Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Pressure test manifold and connected loop?

Options

cloudd

Member Posts: 49

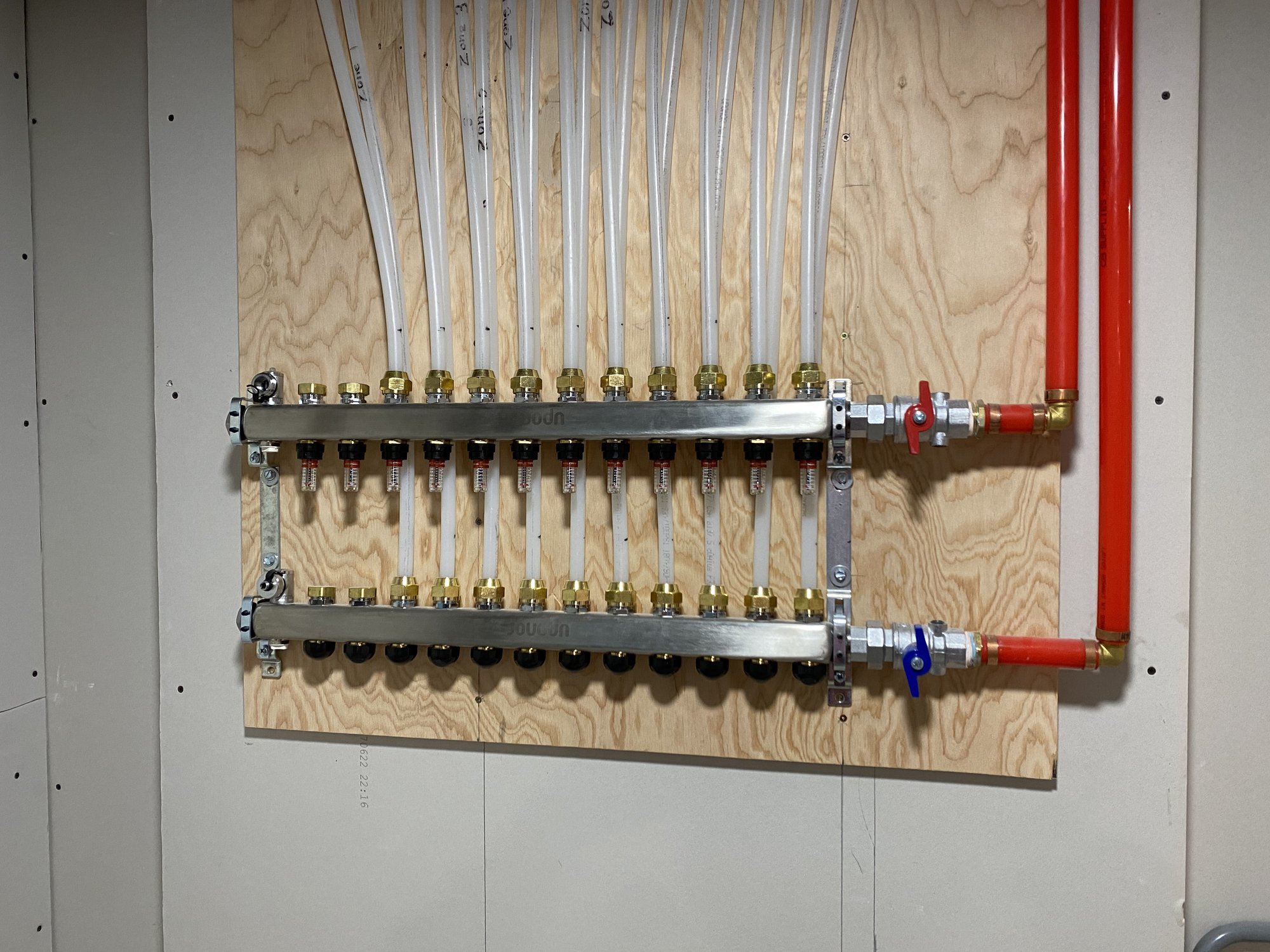

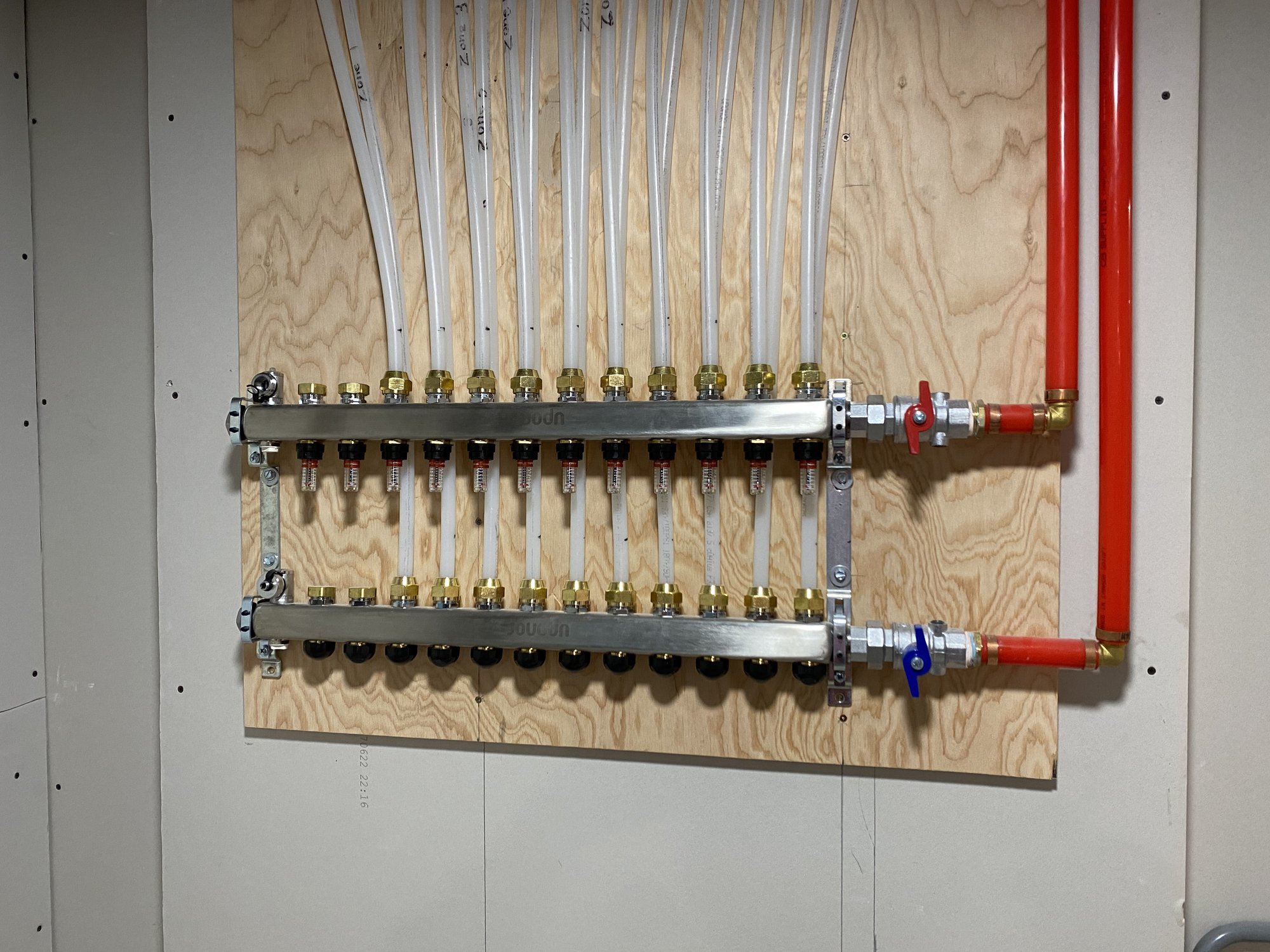

I have an Uponor 12 loop stainless steel manifold.

*All of my loops have been individually pressure tested at 100PSI successfully before boarding of drywall*

*I will be installing the correct elbows to move the red pex onto the plywood.*

*All of my loops have been individually pressure tested at 100PSI successfully before boarding of drywall*

*I will be installing the correct elbows to move the red pex onto the plywood.*

I would like to pressure test all of my loops connected to my manifold as one system up to the manifold at 100PSI to make sure a drywaller did not put a screw through any of my pex before taping and mudding. I just want to be sure I won’t have a problem before I move forward.

Can I manually open all of the balancing valves and connect a pressure gauge to the drain valve on the manifold and fill the system with 100PSI while the supply and return lines are closed to pressure test?

The problem I am having is that the gas pressure gauge I have appears to have a finer thread than the manifolds’s drain valve. Is the possible? I can only turn my reassure gauge 1/2 a turn onto the drain valve. See pictures.

Is their and easier way to do this pressure test of the manifold and loops?

Can I manually open all of the balancing valves and connect a pressure gauge to the drain valve on the manifold and fill the system with 100PSI while the supply and return lines are closed to pressure test?

The problem I am having is that the gas pressure gauge I have appears to have a finer thread than the manifolds’s drain valve. Is the possible? I can only turn my reassure gauge 1/2 a turn onto the drain valve. See pictures.

Is their and easier way to do this pressure test of the manifold and loops?

0

Comments

-

That is a garden hose thread on the manifold valve. The gauge is a NPT thread.

A connection similar to these, female garden hose to 3/4 male

The one below is 1/2” NPT, they should have a 3/4 NPT male.

Ace hardware, any of the box storesBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Can pipe dope be used on the 1/2” pex compression fittings that go into the manifold or should something else be used?0

-

It would be best to pressurize the system with water .Striker plates are on you . If they hit one everyone would know ..

Noticed a mistake on your manifold the way it is piped , Flip one of them to reverse return which would equalize the pressure drops across the takeoffsThere was an error rendering this rich post.

0 -

-

It can be overwhelming, but not insurmountable. Keep up the good work caring for your mom and her placeBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

The manifold is in the basement. I have striker plates in most areas but not possible behind the manifold wall in my bathroom ceiling where all pipes from one side of the house cross. The ceiling has been dropped a 2x4 width (1-1/2”) and the pipes are within this area. The basement is completely finished except for a few areas with drop ceiling. I don’t want to lose anymore ceiling height I’m already at 7’ in the bathroom area.Big Ed_4 said:It would be best to pressurize the system with water .Striker plates are on you . If they hit one everyone would know .. Noticed a mistake on your manifold the way it is piped , Flip one of them to reverse return which would equalize the pressure drops across the takeoffs.Please explain the mistake in more laymen terms. Perhaps a sketch.0 -

hot_rod said:Are there o rings on the fitting that goes into the manifold? Pipe dope on that connection could cause a problem. A pressure test will tell.There are O rings on the compression fitting connections. The plumber who just installed my Bosch singular 5200 told be to use pipe dope. I should have asked here first. Anyways I am testing at 60psi at the moment and it seems good for an hour. I will leave it until tomorrow.If the seal is good and the psi is stable should Move forward and leave compression fittings with the pipe dope on the O ring seals or should I remove the pipe dope before moving forward?Will the pipe dope damage the seals overtime vs no pipe dope?0

-

If your emitters are installed be careful to check their specs. They usually are rated for a lot less than 100 psig. Make sure you don't exceed the rating of any of the components. Check the specs on the manifold too.0

-

If he just put a small dab on the threads you are fine. If he coated the o ring with pipe dope, not so good. It would be a job to disassemble and clean them all off. See how the pressure test goes.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

No one who pipe dopes everything and anything with a thread only puts a dab.0

-

I ended up testing at 90 PSI. Good thing I cut it off there. The uponor manual says 100PSI max. There are no other components other that the HelioPEX and the the uponor manifold with compression fittings in the psi test.

I did coat the compression fittings and o-ring with blue magic pipe dope as per the plumbers instructions (that was a mistake) There is no water in the system and I have not had any water in the system. I thought about the pipe dope in the system afterwards (closed system) and thought that pipe dope in the system/boiler might not be good idea as it would be an impurity circulating in the water through the system.

I did coat the compression fittings and o-ring with blue magic pipe dope as per the plumbers instructions (that was a mistake) There is no water in the system and I have not had any water in the system. I thought about the pipe dope in the system afterwards (closed system) and thought that pipe dope in the system/boiler might not be good idea as it would be an impurity circulating in the water through the system.

So perhaps I should save myself the future hassle / expense (pipe dope circulating through the combi causing corrosion…rust?) and clean all of the pipe dope off of the o-rings and compression fittings.0 -

Your manifold is piped Direct return . The first loop would have the highest pressure drop and the last would have the least . By flipping one of the manifolds it will change it to a reverse return system . Now the first loop would be the first supply and the last return . Reverse return equalizes the pressure drop in an manifold ..

Helps you with the balance .There was an error rendering this rich post.

0 -

I always keep the system charged with water , it keeps the other contractors honest ...

There was an error rendering this rich post.

0 -

Big Ed_4 said:

Your manifold is piped Direct return . The first loop would have the highest pressure drop and the last would have the least . By flipping one of the manifolds it will change it to a reverse return system . Now the first loop would be the first supply and the last return . Reverse return equalizes the pressure drop in an manifold ..

Helps you with the balance . Is this a preference but not a must. Is this used to simply the balancing process but optional?

Your manifold is piped Direct return . The first loop would have the highest pressure drop and the last would have the least . By flipping one of the manifolds it will change it to a reverse return system . Now the first loop would be the first supply and the last return . Reverse return equalizes the pressure drop in an manifold ..

Helps you with the balance . Is this a preference but not a must. Is this used to simply the balancing process but optional?

I have not noticed this on other setups and no one has mentioned it except you.0 -

Maybe not, just trying to help. ...

There was an error rendering this rich post.

0 -

So far I have cleaned off (o-ring and compression fitting) 12 of the 24 connections using Q-Tips, tootbrush, paper towel and a vacuum. It’s a little painful but now I don’t have to think about pipe dope circulating through my new combi boiler.

0

0 -

-

Just label all the tubes if you stagger them so you know which two ends are the various loopsBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

But it’s still Good Piping Practice!pecmsg said:GroundUp said:The whole "reverse return" thing is hogwash with radiant like this. The pressure drop between the first and last loop is immeasurable.

What makes it "good piping practice" when it serves no functional purpose? All it does is confuse the next person to work on it because the loops aren't piped as they should be.2 -

-

All parallel systems should be RR . Our mistakes are found in the Dead of Winter . Normally someone ends up buying a bigger circulator or the expensive manifold . Zone valves are normally piped in parallel , The end zones will dog to the first .

Twin in hot water heaters direct return , what will happen ?There was an error rendering this rich post.

0 -

Unless your manifold is undersized the pressure difference from one end of the manifold to the other will be negligible.0

-

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements