Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Boiler and floor heating system

Options

javajedi

Member Posts: 9

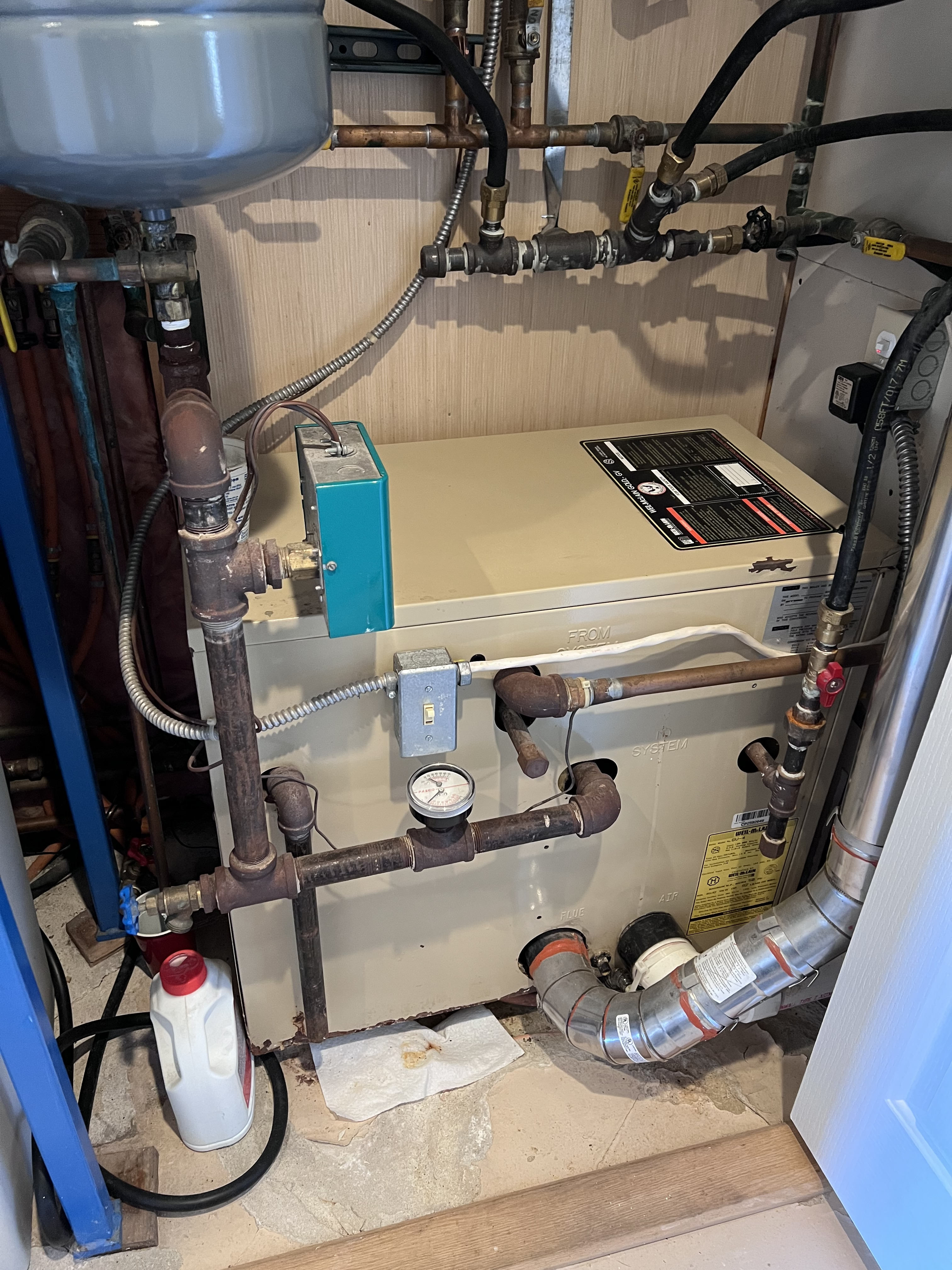

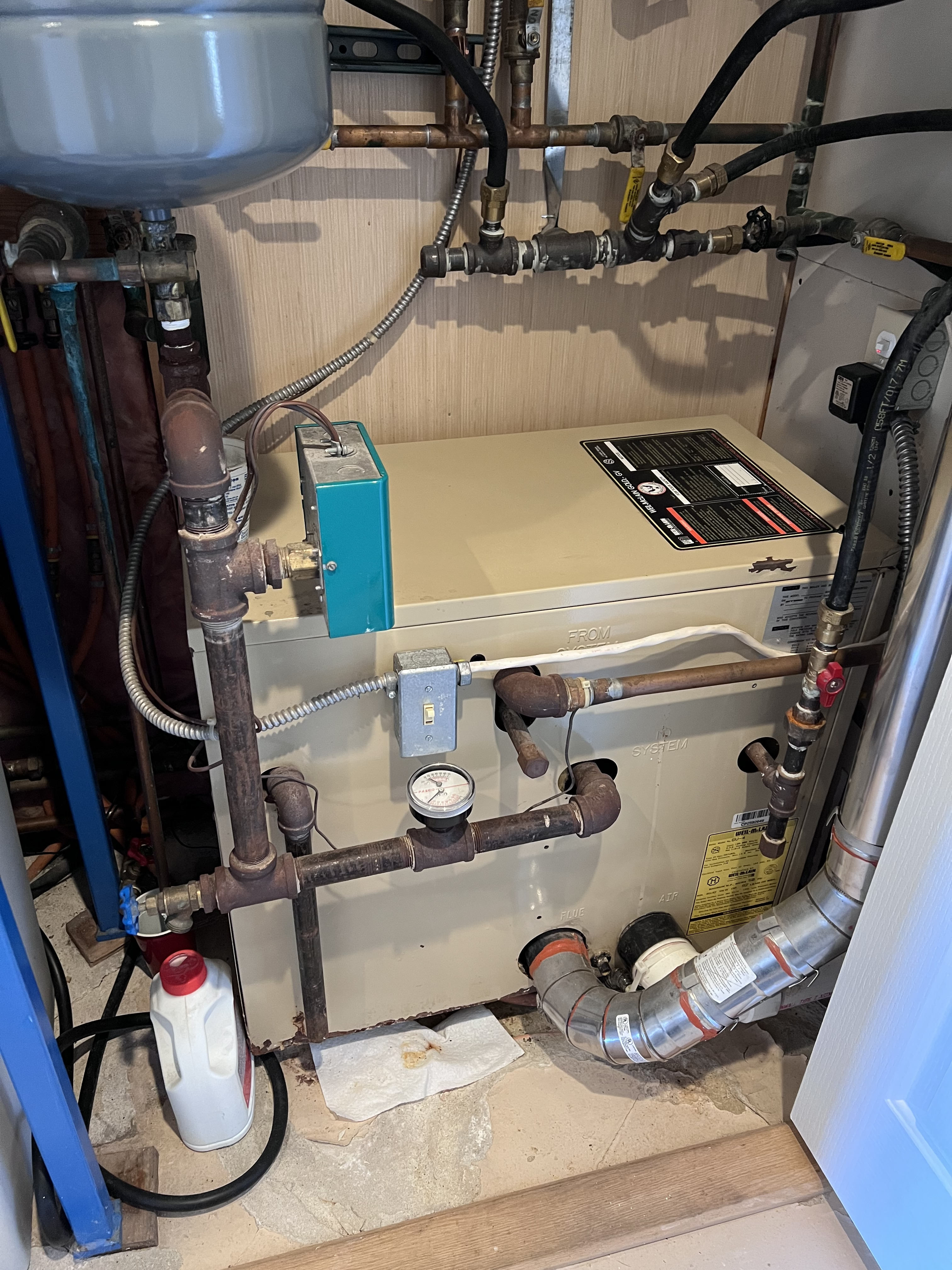

Hello all. I need some advise. I have a hydronic heating system that got install in1995 and I has been working great most of the time. What I did not know that the system should be flushed every so often. The installer never said anything about it. So now I am getting worried about it and how much longer the boiler will last. It’s a Weil McLean and I was told it was a good boiler. The air vent does not work anymore and I can hear some air in the lines. Trying to do some maintenance without spending a lot. My first question is: Can I blow out all the antifreeze water mixture, pump it thru a filter and then pump it back into the system? Does the antifreeze solution breaks down over the years and do I have to replace it? It’s been in there from the beginning. And also can I get parts to repair the automatic air vent or do I have to replace it?

0

Comments

-

-

Do you need antifreeze in the system. Are there exposed pipes, a garage zone.

A ph test is the best way to check glycol condition, if it is in the 7s, time to dump it. If it is 9 or more it could be ok.

Also test the freeze protection level. A simple auto parts store floating ball type check is close enough

If you flush it, I would run a cleaner first, flush that and refill with premixed glycol

You will need a pump to get the glycol in, some purge hoses and a bucket

Assuming you have good, working purge valves.

That looks like a backflow preventer behind the air purger, capped off, I think? You do not want a water connection on a glycol system, and a low water cutoff is a good idea.

You could buy another PowerVent and swap the inside and top, or replace it. It will be a task to remove and sweat a new one in.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Thanks for the advice so far. Yes it is a backflow preventer and it is hooked up to the water supply but it has ball valves on both sides. It started to leak last weekend. This is inside my cottage and the antifreeze is in case there is a power outage. I found a replacement for the back flow preventer and it should bolt right in there. Here are more pictures. I was trying to open the vent to get air out but nothing happened. I unscrewed it and found out that it top of the stack was plugged up with dark brown granules almost like coffee grounds. I cleaned it out and replaced it with a new vent

0

0 -

This is the antifreeze in my system.

0

0 -

I will have to look at the paperwork I have from the installer and see if there is any info about the capacity of the system.0

-

You do not need or want a fill valve connected to a system with glycol. Any water added will dilute your glycol mixture.

You do want that air purger in working condition. I suspect the inside parts have not changed. Buy a new one and swap the inside parts.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

What freeze protection are you trying to maintain?

why do you need glycol?

0 -

So I have to get a new air vent and replace it with the old one. The sweat part will not be a problem for me. What is a good brand/model for 3/4 copper? Also will get a cleaner than works together with NoBurst. Should I replace the air vent first before running the cleaner through the system? Definitely will get the NOBURST 100 to fill the system again to protect from freezing in case we loose power. The floor heating system is installed at my cottage in mid Michigan and can’t monitor it.

0

0 -

0 -

-

Yes it is 3/4 0

Yes it is 3/4 0 -

I am planning on going up north this weekend to replace the Air Vent. I will post pictures next week.0

-

Just got done changing the Air Vent. It should be good for many years again. Next will be flushing the system and filling with new antifreeze. Took the old air vent apart and it’s full of contamination.

0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements