow.com/the-aultman-and-taylor-saw-mill/

The NISPC also has a 1952 stationary Kewanee boiler which runs a 1920 Vilter ammonia compressor. Vintage heat pump?

https://sycamoresteamshow.com/the-kewanee-stationary-boiler/

https://sycamoresteamshow.com/the-vilter-tandem-compound-corliss-steam-engine-ammonia-compressor/

2 -

Maybe you could get some advice from The Rough & Tumble Engineers Historical Association in Pennsylvania. Some years ago they put a big boiler in their stationary steam engine building.0

-

If you are looking to fire this boiler with soft coal you will probably have to clean the boiler tubes monthly if not more often. If you are using hard coal, anthracite, tube cleaning is almost never. Make sure that the boiler is designed for the type of coal you will be using. There is a definite firebox design for each type of coal to be burned since each type of coal has different burning characteristics. If you can't get all the information you want you could try calling CS&E in Pittsburgh, Pa at 412-821-8900 and ask for Tim Fugh, and tell him David gave his phone number and explain what you are trying to accomplish. You may be able to retrofit an older, used boiler in good condition that you can find locally.0

-

As an aside, I recently learned that the expression, "running balls out*," was a reference to the old steam engine speed governors, like the one shown in the last picture above. It has nothing to do with a wardrobe malfunction.

________

*Not to be confused with "balls to the walls," which is an aviation metaphor with a similar meaning but different origin.Just another DIYer | King of Prussia, PA

1983(?) Peerless G-561-W-S | 3" drop header, CG400-1090, VXT-241 -

A lot of great ideas. I knew this was the right place for this.

I was set up to go there in a couple weeks but they are going to open it up for me tomorrow to take a look at it. It's going to be raining and the boiler is outside so it will be interesting.

Fortunately I'm water resistant.0 -

@Big Will, if you could find a used boiler similar to the middle picture that @WMno57 posted, it could be rebuilt and retrofitted with a screw or ram stoker or it could be "hand fired" if that is your choice. Just make sure that the boiler is rated for the steam pressure that you need. Almost any horizontal firetube boiler with a firebox below could be made to fire soft coal.0

-

I think the company's name was Ameritherm who sold unfired boilers. Hog fuel heated stuff to very high temperature at no pressure. The hot stuff produced high pressure steam safely. Forget why steam from hot stuff is safer than from fired boiler.

If you really intend to build your own power boiler then first read a book about ASME pressure vessel construction requirements.0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements