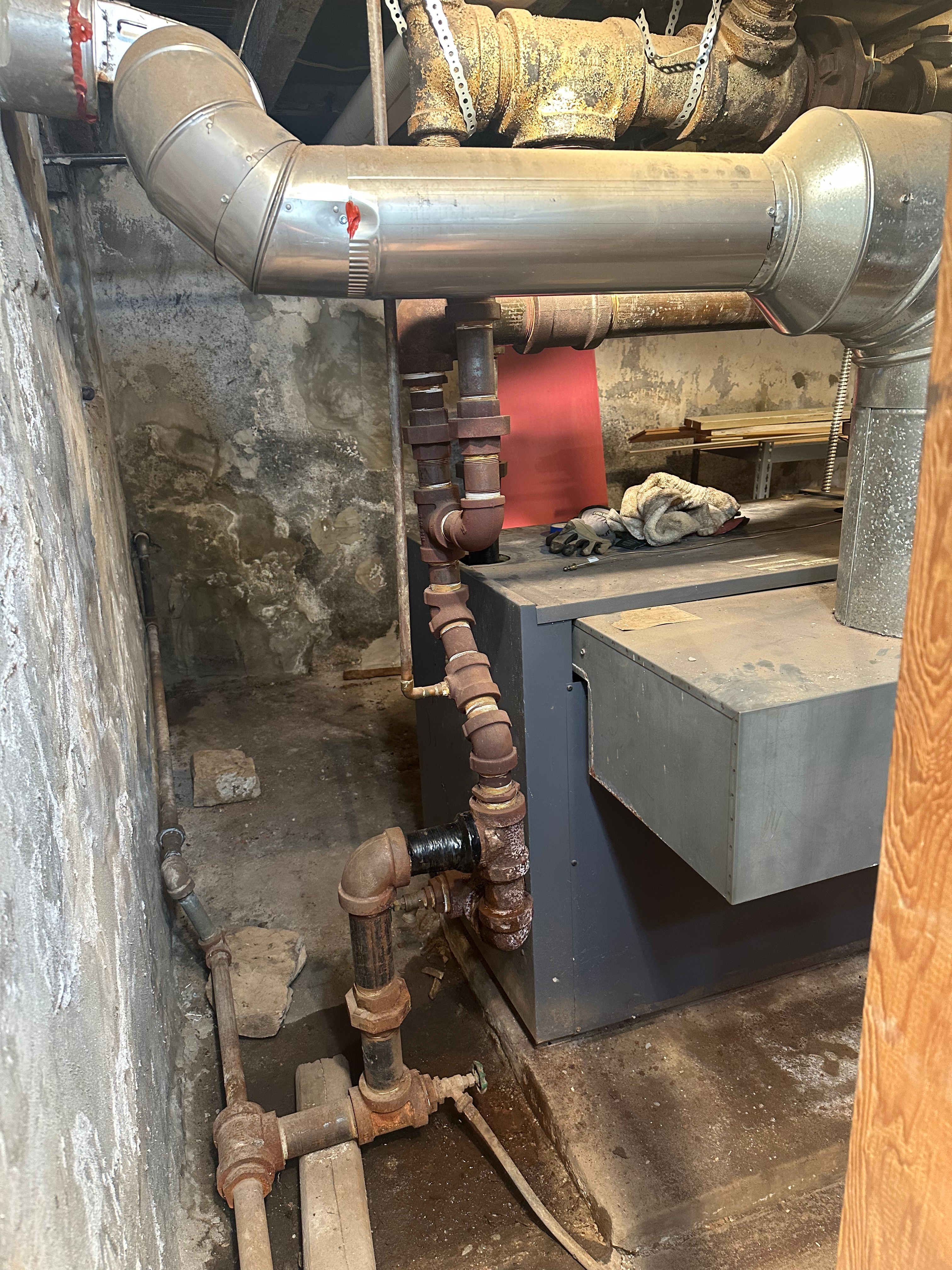

Corroded return pipe

Not sure how much time I have left, or if it is something I can do but working with pipe fitting is a pita from my limited experiences. I think the boiler is probably 12-15 years old but works fine.

Comments

-

Corrosion on the outside of the pipes is common in damp basements. Consider using a dehumidifier. If you're filling the boiler from your household water supply, make sure it comes off before the water softener. Never use softened water in a steam boiler.Just another DIYer | King of Prussia, PA

1983(?) Peerless G-561-W-S | 3" drop header, CG400-1090, VXT-241 -

It looks like a combination of an active leak since it looks wet and remnants of asbestos that weren't completely removed. Or maybe something else is leaking on it.

Don't use softened water in the boiler, that is worse on it than hard water.0 -

To me that looks like old paint. When I replaced my wet return, it seemed like the parts of it that someone had painted with interior house paint were rusted worse than the parts that weren't painted. It's almost like it lets moisture in and traps it there.mattmia2 said:It looks like a combination of an active leak since it looks wet and remnants of asbestos that weren't completely removed.

Just another DIYer | King of Prussia, PA

1983(?) Peerless G-561-W-S | 3" drop header, CG400-1090, VXT-240 -

Let me address some of the comments:

The water hardness in my region is classified as "very hard"

~200 to ~350 mg/l as calcium carbonate or 1 gpg = 17.1 mg/l o

I also have a second stage carbon filter that is part of the whole house system.

The system is 5 years old. The boiler is approx 13 years old. Not sure if the feed pipes are typically the same age, I would think they have to be fitted at the time of install.

It looks like the pipes are corroded from the inside out with the steel flaking off in layers. I keep a dehumidifier running in the basement, it is pretty dry. The corrosion seems to be where the fresh eed water is mixing into the system.

My goals here are:

1: Prevent an interruption during the heating season.

2: Fix myself if possible, or find someone to fix it.

3: Preventative measures to keep repairs from failing again.

0 -

If you're re-piping the return, do it correctly. I see a couple of issues there, most notably the Hartford loop. It needs to be shorter. Much shorter. It's probably making some noise now. If you can, post some pictures of the whole return, if not a complete view of the near-boiler piping.Just another DIYer | King of Prussia, PA

1983(?) Peerless G-561-W-S | 3" drop header, CG400-1090, VXT-240 -

0 -

Hmm. You might want to wait until summer and re-pipe the boiler. The header is big enough, but the system riser and the equalizer are at opposite ends, so you're not getting good steam-water separation. Also, the supply risers could be higher. You're probably getting pretty wet steam. The equalizer should also be bigger. At least get rid of all the reducers between the header elbow and the tee on the return and use the biggest pipe size you can.Just another DIYer | King of Prussia, PA

1983(?) Peerless G-561-W-S | 3" drop header, CG400-1090, VXT-241 -

Yea… I waited too long and the fittings below the water line are leaking. I was able to successfully repair some segments of the condensate line away from the boiler, but now this is an issue.

Not sure where to begin here, There are so many fittings, looks like it was not piped optimally to begin with. There are some unions I can probably separate. I assume I need to remove everything corroded and start piping from the boilier return? Guessing to save the good fittings they will still have to all be loosened and reconnected in order from bottom up to the unions? Do I have this right?

0 -

I assume you are leaking on that horizontal part of the Hartford Loop where the tar-looking substance is applied? Yeah that area is where it always rots out first. You just gotta remove what's rotten and build it back up. The installer did pick a weird place to tie in the makeup water supply line—half way down the equalizer, pretty odd.

He also didn't do you any favors keeping the ancient header and adding a new one under it, but that shouldn't hurt you too much either.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

-

I think I will work from the boiler up to the 45 degree run where the makeup water connector is put a union somewhere there. Is there a better place for the makeup water to enter the system?

0 -

Anywhere works that's convenient. I like it in the return under the water line. But I don't even use it anymore. I add distilled water via my skim port now.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Do you mean in one of these segments?

0 -

Also, what is the risk of damaging the boiler when I remove the tee coming off the return feed nipple going into the boiler? This unit is about 15 years old

0 -

At the red arrow is where I would tell you to put it if you twisted my arm.

You always run the risk of hurting something when you touch it, but you should be OK. Worst case is probably the nipple that is in the boiler partially disintegrates leaving you to scrape the remains out of the boiler and clean up the threads.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Thanks. Am I ok to put a union in the 1-1/2" diagonal run where the makeup line is now? I think that will allow me to replace the bad pipe without messing with the rest for now.

0 -

You are definitely OK by me to put a union anywhere it will make your job easier!

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Is anything other than the nipple leaking?

You could probably break this union and replace the nipple, cutting the pieces out of the existing fittings:

0 -

The tee is wet. Cant really tell if it is also leaking or just wet from the nipple until I get in there and remove the nipple. Would love to get away with just putting in a new nipple for now, but if I have to replace more, I think it would be good to put a close nipple there like others have suggested.

0 -

if it never bangs I wouldn't bother with the close nipple. it is supposed to be a close nipple but that makes it a much bigger project. If it is 1 pipe steam the supply and return are connected out in the system and it should never need to equalize so steam should never get down the equalizer in the first place.

1 -

It is one pipe system. Never heard banging at the boiler. Pipe is a weird size 5-1/2". The 2" diameter is at the maximum capacity of my HF pipe threader. Hopefully I can thread it, last time the vice ripped out of my table and hit me in the face cause when the bolts snapped. I have thicker bolts now. Will buy all the fittings in case I need to cut more and maybe try tonight if I am feeling crazy enough.

0 -

-

-

nice, it will be fine

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements